5-Operation & Cleaning of Ropp Sealing Machine

5-Operation & Cleaning of Ropp Sealing Machine

Uploaded by

ananthCopyright:

Available Formats

5-Operation & Cleaning of Ropp Sealing Machine

5-Operation & Cleaning of Ropp Sealing Machine

Uploaded by

ananthOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

5-Operation & Cleaning of Ropp Sealing Machine

5-Operation & Cleaning of Ropp Sealing Machine

Uploaded by

ananthCopyright:

Available Formats

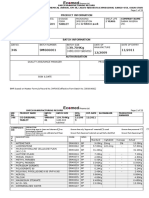

FOR RESTRICTED CIRCULATION ONLY

Indchemie

Health Specialities Pvt. Ltd.

Thana, Baddi

STANDARD OPERATING PROCEDURE

Title:

Procedure for Operation & Cleaning of ROPP Sealing /HDPE Capping Machine

Department : Production (Dry Syrup)

SOP No. : IB/BD/05/005

Issue No.

Revision No.

Effective Date

Review Before

Page No.

01

03

05.06.2011

05.06.2013

01 of 03

1.0

OBJECTIVE

To lay down a procedure for operation and cleaning of ROPP sealing/HDPE capping

machine.

2.0

SCOPE

This procedure shall be applicable to operation and cleaning ROPP sealing/HDPE

capping machine.

3.0

RESPONSIBILITY

Production Operators/ Chemist / Officer

IPQA Chemist / Officer

4.0

ACCOUNTABILITY

Head - Production

5.0

PROCEDURE

5.1

5.1.1

5.1.2

5.1.3

5.1.4

Pre-start up

Wear clean nose mask and hand gloves.

Check the status label.

Check the area & machine for cleanliness.

Ensure the temperature (NMT-20C) & RH (NMT-20 %) for Amoxy-Clave product.

Temperature (NMT-25C) & RH (505%) for plain Amoxy product. Record the same in

5.1.5

5.1.6

5.1.7

5.2

5.2.1

5.2.2

BPR.

Ensure the line clearance from IPQA.

Ensure the machine for proper operational setting.

Ensure the status label of upcoming product blend.

5.2.3

Operation

Set the all the sealing heads as per the requirement/production batch requirement.

Set the bottle guide, in-feed guide, out-feed guide, feed worm, cap chute and cap

chamber properly and correctly.

Start the sealing/capping by placing bottles on the conveyor.

5.3

Cleaning

Particulars

Sign.

Date

Name

Prepared By

Checked By

Approved By

Authorized By

FOR RESTRICTED CIRCULATION ONLY

Indchemie

Health Specialities Pvt. Ltd.

Thana, Baddi

STANDARD OPERATING PROCEDURE

Title:

Procedure for Operation & Cleaning of ROPP Sealing /HDPE Capping Machine

Department : Production (Dry Syrup)

SOP No. : IB/BD/05/005

Issue No.

Revision No.

Effective Date

Review Before

Page No.

01

03

05.06.2011

05.06.2013

02 of 03

5.3.1

5.3.2

5.3.3

5.3.4

5.3.5

5.3.6

5.3.7

5.3.8

5.3.9

Turn the main switch Off.

Clean all the viable surfaces.

Clean the centre of sealing/capping heads.

Ensure complete removal of previous materials.

Wipe & clean with a dry and clean duster or lint free cloth.

Set the machine as per the operational need.

Check the machine for correct operational setting.

Affix CLEANED label on the machine

Record the cleaning details in Equipment Log Book.

6.0

REFERENCE (S)

In house

7.0

ANNEXURE (S)

Nil

8.0

ABBREVIATION (S)

SOP :

Standard Operating Procedure

No.

Number

BPR :

Batch Production Record

ROPP :

Round Oriented Poly Propylene

HDPE :

High Density Poly Ethylene

IPQA :

In Process Quality Assurance

RH

Relative Humidity

NMT :

Particulars

Sign.

Date

Name

Not More Than

Prepared By

Checked By

Approved By

Authorized By

FOR RESTRICTED CIRCULATION ONLY

Indchemie

Health Specialities Pvt. Ltd.

