General Information: Intake and Exhaust

General Information: Intake and Exhaust

Uploaded by

احمدميدوCopyright:

Available Formats

General Information: Intake and Exhaust

General Information: Intake and Exhaust

Uploaded by

احمدميدوOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

General Information: Intake and Exhaust

General Information: Intake and Exhaust

Uploaded by

احمدميدوCopyright:

Available Formats

INTAKE AND EXHAUST

General Information/Service Specifications/Special tool

Main

Index

GENERAL INFORMATION

The intake manifold is made of an aluminium alloy,

and the shape provides an increased intake inertia

effect and has a good volumetric efficiency.

The exhaust pipe is divided into four parts.

15

Index

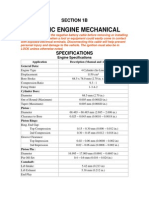

SERVICE SPECIFICATIONS

Items

Intake manifold

Distortion of the installation surface mm

Standard value

Limit

0.15 or less

0.2

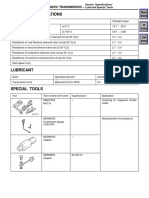

SPECIAL TOOL

Tool

Tool number and name

Supersession

Application

MD998770

Oxygen sensor wrench

Removal/Installation of oxygen

sensor <Vehicles with catalytic

converter>

ON-VEHICLE SERVICE

INTAKE MANIFOLD VACUUM CHECK

Refer to Group 11 On-vehicle Service

INTAKE AND EXHAUST Air Cleaner

Main

Index

AIR CLEANER

REMOVAL AND INSTALLATION

15

Index

9 Nm

10

4 Nm

11

9 Nm

2

9

6

9 Nm

1

5

9 Nm

4 Nm

Removal steps

1. Air cleaner element

2. Breather hose

3. Air flow sensor

4. Gasket

5. Air cleaner cover

6. Air intake hose assembly

7.

8.

9.

10.

11.

Resonator A

Resonator B

Air intake hose

Air duct

Air cleaner body

INTAKE AND EXHAUST Intake Manifold Plenum

Main

Index

INTAKE MANIFOLD PLENUM

REMOVAL AND INSTALLATION

Pre-removal Operation

(1) Remove the engine cover (Refer to GROUP 11B

Intake manifold plenum and throttle body)

(2) Remove the throttle body (Refer to GROUP 13A

Fuel)

(3) Drain the power steering fluid

(Refer to GROUP 37 On-vehicle service)

Post-installation Operation

(1) Install the throttle body (Refer to GROUP 13A

Fuel)

(2) Install the engine cover (Refer to GROUP 11B

Intake manifold plenum and throttle body.)

(3) Add power steering fluid and bleed

(Refer to GROUP 37 On-vehicle service.)

(4) Adjust the tension of the oil pump belt (Refer to

GROUP 11A On-vehicle service.)

18 Nm

1012

13

18 Nm

10 Nm

18 Nm

39 Nm

18 Nm

5

24 Nm

13

10

3

2

7

22 Nm

11

35 Nm

9

49 Nm

Removal steps

1. Crank angle sensor connector

2. EGR valve assembly

3. Brake booster vacuum hose

connection

4. EGR pipe assembly connection

5. Fuel pressure regulator vacuum

hose connection

6. Oil pump belt

"BA 7.

8.

9.

10.

11.

12.

"AA 13.

Pressure hose

Power steering

Pump bracket

Intake manifold

Intake manifold

Intake manifold

Intake manifold

24 Nm

oil pump

plenum stay, front

plenum stay, rear

plenum

plenum gasket

15

Index

INTAKE AND EXHAUST Intake Manifold Plenum

INSPECTION

Main

Index

INTAKE MANIFOLD PLENUM

1. Check that the intake manifold plenum is not damaged

15

or cracked.

2. Check that the vacuum extraction port is not clogged. Index

If faulty, clean.

3. Using a straight edge and thickness gauge, check the

mounting surface for distortion.

