Amit Kumar Gupta

Amit Kumar Gupta

Uploaded by

amit.guptanimCopyright:

Available Formats

Amit Kumar Gupta

Amit Kumar Gupta

Uploaded by

amit.guptanimOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Amit Kumar Gupta

Amit Kumar Gupta

Uploaded by

amit.guptanimCopyright:

Available Formats

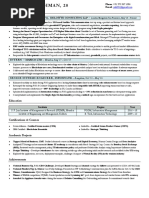

Amit Kumar Gupta

amit.guptanim@gmail.com

Ph- 9632767347

ACADEMIC PROFILE

MBA (Finance) from Institute of Management, Nirma University 2006-08 (CAT

-90+)

B.Tech (Mechanical Engg.) from IT- BHU (IIT) in 1999-2003 (AIR – 1947)

Candidate for Financial Risk Manager (FRM) -2009 from GARP

Cleared AMFI – NCFM Mutual Fund Advisory Module

Electives: Macro and Micro Economics, Investment Banking, Mergers and

Acquisitions, Investment and Portfolio Management, Derivative and Risk

Management, Valuation, Wealth Management , Foreign Exchange Management

Enterprise Resource Planning , Operation Management , Supply Chain

Management, Business Process Re-engineering, IT strategy for Business etc

PROFESSIONAL EXPERIENCE

Over 3.75 years

Associate Manager- Marketing, Collabera (April

2008 – till date)

Key performance Area

Solution Marketing – Banking and Financial Services

Develop and manage the overall marketing plan Research, market

identification, solution thought generation, solution short-listing and managing

solution development

Go-To-Market readiness for the services identified under each vertical and

horizontal services

Class 1 offering - go to market responsibility

Campaign planning and execution for identified services and solutions

Manage training activities for sales and inside sales

Information push to - website, conferences, publications, internal and external

communication

Created demos for Solutions

Competitive Intelligence

Identification of client goals, financial performance, product and service offering,

market share, IT outsourcing history

Competitive landscape analysis and comparison in terms of service focus,

industry focus, positioning, differentiation, recommendations

Knowledge Management

Generate, share, update and manage knowledge artifacts - case studies,

research papers, white papers, service presentations, sales support materials

Senior Engineer, Ispat Industries Limited- Manufacturing

(June 2003 – Apr 2005)

Key Performance Areas

Quality Assurance

Handling the implementation of Six Sigma projects till completion.

Identifying factors critical to quality, reducing process variation, improving

capabilities & increasing stability to support Six Sigma goals.

Implementing Gemba Kaizen, TPM to streamline and standardise work flow

Planning & Research

Evaluation of vendors, Procurement Planning & Inventory management to

provide best possible sourcing opportunities for my BU.

Cost and consumption analysis for my BU

Analyzing data of steel and mining companies, basically financial snapshot and

operation matrices

Maintenance/Operations

Managing the preventive/breakdown maintenance of hydraulic equipment to

reduce breakdowns and downtime to minimum.

Conducting tests to prevent accidents and ensure adherence to safety norms.

SUMMER INTERNSHIP PROJECT

2 Months

Standard Chartered Asset Management Co.

Department: Finance/Marketing

Project title: Role of Distribution Channel in an AMC.

Description: The project was aimed at studying the distribution channel process at

Standard Chartered AMC. Another aspect of the project was to decipher the psyche

of the broker because it is the brokers which bring the business to the AMC. I

conducted a survey for Standard Chartered AMC to get what the needful can be

done to improve the services and enhance the sale of different products. The

survey consisted of questionnaire which was being asked to fill up by the brokers.

Based on the answers, I evaluated the performance and services expected by these

brokers and distributors.

SIGNIFICANT ACCOMPLISHMENT

Ispat Industries Ltd: Six Sigma Projects

Hold the distinction of successfully executing the following Six Sigma projects:

− Green Belt project for ensuring availability of screw compressor in

year2005. Achieved saving of Rs. 1 million.

− Key member of team that executed the project to detect root cause of

BLT Failure. The problem was successfully resolved.

Member of team that executed the project to rectify the MUDGUN failure.

Underwent cross functional training across the Blast Furnace, Sponge Iron Plant

(Midrex), Steel Melt Shop, CSP Caster and 6 Stands 4 Hi Hot Rolling Mill as well

as in Marketing and Finance from Jun’03-Sep’03.

TRAINING PROGRAMS ATTENDED

Participated in a seminar on “3rd Conference in Digital Media” in 2008.