Thana, Baddi

STANDARD OPERATING PROCEDURE

Title:

Procedure for Operation & Cleaning of ROPP Sealing /HDPE Capping Machine

Department : Production (Dry Syrup)

SOP No. : IB/BD/05/005

Issue No.

Revision No.

Effective Date

Review Before

Page No.

01

03

05.06.2011

05.06.2013

03 of 03

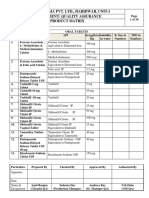

9.0 REVISION CARD :

Sr.

No.

Date

Revision

No.

Issue

No.

01

25.05.2007

00

01

02

26.05.2009

01

01

- Scheduled Revision

- Need Based

03

26.05.2011

02

01

- Scheduled Revision

- Need Based

Particulars

Sign.

Date

Name

Prepared By

Details of revision

- Footer of SOP is revised

As per SOP No. IB/QA/05/001.

Checked By

Approved By

Reason for revision

- Need Based

Authorized By

You might also like

- Instant Download Heat and Mass Transfer Fundamentals and Applications 5th Edition Cengel Solutions Manual PDF All ChapterDocument51 pagesInstant Download Heat and Mass Transfer Fundamentals and Applications 5th Edition Cengel Solutions Manual PDF All Chaptervilinmesuli0% (1)

- Index of QC SopDocument6 pagesIndex of QC SopBeduin Mahanti50% (2)

- Gamma Radiation SterilizationDocument2 pagesGamma Radiation Sterilizationananth67% (3)

- Electric 2 Suzuki VL800Document19 pagesElectric 2 Suzuki VL800Crisan SorinNo ratings yet

- Barge Form Checklist: No. Check Item Condition Remarks Y N N/A I Manning (Crew) DeckDocument4 pagesBarge Form Checklist: No. Check Item Condition Remarks Y N N/A I Manning (Crew) DeckHermawan Alief100% (1)

- Batch Manufacturing RecordDocument7 pagesBatch Manufacturing RecordAnu Joshi100% (1)

- Secondary Change Room VisitorDocument1 pageSecondary Change Room VisitorAshok Lenka100% (2)

- Aphrin Pfs BPR p1 v-1Document13 pagesAphrin Pfs BPR p1 v-1ShagorShagor100% (1)

- SOP On Cleaning of Shrink Wrapping MachineDocument3 pagesSOP On Cleaning of Shrink Wrapping MachineYousifNo ratings yet

- SOP of Cleaning of Equipment and Accessories in Production: 1.0 ObjectiveDocument2 pagesSOP of Cleaning of Equipment and Accessories in Production: 1.0 ObjectiveYousif100% (2)

- Protocol Design Qualification (DQ) : Romaco Kilian S 710 PrimeDocument6 pagesProtocol Design Qualification (DQ) : Romaco Kilian S 710 PrimeTim100% (1)

- BPR - FP025-1 V-1Azinil 35ml PFSDocument17 pagesBPR - FP025-1 V-1Azinil 35ml PFSShagorShagor100% (2)

- Unplanned Cleanroom Power Outage Time Limit and Recovery Determinations For Aseptic Processing AreasDocument2 pagesUnplanned Cleanroom Power Outage Time Limit and Recovery Determinations For Aseptic Processing Areasananth100% (1)

- CR013 SOP Statistical Analysis PlanDocument4 pagesCR013 SOP Statistical Analysis PlanananthNo ratings yet

- Custom GENIL Objects and BOL CreationDocument13 pagesCustom GENIL Objects and BOL Creationjuni0001No ratings yet

- New+holland B110-B115 en Service+manual PDFDocument993 pagesNew+holland B110-B115 en Service+manual PDFAndresSuarez100% (2)

- Solitaire Pharmacia Pvt. LTD.: Restricted Circulation Authorised Persons OnlyDocument8 pagesSolitaire Pharmacia Pvt. LTD.: Restricted Circulation Authorised Persons OnlyNgoc Sang HuynhNo ratings yet

- SOP For Operation of Carton Coding MachineDocument3 pagesSOP For Operation of Carton Coding MachineJayant Kumar JhaNo ratings yet

