1.2.6 - Internal Inspection Guidelines - Edition July 2012

1.2.6 - Internal Inspection Guidelines - Edition July 2012

Uploaded by

LâmViênCopyright:

Available Formats

1.2.6 - Internal Inspection Guidelines - Edition July 2012

1.2.6 - Internal Inspection Guidelines - Edition July 2012

Uploaded by

LâmViênOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

1.2.6 - Internal Inspection Guidelines - Edition July 2012

1.2.6 - Internal Inspection Guidelines - Edition July 2012

Uploaded by

LâmViênCopyright:

Available Formats

Inspection Guidelines Raw Material

(Edition: July 2012)

Corporate Quality Assurance Department

~Internal Use Only~

Internal Inspection Guidelines - Raw Material (Edition: July 2012)

List of Contents

Objectives and Scope of the Inspection Guidelines 1

1.1 Objectives 1

1.2 Scope.................... 1

Responsibility for Material Inspection 2

Sampling Guidelines

Fabric Inspection Guidelines.

4.1 Fabric inspection procedure.

4.2 Documentation

4.3 Quality expectations

4

4

5

6

Inspection Guidelines for Materials (Excluding Fabrics). 6

5.1 Materials (excluding fabrics) inspection procedure 6

5.2 Quality Expectations.............. 6

Triumph Internal Inspection Guidelines Raw Material

Edition: July 2012

1 Objectives and Scope of the Inspection Guidelines

1.1 Objectives

This guideline shall be used in conjunction with the Triumph Global Quality Manual

Raw Material to determine the quality and acceptability of materials for our

garments. The objective of this guideline is to provide general instructions for

performing receiving inspection.

This guideline aims to ensure that inspections are carried out efficiently, uniformly

and to a high standard. For Triumph Centres it is intended for use as guidance,

outlining typical procedures and defining normal requirements for the various

categories of inspection. It is not intended to provide a definitive solution in all

situations, as the party best able to decide on the appropriate course of action is

the inspector undertaking the work and the Quality Managers in each Production

Centre.

1.2 Scope

This guideline applies exclusively for Triumph International.

companies may have their own method and requirements.

Other Triumph

The procedures and requirements described in this guideline are applicable to

material and components that will be used in the final garment. However, this

guideline does not cover packaging materials such as hangers, boxes and bags.

Triumph Internal Inspection Guidelines Raw Material

Edition: July 2012

2 Responsibility for material inspection

- Production centres must carry out material inspection for each delivery upon

arrival.

- It is the responsibility of the Quality Manager in the Production Centres to discuss

internally and decide the appropriate course of action when any inspection issues

arise.

- Material suppliers must be able to show the quality of their material by providing

completed inspection reports together with the goods shipped to all Triumph

Production Centres.

3 Sampling Guidelines

Sampling of incoming shipments of material of a continuous length in roll form

such as fabric, lace etc. shall be performed at random. A general guideline for

the minimum amount of material to be inspected is shown in Table 1. If any

quality problems are found during the random inspection, increase the inspection

quantity as necessary in order to quantify the problem. (Random inspection

means selecting the material for inspecting according to no specific pattern.)

The material must be placed in a quarantined area or computer quarantined

stock status until inspection and testing has taken place and can only be issued

to production once it can meet the inspection and testing requirements. Any rolls

of rejected material should be clearly marked with a QA rejected label.

Table 1 Minimum sample inspection for material of continuous length in rolls

Shipment lot size

Minimum Sample Inspection

Up to100m

100%

100-500m

30%

500m up

10%

*Note: The inspected quantity in Table 1 is proposed as a general guideline for minimum

sample inspection. The final decision shall be made by Production Centres based on their

experience and the overall quantity of material to ensure that the material is adequately

inspected before it is released to production.

If the material is of a continuous length but packed in boxes such as narrow

elastics, a general guideline for the minimum number of boxes to be inspected is

shown in Table 2. Within each inspected box it is suggested to pull out at least

six strands of material for checking the appearance, handfeel and width of the

material. The length of the strands for checking should be at least 0.5m or

sufficient to cover one pattern repeat.

If any quality problems are found during the random inspection, increase the

inspection quantity as necessary in order to quantify the problem. The material

must be placed in a quarantined area or computer quarantined stock status until

inspection and testing has taken place and can only be issued to production once

it can meet the inspection and testing requirements. Any boxes of rejected

material should be clearly marked with a QA rejected label.