Participated in training program on commodities trading conducted by MCX in

2007.

Certified Training on Hydraulics by Botsch Rexroth at Ahmedabad in 2005.

Participated in a special training program for TPM conducted by JIPM at ISPAT in

2005.

Six Sigma Green Belt Training (DMAIC) conducted by Ispat in 2003.

You might also like

- Project Proposal To Dairy Farm and Milk Processing PlantDocument50 pagesProject Proposal To Dairy Farm and Milk Processing PlantTesfaye Degefa100% (11)

- Joint Arrangements: Use The Following Information For Questions 1 and 2Document1 pageJoint Arrangements: Use The Following Information For Questions 1 and 2Mary Jescho Vidal AmpilNo ratings yet

- XLRI CV Manish KumarDocument2 pagesXLRI CV Manish KumarobvertNo ratings yet

- SACHIN KUMAR Project Report Final Ready 1 PDFDocument37 pagesSACHIN KUMAR Project Report Final Ready 1 PDFaditya sharmaNo ratings yet

- SAP PM SAMPLE ResumeDocument5 pagesSAP PM SAMPLE ResumesrinivasNo ratings yet

- Resume SampleDocument2 pagesResume SampleDebarchan MishraNo ratings yet

- Hesham Elmahdy: Reliability, Account ManagerDocument5 pagesHesham Elmahdy: Reliability, Account ManagerHesham MahdyNo ratings yet

- Vikrant Ghai 2010Document2 pagesVikrant Ghai 2010vikrantghaiNo ratings yet

- Profile PDFDocument5 pagesProfile PDFnikogeorgievNo ratings yet

- CV KhirullahDocument6 pagesCV Khirullahkyle1991No ratings yet

- Liladhar Prabhakar ChaudhariDocument4 pagesLiladhar Prabhakar ChaudhariMohammed Gufran SayedNo ratings yet

- Assignments-Mba Sem-Iii: Subject Code: QM0004Document16 pagesAssignments-Mba Sem-Iii: Subject Code: QM0004Mithesh KumarNo ratings yet

- Amit PP QM ResumeDocument10 pagesAmit PP QM ResumephalgunsapNo ratings yet

- Resume Vikas KhareDocument2 pagesResume Vikas KhareK Srinivasa RaoNo ratings yet

- DeepakKumarDeb 13463624 - 09 00 - 1Document3 pagesDeepakKumarDeb 13463624 - 09 00 - 1Mayur ShindeNo ratings yet

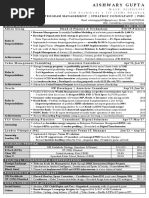

- Aishwary Gupta IIMK IIT (ISM)Document1 pageAishwary Gupta IIMK IIT (ISM)Aishwary GuptaNo ratings yet

- IND AS ProjectDocument11 pagesIND AS ProjectRohit PandeyNo ratings yet

- 0 - Siddharth Murarka - CVDocument2 pages0 - Siddharth Murarka - CVshivNo ratings yet

- Resume - Chirag Madaan (September 2024)Document2 pagesResume - Chirag Madaan (September 2024)Nipun SadanaNo ratings yet

- Executing Lean Sigma Outline in An Indian MsmeDocument12 pagesExecuting Lean Sigma Outline in An Indian MsmeSalah HammamiNo ratings yet

- Rahul Kale Resume Ver 4 (08-07-2012)Document2 pagesRahul Kale Resume Ver 4 (08-07-2012)RahuldkaleNo ratings yet

- Managment by AkkuDocument9 pagesManagment by AkkuAnkush PardhiNo ratings yet

- Arpit - SAP SD ResumeDocument4 pagesArpit - SAP SD ResumeAarav ChoudharyNo ratings yet

- 877c8orient Electricals Revised Final Placement NoticexxDocument6 pages877c8orient Electricals Revised Final Placement Noticexxmicky_chhabra55No ratings yet

- Key Skills Profile Summary: Krishan Mohan SharmaDocument3 pagesKey Skills Profile Summary: Krishan Mohan SharmaSAMSON GLOBALNo ratings yet

- Certified Six Sigma Black Belt PDFDocument2 pagesCertified Six Sigma Black Belt PDFthindmanmohanNo ratings yet

- CV - Zafryll Amir ZulkiflyDocument3 pagesCV - Zafryll Amir ZulkiflyZaf AmirNo ratings yet

- Ashish Kaushik CVDocument3 pagesAshish Kaushik CVashishkaushik19826508No ratings yet