Standard value: 0.15 mm or less

Limit: 0.2 mm

INSTALLATION SERVICE POINT

"AA INTAKE MANIFOLD PLENUM GASKET

Install so that the projection on the gasket is as shown in

the diagram.

Front

Projection

Eye joint

notched part

Suction

connector

"BA PRESSURE HOSE

Secure the notched part of the pressure hose eye joint at

the position where it contacts the oil pump suction connector.

INTAKE AND EXHAUST Intake Manifold

Main

Index

INTAKE MANIFOLD

REMOVAL AND INSTALLATION

15

Index

Pre-removal and Post-Installation Operations

D Remove or install the intake manifold plenum

(Refer to P.15-4.)

D Fuel discharge prevention (Refer to GROUP.13

On-vehicle service)

12 Nm

5

12 Nm

1

4

5 Nm

20 - 23 Nm

2

24 Nm

3

20 - 23 Nm

10 - 12 Nm

9

7

8

Intake

manifold

mounting

stud

Cylinder

head

Engine oil

O-ring

Engine oil

Removal steps

1. Injector connector

"CA 2. Fuel high pressure hose connection

3. Return hose connection

4. Vacuum hose connection

AA"

5. Injector and delivery pipe assembly

6.

7.

"BA 8.

"AA 9.

PCV hose connection

Timing belt cover(Front upper)

Intake manifold

Intake manifold gasket

REMOVAL SERVICE POINT

AA" INJECTOR AND DELIVERY PIPE ASSEMBLY

Remove the delivery pipe with the injectors fitted to the delivery

pipe.

Caution

Do not drop the injectors when removing the delivery

pipe.

INTAKE AND EXHAUST Intake Manifold

Main

Index

INSPECTION

INTAKE MANIFOLD

1. Check that the intake manifold is not damaged or cracked.

15

If faulty, replace.

2. Check that the vacuum extraction port is not clogged. Index

If faulty, clean.

3. Using a straight edge and thickness gauge, check the

mounting surface for distortion.

Standard value: 0.15 mm or less

Limit: 0.2 mm

INSTALLATION SERVICE POINT

Front

Projection

"AA INTAKE MANIFOLD GASKET

Install so that the projection on the gaskets is as shown in

the diagram.

Projection

"BA INTAKE MANIFOLD

1. Coat the intake manifold mounting studs with engine oil.

2. Tighten the intake manifold mounting nuts in the following

sequence.

Left bank side

Right bank side

Intake manifold

Sequence

Tightening nuts

Tightening Torque

Nm

Left bank side nuts

Right bank side nuts

20 to 23

Left bank side nuts

20 to 23

Right bank side nuts

20 to 23

Left bank side nuts

20 to 23

INSTALLATION SERVICE POINT

5 Nm

Fuel

pressure

hose

"CA FUEL HIGH PRESSURE HOSE CONNECTION

1. When connecting the high-pressure fuel hose to the fuel

rail, apply a drop of new engine oil to the O-ring, and

then insert, being careful not to damage the O-ring.

Caution

Do not let engine oil in the fuel rail.

Fuel rail

O-ring

5 Nm

2. Check that the high-pressure fuel hose turns smoothly.

If not, remove the hose and then re-insert it into the fuel

rail and check again.

3. Tighten the bolts to the specified torque.

INTAKE AND EXHAUST Exhaust Manifold

Main

Index

EXHAUST MANIFOLD

REMOVAL AND INSTALLATION

15

Index

Pre-removal and Post-Installation Operations

D Remove or install the front exhaust pipe (Refer

to P.15-9.)