2

Triumph Internal Inspection Guidelines Raw Material

Edition: July 2012

Table 2 Minimum sample inspection for material of continuous length in boxes

Number of boxes per shipment

Minimum Sample Inspection

1-3

All boxes

4-10

3 boxes randomly

11 or more

5 boxes randomly

*Note: The inspected quantity in Table 2 is proposed as a general guideline for minimum

sample inspection. The final decision shall be made by Production Centres based on their

experience and the overall quantity of material to ensure that the material is adequately

inspected before it is released to production.

If the material is offered in a packed condition and is comprised of pieces such

as PU cups, motifs etc., 10% of the packages in the lot (per item, colour and size)

subject to a minimum of two and a maximum of 5 packages shall be opened by

selection on a random sampling basis.

Pieces (per unit of product which may be single article or a pair) required for

detailed inspection shall also be selected on a random basis from all the opened

packages. Based on the total shipment quantity, the minimum number of samples

for inspection shall be according to:

Inspection Level General Level II

Sampling Plan Single Normal

Acceptable Quality Level (AQL) 1.5

For example, for a shipment size 30,000 pieces of a bow motif by referring to a

single sampling plan for normal inspection level II table the sample size to inspect

is 315 pieces. By having an AQL of 1.5, the maximum number of defective pieces

acceptable in the sample is 10.

*Note: The inspected quantity is proposed as a general guideline for minimum sample

inspection. The final decision shall be made by Production Centres based on their experience

and the overall quantity of material to ensure that the material is adequately inspected

before it is released to production.

If the number of defects found during the random inspection is greater than the

general accepted quality level, increase the inspection quantity as necessary in

order to quantify the problem. The material must be placed in a quarantined

area or computer quarantined stock status until inspection and testing has taken

place and can only be issued to production once it can meet the inspection and

testing requirements. Any packages containing rejected material should be

clearly marked with a QA rejected label.

Triumph Internal Inspection Guidelines Raw Material

Edition: July 2012

4 Fabric inspection guidelines

4.1 Fabric inspection procedure

The inspector responsible for fabric inspection must have access to the following

facilities and equipment which must be in good working order.

- Fabric inspection machine (sufficiently wide to enable the fabric to be

examined full width.)

- Light cabinet

- Measuring tape and scissors

- Stickers to identify the faults

- Digital camera for taking reference photos if necessary

- Master sample for reference

The inspection procedure should be carried out as follows:

- Determine the fabric quantity to be inspected.

- Select the fabric rolls for inspection

- Put the rolls on the fabric inspection machine.

- Cut off a 15cm piece across the width of the fabric from the beginning of the roll.

Mark this piece to distinguish the right and left side of the fabric. Use the strip to

check the shading side to side and end to end by checking it at least against the

middle of the roll and once at the end of the roll.(*Further details of the colour

checking procedure in the PCs shall be documented in the SOP for Production

Centre colour checking of incoming raw materials.)

- Inspect for visual defects/flaws with the light on at a speed slow enough to find

the defects. Sometimes the light may have to be switched off to see how the

defect/flaw will affect the appearance of the garment. (For further information

on fabric defects/flaws refer to ASTM D3999, ISO 8498 and ISO 8499)

- Check that the roll contains the correct length as stated by the supplier.

- Check for bowing and skewing/spirality of the fabric.

- Mark any defects/flaws found with a sticker during inspection for its traceability

and corrective action during the cutting stage.

- Record the defect/flaws of the fabric on the Fabric Quality Report and calculate

the number of points per 100 metres using the below 4-Point System in Table 3.

This 4-Point System shall be used as a means for communication with the supplier

on the rejection/compensation required for the sections of material containing

the defects/flaws. This only applies if the material received cannot cover the

production requirement to meet the garment delivery schedule. If the material

containing the defect/flaws can cover the production requirement or if the

supplier has already compensated for the defect/flaws this shall be used as a

record only or as a means to request the supplier to improve for future deliveries.

Table 3 Number of points assigned according to the length of the defect

Length of Defect/Flaw

7.5cm

>7.5cm 15cm

>15cm 23cm

>23cm

Points Assigned

1 point

2 points

3 points

4 points

Triumph Internal Inspection Guidelines Raw Material

Edition: July 2012

No more that 4 points can be assigned to any single metre of fabric.

