Concrete Specification

Concrete Specification

Uploaded by

Asad Jamil JawandaCopyright:

Available Formats

Concrete Specification

Concrete Specification

Uploaded by

Asad Jamil JawandaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Concrete Specification

Concrete Specification

Uploaded by

Asad Jamil JawandaCopyright:

Available Formats

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

SECTION 4 - CONCRETE WORKS

Concrete work shall consist of furnishing all materials and constructing structures of the

forms, shapes and dimensions shown on the Drawings or as directed in accordance with

the details shown on the Drawings and these Specifications.

4/1

CEMENT

SULPHATE RESISTING CEMENT

4/1.1

Sulphate Resisting Cement shall comply with BS EN 197-1:2011, Class 42.5N

or ASTM C150/C150M-2012 Type V. In addition the cement shall comply with

the following:-

The acid soluble alkali level measured as (Na 2 O+0.658 K 2 O) shall not

exceed 0.6% by weight determined in accordance with BS EN 196-2 :

2005

The heat of hydration shall not exceed 290 KJ/Kg at 7 days when tested in

accordance with BS 4550: Part 3 Section 3.8.

The specific surface shall be not greater than 375 m/Kg and not less than

280 m/Kg when tested as described in BS EN 196: Part 6: 1992.

The chloride content shall not exceed 0.1% when tested in accordance

with Clause 4 of BS EN 196-2 : 2005

The tricalcium aluminate content shall be 3.5% max when tested according

to the method BS EN 196-2 : 2005

ORDINARY PORTLAND CEMENT

4/1.2

Ordinary Portland Cement shall conform to the requirements of BS EN

197-1:2011, Class 42.5N or ASTM C150 Type I and with the following

amendments: The acid soluble alkali level measured as (Na 2 O+0.658 K 2 O) shall not

exceed 0.6% by weight determined in accordance with in BS EN 196-2

2013.

The heat of hydration shall not exceed 290 KJ/Kg at 7 days when tested in

accordance with BS 4550: Part 3 Section 3.8.

Contain not less than 4% and not more than 8% proportion of tricalcium

aluminate by weight when tested according to the method BS EN 196-2 :

2013.

Contain less than 2.7% proportion of Sulphur Trioxide by weight according

to the method ASTM C563-13 or ASTM C114-2013.

The specific surface (fineness) shall be not greater than 375 m/Kg and not

less than 280 m/Kg when tested as described in BS EN196 : Part 6: 2010.

March 2015

Tender Documents

Page 4/3

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

The chloride content shall not exceed 0.1% when tested in accordance

with Clause 4 of BS EN 196-2: 2013.

For any type of cement, the following physical & mechanical test shall also

to be included:

o

o

o

o

Consistency in accordance with BS EN 196-3:2008.

Setting time in accordance with BS EN 196-3:2008

Soundness in accordance with BS EN 196-3:2008.

Compressive strength in accordance with BS EN 196-1:2005

Requirements of Cementatious Supplementary Materials (CSM)

If fly ash is recommended for concrete works, it shall conform to the requirements

of ASTM C618-12 or BS EN 450-1:2012.

If Ground Granulated Blast Furnace Slag (GGBS) and blended cement is

recommended for concrete works, it shall conform to the requirements of following

standard specifications:

ASTM C595/C595M-07

ASTM C989/C989M-14

MODERATE SULPHATE RESISTING PORTLAND CEMENT

4/1.3

Moderate sulphate resisting Portland Cement shall comply with ASTM C150

Type II. It shall also comply with Clause 4/1.2. In addition the cement shall

comply with the following:-

The acid soluble alkali level measured as (Na 2 0+0.658 K 2 0) shall not

exceed 0.6% by weight determined in accordance with BS EN196 2

2005

The specific surface (fineness) shall not be greater than 375 sq.m/Kg and

not less than 280 sq.m/Kg when tested as described in BS EN 196: Part 6:

1992.

The chloride content shall not exceed 0.1% when tested in accordance

with Clause 4 of BS EN 196-2 : 2005

Contain not less than 4% and not more than 8% proportion of tricalcium

aluminate by weight when tested according to the method BS EN 196-2 :

2005

Contain less than 2.7% proportion of Sulphur trioxide by weight

For any type of cement, the following physical & mechanical test shall also be

included:

Consistency in accordance with BS EN 196-3: 2008

Setting time in accordance with BS EN 196-3: 2008

Soundness in accordance with BS EN 196-3: 2008

March 2015

Tender Documents

Page 4/4

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

Compressive Strength BS EN 196-1: 2005

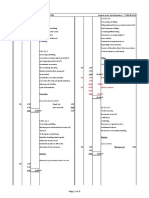

Mechanical and physical requirements given as characteristic values

Compressive Strength MPa

Strength

Class

Early Strength

2 days

7 days

32.5 N

16.0

32.5 R

10.0

42.5 N

10.0

42.5 R

20.0

52.5 N

20.0

52.5 R

30.0

Standard Strength

28 days

32.5

42.5

52.5

52.5

62.5

Initial

Setting

Time

min.

Soundness

(expansion)

mm

75

60

10

45

GENERAL

4/1.4

Each cement batch shall bear manufacturer's name and batch number. Type

of cement shall be the same as mentioned in the approved analysis report.

Each separate consignment of cement shall be tested by the manufacturer

before delivery and certified copies of such tests shall be supplied to the

Engineer before any part of the consignment is used in the works. The

Engineer reserves the right to order a re-test of cement at any time. Approval

of cement does not relieve the Contractor of the responsibility to produce

concrete of the specified strength.

4/1.5

Cement shall be delivered to site in bulk, or with the Engineer's approval, may

be supplied in sealed bags which shall bear the manufacturer's name and the

date of manufacture. Each consignment shall be accompanied by a copy of

the manufacturer's batch test certificate and certificate of guarantee.

4/1.6

Each consignment of cement shall be kept separate, identified and used in

order of delivery.

4/1.7

Any consignment not used within 2 months from the date of manufacture will

not be allowed to be used in the works.

4/1.8

One brand only of cement as approved by the Engineer shall be used

throughout the works unless otherwise authorized by the Engineer in writing.

4/1.9

Each cement batch shall bear manufacturers name and batch number

March 2015

Type of cement shall be the same as mentioned in the approved

analysis report.

Each separate consignment shall be tested by manufacture before

delivery.

Certified copies of batch test certificate and certificate of guarantee

shall be supplied to the Engineer before any part of the consignment is

used in the works.

Tender Documents

Page 4/5

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

The Engineer reserves the right to order a re-test of cement at any time

Approval of cement does not relieve the Contractor of the responsibility

to produce concrete of the specified strength.

Cement shall be delivered to site in bulk, or with the Engineers

approval, may be supplied in sealed bags bearing manufacturers

name and date of manufacture.

Each consignment shall be kept separate, identified and used in order

of delivery.

Any consignment not used within 2 months from the date of

manufacture will not be allowed to be used in the works.

4/2

AGGREGATES GENERAL REQUIREMENTS

4/2.1

Except as may be modified hereunder the aggregate (fine and coarse) for all

types of concrete shall comply in all respects with BS 882 "Concrete

aggregates from natural sources" and the fine aggregate shall also comply

with Dubai Municipality Administrative Order No. 143/91.

4/2.2

The aggregates used in the permanent works shall be naturally occurring or

crushed materials obtained only from approved sources.

4/2.3

Before any material from a particular source is used, the Contractor shall

obtain representative samples of fine and coarse aggregates and carry out the

necessary tests and analyses to show that the samples comply with the

Specification. During the progress of the works, the grading and chemical

characteristics may be checked at frequent intervals.

4/2.4

The results of these tests, etc. shall be submitted to the Engineer and his

approval shall be obtained before any of the material is used in the works.

Part of each sample will be required for concrete trial mixes and part shall be

retained for comparison with subsequent deliveries.

4/2.5

Sampling for testing and analysis shall be carried out, where applicable, in

accordance with BS 812 Part 102:1989.

4/2.6

The maximum size of the aggregate shall not be larger than 1/5 of the

narrowest dimension between sides of the member for which the concrete is to

be used and not larger than 3/4 of the maximum clear distance between

reinforcing bars.