D Remove or install the radiator (Front bank only)

(Refer to GROUP.14)

D Remove or install the alternator (Front bank only)

(Refer to GROUP.16)

13 Nm

6

1

19 Nm

5

59 Nm

29 Nm

2

29 Nm

13 Nm

8

7

4

Removal Procedure for Front Bank

1. Heat protector

2. Exhaust manifold

3. Exhaust manifold gasket

Removal Procedure for Rear Bank

4. Heat protector

5. EGR pipe

6. EGR pipe gasket

7. Exhaust manifold

8. Exhaust manifold gasket

INTAKE AND EXHAUST Exhaust Pipe and Main muffler

Main

Index

EXHAUST PIPE AND MAIN MUFFLER

REMOVAL AND INSTALLATION

18

15

Index

11

49 Nm

44 Nm

17

7 Nm

14

17

15

16

13 Nm

12

13

49 Nm

13 Nm

13 Nm

13 Nm

<SEDAN>

4

9

34 Nm

5

10

49 Nm

13 Nm

1

3

9

13 Nm

13 Nm

<WAGON>

4

6

13 Nm

34 Nm

49 Nm

10

Main muffler removal steps

1. Hanger

2. Main muffler assembly

3. Hanger bracket

4. Gasket

5. Rear floor heat protector panel

Centre exhaust pipe removal steps

6. Hanger

7. Centre exhaust pipe

8. Gasket

9. Damper

10. Hanger bracket

11. Harness protector

12. Catalytic converter or pre-muffler

13. Gasket

Front exhaust pipe removal steps

14. Oxygen sensor

15. Hanger

16. Front exhaust pipe

17. Gasket

18. Front floor heat protector

You might also like

- Mazda FE y F2Document27 pagesMazda FE y F2jads30117976% (17)

- Service Manual 157QMJDocument60 pagesService Manual 157QMJGeert Verfaillie67% (3)

- Paint Manufacturing Feasibility StudyDocument45 pagesPaint Manufacturing Feasibility StudyOlufemi Moyegun100% (4)

- Saturn Check Engine Light CodesDocument20 pagesSaturn Check Engine Light CodesاحمدميدوNo ratings yet

- RB 25 HeadDocument9 pagesRB 25 HeadAlexander Dominguez0% (1)

- Em - Engine Mechanical PDFDocument24 pagesEm - Engine Mechanical PDFMoaed Kanbar86% (21)

- Engine K21 and K25 Engine FuelDocument19 pagesEngine K21 and K25 Engine FuelPablo Rojas Valenzuela100% (1)

- 2000 2 4 Engine OverhaulDocument216 pages2000 2 4 Engine OverhaulquetecojaunburroNo ratings yet

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (17)

- AVEO 2007-2010/wave - 07-10/engine Mechanical - 1.5L/Repair Instructions - Off VehicleDocument39 pagesAVEO 2007-2010/wave - 07-10/engine Mechanical - 1.5L/Repair Instructions - Off VehicleArley Hernandez100% (1)

- Audi 100Document93 pagesAudi 100Dalibor Angelovski100% (1)

- 4.2L EngineDocument28 pages4.2L Engineadnmb100% (7)

- Motor F4RDocument64 pagesMotor F4RPablo OrtizNo ratings yet

- CAT 3412 Air Inlet and Exhaust SystemDocument8 pagesCAT 3412 Air Inlet and Exhaust SystemCEVegaO100% (2)

- Code P1693Document21 pagesCode P1693احمدميدوNo ratings yet

- Manual Pajero 4x4 Intake and ExhaustDocument20 pagesManual Pajero 4x4 Intake and ExhaustGIAN CARLO MAMANI GILES.No ratings yet

- Intake and ExhaustDocument8 pagesIntake and ExhaustAlexandre Da Silva PintoNo ratings yet

- GR00002000 15 PDFDocument12 pagesGR00002000 15 PDFNicu PascalutaNo ratings yet

- GA15 Engine DisassemblyDocument79 pagesGA15 Engine DisassemblyJohn Coxx100% (1)

- Worksheet TurboDocument19 pagesWorksheet TurboAbdul Al-hadiNo ratings yet

- 15sPACE WAGONDocument8 pages15sPACE WAGONrafaelcruzgjaNo ratings yet

- 1 Mitsubishi Lancer Evo IX.Document1,000 pages1 Mitsubishi Lancer Evo IX.seregap84100% (2)

- Chevrolet Lacetti - (Optra) 2005 1.4L-1.6Document45 pagesChevrolet Lacetti - (Optra) 2005 1.4L-1.6Hernan HernandezNo ratings yet