- 44-O&C Blister Packing MachineDocument7 pages44-O&C Blister Packing MachineananthNo ratings yet

- 2-O&c of Paam Af 90 TDocument6 pages2-O&c of Paam Af 90 Tananth100% (1)

- SOP On Operation and Cleaning of Paste KettleDocument3 pagesSOP On Operation and Cleaning of Paste KettleRakesh Rauniyar100% (1)

- Inner Carton Perizol 15 16Document4 pagesInner Carton Perizol 15 16ShagorShagorNo ratings yet

- SOP On Cleaning and Sanitization in PharmaceuticalljhiuDocument13 pagesSOP On Cleaning and Sanitization in PharmaceuticalljhiuMahadi Hasan Khan0% (1)

- Co Dabamal Tablet 9m606001Document22 pagesCo Dabamal Tablet 9m606001joerichladNo ratings yet

- SOP For Operation of Bottle LabelingDocument4 pagesSOP For Operation of Bottle LabelingSolomonNo ratings yet

- SMFDocument39 pagesSMFMohd AkmalNo ratings yet

- BMR Review FormatDocument1 pageBMR Review FormatVishnu Prasad AvasaralaNo ratings yet

- Line Clearence Ravi 17oct14Document31 pagesLine Clearence Ravi 17oct14pooja singhNo ratings yet

- SOP - Operation of Semi-Automatic Capsule Filling MachineDocument3 pagesSOP - Operation of Semi-Automatic Capsule Filling MachineKrishelle Anne Obispo75% (4)

- Aphrin PFS BMR V-01Document13 pagesAphrin PFS BMR V-01ShagorShagorNo ratings yet

- 09 GMP SOP 08 Quality Control LaboratoryDocument5 pages09 GMP SOP 08 Quality Control Laboratorykishan chiraniaNo ratings yet

- SOP of Sanitation of PW SystemDocument6 pagesSOP of Sanitation of PW Systemanon_350461302100% (1)

- What Is BMR (Batch Manufacturing Record) ?Document2 pagesWhat Is BMR (Batch Manufacturing Record) ?Yousif100% (1)

- Standard Operating Procedure (SOP) Blister MachineDocument1 pageStandard Operating Procedure (SOP) Blister MachineSahil Rathore100% (1)

- 01 BMR Placebo TabletsDocument10 pages01 BMR Placebo TabletsIris Patrisha Abigail BalutocNo ratings yet

- Reconciliation SOP NEWDocument4 pagesReconciliation SOP NEWPrince MoniNo ratings yet

- Vatakulantka Rasa TabletDocument7 pagesVatakulantka Rasa Tabletreflectprakash3610No ratings yet

- Santon Drugs Pvt. LTD: 101, Hemanta Basu Sarani, Udayrajpur Madhyamgram, Kolkata-129Document47 pagesSanton Drugs Pvt. LTD: 101, Hemanta Basu Sarani, Udayrajpur Madhyamgram, Kolkata-129aparna tiwariNo ratings yet

- List of Raw Material ActiveDocument11 pagesList of Raw Material ActiveShagorShagor0% (1)

- Raw Material Requisition Slip - For MergeDocument1 pageRaw Material Requisition Slip - For Mergeasit_mNo ratings yet

- Labaid Pharmaceuticals Limited: Standard Operating ProcedureDocument8 pagesLabaid Pharmaceuticals Limited: Standard Operating ProceduremasumNo ratings yet

- Eskag Pharma Pvt. LTD., Haridwar, Unit-I Department: Quality Assurance Product MatrixDocument20 pagesEskag Pharma Pvt. LTD., Haridwar, Unit-I Department: Quality Assurance Product MatrixMohit ChauhanNo ratings yet

- SOP For Cleaning of StirrerDocument2 pagesSOP For Cleaning of StirrerPrince Moni100% (1)

- Sop of Octangonal BlenderDocument3 pagesSop of Octangonal BlenderHamidNo ratings yet

- 1 Pharmaceutical Quality SystemDocument48 pages1 Pharmaceutical Quality Systemalhusseinahmed34No ratings yet

- Finished Product - Test ProcedureDocument13 pagesFinished Product - Test ProcedureShagorShagor100% (3)