4/2.7

Fine aggregate shall be natural or crushed sand and beach sand shall not be

permitted for use in concrete mixes.

4/2.8

Coarse aggregate shall be crushed aggregate obtained from a quarry

approved by the Engineer.

4/2.9

Unless otherwise authorized by the Engineer coarse aggregate shall be

delivered to site in separate sizes according to the maximum specified

aggregate size for each grade of concrete.

4/2.10

Aggregates shall meet the requirements of Table 4.1.

4/2.11

The frequency of testing of aggregates shall be in accordance with Table 4.2

or as directed by the Engineer.

March 2015

Tender Documents

Page 4/6

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

TABLE 4.1: LIMITS FOR PHYSICAL, CHEMICAL AND MECHANICAL

PROPERTIES OF AGGREGATES FOR CONCRETE

SR.

NO.

KIND OF REQUIREMENT

1.

Grading

2.

Material finer

Than 0.075 mm

TEST METHODS

---------------------BS 812 / ASTM

BS EN 933-1: Standard

2012 (Dry)

Standard

BS EN 9331:2012 or

ASTM

C117:2004

(Wet)

Natural, uncrushed/

crushed

Crushed rock

3.

PERMISSIBLE LIMITS

----------------------------------FINES

COARSE

Clay lumps and

friable particles

max.3%

max.7%

max.1%

max.1%

C142/C142M:

2010

max.1%

max.1%

C123

max.0.5%

max.0.5%

The color of

the

Supernatant

liquid is

lighter than

standard

color solution

max.2.3%

max.2.0%

min.2.60

min.2.60

4.

Light weight pieces

5.

Organic impurities for C40 : 2004

fine aggregate

6.

Water absorption

C128 : 2012a

C128 : 2012

7.

Specific Gravity

C128 : 2012a

C128 : 2012

(apparent)

8.

9.

Shell content in

aggregates

Coarser than 10 mm

Between 5mm-10mm

BS EN

7:1998

Particle shape

Flakiness index

BS 812:90

Part

105

:

Section 105.1

Part

105

:

Section 105.2

Elongation index

933max.5%

Max.15%

max.25

max.25

The index shall be max.

March 2015

Tender Documents

Page 4/7

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

TABLE 4.1: LIMITS FOR PHYSICAL, CHEMICAL AND MECHANICAL

PROPERTIES OF AGGREGATES FOR CONCRETE

SR.

NO.

KIND OF REQUIREMENT

TEST METHODS

---------------------BS 812 / ASTM

PERMISSIBLE LIMITS

----------------------------------FINES

COARSE

25

for

combined

aggregates but should

not exceed more than

30 for individual sizes.

9a.

Partially crushed faces DMS 8 : 2001

of coarse aggregate

with at least one

crushed face.

10.

Acid soluble

Part 117,

Chlorides, CL

Appendix C

For reinforced

concrete made with

SRPC cements

OPC

&

MSRPC

cements

max.0.03%

max.0.03%

max.0.01%

max.0.02%

max.0.03%

max.0.03%

max.0.02%

max.0.04%

max.0.03%

max.0.01%

BS EN 17441:1998

max.0.3%

max.0.3%

Soundness, MgS04

(5 cycles)

C88 : 2013

max.12%

max.12%

Mechanical strength

10% fines value

or Impact value

Part 111

Part 112

min100KN

max.30%

C131 : 2014

C535 : 2014

max.30%

Part 120

max.0.05%

For mass concrete

Made with

SRPC cements

OPC

&

MSRPC

cements

For prestressed

concrete & steam

Cured structural

concrete

11.

12.

13.

Acid soluble

sulphates, S03

Los Angeles

Abrasion

March 2015

100%.

14.

Drying Shrinkage

15.

Potential reactivity,

Tender Documents

Page 4/8

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

TABLE 4.1: LIMITS FOR PHYSICAL, CHEMICAL AND MECHANICAL

PROPERTIES OF AGGREGATES FOR CONCRETE

SR.

NO.

KIND OF REQUIREMENT

TEST METHODS

---------------------BS 812 / ASTM

PERMISSIBLE LIMITS

----------------------------------FINES

COARSE

Note 2

Of Aggregates,

Chemical Method

Of Cement-Aggregate

Combination

C289

Innocuous

C227

6 month

expansion

0.10% max.

Innocuous

Note 1 :

There is no requirement of shell content in sands passing 4 mm

sieve size.

Note 2 :

Aggregates may initially be assessed for its reactivity in accordance

with ASTM C289 and if potential reactivity is indicated, then mortar

bar tests in accordance with ASTM C227 shall be carried out.

TABLE 4.2: FREQUENCY OF ROUTINE TESTS ON AGGREGATES

March 2015

SR.

NO.

KIND OF REQUIREMENT TEST METHOD

TEST FREQUENCY RATE

1.

Grading - BS EN 933-1:1997

Per 1,000m3

2.

Material finer than 0.075 mm BS EN 933-1 or ASTM C117:2004

- do -

3.

Clay lumps and Friable Particles

- ASTM C 142

Per 4,000m3

4.

Organic impurities ASTM C 40

Per 2,000m3

5.

Water absorption

2007/C127 : 2007

- do -

6.

Specific Gravity - ASTM C128 : 2007/C127

: 2007

- do -

7.

Shell content - BS EN 933-7:1998

- do -

8.

Particle shape BS 812 :1990 Section 105

- do -

ASTM

Tender Documents

C128

Page 4/9

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

TABLE 4.2: FREQUENCY OF ROUTINE TESTS ON AGGREGATES

SR.

NO.

KIND OF REQUIREMENT TEST METHOD

TEST FREQUENCY RATE

Part 105.1.& Section 105 Part 105.2

9.

Acid soluble chlorides, CL

Qualitative-BS 812 : 1988 Part 117

Appendices A/B

Per 1,000m3

Quantitative-BS 812 : 1988 Part 117

Appendix C

Each 12 concrete

days if result is

more than 75% of

the limit and each

month if result is

less than 75% of

the limit.

10.

Acid soluble sulphates,

S03 - BS EN 1744-1:1998

Per 1000 M3 or Each 24

concrete days if

result is more than 75%

of the limit & each 2

months if result is less

than 75% of the limit

which ever is less

11.

Soundness, Mg S04 (5 cycles)

ASTM C88 : 2005

Each 48 concrete

Days or 2,000 m3

12.

Mechanical Strength

10% Fines or impact value

- BS 812 Parts 111, 112

Each 72 concrete

Days or 4,000 m3

Los Angeles abrasion ASTM C 131/C 535

- do -

13.

Moisture variation in sand - by

Moisture Meters

Twice daily

14.

Drying Shrinkage

BS 812 Part 120

At the start of the project

and whenever there is a

change in the source of

supply.

15.

Potential Reactivity:

of aggregates

(ASTM C 295, C 289)

At the start of the project

and wherever there is a

change in the source of

Supply

of Carbonate (ASTM C 586)

March 2015

Tender Documents

Page 4/10

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

TABLE 4.2: FREQUENCY OF ROUTINE TESTS ON AGGREGATES

SR.

NO.

KIND OF REQUIREMENT TEST METHOD

TEST FREQUENCY RATE

of Cement aggregate

combination

(ASTM P214 and C 227)

16

Note :

Light weight pieces test (ASTM C 123)

Per 2,000 m3

Drying Shrinkage and potential reactivity of aggregates shall be

determined initially at the start of the project or whenever there is a

change in the source of supply.

4/3

FINE AGGREGATES

4/3.1

The gradation of fine aggregate shall be in accordance with BS 882 latest

edition.

4/3.2

Each batch of aggregate delivered to site shall be kept separate from previous

batches and shall be stored for at least 3 (three) working days before use to

allow inspection and tests to be carried out.

4/3.3

Fine Aggregate shall be clean sharp natural and/or crushed sand.

4/3.4

The Contractor shall mechanically wash aggregate to remove salts and other

impurities in order to meet the requirement specified.

4/4

COARSE AGGREGATE FOR CONCRETE

4/4.1

Coarse aggregate shall be prepared as single sized aggregate and blended to

produce normal size grading. The combined grading shall be within the

appropriate grading limits given in BS EN 12620: 2000.