- Piaggio X9 500 Service Station Manual (2002-EnGLISH-70 Pages)Document69 pagesPiaggio X9 500 Service Station Manual (2002-EnGLISH-70 Pages)Enis MurgicNo ratings yet

- Intake AndDocument16 pagesIntake AndGonzalez RubenNo ratings yet

- MBE4000 EGR Connector Pipe InstallationDocument6 pagesMBE4000 EGR Connector Pipe InstallationАндрейNo ratings yet

- Fuel Pumps Install and CheckDocument37 pagesFuel Pumps Install and CheckLionnel ParantNo ratings yet

- 17 Engine and Emission ControlDocument38 pages17 Engine and Emission ControlJoaoBorgesNo ratings yet

- Series 60 - Section 6.3 Intake ManifoldDocument7 pagesSeries 60 - Section 6.3 Intake ManifoldJuan Rivera100% (1)

- 988B ServiceDocument115 pages988B Service69v29snjcmNo ratings yet

- 00M12 PDFDocument6 pages00M12 PDFurania22000No ratings yet

- Subaru - Impreza - Workshop Manual - 1999 - 2002Document8,373 pagesSubaru - Impreza - Workshop Manual - 1999 - 2002bart3omiej3boguszewiNo ratings yet

- Engine AssemblyDocument20 pagesEngine AssemblymanualNo ratings yet

- Engine Mechanical PDFDocument115 pagesEngine Mechanical PDFAndrey GladyshevNo ratings yet

- Fuel Injection Pump Timing - AdjustDocument6 pagesFuel Injection Pump Timing - AdjustRonald Yucra Cadena100% (2)

- Motor Daewod 1.0-1.2l Aveo, Spark, MatizDocument155 pagesMotor Daewod 1.0-1.2l Aveo, Spark, MatizAndrea Molina LezamaNo ratings yet

- Operating Instructions & Service Manual Blue Max Ii Hydrostatic Test PumpDocument10 pagesOperating Instructions & Service Manual Blue Max Ii Hydrostatic Test PumpdocrafiNo ratings yet

- Accelerator Control, Fuel & Exhaust Systems: Draining Water Fuel Filter CheckDocument22 pagesAccelerator Control, Fuel & Exhaust Systems: Draining Water Fuel Filter CheckDwight GeorgeNo ratings yet

- Piaggio X9 500 Service Station Manual (2002-EnGLISH-70 Pages)Document69 pagesPiaggio X9 500 Service Station Manual (2002-EnGLISH-70 Pages)Alessandro MigliettaNo ratings yet

- Manual TransmissionDocument16 pagesManual TransmissionKalGeorgeNo ratings yet

- Air Dryer - Maint - Manual - Rev - 1 PDFDocument34 pagesAir Dryer - Maint - Manual - Rev - 1 PDFCristiTancuNo ratings yet

- Engine Overhaul: PrintDocument216 pagesEngine Overhaul: PrintBrian Conejo SolisNo ratings yet

- Fuel System: SectionDocument15 pagesFuel System: SectionRonildo GirardiNo ratings yet

- Clutch Master Cylinder 7 - . - . - . - . - . - . - . - . - . - . - .Document8 pagesClutch Master Cylinder 7 - . - . - . - . - . - . - . - . - . - . - .rafaelcruzgjaNo ratings yet

- (FORD) Diagrama de Cableado Ford FocusDocument29 pages(FORD) Diagrama de Cableado Ford FocusArturoNoCesaNo ratings yet

- Aab Acv DisassemblDocument78 pagesAab Acv DisassemblkwlutnikNo ratings yet

- Procedimietos CulataDocument15 pagesProcedimietos CulataSERVICIO TECNICO AUTOMOTRIZ TONATONo ratings yet

- Repair Instructions - Off Vehicle PDFDocument37 pagesRepair Instructions - Off Vehicle PDFFernando Ortiz100% (1)