- Prepared by Production: Approved by QA/QC:: TERASOL® 600 BolusDocument19 pagesPrepared by Production: Approved by QA/QC:: TERASOL® 600 BolusLegese HailuNo ratings yet

- SOP For Cleaning and Polishing of Punches and DiesDocument3 pagesSOP For Cleaning and Polishing of Punches and DiesMubarak PatelNo ratings yet

- Product Reference & Its Specification : Master FormulaeDocument2 pagesProduct Reference & Its Specification : Master FormulaenutrimakeNo ratings yet

- Vibratory SifterDocument1 pageVibratory SifterananthNo ratings yet

- Annexure - II Product DevelopmentDocument50 pagesAnnexure - II Product DevelopmentLife PearlNo ratings yet

- Procedure For Preparation of Disinfectant and Sanitization SolutionDocument2 pagesProcedure For Preparation of Disinfectant and Sanitization SolutionPrince Moni100% (1)

- Aromet ER 1000Document14 pagesAromet ER 1000HamidNo ratings yet

- Cefpodoxime 200 Tab New 1Document25 pagesCefpodoxime 200 Tab New 1Gurdev SinghNo ratings yet

- Sterille Production AreaDocument12 pagesSterille Production AreaNavdeep ChaudharyNo ratings yet

- Site Master File of PharmacureDocument43 pagesSite Master File of PharmacureAbebe100% (2)

- Index For SOP-newDocument3 pagesIndex For SOP-newvibhutiNo ratings yet

- Batch Production RecordDocument83 pagesBatch Production Recordsina yadegari100% (1)

- A Product Which Has Completed All Stages of Manufacture, Including Final PackagingDocument4 pagesA Product Which Has Completed All Stages of Manufacture, Including Final Packagingom shankar JhaNo ratings yet

- Miconazole Nitrate PreparationsDocument3 pagesMiconazole Nitrate Preparationsasit_m100% (2)

- Flow Process Chart - TabletsDocument1 pageFlow Process Chart - Tabletsreflectprakash3610No ratings yet

- StorageDocument2 pagesStorageShagorShagorNo ratings yet

- Basic Questionnaire For Kosher Certificate 2Document1 pageBasic Questionnaire For Kosher Certificate 2C P TiwariNo ratings yet

- SOP For Raw Material ReleaseDocument4 pagesSOP For Raw Material ReleaseSolomonNo ratings yet

- Amit ResumeDocument5 pagesAmit ResumeASHOK KUMAR LENKANo ratings yet

- Good Documentation Practices (GDP) in Pharmaceutical IndustryFrom EverandGood Documentation Practices (GDP) in Pharmaceutical IndustryNo ratings yet

- Sch. L1 Open LetterDocument4 pagesSch. L1 Open LetterananthNo ratings yet

- Vibratory SifterDocument1 pageVibratory SifterananthNo ratings yet

- 43-O&C Strip Sealing MachineDocument6 pages43-O&C Strip Sealing MachineananthNo ratings yet

- Certifying A Cleanroom To ISO 14644-1 Class 5Document3 pagesCertifying A Cleanroom To ISO 14644-1 Class 5Hassan HoudoudNo ratings yet

- 57-Online Rejection Note, Material ReturnDocument3 pages57-Online Rejection Note, Material Returnananth100% (2)

- The NDAC (Gastroenterology & Hepatology) NewDocument4 pagesThe NDAC (Gastroenterology & Hepatology) NewananthNo ratings yet

- Sterilization or Depyrogenation Validation - Non ProductDocument2 pagesSterilization or Depyrogenation Validation - Non ProductananthNo ratings yet

- Particle Monitoring Requirements in Pharmaceutical CleanroomsDocument7 pagesParticle Monitoring Requirements in Pharmaceutical CleanroomsananthNo ratings yet

- Specs RlamfiltersDocument4 pagesSpecs RlamfiltersananthNo ratings yet

- The Tanzania Food, Drugs and Cosmetics Act, 2003Document89 pagesThe Tanzania Food, Drugs and Cosmetics Act, 2003ananthNo ratings yet