4/4.2

Aggregates that are deleteriously reactive with the alkalis in the cement in an

amount sufficient to cause excessive expansion of concrete shall not be used.

4/4.3

The Contractor shall mechanically wash aggregate to remove salts and other

impurities in order to meet the requirement specified.

March 2015

Tender Documents

Page 4/11

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

4/5

COMBINED AGGREGATE

4/5.1

Approved coarse aggregate and fine aggregate in each batch shall be

combined in proportions as specified in BS EN 12620:2000 and as approved

by the Engineer. However, in no case shall materials passing the 0.075mm,

sieve exceed three (3) percent by weight of the combined aggregate.

4/5.2

The combined aggregate gradation used in the work shall be as specified,

except when otherwise approved or directed by the Engineer. Changes from

gradation to another shall not be made during progress of the work unless

approved by the Engineer.

4/6

WATER FOR CONCRETE

4/6.1

The Contractor shall make his own arrangement and obtain approval for the

supply of water.

4/6.2

The mixing water should be clear, apparently clean and free from matter

harmful to concrete in its fresh or hardened state. Potable water can be used.

Water of questionable quality should comply with the physical tests of Table

4.3 and chemical limitation listed in Table 4.4. Water shall also meet the

requirement of BS EN 1008:2002.

4/6.3

The temperature of water for concrete should not be less than 5 degree

Celsius nor more 25 degree Celsius. Water may be cooled to not less than 5

degree Celsius by the gradual addition of chilled water or ice but on mixing, no

ice particles should be present in the mix. Alternatively, flaked ice may be

used. The ice to be used should be crushed and should be the product of

frozen water which complies with acceptance criteria of Tables 4.3 and 4.4.

4/6.4

Water for curing concrete shall not contain impurities in sufficient amounts to

cause discoloration of the concrete. Sources of Water shall be maintained at

such depth and the water shall be withdrawn in such a manner as to exclude

silt, mud, grass and other foreign matter.

TABLE 4.3

ACCEPTANCE CRITERIA AND PHYSICAL

TESTS FOR MIXING WATER

March 2015

Limits

ASTM Test

Compressive strength,min.%

control at 7 days

90

C 109 : 2002

Setting time, deviation

from control,h:min.

from 1:00 early

to 1:30 later

C 191 :2004

Tender Documents

Page 4/12

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

TABLE 4.4: CHEMICAL LIMITATIONS FOR MIXING WATER

Max. Concentration,

Limit, ppm

Test Method

1.

Chloride as C1

250

ASTM D 512:

(2004)

2.

Sulphates as SO4

350

ASTM D 516:2002

3.

Alkali carbonates

and bicarbonates

500

ASTM D 513:2006

4.

Total dissolved

solids, including

1, 2 & 3 above

2000

BS 1377 : Part 3 :

1990:

Test 8

PH

min.7/max. 9

ASTM

1999

5.

D1293

4/7

APPLICABLE TESTS AND CODES

4/7.1

All concrete, aggregate, cement, steel and water shall be tested during the

construction as per frequency in Tables 4.2 and 4.6 or as directed by the

Engineer. All test samples shall be supplied by the Contractor at his expense.

Samples shall be obtained in accordance with BS 812, BS EN 1008, BS 1881

and BS EN 196. Testing shall be at the frequencies stated above or relevant

standards. All sampling shall be carried out by the Engineer.

Table 4.6 Frequency of Routine Testing:

Sampling

Method

Test

Method

Test Frequency Rate

BS EN

196-7

BS EN-196

Each 500m3 of concrete

poured.

1. Deformed S. Bar as

BS

4449:2005

per BS 4449:2005

ASTM E415

Each size 100 ton

2. Strand

as

per

BS

5896:1980

if

needed

BS 5896

BS 5896 APPENDIX

A

As per Clause 23.3 of

BS 5896

BSEN

12350-1

BSEN

123507:2009

Once at the time of mix

design of concrete or as

directed by the Engineer.

ITEM

a.

Cement - as per BS EN

196

b.

Steel

c.

Concrete

1. Air content, as per BS

EN 12350-7:2009

March 2015

Tender Documents

Page 4/13

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

Sampling

Method

Test

Method

2. Flexural strength of

Prism as per BS EN

12390-5

BSEN

12350-1

BSEN

12390-5

Once at the time of mix

design of concrete or as

directed by the Engineer.

3. Bleeding

as

per

ASTM C232/C232M14

BS EN

123501:2000

ASTM C

232/C32M14

One at the time of mix

design of concrete or as

directed by the Engineer.

4. Splitting Tensile of

Conc. Cylinder as per

ASTM C-496:1996 &

others

BS EN

123501:2000

C-496

One at the time of mix

design of concrete or as

directed by the Engineer.

5. Depth

of

Water

Penetration (BS EN

12390 P-8:2000)

BSEN

123501:2000

BS EN

12390-8

Each

2000m3

of

a

particular

grade

of

structural concrete or as

directed by the Engineer.

6. ISAT as per BS 1881p-208:1996

BS EN

123501:2000

BS 1881 208:1996

Each

2000m3

of

a

particular

grade

of

structural concrete or as

directed by the Engineer.

7. Water absorption of

Hardened Conc. As

per BS 1881 P122

BS EN

123501:2000

BS 1881122:1983

Each

2000m3

of

a

particular

grade

of

structural concrete or as

directed by the Engineer.

8. Rapid

permeability

chloride

BS EN

12350-1

:2000

ASTM C

1202

Each

2000m3

of

a

particular

grade

of

structural concrete or as

directed by the Engineer.

9. Slump test - as per

BS EN 12350-2:2009

BS EN

12350-1

BS EN

123502:2009

From each transit mixture

load arrived at site

ITEM

10. Concrete Mix Design

(Mixing and Sampling

in the lab) as per BS

1881 P125 & In Site

(Sampling) as per BS

EN 12350-1:2000

d.

Test Frequency Rate

All mixes are to be

designed

once

for

verification and approval.

11. Kerbs-as per BS 7263

BS EN

1339:2003

BS EN

1339:2003

Sample to be taken from

each batch of upto 1000

kerb in whole consignment

Water

BS EN

1008:2002

BS EN

1008-:2002

For DEWA WD no test is

required or other than

DEWA twice a week or as

directed by the Engineer.

March 2015

Tender Documents

Page 4/14

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

4/7.2

Volume 2 Part I

WORKABILITY

Workability shall be assessed by the following tests the requirements for which

shall be as specified elsewhere in the documents.

Slump test shall be performed according to BS EN 12350-2:2009

Compaction factor shall be performed according to BS EN 12350-4:2000

Vebe time shall be performed according to BS EN 12350-3:2000

Flow test shall be performed according to BS EN 12350-5:2000

4/7.3

COMPRESSION TEST

The Compression tests shall be performed on cubes 150 x 150 x 150 mm as

described in BS EN 12390-3:2002. Sampling, making test cubes and curing of

cubes shall be in accordance with BS EN (12350-1:2000 and 12390-1:2000)

respectively.

4/8

REINFORCEMENT BARS

4/8.1

All reinforcement bars shall be of a deformed type in accordance with

BS 4449:2005, except that plain bars may be used where specifically indicated

on the Drawings. Plain bars shall be in accordance with BS 4449:2005.

4/8.2

All steel reinforcement shall conform to the requirements of the Specifications

for Deformed High Yield Steel Bars grade 500 N/mm2 Type 2, unless

otherwise shown on the Drawings or specified by the Engineer. The Bond

Strength and Surface Geometry requirements as per Clause No. 7.4 of BS EN

4449:2005

4/8.3

Certification. Three (3) copies of a mill test report shall be furnished to the

Engineer for each lot of steel reinforcement bars proposed for use on the

project.

4/8.4

Identification. The bars in each lot shall be legibly tagged by the manufacturer

and/or fabricator before being offered for inspection. The tag shall show the

manufacturer's test number and lot number and other applicable data that will

identify the material with the certificate issued for that lot of steel.

4/8.5

The fabricator shall furnish three (3) copies of a certification which shows the

heat number or numbers from which each size of bar in the shipment was

fabricated.