- 902 PistonDocument42 pages902 PistonSumit SinhaNo ratings yet

- Esquema Hidraulico ManitouDocument26 pagesEsquema Hidraulico Manitouctorres_505746No ratings yet

- zxr400 H 04Document23 pageszxr400 H 04hugo_bikerNo ratings yet

- Installation Procedure For Vertical Glandless Process PumpDocument22 pagesInstallation Procedure For Vertical Glandless Process PumpYoutube For EducationNo ratings yet

- Bomba Primaria e CombustibleDocument8 pagesBomba Primaria e CombustibleoscarNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- How to Power Tune the BMC/BL/Rover 998 A-Series Engine for Road and TrackFrom EverandHow to Power Tune the BMC/BL/Rover 998 A-Series Engine for Road and TrackNo ratings yet

- The Red Baron’s Ultimate Ducati Desmo Manual: BELT-DRIVEN CAMSHAFTS L-TWINS 1979 TO 2017From EverandThe Red Baron’s Ultimate Ducati Desmo Manual: BELT-DRIVEN CAMSHAFTS L-TWINS 1979 TO 2017No ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- 00 General: How To Use This ManualDocument2 pages00 General: How To Use This ManualاحمدميدوNo ratings yet

- 23C Automatic Transmission F5A51: Service Specifications Lubricant Special Tools TroubleshootingDocument2 pages23C Automatic Transmission F5A51: Service Specifications Lubricant Special Tools TroubleshootingاحمدميدوNo ratings yet

- 23A Automatic Transmission: Service Specifications Lubricant Special Tools Troubleshooting On-Vehicle ServiceDocument2 pages23A Automatic Transmission: Service Specifications Lubricant Special Tools Troubleshooting On-Vehicle ServiceاحمدميدوNo ratings yet

- Service Specifications: 23A Automatic TransmissionDocument67 pagesService Specifications: 23A Automatic TransmissionاحمدميدوNo ratings yet

- How To Test The Rear O2 HeaterDocument120 pagesHow To Test The Rear O2 Heaterاحمدميدو100% (3)

- Kia EDDocument22 pagesKia EDscrewyoureg100% (1)

- 23 Toccd 1Document1 page23 Toccd 1احمدميدوNo ratings yet

- AC Level 2 Electric Vehicle Charging Station: The Most Robust, FL Exible Offering of EVSE On The MarketDocument2 pagesAC Level 2 Electric Vehicle Charging Station: The Most Robust, FL Exible Offering of EVSE On The MarketاحمدميدوNo ratings yet

- Dual AC Level 2 Commercial Electric Vehicle Charging StationDocument4 pagesDual AC Level 2 Commercial Electric Vehicle Charging StationاحمدميدوNo ratings yet

- Powertrain CodesDocument17 pagesPowertrain CodesاحمدميدوNo ratings yet

- Code DescriptionDocument37 pagesCode DescriptionاحمدميدوNo ratings yet

- Hicom Manual Keys enDocument11 pagesHicom Manual Keys enاحمدميدوNo ratings yet

- Modeling and Analyzing Real-Time Data Streams: NtroductionDocument8 pagesModeling and Analyzing Real-Time Data Streams: NtroductionاحمدميدوNo ratings yet

- A DTC Fault CodeDocument6 pagesA DTC Fault CodeاحمدميدوNo ratings yet

- DS Sensor05Document12 pagesDS Sensor05احمدميدوNo ratings yet

- U0100Document4 pagesU0100احمدميدو100% (1)

- Have ADocument1 pageHave AاحمدميدوNo ratings yet

- 10th English Questions Answers and Objective NotesDocument26 pages10th English Questions Answers and Objective NotesI the only soulNo ratings yet

- The Truth About Leadership Outline PDFDocument7 pagesThe Truth About Leadership Outline PDFRizka Lashirah SafitriNo ratings yet

- Ashish Joshi ResumeDocument2 pagesAshish Joshi Resumeashish joshiNo ratings yet

- Fast Track Pro Drivers Read MeDocument3 pagesFast Track Pro Drivers Read MeMatt JerniganNo ratings yet