Any hole (other than a pin hole at the fabric selvedge) shall be considered a major

defect and assigned 4 points for penalty

Any defects of a continuous/running nature i.e. barre and full width defects are

not assigned penalty points. These conditions must be judged as to extent and

degree to which they affect the garment being produced.

Irregularities which are normal to the existing state of art i.e. the nature of the

material or beyond reasonable control of the manufacturer shall not be classified

as defects and shall not bear penalty points.

Defects/flaws appearing outside the usable width shall be disregarded.

Regardless of the length of the fabric, the quality shall be expressed as the number

of penalty points per 100 metres and number of defect/flaws per 100m.

Calculations

1) Points:

Total number of points for a roll:

Points per 100m= 100 x Total points for the roll

Inspected length (m)

Total number of points for a shipment:

Total shipment points per 100m= 100 x Total shipment points

Shipment Inspected length (m)

2) Number of flaws and defects:

Total Number of defects/flaws per 100m = 100 x Number of defects/flaws

Inspected length (m)

4.2 Documentation

Fabric inspection documentation on the inspection report shall include the

following information:

- Fabric supplier

- Fabric item number

- Colour reference

- Batch/Dye lot number

- Purchase order number

- Piece number(s)

- Useable width per piece and contracted width

- Piece length

- Number of defects/flaws

5

Triumph Internal Inspection Guidelines Raw Material

Edition: July 2012

- Inspector comments if any per roll

- Date of inspection

- Name of inspector

4.3 Quality expectations

For quality expectations refer to the latest version of the Triumph Global Quality

Manual Raw Material.

5 Inspection guidelines for materials (excluding fabrics)

5.1 Materials (excluding fabrics) inspection procedure

For all other materials the assessment and measurement methods in Section 1 in

the catalogue of test methods in latest edition of the Triumph Global Quality

Manual shall be performed.

5.2 Quality Expectations

For quality expectations refer to the latest version of the Triumph Global Quality

Manual Raw Material.

You might also like

- MechVibration Lec1 PDFDocument45 pagesMechVibration Lec1 PDFEngSafwanQadous100% (1)

- 1.2.1 - Triumph Global Quality Manual and Appendix - Edition Jan 2010Document118 pages1.2.1 - Triumph Global Quality Manual and Appendix - Edition Jan 2010LâmViên100% (1)

- Jadwal Internal InspectionDocument8 pagesJadwal Internal InspectiondindarizalNo ratings yet

- Top Head and NozzlesDocument4 pagesTop Head and NozzlesShamsul AffendiNo ratings yet

- IOC, BPCL, HPCL Join Hands To Set Up India's Biggest Oil RefineryDocument2 pagesIOC, BPCL, HPCL Join Hands To Set Up India's Biggest Oil RefinerymANISH THIRANINo ratings yet

- Tube InspectionDocument6 pagesTube InspectionaamirsaddiqNo ratings yet

- All Techniques - in BriefDocument87 pagesAll Techniques - in BriefWmfaiz KarcelloNo ratings yet

- Dead Leg SectionDocument1 pageDead Leg SectionMuchamad Luthfi AliNo ratings yet

- Internal Inspection Report HopperDocument10 pagesInternal Inspection Report HopperCepi Sindang KamulanNo ratings yet

- Flange Integrity ManagementDocument30 pagesFlange Integrity ManagementsafwanNo ratings yet

- AIE-PR-PRJ-005 - in Service Pipework Inspection Procedure Rev 01Document20 pagesAIE-PR-PRJ-005 - in Service Pipework Inspection Procedure Rev 01faraz_muslimNo ratings yet

- Vibration AnalysisDocument4 pagesVibration Analysisrishan33100% (1)

- Arise Global Inspection Services Company BrochureDocument35 pagesArise Global Inspection Services Company BrochuremaroofNo ratings yet

- Presentation On Internal Inspection of Vessels TanksDocument39 pagesPresentation On Internal Inspection of Vessels TanksAbiram VSNo ratings yet

- A Study Done On Cups by Ali 9645459885Document4 pagesA Study Done On Cups by Ali 9645459885ALI KHANNo ratings yet

- A Brief Presentation On Hot and Cold InsulationDocument5 pagesA Brief Presentation On Hot and Cold InsulationMubarik AliNo ratings yet

