Sodium Hypochlorite - Storage: Please Consult Our Safety Data Sheet

Sodium Hypochlorite - Storage: Please Consult Our Safety Data Sheet

Uploaded by

Ioana PopescuCopyright:

Available Formats

Sodium Hypochlorite - Storage: Please Consult Our Safety Data Sheet

Sodium Hypochlorite - Storage: Please Consult Our Safety Data Sheet

Uploaded by

Ioana PopescuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Sodium Hypochlorite - Storage: Please Consult Our Safety Data Sheet

Sodium Hypochlorite - Storage: Please Consult Our Safety Data Sheet

Uploaded by

Ioana PopescuCopyright:

Available Formats

DOC-1400-0003

Introduction

Sodium hypochlorite must be stored and disposed of in compliance with relevant laws and

regulations.

Handling of sodium hypochlorite should be accompanied by collective protective measures

(clearly signalled showers and eye baths in the vicinity).

Please consult our safety data sheet.

Storage tank capacity

The tank capacity should be adequate to carry a sufficiently large stock and be able to receive

the total amount of volume from the road tanker. If the consumption of sodium hypochlorite is

less than 50 tonnes per month, the ideal storage capacity should be at least 1,5 x the volume

of the road tanker. This should be suitably adapted if the consumption of sodium hypochlorite

is higher than 50 tonnes per month.

Storage tank labelling

The storage tank should be labelled with the product name, the safety symbol, the tank

identification as well as with the orange ADR plate.

Sodium hypochlorite

Tank #

Example: tank label

Storage tank materials

Sodium hypochlorite is a corrosive and oxidising product. Because of its instability, it must not

be in contact with metals (cobalt, copper, iron, nickel and their alloys and salts) and must not

be exposed to heat or to direct sunlight.

Sodium hypochlorite is currently stored in certain types of plastic materials and sometimes in

lined steel.

Plastics

The maximum allowed pressure and vent line must be checked if compressed air is used

during unloading.

- GFRP with PVC lining; the condition of the liner should be checked according to supplier

specification.

- PVC (dual laminate) or HDPE are adequate for small storage tanks.

Lined steel

Vinyl ester, epoxy or ebonite are suitable liners; the condition of the liner should be checked

according to supplier specification.

Solvay Chemicals International SA

Rue du Prince Albert 44

B - 1050 Brussels

Brussels, RPM 0406804736

+32 2 509 61 11

www.solvaychemicals.com

DOC-1400-0003-W-EN (WW)

Issue 3 - June 2009

1/4

SODIUM HYPOCHLORITE

Technical Documentation

SODIUM HYPOCHLORITE - STORAGE

Storage tank equipment

The tank must be fitted with the following:

- filling line of at least DN 50, with a clearly labelled coupling point at a maximum of one meter

above ground level,

- vent line of at least DN 100 on top of the storage tank,

- overflow line of at least DN 100, directed towards the ground and inside the bund,

- manhole,

- tank fluid level measurement device,

- high-level alarm, to avoid overflow and in the case of unloading with pump to switch it off,

- low-level alarm, to avoid cavitation and to switch off the transfer pump to the end-use.

- discharge line.

Note: The size of vent and overflow lines should be larger or equal in size to the filling line.

Bund

The storage tank must be placed on an adequate reinforced concrete foundation to support

the tank and must be placed in a bund, containment dyke or be double walled.

Sodium hypochlorite corrodes concrete. Epoxy paint coating gives good corrosion protection.

At least potentially exposed surfaces i.e. pump base/foundation, etc. be should protected.

Rainwater collected inside the bund may contain sodium hypochlorite. Connecting the bund

area to the sewer system is not recommended. A valve between the bund and a sewer

system is not sufficient to protect the sewer system from possible contamination of sodium

hypochlorite i.e. valve may be left open by mistake. The safest way of emptying the bund is to

use a manually operated pump.

Pipes should be passed over the bund walls and not through them. It is essential that the

bund and bund wall is sealed liquid-tight from the top to the bottom.

Caution: Storage tanks of products which are not compatible with sodium hypochlorite

(e.g., hydrochloric acid) should not be placed in the same bund.

Solvay Chemicals International SA

Rue du Prince Albert 44

B - 1050 Brussels

Brussels, RPM 0406804736

+32 2 509 61 11

www.solvaychemicals.com

DOC-1400-0003-W-EN (WW)

Issue 3 - June 2009

2/4

SODIUM HYPOCHLORITE

Technical Documentation

SODIUM HYPOCHLORITE - STORAGE

Pipes, valves and pumps

Pipes

The storage facility should be designed in a way which limits the possibility of trapping a

section containing sodium hypochlorite.