- Candidates Are Required To Give Their Answers in Their Own Words As Far As Practicable. The Figures in The Margin Indicate Full MarksDocument5 pagesCandidates Are Required To Give Their Answers in Their Own Words As Far As Practicable. The Figures in The Margin Indicate Full MarksAdhikari SushilNo ratings yet

- How Does Grit Impact College Students Academic Achievement in ScienceDocument11 pagesHow Does Grit Impact College Students Academic Achievement in SciencePATRICIA KATE CELSONo ratings yet

- Tax Invoice: Blupin Technologies Private LimitedDocument2 pagesTax Invoice: Blupin Technologies Private LimitedRahNo ratings yet

- Which of These Do You Consider To Be Unacceptable?Document6 pagesWhich of These Do You Consider To Be Unacceptable?Antonia PrgometNo ratings yet

- Assignment 5 - Construction-Management-GEPULLANODocument4 pagesAssignment 5 - Construction-Management-GEPULLANOELIJAH GEPULLANONo ratings yet

- ESR Meter Al Lui GoDocument20 pagesESR Meter Al Lui GoLaurentiu IacobNo ratings yet

- Equations of Motion 1 AnswersDocument1 pageEquations of Motion 1 AnswersckNo ratings yet

- Formulating Mission StatementDocument3 pagesFormulating Mission Statementkristinatambis28No ratings yet

- Is A Process in Which Ethical Issues and Problems Are Benchmarked Against A MoralDocument3 pagesIs A Process in Which Ethical Issues and Problems Are Benchmarked Against A MoralGround ZeroNo ratings yet

- Apc smx3000lv User ManualDocument10 pagesApc smx3000lv User ManualColour BlindNo ratings yet

- P4 - U8 Vocabulary & Reading ExtensionDocument4 pagesP4 - U8 Vocabulary & Reading ExtensionTran Ngoc LinhNo ratings yet

- A STUDY On Employee Stress RDocument15 pagesA STUDY On Employee Stress Rchavsnarayana93No ratings yet

- A. T. S. - Switching Line BoardDocument6 pagesA. T. S. - Switching Line BoardAsif ShahNo ratings yet

- GOLDEN DAWN 3 8 Energy Influences On The PathsDocument4 pagesGOLDEN DAWN 3 8 Energy Influences On The PathsF_RCNo ratings yet

- Catalog: Control Valves For Heating, Ventilation and Air-Conditioning SystemsDocument278 pagesCatalog: Control Valves For Heating, Ventilation and Air-Conditioning SystemsandreyNo ratings yet

- The MultitesterpowerpointDocument21 pagesThe MultitesterpowerpointAngel AlarasNo ratings yet

- Daewoo Training Washing MachineDocument21 pagesDaewoo Training Washing MachinevictorNo ratings yet

- Nursing Theory:: "Theories Are Not Discovered in Nature But Are Human Inventions."Document15 pagesNursing Theory:: "Theories Are Not Discovered in Nature But Are Human Inventions."Simon JosanNo ratings yet

- Ford Strategic Mangement - Chevy VoltDocument2 pagesFord Strategic Mangement - Chevy VoltVikram Santhanam100% (5)

- HDD Hitachi HTS547564A9E384Document170 pagesHDD Hitachi HTS547564A9E384scrib3dsNo ratings yet

- Chapter 8 Financial Auditing SlidesDocument13 pagesChapter 8 Financial Auditing SlidesLuong Thao LinhNo ratings yet

- Articulo de Investigacion Sobre Digitalizacion 3DDocument20 pagesArticulo de Investigacion Sobre Digitalizacion 3DAlex HillarNo ratings yet

- CablesDocument2 pagesCablesbertinNo ratings yet

- Road Transport Year Book 2015 16 PDFDocument156 pagesRoad Transport Year Book 2015 16 PDFGowtham AmirNo ratings yet

- Heavyduty Kits Catalog 2017Document8 pagesHeavyduty Kits Catalog 2017panamapuro100% (1)