- SAEP-1135 On-Stream Inspection AdministrationDocument26 pagesSAEP-1135 On-Stream Inspection AdministrationMAT-LIONNo ratings yet

- Duplex Stainless Steels PDFDocument1 pageDuplex Stainless Steels PDFjontylee87No ratings yet

- What'S in Your Coiled Tubing?: Roderic K. Stanley, PH D, I. EngDocument30 pagesWhat'S in Your Coiled Tubing?: Roderic K. Stanley, PH D, I. EngAriel TerrensNo ratings yet

- RIR PEP-Dec 2011Document13 pagesRIR PEP-Dec 2011arslanhamidNo ratings yet

- Leak Detection InspectorDocument41 pagesLeak Detection InspectortonNo ratings yet

- Session 2 Overview of IntegrityDocument19 pagesSession 2 Overview of IntegritysahandstmNo ratings yet

- 02 API 570 Points To RecallDocument6 pages02 API 570 Points To RecallAshish PatelNo ratings yet

- PRD Inspection NBIC PDFDocument42 pagesPRD Inspection NBIC PDFAsadAliNo ratings yet

- NormDocument16 pagesNormAnnNo ratings yet

- Technology - Magnetic Eddy Current MEC Inspection TechniqueDocument12 pagesTechnology - Magnetic Eddy Current MEC Inspection TechniqueCepi Sindang KamulanNo ratings yet

- Gamma Scanning TechniqueDocument26 pagesGamma Scanning TechniqueWillykateKairu75% (4)

- Operation and Maintenance of PumpsDocument17 pagesOperation and Maintenance of PumpsAbdul AzizNo ratings yet

- NDTDocument9 pagesNDTrajbubl23No ratings yet

- An Overview of Pipeline Leak Detection TechnologiesDocument9 pagesAn Overview of Pipeline Leak Detection TechnologiesharmlesdragonNo ratings yet

- AZ008-TQ-004776 ResponseDocument6 pagesAZ008-TQ-004776 ResponseAdil HasanovNo ratings yet

- Rotary Kiln Inspections Leaflet - en - WebDocument4 pagesRotary Kiln Inspections Leaflet - en - WebPankaj KumarNo ratings yet

- Chime and Multiskip InspectionDocument10 pagesChime and Multiskip InspectionVignesh VelNo ratings yet

- Safety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingDocument5 pagesSafety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingvietnampetrochemicalNo ratings yet

- Infrared Optical PyrometerDocument6 pagesInfrared Optical PyrometerinstrutechNo ratings yet

- API 510 PC 20 31 Aug05 Bench MarkDocument4 pagesAPI 510 PC 20 31 Aug05 Bench MarknikafiqNo ratings yet

- Module 3. Pipe Scanning: 3.1. PrinciplesDocument8 pagesModule 3. Pipe Scanning: 3.1. PrinciplesWillykateKairuNo ratings yet

- 10.1515 - htmp-2013-0041 Performance and Life Assessment of Reformer TubesDocument14 pages10.1515 - htmp-2013-0041 Performance and Life Assessment of Reformer TubesFrancisco GonzalezNo ratings yet

- API Standards WhitepaperDocument6 pagesAPI Standards WhitepaperISHUNo ratings yet

- Slides - AST Non-Intrusive Inspection Optimizing API 653 Inspections and Driving Operational EfficienciesDocument23 pagesSlides - AST Non-Intrusive Inspection Optimizing API 653 Inspections and Driving Operational EfficienciesShiva YadavNo ratings yet

- STD 133Document37 pagesSTD 133ck19654840No ratings yet

- Fitness For Service An Overview For HL Pipelines: Larry SheltonDocument16 pagesFitness For Service An Overview For HL Pipelines: Larry SheltonAndrew Carr0% (1)

- FlexoFORM BrochureDocument4 pagesFlexoFORM BrochureDennis ChaiNo ratings yet

- PAUT Inspection of Corrosion-Resitant Alloys and Dissimilat Weld MaterialsDocument20 pagesPAUT Inspection of Corrosion-Resitant Alloys and Dissimilat Weld MaterialsRupam BaruahNo ratings yet

- Pipeline and Piping Inspection, Maintenance, Repair & Integrity AssessmentDocument7 pagesPipeline and Piping Inspection, Maintenance, Repair & Integrity Assessmentamr habibNo ratings yet