4/8.6

The Engineer reserves the right to sample and inspect all reinforcement steel

upon its arrival at the work site. The Contractor shall provide a certificate

confirming that samples taken from the bars delivered to the works pass all the

required tests. The frequency of sampling and the method of quality control

shall be in accordance with BS 4449 2005.

4/8.7

All reinforcement bars shall be free from detrimental dirt, mill scale, loose rust,

paint, grease, oil or other foreign substance, fins, or tears. There shall be no

March 2015

Tender Documents

Page 4/15

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

evidence of visual flaws in the bars, test specimens or on the sheared ends of

the bars.

4/8.8

Uncoated reinforcement shall be grit-blasted before use to remove rust, oil,

grease, salt and other deleterious materials and where pitting has occurred the

causes and products thereof. Repeated blasting may be required when the

reinforcement is in position, or partially cast in. Partially set concrete adhering

to exposed bars during concreting operations shall be removed.

4/8.9

The minimum thickness of concrete cover to reinforcement shall be as shown

on the drawings. Only approved concrete spacers shall be used. The

concrete shall be of similar grade to the main concrete and shall have non

metallic ties.

4/9

BAR SCHEDULES AND SHOP DRAWINGS

4/9.1

Before ordering reinforcing steel, the Contractor shall check the bar schedules

and adjust them if necessary to the approval of the Engineer. Bar schedules

shall show the weight of each bar, the total weight of each bar size and the

total weight of bars, and bending diagrams for bars in accordance with BS

4466.

4/9.2

The Contractor shall provide and submit to the Engineer for approval any

working drawings additional to the Contract Drawings which may be found

necessary for the production of revised bar schedules or for the completion of

the works.

4/9.3

The approval of working drawings, or revised bar schedules by the Engineer

shall in no way relieve the Contractor of responsibility for the correctness of

such drawings or schedules.

4/10

BAR CUTTING AND BENDING

4/10.1

Reinforcement shall be cut and bent in accordance with BS 8666:2005.

Cutting or bending by the application of heat is not permitted. Welding of

reinforcement shall only be permitted when approved in writing by the

Engineer. If such approval is given then the workmanship shall be in

accordance with BS EN 1011. The Contractor shall submit full technical

details of his proposed procedures prior to seeking approval.

4/10.2

Hot rolled high yield bars shall not be straightened or bent again, having once

been bent. If the Engineer gives approval to bend mild steel reinforcement

projecting from the concrete, the internal radius of bend shall not be less than

four times the nominal size of the bar.

4/11

PLACING AND FIXING REINFORCEMENT

4/11.1

Reinforcement shall be placed and maintained in the position shown in the

Contract Drawings. Unless otherwise permitted by the Engineer, all bar

intersections shall be tied together using 1.2mm diameter steel wire or No. 18

gauge stainless steel wire as indicated on the drawings and the ends of the

tying wire shall be turned into the main body of the concrete.

March 2015

Tender Documents

Page 4/16

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

4/11.2

Metal supports, approved by the Engineer, shall be provided and used to

retain the reinforcement at proper distances from the forms. Supports under

horizontal bars at the bottom of base slabs shall be spaced at not more than

eighty (80) diameters of the bar. All reinforcement shall be so rigidly

supported and fastened that displacement will not occur during construction.

Reinforcing steel shall be inspected in place and must be approved by the

Engineer before any concrete is deposited.

4/11.3

No splices shall be made in the reinforcement except where described in the

Contract Drawings or where approved by the Engineer.

4/11.4

Reinforcement temporarily left projecting from the concrete at construction or

other joints shall not be bent out of position during the periods in which

concreting is suspended, except with the approval of the Engineer.

4/12

WELDED WIRE FABRIC

4/12.1

Welded wire fabric to be used for the reinforcement of concrete shall conform

to the following requirements:

-

Dimensions. Welded steel wire fabric shall conform to the size and

dimensions shown on the Drawings.

Properties. Wire fabric furnished under this specification shall conform to

the requirements for "Welded Steel Wire Fabric for Concrete

Reinforcement" BS 4483 or equivalent.

4/13

SPACER BLOCKS

4/13.1

Spacers as approved by the Engineer shall be of such material and design as

will be durable, not lead to corrosion of the reinforcement and not cause

spalling of the concrete cover.

4/13.2

Spacer blocks made from cement, sand and small aggregate shall match the

mix proportions of the surrounding concrete so far as is practicable with a view

to being comparable in strength, durability and appearance.

4/14

ADMIXTURES

4/14.1

Unless agreed by the Engineer neither admixtures nor cements containing

additives shall be used.

4/14.2

Where the use of admixture had been agreed by the Engineer, they shall

conform to the requirements of Type A, Type D, Type F or Type G as specified

in ASTM C494 and shall be used in strict accordance with the manufacturer's

instructions.

Preliminary tests of cube strength and other tests shall be carried out using the

combination of aggregates cements and admixtures proposed for use.

4/14.3

March 2015

The Contractor shall be entirely responsible for the use of any approved

admixtures.

Tender Documents

Page 4/17

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

4/14.4

Approved methods and equipment shall be used for dispensing and

incorporating the admixture into the concrete. The dispensing unit shall be

designed so that the discharge of the admixture is visible.

4/15

CONCRETE MIX SPECIFICATION

4/15.1

Concrete shall be as shown in the Table of 4.5. The number of mixes may

require to be increased.

The criteria given in the Table are designed to produce concrete of the

required strength and durability.

If the maximum aggregate size is 10 mm then the cement content stipulated

for the class of concrete given in table 4.5 shall be increased by 40 Kg per m3.

All concrete mixes shall be verified by DM - DCL

TABLE 4.5

TABLE OF MIXES WITHOUT ANY ADMIXTURE OR ADDITIVE

Concrete

Class

45/20

40/20

37/20

35/20

30/20

25/20

15/20

Max.

Size

Agg

Min.

Qty of

Cement

mm.

kg.per m3

20

20

20

20

20

20

20

400

370

350

330

310

275

250

Max.

Free

Water/

Cement

Ratio

0.425

0.475

0.50

0.525

0.55

0.60

0.65

Characteristic Cube

Strength

CCS

7-day

N/mm2

28-day

N/mm2

33

30

26

25

20

16

10

45

40

37

35

30

25

15

The CCSs are for concrete which has been cured at a temperature of 23

degrees C + 2 degree C, and are the values below which no more than 5% of

the test results fall. The 7-day strengths shall be used only as a guide.

4/15.2

Concrete shall comply with BS 8110 except where BS 8007 or this

specification differs. Sampling for test purposes shall comply with BS EN

12350-1:2000 (on site) & BS 1881 Part 125:1986 (in laboratory).

If air-entertainment is specified the average air content at the time of placing

measured in accordance with BS EN 12350-7:2009 shall be:

Concrete containing 20mm

Maximum size aggregate 5% + 1%

March 2015

Tender Documents

Page 4/18

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

Concrete for water-retaining shall be watertight and shall comply with the

recommendations of BS 8007.

Concrete for paving or precast units shall be tested to BS EN 12390: Part 5:

2000 and shall have minimum flexural beam strength of 3.5N/mm2 at 28 days.

If the concrete has a specified CCS of 40N/mm2 or greater, then the minimum

flexural strength shall be 4N/mm2.

If concrete specimens are cured at higher temperatures or for longer periods

than BS EN 12390-1:2000 requires, the adjusted CCS shall be calculated as

follows:

100f'/f

f

f

T

D

A&B

A + B log {24D (T+12)/1000}

=

=

=

=

=

adjusted CCS

specified CCS

curing temperature

age at testing in days

are coefficients given in the

following table.

The above equation applies only to OPC, MSRPC and SRPC.

Recorded Cube Strength N/mm2

Less than 15

15 to 35

Greater than 35

10.0

20.0

30.0

67.5

60.0

52.5

This calculation may be applied for curing at temperatures up to 27 degrees C.

Before placing concrete the Contractor shall obtain approval of the mixes

proposed for each class of concrete and the average target strengths. The

mixes shall be designed to achieve the minimum workability for the Contractor

to place and compact the concrete with the equipment proposed for use.