- Specs RlamfiltersDocument8 pagesSpecs RlamfiltersananthNo ratings yet

- #7 ISPE Environmental MonitoringDocument40 pages#7 ISPE Environmental Monitoringananth100% (3)

- Introduction To Generic Drug Product DevelopmentDocument16 pagesIntroduction To Generic Drug Product Developmentananth100% (1)

- #2 ISPE Schedule L1Document48 pages#2 ISPE Schedule L1ananthNo ratings yet

- Cleaning RequirementsDocument2 pagesCleaning RequirementsananthNo ratings yet

- Biphasic Liquid Dosage FromDocument8 pagesBiphasic Liquid Dosage FromSwaroopSinghJakhar100% (1)

- GE Lighting Systems ALGLAS Reflector Finish Spec Sheet 4-76Document2 pagesGE Lighting Systems ALGLAS Reflector Finish Spec Sheet 4-76Alan MastersNo ratings yet

- BOM Profiles - OracleDocument3 pagesBOM Profiles - OracletsurendarNo ratings yet

- Modeling and Control of A Magnetic Levitation System: Bradley UniversityDocument4 pagesModeling and Control of A Magnetic Levitation System: Bradley UniversityAsma AdeelNo ratings yet

- BH US 12 Branco Scientific Academic SlidesDocument50 pagesBH US 12 Branco Scientific Academic SlidesNks KontosNo ratings yet

- LatheDocument60 pagesLatheMalaika KhursheedNo ratings yet

- Iz9361 Ehdatasheet EnglishDocument3 pagesIz9361 Ehdatasheet EnglishHercules Sofio SanchezNo ratings yet

- Structural Behavior of Lightweight Interlocking Brick SystemDocument13 pagesStructural Behavior of Lightweight Interlocking Brick SystemnawirNo ratings yet

- Bridge Engg - TheoryDocument2 pagesBridge Engg - TheoryPratik KalmekarNo ratings yet

- Dynamics and Statics PDFDocument16 pagesDynamics and Statics PDFaishwarya maheshwariNo ratings yet

- Parts Location: Supplemental Restraint System - Airbag SystemDocument3 pagesParts Location: Supplemental Restraint System - Airbag SystemFernando CorreiaNo ratings yet

- Basic TPS HandbookDocument33 pagesBasic TPS HandbookSumith KobewattaNo ratings yet

- Save Time & Cost WITH: M2FleetDocument13 pagesSave Time & Cost WITH: M2FleetBang OprekNo ratings yet

- Instalacion Cabezal HP A3Document20 pagesInstalacion Cabezal HP A3colorestec28No ratings yet

- EnerguBalanceofSolarCollector PDFDocument36 pagesEnerguBalanceofSolarCollector PDFPV DouzNo ratings yet

- HMT Unit 1Document17 pagesHMT Unit 1Thulasi RamNo ratings yet

- Spesifikasi CAT 385C/385C LDocument28 pagesSpesifikasi CAT 385C/385C LGandang Fawaz100% (1)

- Pentaho Advanced Reporting GuideDocument64 pagesPentaho Advanced Reporting GuideDániel TodorovityNo ratings yet

- Kyocera Fs-2000d, Fs-3900dn, Fs-4000dn Service ManualDocument144 pagesKyocera Fs-2000d, Fs-3900dn, Fs-4000dn Service Manualsupervisor3525100% (2)

- Le Quai de L'horloge No. 1. (Breguet)Document61 pagesLe Quai de L'horloge No. 1. (Breguet)Simon LászlóNo ratings yet

- Bipolar TransistorDocument32 pagesBipolar TransistorRashad Biomedical EngineerNo ratings yet

- Microphone Array BeamformingDocument12 pagesMicrophone Array BeamformingigreenNo ratings yet

- Performance of CNSL-based Polyols Vs Castor Oil Based PolyolsDocument15 pagesPerformance of CNSL-based Polyols Vs Castor Oil Based PolyolsA VasNo ratings yet

- NBC Part 4 Fire SafetyDocument82 pagesNBC Part 4 Fire SafetyKaushik DasNo ratings yet

- BP Eternus cs200c Inst Conf Guide WW en PDFDocument56 pagesBP Eternus cs200c Inst Conf Guide WW en PDFJinu Varghese100% (1)