- Boiler Inspection Plan 2023 (CO Gas Boiler)Document4 pagesBoiler Inspection Plan 2023 (CO Gas Boiler)md faiza riza yusoffNo ratings yet

- Understanding API 1169 New Pipeline Cons PDFDocument161 pagesUnderstanding API 1169 New Pipeline Cons PDFMohmed AllamNo ratings yet

- HTR900 Inspection, Maintenance, and TestingDocument27 pagesHTR900 Inspection, Maintenance, and TestingVicente Regulez FernandezNo ratings yet

- Pipeline SlidesDocument14 pagesPipeline Slidesc丽诗No ratings yet

- Internal Incpection ProcedureDocument6 pagesInternal Incpection Procedureevrim korıNo ratings yet

- Fitness For Service Assesment DentDocument1 pageFitness For Service Assesment DentFebri Ramdani NugrahaNo ratings yet

- Saes A 004 HT WaiverDocument1 pageSaes A 004 HT WaiverSOWJANYA KIRANKUMARNo ratings yet

- FFS 3Document2 pagesFFS 3phutiNo ratings yet

- Innerspec TechnologiesDocument17 pagesInnerspec TechnologiesNatrajiNo ratings yet

- Radiography of Welded Piping - A30101Document22 pagesRadiography of Welded Piping - A30101Muhammed BatureNo ratings yet

- Internal Rotating Inspection SystemDocument2 pagesInternal Rotating Inspection SystemAntonio PerezNo ratings yet

- Andreas Boenisch - InnospectionDocument41 pagesAndreas Boenisch - Innospectiondiaccessltd_17172961No ratings yet

- Asset Integrity Management A Complete Guide - 2020 EditionFrom EverandAsset Integrity Management A Complete Guide - 2020 EditionNo ratings yet

- Bolted Flanged Joint: Flanges, Studs & Gaskets. Recommended Practices for the Assembly of a Bolted Flange Joint.From EverandBolted Flanged Joint: Flanges, Studs & Gaskets. Recommended Practices for the Assembly of a Bolted Flange Joint.No ratings yet

- Case Study - House For Sale - Team NegotiationDocument5 pagesCase Study - House For Sale - Team NegotiationLâmViênNo ratings yet

- Vincenzo Bellini: I Capuleti e I Montecchi: Act I. "Oh! Quante Volte"Document1 pageVincenzo Bellini: I Capuleti e I Montecchi: Act I. "Oh! Quante Volte"LâmViênNo ratings yet

- Factory Tour ExplainDocument8 pagesFactory Tour ExplainLâmViênNo ratings yet

- Communication Foundations SharingDocument19 pagesCommunication Foundations SharingLâmViênNo ratings yet

- 1.2.4 - Colour Check On Incoming Material - 090712Document6 pages1.2.4 - Colour Check On Incoming Material - 090712LâmViênNo ratings yet

- 1.2.8 - Sewability Test - Edition Jan 2009 - Needle CutDocument2 pages1.2.8 - Sewability Test - Edition Jan 2009 - Needle CutLâmViênNo ratings yet

- 1.2.5 - Incoming Testing and Inspection - V201207Document1 page1.2.5 - Incoming Testing and Inspection - V201207LâmViênNo ratings yet

- 1.1.7 - Cup Shape SOPDocument10 pages1.1.7 - Cup Shape SOPLâmViênNo ratings yet

- 1.1.3 - AQL FG Training PresentationDocument25 pages1.1.3 - AQL FG Training PresentationLâmViênNo ratings yet

- 1.2.3 - Handling of Sensitive MaterialsDocument4 pages1.2.3 - Handling of Sensitive MaterialsLâmViênNo ratings yet

- 1.1.5 - SOP Wire & StrapDocument6 pages1.1.5 - SOP Wire & StrapLâmViênNo ratings yet

- 1.1.3 - AQL FG Training PresentationDocument25 pages1.1.3 - AQL FG Training PresentationLâmViênNo ratings yet

- As 1473.2-2001 Wood Processing Machinery - Safety Finishing Machinery - Common RequirementsDocument8 pagesAs 1473.2-2001 Wood Processing Machinery - Safety Finishing Machinery - Common RequirementsSAI Global - APACNo ratings yet

- CQI-IRCA Certified PR320: ISMS ISO 27001:2013 Lead Auditor Training CourseDocument1 pageCQI-IRCA Certified PR320: ISMS ISO 27001:2013 Lead Auditor Training Coursece0906No ratings yet