The mean strength shall exceed the CCS by a margin of 1.64 times the

standard deviation expected from the concreting plant, except that no standard

deviation less than 3.5 N/mm2 shall be used as a basis for designing a mix.

Unless otherwise approved a standard deviation of 7 N/mm2 shall be used for

initial mixes.

4/15.3

The ultimate compressive strength of the concrete shall be determined on test

specimens obtained and prepared in accordance with BS EN 12390-1:2000.

4/15.4

Mixes for structural concrete shall be designed by the Contractor. The class of

concrete (shown on the drawings) is denoted by the 28 day characteristic cube

strength and the maximum size of aggregate.

March 2015

Tender Documents

Page 4/19

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

4/15.5

Volume 2 Part I

The chloride and sulphate levels in the concrete mix shall comply with the

following requirements:Maximum Limits of acid soluble Chloride and Sulphate content as a

percentage by Weight of Cement in the Mix.

TYPE OF CONCRETE

CHLORIDES

SULPHATES

AS Cl

AS SO3

ACCORDING TO BS-1881 : 1988

PART 124

Amd 01:1998

a.

For reinforced concrete

if made with OPC/MSRPC

if made with SRPC

b.

Prestressed concrete &

Heat-cured reinforced

concrete

c.

For mass concrete

if made with OPC/MSRPC

if made with SRPC

Amd 06:2002

0.30

0.06

3.70

3.70

0.10

3.70

0.60

0.12

3.70

3.70

Note: BSEN 196-21: 1992 Clause 8, Method of Testing Cement Part 21 will be

used to determine the percentage chloride by weight of cement. The

OPC and MSRPC cements can also contain chlorides, the relevant

standard BS EN 197-1 allows up to 0.1% Cl. Therefore any chloride

content present in the cement has to be taken into account while

computing total Cl in the mix. In case the cement contains the

maximum limit of 0.1% Cl, then the aggregates, water and admixtures

used for prestressed concrete or heat cured reinforced concrete should

be absolutely free of chlorides.

4/16

CONCRETE MIX DESIGN

TRIAL MIXES

4/16.1

Preliminary laboratory tests shall be carried out to determine the mixes to

satisfy the specification with the approved materials.

Trial mixes shall be tested to determine the following properties of mixes

proposed for initial field tests:

March 2015

a)

Bleeding in accordance with ASTM C232/C232M-14 (non-vibrating) shall

not exceed 0.5%.

b)

Drying shrinkage in accordance with BS 1881 Part 5.

c)

Air content if applicable BS EN 12350: P7: 2009.

Tender Documents

Page 4/20

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

d)

Free water/cement ratio.

e)

Workability BS EN 12350-2:2000

f)

Chloride permeability shall be maximum 2,000 coulombs, when tested in

accordance with ASTM C-1202: 2007.

Fresh and hardened concrete densities BS EN (12350-6:2000 and

12390-7:2000) respectively.

g)

h)

Compressive strength BS EN 12390-3:2000.

i)

Depth of Water Penetration Test BS EN 12390 Part 8 : 2000

(maximum 10 mm at 28 days)

(maximum 15 mm at 7 days).

j)

The Initial Surface Water Absorption Test as per BS 1881: P-208: 1996.

Maximum permissible limit for ISAT is 0.2 ml/m2/sec

k)

Water absorption of Hardened concrete as per BS 1881: P122: 1983 and

the maximum permissible limit shall be 2.0%.

If the values obtained are unacceptable, the mixes shall be re-designed.

4/16.2

The concrete mixes shall be prepared as per BS 1881-125-2013 and tests

shall be carried out as per BS EN 12504 and BS EN 12390.

At least 35 days before commencement of concreting trial mixes shall be

prepared under full-scale site conditions and tested in accordance with BS

1881: 1983.

Samples of concrete incorporating the reinforcing details to be used shall be

cast and examined, before hardening using hand tools, and after hardening by

coring to assess the mixes. Cores shall be taken in accordance with BS EN

12504-1:2009.

Trial mixes shall be made on each of three days; the workability shall equate

to the designed target value. Six cubes from each mix shall be taken, three for

test at 28 days.

Further trial mixes shall be made if the range (the maximum minus the

minimum of the three cube results in any batch) exceeds 15% of the average

of that batch, or if the range of the three batch averages exceeds 20% of the

overall average of the batches.

The mixes shall be tested to determine the following properties:

a)

Bleeding in accordance with ASTM C232/C232M-14

b)

Air content if applicable BS 12350: P7: 2009.

c)

Free water/cement ratio

d)

Flexural strength of concrete specimen as per BS EN 12390-5:2009.

Splitting tensile strength of concrete cylinder shall be in accordance with

ASTM C496-11.

The average 28-day CCS of the three trial mixes shall not be less than the

designed mean strength, and the results of the above tests shall be

acceptable before the mix is approved.

Otherwise the mix shall be

re-designed.

March 2015

Tender Documents

Page 4/21

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

4/16.3

The Engineer will review the Contractor's trial-mixes and test the test cubes at

seven (7) and twenty-eight (28) days. The Engineer will then determine which

of the trial mixes shall be used. If none of the trial mixes for a class of

concrete meets the Specifications, the Engineer will direct the Contractor to

prepare additional trial-mixes. No class of concrete shall be prepared or

placed until its job-mix proportions have been approved by the Engineer.

4/16.4

The approval of the job-mix proportions by the Engineer or his assistance to

the Contractor in establishing those proportions, in no way relieves the

Contractor of the responsibility of producing concrete which meets the

requirements of these Specifications.

4/16.5

The Engineer may also require practical tests to be made on the Site by filling

trial moulds to confirm the suitability of the mix for the works, the type of plant

used for mixing, the method of compaction used and the formwork face

intended for use in the works.

4/16.6

All costs connected with the preparations of trial-mixes and the design of the

job-mixes shall be borne by the Contractor.

4/16.7

In the event, any Concrete mix that is currently being used in another running

RTA projects, is proposed by the contractor for approval of using that mix in

this contract, then

1. Prior to according the approval or otherwise, the Engineer must ensure

that all copies of test results pertaining to another running RTA project

submitted by that contractor comply with all specifications as stated in this

contract and shall also ensure that the proposed mix complies with clause

4/16 by verifying that proposed mix at DCL.

2.

The Engineer has to make sure that all constituents of concrete are tested

and meeting the standard specified requirements. In case there are

changes in the materials or constituents, which may affect the properties of

the concrete. Then the mix design shall be re-verified. All the mix designs

verification shall be done at DCL.

NOTE: Any mix that is obsolete & currently not in use shall not be

accepted at all for re-approval.

4/17

QUALITY CONTROL

4/17.1

TEST CUBES

Cubes shall be manufactured in an on-site laboratory, specially equipped for

the purpose, in controlled conditions. They shall be made, cured, stored,

transported and tested to BS EN (12390-1 and 12390-3:2000). The method of

compacting cubes shall be as approved and shall be means of vibrating table

in the laboratory or 25mm vibrating poker on site.

4/17.2

March 2015

SAMPLING CUBES

Tender Documents

Page 4/22

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

A sample of concrete shall be taken at random on eight separate occasions

during the first five days of using a mix at least one sample being taken each

day. The standard deviation shall be calculated from at least 40 individual

cube results each representing separate batches of similar concrete produced

by the same plant under the same supervision. The current margin for the

plant shall be thus established as 1.64 times the standard deviation.

Thereafter one sample shall be taken at random for each class of concrete in

accordance with Clause 4/31 of the Specification.

In addition to the above requirements, at least one sample shall be taken from

each individual structural unit, or part of a unit, when the latter is the product of

a single pour.

From each sample three cubes shall be made for testing at 28 days and three

for testing at 7 days for control purposes.

Six cylinder samples shall also be taken to determine the split tensile strength

of the concrete 3 at 7 days and 3 at 28 days, as specified in ASTM C496:

1996. These samples shall be taken from every 100 batches, but at least

once a week during concreting operations, and shall coincide with samples

taken for test cubes.

The frequency of sampling may be required to be varied if directed by the

Engineer.

The procedures shall be repeated when materials or design mixes are

changed.