- Module-6:: Project Preparation & Appraisal Definition:-Project Is The Whole Complex of Activities Involved in UsingDocument9 pagesModule-6:: Project Preparation & Appraisal Definition:-Project Is The Whole Complex of Activities Involved in UsingMehul_Singh_7900No ratings yet

- Resume Nitish Pandey ExtDocument3 pagesResume Nitish Pandey Extni19ti82shNo ratings yet

- Amit Mudgal - Polymer Technologist With Work Ex of More Than 7 Years in Research & Business DevelopmentDocument4 pagesAmit Mudgal - Polymer Technologist With Work Ex of More Than 7 Years in Research & Business Developmentamit_mudgal2007No ratings yet

- A Study On Marketing Mix Strategies and Impact of Consumer Behavior On Piaggio APE Autos and TrucksDocument163 pagesA Study On Marketing Mix Strategies and Impact of Consumer Behavior On Piaggio APE Autos and Trucksveerabhadraswamy100% (5)

- Ajay Resume'Document2 pagesAjay Resume'Ajay KumarNo ratings yet

- Ankit Gupta SAP PMDocument4 pagesAnkit Gupta SAP PMarpangupta007No ratings yet

- Amita Deshpande-CV-Visiting FacultyDocument4 pagesAmita Deshpande-CV-Visiting FacultyamitaNo ratings yet

- Maya More-18, Ctc-28 LacsDocument6 pagesMaya More-18, Ctc-28 LacsSamsher SinghNo ratings yet

- RadhikaNalawade 8 0Document4 pagesRadhikaNalawade 8 0Mohammed Gufran SayedNo ratings yet

- ResumeDocument4 pagesResumeAsh Asif GaniNo ratings yet

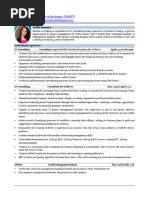

- Anu Kharwal BADocument2 pagesAnu Kharwal BASukanta JanaNo ratings yet

- KunalNagpal (4,0)Document3 pagesKunalNagpal (4,0)venkatmatsNo ratings yet

- Group 4 - ACS Project Report On 3M India PDFDocument31 pagesGroup 4 - ACS Project Report On 3M India PDFPiyush KumarNo ratings yet

- Mining Operational ExcellenceDocument12 pagesMining Operational Excellencegarozo100% (1)

- " Six Sigma in Indian Industries": Project ProposalDocument7 pages" Six Sigma in Indian Industries": Project ProposalParvez AlamNo ratings yet

- Syed Saif Rahman02032020Document2 pagesSyed Saif Rahman02032020Saif RahmanNo ratings yet

- Varun-Kumar 1209Document1 pageVarun-Kumar 1209kumaraiesecadityaNo ratings yet

- P.K. Singh 12Document85 pagesP.K. Singh 12Pradeep Kumar SinghNo ratings yet

- Six Sigma PHD ThesisDocument5 pagesSix Sigma PHD Thesiscarolelmonte100% (2)

- Mark Knofler: Career OverviewDocument2 pagesMark Knofler: Career OverviewknoflerNo ratings yet

- Shree NanguneriDocument20 pagesShree NangunerivarungoenkaNo ratings yet

- SM AssDocument19 pagesSM Assjollylancher100No ratings yet

- P GoyalDocument6 pagesP GoyalMridul GoelNo ratings yet

- Aloksrivastava: Profile SummaryDocument3 pagesAloksrivastava: Profile SummarySuman SharmaNo ratings yet

- Six Sigma Executive Overview Brochure NadeemDocument4 pagesSix Sigma Executive Overview Brochure NadeemSyedNadeemAhmedNo ratings yet

- 3531 MBA LE Programme GuideDocument48 pages3531 MBA LE Programme GuideSahendra PandeyNo ratings yet

- Corse Toitle Code 1102 Management of OrganizationDocument55 pagesCorse Toitle Code 1102 Management of OrganizationsaniNo ratings yet

- Resume RachnaDocument2 pagesResume RachnaPallav AbhishekNo ratings yet

- Redesign and Manufacturing by Using DmadDocument6 pagesRedesign and Manufacturing by Using Dmadblackberry7130gNo ratings yet

- Prepare The List On World Class Industries Using Six Sigma Technique Present and Write Detail Report On Anyone of ThemDocument11 pagesPrepare The List On World Class Industries Using Six Sigma Technique Present and Write Detail Report On Anyone of ThemMe Samarth BadsalNo ratings yet