- Better Cotton Chain of Custody Guidelines 2018 v1.3Document24 pagesBetter Cotton Chain of Custody Guidelines 2018 v1.3Max SmokeNo ratings yet

- Cisco ASA Remote Access VPN Syslog MessagesDocument2 pagesCisco ASA Remote Access VPN Syslog Messagesmasterone1810No ratings yet

- Delta Rpi m15 30a Inverter Data SheetDocument4 pagesDelta Rpi m15 30a Inverter Data SheetDavid SaymonNo ratings yet

- CCIDDocument7 pagesCCIDsatish1981No ratings yet

- STM-1/4 SDH Multiplexer: Aliant OmmunicationsDocument2 pagesSTM-1/4 SDH Multiplexer: Aliant OmmunicationsAlberto José Escalona PiñeroNo ratings yet

- Tables PPDocument4 pagesTables PPFabiano Dos SantosNo ratings yet

- Cyclones For Fluidized Bed ProcessesDocument4 pagesCyclones For Fluidized Bed ProcessesswatkoolNo ratings yet

- G7 Q2 Measurements Learning MaterialDocument5 pagesG7 Q2 Measurements Learning MaterialAnthonyYbañezNo ratings yet

- LG TV Service ManualDocument20 pagesLG TV Service ManualNisar AhmedNo ratings yet

- EASA TCDS A.110 Airbus A380Document17 pagesEASA TCDS A.110 Airbus A380kiecard33% (3)

- ST-125™ Control System For Stanadyne DB-4 Series Pumps: Product Manual 04169 (Revision D)Document24 pagesST-125™ Control System For Stanadyne DB-4 Series Pumps: Product Manual 04169 (Revision D)Arc HieNo ratings yet

- Liebherr LHM 600 High Rise Mobile Harbour Crane Datasheet EnglishDocument4 pagesLiebherr LHM 600 High Rise Mobile Harbour Crane Datasheet EnglishMaikol Mell Ferrer GuzmanNo ratings yet

- Snake InstructionsDocument2 pagesSnake InstructionsSushaanth PsNo ratings yet

- GIGABYTE GA-970A-D3 Rev.1.01 PDFDocument33 pagesGIGABYTE GA-970A-D3 Rev.1.01 PDFdiana441No ratings yet

- EEBus UC TS MonitoringOfGridConnectionPoint V1.0.0 PublicDocument87 pagesEEBus UC TS MonitoringOfGridConnectionPoint V1.0.0 PublicWnenjin ZhangNo ratings yet

- A10 EX SeriesDocument3 pagesA10 EX SeriesRizqi Angga PratamaNo ratings yet

- SeaPerch ROV Build Manual 2011-02Document33 pagesSeaPerch ROV Build Manual 2011-02budituxNo ratings yet

- Airline ReservationDocument92 pagesAirline ReservationKOHINOORNo ratings yet

- TriggerDocument5 pagesTriggermohd127No ratings yet

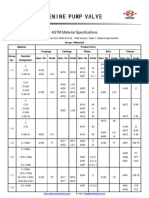

- ASTM Material SpecificationsDocument6 pagesASTM Material SpecificationsLim SenglinNo ratings yet

- What Is A Risk-Based Audit Approach?Document4 pagesWhat Is A Risk-Based Audit Approach?migraneNo ratings yet

- Tadano JapanDocument31 pagesTadano Japananggie100% (2)

- Diesel Locomotive WorksDocument15 pagesDiesel Locomotive WorksAbhishek BhattNo ratings yet

- Design and Analysis of Disk Brake: Vishlawath Raju Ms G. Pranathi, M.TechDocument8 pagesDesign and Analysis of Disk Brake: Vishlawath Raju Ms G. Pranathi, M.TechYuva RajNo ratings yet

- Geocells: Product DataDocument4 pagesGeocells: Product DataFernando Terán ToledoNo ratings yet

- Welders QualificationDocument22 pagesWelders QualificationSreedhar Patnaik.M100% (2)

- WFL Programming Reference ManualDocument468 pagesWFL Programming Reference ManualRoberto García de LeónNo ratings yet

- Ingles Homework 215Document5 pagesIngles Homework 215Andrea Alvarez MontoyaNo ratings yet