4/17.3

CUBE STRENGTH RESULTS

The results will be acceptable if:

i)

The average strength determined at the age of 28 days from a sample of

three or more cube test results exceed the Characteristic Cube Strength

(CCS) which is the 28 days cube strength obtained in the approved trial

mix by 0.5 times the current margin.

ii)

No individual result of the sample is less than that (CCS which is the 28

days cube strength obtained in the approved trial mix minus 3 N/mm2),

iii)

Number of individual results in the sample below CCS which is the 28

days cube strength obtained in the approved trial mix is not more than

one.

If the above criteria is not satisfied, the unit represented by the sample is

questionable and the following actions may be instructed as appropriate:

i)

Cutting and testing cores from placed concrete.

ii)

Non-destructive testing of placed concrete.

iii) Load-testing relevant structural units.

iv) Cutting out and replacing defective concrete.

If the range of individual cube strengths made from the same sample

exceeds 15% of the mean, then the method of making, curing and

testing cubes shall be checked. In the event of a sample having a range

March 2015

Tender Documents

Page 4/23

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

exceeding 20%, then the result shall be unacceptable and the Engineer

may order any of the following actions:

a)

b)

c)

d)

Changing the mix.

Improving quality control.

Cutting and testing cores from placed concrete.

Non-destructive testing of placed concrete.

In the event of cutting and testing of cores are required, the Contractor

shall cut cores from approved locations and test them to BS EN 125041:2009.

4/17.4

DURABILITY TESTS

Concrete shall be tested for durability properties by undertaking absorption

and permeability tests where appropriate, or directed by the Engineer, as

directed below:

Water absorption tests shall be carried out in the laboratory on 75mm diameter

cores cut at an age of 24 to 28 days to enable the tests to be carried out

between 28 and 32 days in accordance with BS 1881-122: 2011. The upper

acceptable limit for absorption after 30 minutes shall be 2%.

Effective permeability tests in accordance with the method described in BS EN

12390-8: 2009 shall be carried out. The maximum acceptable penetration at

seven days shall be 15 mm and the maximum acceptable penetration at 28

days shall be 10mm.

Initial surface absorption test as per BS 1881: P-208: 1996 shall be carried

out.

Maximum permissible limit for ISAT is 0.2 ml/m2/sec.

Rapid chloride penetration test as per ASTM C1202-12 shall be carried out.

4/17.5

OTHER TESTS

When instructed by the Engineer concrete shall be tested for drying shrinkage

and wetting expansion, for which 75x75mm prisms shall be prepared and

tested in accordance with BS ISO 1920-8:2009 or BS EN 772:98 and BS EN

771-2:2011. The maximum acceptable limits shall be:

Drying Shrinkage

Wetting Expansion

:

:

0.05%

0.03%

Cubes may be required and trials carried out to determine stripping times for

formwork, the duration of curing and to check testing and sampling errors.

The air content of air-entrained concrete shall be determined 12350-7:2009 for

each batch produced until consistency has been achieved, when batches may

be tested. The maximum value shall not exceed 2%.

Compaction factor, slump, veb or other workability tests shall be carried out as

required during concreting of permanent works to control workability at the

March 2015

Tender Documents

Page 4/24

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

batching plant at the site of the pour. The degree of workability shall be as for

the trial mixes; permitted tolerances shall be in accordance with BS 5328.

4/18

CONCRETE DESIGN LIMITS

4/18.1

The following will be designated by the Engineer within the limits of the

Specifications.

4/19

a)

The minimum Cement content in kg. per cubic metre of concrete.

b)

The maximum allowable water/cement ratio including surface moisture,

but excluding water absorbed by the aggregates.

c)

d)

Slump or Slumps designated at the point of delivery.

Changes requested by the Contractor in mix proportioning previously

approved shall be made only with the agreement of the Engineer.

e)

When, in the opinion of the Engineer, cement is being lost due to windy

conditions, the Contractor shall add additional amounts of cement as

directed by the Engineer. No additional payment shall be made for the

added cement.

f)

Failure of the mixed concrete to meet specifications as determined by

the Engineer will be grounds for the Engineer to reject the concrete.

g)

Bleeding limitations

C232/C232M-14.

when

tested

in

accordance

with

ASTM

CONSISTENCY OF CONCRETE

4/19.1

The consistency of concrete shall be determined in the field by the Slump

Test. The consistency of concrete at the time of delivery will be designated by

the Engineer and shall not vary by more than 25mm from the designated

consistency.

4/20

TOLERANCES IN PROPORTIONING THE MATERIALS

4/20.1

CEMENT

In the case of bagged cement it shall be measured as packed by the

manufacturer: a sack of cement shall weigh fifty (50) kilograms. Measurement

for proportioning all cement shall be accurate to within two (2) percent

throughout the range of use. Only full bags, undamaged or unbroken will be

permitted.

4/20.2

WATER

The mixing water shall be measured by weight or by volume. In either case

the measurement shall be accurate to within one (1) percent throughout the

range of use.

March 2015

Tender Documents

Page 4/25

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

4/20.3

Volume 2 Part I

AGGREGATE

The aggregates shall be measured by weight to an accuracy within two (2)

percent through-out the range of use.

4/21

ASSEMBLY AND HANDLING MATERIALS

ASSEMBLY

4/21.1

Aggregates shall be assembled in such quantities that sufficient material

approved by the Engineer is available to complete any continuous pour

necessary for any element. The batching site shall be of adequate size to

permit the stockpiling of sufficient, unsegregated materials, having proper and

uniform moisture content, to ensure continuous and uniform operation.

Aggregates shall enter the mixer in a manner approved by the Engineer and in

such a manner to ensure that no matter foreign to the concrete or matter

capable of changing the desired proportions is included. In the event two (2)

or more sizes or types of coarse or fine aggregates are used on the same

project, only one (1) size or type of each aggregate may be used on one

continuous concrete pour.

STOCKPILING Of AGGREGATES

4/21.2

All aggregates shall be stockpiled before use in order to prevent segregation

of material, to ensure uniform moisture content and to provide uniform

conditions for proportioning plant control.

4/21.3

The use of equipment or methods of handling aggregates which result in the

degradation and contamination of the aggregates is strictly prohibited.

Bulldozers with metal tracks shall not be used on coarse aggregate stockpiles.

All equipment used for handling aggregates shall be approved by the

Engineer.

4/21.4

Stockpiling of aggregates shall be in the manner approved by the Engineer,

and in addition, every precaution shall be taken to prevent segregation.

Segregation shall be prevented by making no layer higher than one and

one-half (1.5) metres and if two (2) or more layers are required, each

successive layer shall not be allowed to "cone" down over the next lower layer.

4/21.5

Aggregates shall not be stockpiled against the supports of proportioning

hoppers and weighing devices.

SEGREGATION

4/21.6

Segregated aggregates shall not be used until they have been thoroughly

remixed and the resultant pile is of uniform and acceptable gradation at any

point from which a representative sample is taken. The Contractor shall

re-mix aggregate piles when ordered by the Engineer.

TRANSPORTING Of AGGREGATES

4/21.7

March 2015

If aggregates are to be transported from a central proportioning plant to the

mixer in batch-boxes or dump trucks, such equipment shall be of sufficient

Tender Documents

Page 4/26

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

capacity to carry the full volume of materials for each batch of concrete.

Partitions separating batches shall be approved by the Engineer and shall be

adequate and effective to prevent spilling from one compartment to another

whilst in transit or being dumped.

CEMENT

4/21.8

Cement shall be stored in a dry weather-proof shed with a raised wooden floor

or in a silo and shall be delivered in quantities sufficient to ensure that there is

no suspension or interruption of the work of concreting at any time. If stored in

sheds, each consignment shall be kept separate and distinct.

4/22

MIXING CONCRETE

4/22.1

The weighing and water-dispensing mechanisms shall be maintained in good

order. Their accuracy shall be maintained within the tolerances described in

BS 1305 and checked against accurate weights and volumes when required

by the Engineer.

4/22.2

The mass of cement and of aggregate indicated by the mechanism employed

shall be within a tolerance of 2% of the respective mass per batch agreed by

the Engineer. The mass of the fine and coarse aggregates shall be adjusted

to allow for the free water contained in them. The water to be added to the

mix shall be reduced by the quantity of free water contained in the fine and

coarse aggregates, which shall be determined by the Contractor by a method

approved by the Engineer immediately before mixing begins and further as the

Engineer requires.