- A STUDY ON IMPACT OF SIX SIGMA PRACTICES AT Harita Tvs Technologies LTDDocument7 pagesA STUDY ON IMPACT OF SIX SIGMA PRACTICES AT Harita Tvs Technologies LTDAnonymous WtjVcZCgNo ratings yet

- Six Sigma Green Belt 1Document2 pagesSix Sigma Green Belt 1Maaz IdreesNo ratings yet

- A Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessFrom EverandA Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessNo ratings yet

- A Study of the Supply Chain and Financial Parameters of a Small BusinessFrom EverandA Study of the Supply Chain and Financial Parameters of a Small BusinessNo ratings yet

- Chapter 3Document5 pagesChapter 3Julie Neay AfableNo ratings yet

- Sub Order LabelsDocument21 pagesSub Order LabelsBitu singh ShekhawatNo ratings yet

- The Communication Management and Entrepreneurship As A Field of StudyDocument15 pagesThe Communication Management and Entrepreneurship As A Field of StudyJezelle CorbetaNo ratings yet

- Adding Value To Poultry ProductionDocument9 pagesAdding Value To Poultry Productionjiningweye100% (1)

- Study On Asset and Liability Managment at Heritage Foods Ltd.Document52 pagesStudy On Asset and Liability Managment at Heritage Foods Ltd.Paavan Kumar20% (5)

- All Updated Follow Up NewDocument267 pagesAll Updated Follow Up Newarefayne wodajoNo ratings yet

- Keywords XlssDocument11 pagesKeywords XlssAbdullah BalouchNo ratings yet

- f5 2014 Dec Q PDFDocument14 pagesf5 2014 Dec Q PDFawlachewNo ratings yet

- MCQ IdtDocument30 pagesMCQ IdtkartikNo ratings yet

- Tourism Plan and Code - Zamboanga Del NorteDocument6 pagesTourism Plan and Code - Zamboanga Del NorteMelissa FNo ratings yet

- 03 Swapna Banerjee-Guha - Homeless in Neoliberal Cities, View From MumbaiDocument7 pages03 Swapna Banerjee-Guha - Homeless in Neoliberal Cities, View From Mumbaipriyam_tripathyNo ratings yet

- Ch. 1 P1 - The Economic ProblemDocument18 pagesCh. 1 P1 - The Economic ProblemyeyeNo ratings yet

- A Study On Capital BudgetingDocument2 pagesA Study On Capital BudgetingANKIT SINGHNo ratings yet

- Resume Abhay JaiswalDocument2 pagesResume Abhay Jaiswalabhay jaiswalNo ratings yet

- SHRM Report of Coca COLADocument18 pagesSHRM Report of Coca COLAMalik Atif Zaman100% (1)

- The Role of Extension Officers and Extension Services in The Development of Agriculture in NigeriaDocument6 pagesThe Role of Extension Officers and Extension Services in The Development of Agriculture in NigeriaANAETO FRANK C.100% (1)

- Final Bank Alfalah ProjectDocument29 pagesFinal Bank Alfalah ProjectumairsanaNo ratings yet

- Purchase Order LetterDocument15 pagesPurchase Order LetterAditia Rahman0% (1)

- Ministry of Industry ReportDocument76 pagesMinistry of Industry ReportShiv Shankar MandalNo ratings yet

- Marketing Strategies of TATA MotorsDocument122 pagesMarketing Strategies of TATA MotorsPrikshit Sharma100% (1)

- FINANCIAL MATHEMATICS Notes PDFDocument7 pagesFINANCIAL MATHEMATICS Notes PDFpraveen100% (1)

- Finance in IndiaDocument6 pagesFinance in IndiamanojNo ratings yet

- RTB Taxation II ReviewerDocument59 pagesRTB Taxation II Reviewerdiazadie100% (1)

- Wishup JDDocument2 pagesWishup JDSaran KoolNo ratings yet

- Ia2 LiabilitiesDocument14 pagesIa2 LiabilitiesMeiNo ratings yet

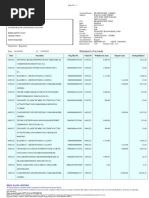

- Acct Statement XX0311 07062022Document4 pagesAcct Statement XX0311 07062022RAJKUMAR NAYAKNo ratings yet

- Chapter 21 Introduction To Derivative MarketsDocument31 pagesChapter 21 Introduction To Derivative MarketsSarika Thakur100% (1)

- Far - Module 1 (Apol)Document10 pagesFar - Module 1 (Apol)Patricia may RiveraNo ratings yet