4/22.3

Unless otherwise agreed by the Engineer, concrete shall be mixed in a batch

type mixer manufactured in accordance with BS 1305. Where appropriate the

batch capacity, method of loading, mixing time and drum speed shall conform

to the details furnished in accordance with the requirements of BS 3963 for the

mix which corresponds most closely to the mix proportions being used. The

mixing blades of pan mixers shall be maintained within the tolerances

specified by the manufacturer of the mixer and the blades shall be replaced

when it is no longer possible to maintain the tolerance by adjustment. The

period of mixing, judged from the time that all the ingredients including water

are in the mixing drum shall be as ordered by the Engineer's representative

but shall not be less than 2 minutes or 20 revolutions of the drum whichever is

the longer.

All plants shall be equipped with an approved automatic cycling and

monitoring system installed as part of the batching equipment. The system

shall include equipment for accurately proportioning the various components

of the mixture by mass. Admixtures may be measured volumetrically. The

automatic proportioning system shall be capable of consistently delivering

each constituent within the tolerances specified. All records of batches shall

show the batch weights, the batch number, the day, the month, the year and

the time of day to the nearest minute for each batch. This information shall be

imprinted on the record so that each batch may be permanently identified.

The Engineer will be provided with a clear and legible copy of all batch records

for concrete supplied for the project.

March 2015

Tender Documents

Page 4/27

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

4/22.4

Mixers which have been out of use for more than 30 minutes shall be

thoroughly cleaned before any fresh concrete is mixed.

4/22.5

The method of discharge from the mixer shall be such as to cause no

segregation whether partial or otherwise of the concrete materials.

4/22.6

The Contractor shall ensure that the constituent materials of the concrete are

sufficiently cool to prevent the concrete from stiffening in the interval between

its discharge from the mixer and compaction in its final position. Precautions

shall include the shading of aggregate stockpiles and the use of chilled water.

4/23

READY MIXED CONCRETE

4/23.1

Ready mixed concrete as defined in BS 5328, batched off the site, may be

used only with the agreement of the engineer and shall comply with all

requirements of the Contract.

4/23.2

The Concrete shall be carried in purpose-made agitators, operating

continuously, or truck mixers. The concrete shall be compacted and in its final

position within 1 hour of the introduction of cement to the aggregates, unless a

longer time is agreed by the Engineer. The time of such introduction shall be

recorded on the delivery note together with the weight of the constituents of

each mix.

4/23.3

When truck mixed concrete is used, water shall be added under the

supervision, either at the Site or at the central batching plant as agreed by the

Engineer but in no circumstances shall water be added in transit.

4/23.4

Unless otherwise agreed by the Engineer, truck mixer units and their mixing

and discharge performance shall comply with the requirements of BS 4251.

Mixing shall continue for the number and rate of revolutions recommended in

accordance with Item 9 in Appendix B of BS 4251 or, in the absence of the

manufacturer's instructions, mixing shall continue for not less than 100

revolutions at a rate of not less than 7 revolutions per minute.

4/23.5

Pumping concrete through delivery pipes may be permitted but only with the

prior approval of the Engineer.

4/23.6

Re-mixing of concrete which has commenced to set shall not be allowed and

in no case shall such concrete be used in the Works.

Coarse aggregate shall be kept in identified stockpiles from which samples

can be collected and tested as specified.

4/23.7

4/23.8

The concrete supplier is required to certify that the Cl content in the mix being

delivered is within the limits specified in Clause 4/15.5. The Cl and SO3

content shall be checked at frequent intervals.

4/24

TRANSPORT AND PLACING

4/24.1

The method of transport and placing concrete shall be to the approval of the

Engineer. Concrete shall be so transported and placed that contamination,

segregation or loss of the constituent materials does not occur.

March 2015

Tender Documents

Page 4/28

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

4/24.2

Volume 2 Part I

All formwork and reinforcement shall be clean and free from standing water

immediately before placing concrete.

No concrete work shall be stopped or temporarily discontinued within forty-five

(45) centimeters of the top of any finished surface, unless such work is

finished with a coping having a thickness less than forty-five (45) centimeters

in which case the joint shall be made at the under edge of the coping.

Concrete in simple slab spans shall be placed in one (1) continuous operation

for each span, unless otherwise indicated on the drawings or approved by the

Engineer.

4/24.3

Prior to placing any concrete on natural surfaces a blinding layer of Class 15

concrete shall be laid to a minimum of 75 mm thickness unless otherwise

specified on the drawings. This blinding shall be suitably cured prior to

subsequent concrete placement. The blinding shall be clean and free from

any dust or impurities prior to subsequent concrete placement.

4/24.4

No concrete shall be placed in a foundation until the extent of excavation and

the character of bearing material have been approved and no concrete shall

be placed in any structure until the placement of reinforcing steel and the

adequacy of the forms and falsework have been approved.

4/24.5

Concrete shall not be placed in any part of the Works until the Engineer's

approval has been given. If concrete has not started within 24 hours of such

approval being given, approval shall again be requested. Concreting shall

then proceed continuously over the area between construction joints. Fresh

concrete shall not be placed against in-situ concrete which has been in

position for more than 30 minutes unless a construction joint is formed in

accordance with the Specification. When the concrete has been in place for 4

hours, or less as directed by the Engineer, further concrete shall not be placed

against it for a further 20 hours.

4/24.6

Concrete when deposited shall have a temperature of not more than 32 deg. C

unless otherwise specified. Concrete shall be compacted in its final position

within 30 minutes of discharge from the mixer unless carried in purpose made

agitators operating continuously, when the time shall be within 1 hour of the

introduction of cement to the mix and within 30 minutes of discharge from the

agitator.

Except where otherwise agreed by the Engineer, concrete shall be deposited

in horizontal layers to a compacted depth not exceeding 400mm where

internal vibrators are used or 300mm in all other cases.

4/24.7

4/24.8

March 2015

Unless otherwise agreed by the Engineer, concrete shall not be dropped into

place from a height exceeding 2m. When trunking or chutes are used they

shall be kept clean and used in such a way as to avoid segregation. Where

steep slopes are required for placing concrete with chutes, the chutes shall be

equipped with baffle boards or be in short lengths that reverse the direction of

the movement. Chutes and the use of chutes must be approved by the

Engineer. All chutes shall be kept clean and free from coating of hardened

concrete by thoroughly flushing with water after each run. The water used for

flushing shall be discharged clear of the concrete already in place.

Tender Documents

Page 4/29

Project R1041: Dubai Parks Access from Sheikh Zayed Road

General Specifications

Volume 2 Part I

4/24.9

No concrete shall be placed in flowing water. Underwater concrete shall be

placed in position by tremies, or by pipeline from the mixer.

4/24.10

Full details of the method proposed shall be submitted in advance to the

Engineer and his approval obtained before placing begins. Where the

concrete is placed by the tremie, its size and method of operation shall be in

accordance with BS 8004. During and after concreting under water, pumping

or dewatering operations in the immediate vicinity shall be suspended until the

Engineer permits them to be continued.

4/24.11

Approved measures shall be taken to avoid premature stiffening of concrete

placed in contact with hot, dry surfaces. Surfaces including reinforcement

against which concrete is to be placed shall be shielded against the direct rays

of the sun and shall be sprayed with water to prevent excessive absorption by

the surfaces of water from the fresh concrete.

4/24.12

A complete record shall be kept of the date, time, temperature and conditions

of placing the concrete in each portion of the work and shall be available for

inspection by the Engineer at any time.

4/24.13

Unless otherwise shown on the drawings all concrete placed below ground

level shall have a minimum protection to its outside faces as follows:

Underside - Protected by the laying of a grade 1000 approved polyethylene

sheeting on the blinding concrete. The sheeting shall be returned up the

outside faces of the concrete and suitably sealed.

Sides - Coated with 3 coats of an approved bitumen rubber latex emulsion

flexible damp and vapour-proof liquid membrane conforming to BRE Digest

No. 54.

4/25

COMPACTION OF CONCRETE

4/25.1

All concrete shall be compacted to produce a dense homogeneous mass.

Unless otherwise agreed by the Engineer, it shall be compacted with the

assistance of vibrators. Sufficient vibrators in serviceable condition shall be on

site so that spare equipment is available in the event of breakdown. A 50mm

diameter internal vibrator shall be deemed capable of compacting 20 Cu.

m./hr. Internal vibrators shall be capable of producing not less than 10,000

cycles per minute.

4/25.2

Vibration shall not be applied by way of the reinforcement. Where immersion

vibrators are used, contact with reinforcement and all inserts shall be avoided.

4/25.3

Concrete shall not be subject to vibration between 4 and 24 hours after

placing.

4/25.4

Vibrators shall be so manipulated as to work the concrete thoroughly around

the reinforcement and embedded fixtures and into corners and angles of the

forms. Vibrators shall not be used as a means to cause concrete to flow or its

position in lieu of placing. The vibration at any point shall be of sufficient

duration to accomplish compaction. After initial set of the concrete, the forms

March 2015

Tender Documents

Page 4/30

You might also like

- Aci PRC 211.1-22Document38 pagesAci PRC 211.1-22kashif100% (3)

- BS 3690-2 1989Document10 pagesBS 3690-2 1989Kenji LauNo ratings yet

- QCS 2010 Section 4 Part 2 General Requirements For Concrete PilesDocument6 pagesQCS 2010 Section 4 Part 2 General Requirements For Concrete Pilesbryanpastor106No ratings yet

- PQCP-06.03.09 Concrete Crack RepairDocument3 pagesPQCP-06.03.09 Concrete Crack RepairmiaicarbaNo ratings yet

- Concrete Placement Inspection Check List - Rev00Document1 pageConcrete Placement Inspection Check List - Rev00IrfanNo ratings yet

- Lecture 04-Design of T and L Beams Section in Flexure PDFDocument20 pagesLecture 04-Design of T and L Beams Section in Flexure PDFSadam Birmani100% (1)

- Check List For DB InstallationDocument2 pagesCheck List For DB InstallationNaing Win TunNo ratings yet

- Concrete Work 1. Standard and Codes of PracticeDocument28 pagesConcrete Work 1. Standard and Codes of PracticeArka ShahRilNo ratings yet

- Format of Plaster, Plumbing and Hydro TestDocument1 pageFormat of Plaster, Plumbing and Hydro Testmratyunjay tripathiNo ratings yet

- Crack & Honeycomb Repair MethodDocument15 pagesCrack & Honeycomb Repair MethodNorazly Awang67% (3)

- Cement Testing: Setting Time & Le Chatelier's Soundness TestDocument34 pagesCement Testing: Setting Time & Le Chatelier's Soundness TestAshuNo ratings yet

- Methodology Water ProofingDocument4 pagesMethodology Water ProofingTVS GRCNo ratings yet

- EARTHWORK SpecificationDocument3 pagesEARTHWORK Specificationczarjeff3497No ratings yet

- SGM - Struct SpecDocument112 pagesSGM - Struct SpecabdouNo ratings yet

- Structural Behaviour of Bubble Deck Slab: November 2015Document52 pagesStructural Behaviour of Bubble Deck Slab: November 2015Davor VasiljNo ratings yet

- Is Codes ListDocument132 pagesIs Codes ListMuralidhar BalekundriNo ratings yet

- MasonDocument7 pagesMasonMichael Jherome NuqueNo ratings yet

- Concrete Repair Quality ControlDocument3 pagesConcrete Repair Quality ControlRisath AzeezNo ratings yet

- Post Tension Grouts and Grouting Equipment - tcm45-340366Document3 pagesPost Tension Grouts and Grouting Equipment - tcm45-340366MosstafaNo ratings yet

- Chapter 5 - Footings - Sp17!9!07Document38 pagesChapter 5 - Footings - Sp17!9!07aldwinNo ratings yet

- QCS 2010 Section 5 Part 11 ReinforcementDocument10 pagesQCS 2010 Section 5 Part 11 Reinforcementbryanpastor106No ratings yet

- 2.Ms Excavation Back FillingDocument9 pages2.Ms Excavation Back FillingShenbagaraja PandianNo ratings yet

- Flamex Fire ProtectionDocument4 pagesFlamex Fire ProtectionTori SmallNo ratings yet

- FOSROC WaterproofingDocument20 pagesFOSROC WaterproofingMurthy BabuNo ratings yet

- Civil4M Solutions LLP: Internal Plumbing WorksDocument1 pageCivil4M Solutions LLP: Internal Plumbing Workssenthil dharunNo ratings yet

- Method Statement: Underground Waterproofing Using Hdpe Waterproofing System From FosrocDocument10 pagesMethod Statement: Underground Waterproofing Using Hdpe Waterproofing System From Fosrocdindo lauronNo ratings yet

- Renderoc LAXtraDocument2 pagesRenderoc LAXtraMansoor Ali100% (1)

- Takeoff Steel1Document8 pagesTakeoff Steel1rishiNo ratings yet

- Sika WaterbarsDocument5 pagesSika WaterbarschaubeyskcNo ratings yet

- QCP-Soil Investigation WorksDocument9 pagesQCP-Soil Investigation WorksManash Protim GogoiNo ratings yet

- Is 6313 Part2 2022 Anti TermiteDocument26 pagesIs 6313 Part2 2022 Anti Termitevipul100% (1)

- Door Frame, Shutter Installation & PolishingDocument16 pagesDoor Frame, Shutter Installation & PolishingQAQC NandanamNo ratings yet

- Duracord & Durasheet 40/100: Bond-Breaker and Closed-Cell Back-Up Material For Use With Joint SealantsDocument2 pagesDuracord & Durasheet 40/100: Bond-Breaker and Closed-Cell Back-Up Material For Use With Joint SealantspbodooNo ratings yet

- Good Construction Practices PDFDocument9 pagesGood Construction Practices PDFKrishnan SubraNo ratings yet

- Reinforcement Steel WorksDocument28 pagesReinforcement Steel WorksPooja PawarNo ratings yet

- Bs 2994-1976 PDFDocument38 pagesBs 2994-1976 PDFmaldushNo ratings yet

- NP4 Pipe Installation and Backfill - MethodologyDocument4 pagesNP4 Pipe Installation and Backfill - MethodologyRabnawaz Imam100% (1)

- Hafiz (Low Coast Building Design Architecture)Document14 pagesHafiz (Low Coast Building Design Architecture)Mig TigNo ratings yet

- Inspection Checklist Masonry WallDocument3 pagesInspection Checklist Masonry WallJonatan LopezNo ratings yet

- Metod Statement of Well Point De-Watering For Cement SiloDocument5 pagesMetod Statement of Well Point De-Watering For Cement SiloSmart ShivaNo ratings yet

- Reaffirmed 1996Document10 pagesReaffirmed 1996prashantkothariNo ratings yet

- Measurement SheetDocument6 pagesMeasurement SheethafizNo ratings yet

- Lecture 02-Design of Singly Reinforced Beam in FlexureDocument34 pagesLecture 02-Design of Singly Reinforced Beam in FlexureOsamaZaid100% (2)

- Screed Bases and In-Situ FlooringsDocument28 pagesScreed Bases and In-Situ Flooringsrekcah ehtNo ratings yet

- Thioflex 600wP7E PDFDocument52 pagesThioflex 600wP7E PDFAjit Singh Rathore100% (2)

- Cebex 100 PDFDocument2 pagesCebex 100 PDFBijaya RaulaNo ratings yet

- Qualtiy Checklist For Finishing ActivitiesDocument6 pagesQualtiy Checklist For Finishing ActivitiesSamratTalukdarNo ratings yet

- Chain Link Fencing and GateDocument9 pagesChain Link Fencing and GateMohammad Sahmoud100% (1)

- Good Construction Practise - Handouts - ConcreteDocument18 pagesGood Construction Practise - Handouts - Concretehitesh16No ratings yet

- DPC PPT-1Document15 pagesDPC PPT-1dagangjudamNo ratings yet

- Mix Design Using Rheology MeterDocument5 pagesMix Design Using Rheology MeterBhupesh MulikNo ratings yet