Plastic pipes are adequate for transporting sodium hypochlorite and should be applied in the

following order of preference:

- GFRP with PP or PVC lining,

- HDPE,

- PP.

Plastic pipes should be supported over their whole length.

Supplier specifications should be followed.

Valves

Ball valves in PVC or PP should be used.

To avoid trapping of sodium hypochlorite inside the valve we recommend to use vented

valves. The vent is normally designed as a hole through the side of the ball. This will allow

any liquid or gas in the ball to remain in contact with the upstream side whenever the valve is

in the closed position.

Pumps

Pumps made of PVC, PP or titanium are suitable for sodium hypochlorite transfer.

Issues with shaft tightening are avoided by using magnetic driven pumps.

Membrane pumps are suitable for a consistent delivery dose of sodium hypochlorite.

Gaskets

Gaskets made of flexible PVC, modified PTFE or EPDM should be used.

EPDM:

GFRP:

HDPE:

PP:

PTFE:

PVC:

Ethylene Propylene DiMonomer

Glass Fibre Reinforced Polyester

High-Density PolyEthylene

PolyPropylene

PolyTetraFluoroEthylene

PolyVinyl Chloride

Solvay Chemicals International SA

Rue du Prince Albert 44

B - 1050 Brussels

Brussels, RPM 0406804736

+32 2 509 61 11

www.solvaychemicals.com

DOC-1400-0003-W-EN (WW)

Issue 3 - June 2009

3/4

SODIUM HYPOCHLORITE

Technical Documentation

SODIUM HYPOCHLORITE - STORAGE

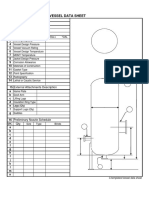

Example: Storage tank bottom unloading with compressed air

Example: Storage tank bottom unloading with pump

1

2

3

3

4

5

6

7

Flexible hose

Flushing water

Unloading pump

Transfer pump (to the end-use)

Pressure gauge

Filling line

Overflow line

Level measurement

8

8

9

10

11

12

13

17

High level alarm

Low level alarm

Vent line

Drain valve

Bund

To end use

To waste treatment

Collection sump

__________________________________________________________________________________________________________

To our present knowledge, the information contained herein is accurate as of the date of this document. However, we do not make

any warranty, express or implied, or accept any liability in connection with this information or its use. This information is for use by

technically skilled persons at their own discretion and risk and does not relate to the use of this product in combination with any other

substance or any other process. This is not a license under any patent or other proprietary right. The user alone must finally determine

suitability of any information or material for any contemplated use, the manner of use in compliance with relevant legislations and

whether any patents are infringed. We reserve our right to make additions, deletions, or modifications to the information at any time

without prior notification.

Solvay Chemicals International SA

Rue du Prince Albert 44

B - 1050 Brussels

Brussels, RPM 0406804736

+32 2 509 61 11

www.solvaychemicals.com

DOC-1400-0003-W-EN (WW)

Issue 3 - June 2009

4/4

SODIUM HYPOCHLORITE

Technical Documentation

SODIUM HYPOCHLORITE - STORAGE

You might also like

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionFrom EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNo ratings yet

- Operation and Maintenance Manual For The Lo/Pro Odor Control SystemDocument48 pagesOperation and Maintenance Manual For The Lo/Pro Odor Control SystemVinish HARIDAS NAIRNo ratings yet

- The New NSF 350 AND 350-1Document6 pagesThe New NSF 350 AND 350-1Rossy IP100% (1)

- Ansi Z400.1Document2 pagesAnsi Z400.1chaloNo ratings yet

- Vinyl Acetate Safe Handling GuideDocument63 pagesVinyl Acetate Safe Handling GuideNigel KowNo ratings yet

- 37R 06Document8 pages37R 06mirakul100% (2)

- Structural Steel LessonsDocument7 pagesStructural Steel LessonsIngeniero EstructuralNo ratings yet

- 21 CFR Part 177Document185 pages21 CFR Part 177อิอิ อิอิ100% (1)

- Corrosion PreventionDocument2 pagesCorrosion Preventionandrew myintmyatNo ratings yet

- Aluminum A Good Alternative To Steel For Fixed-Roof Tanks - Oil & Gas JournalDocument8 pagesAluminum A Good Alternative To Steel For Fixed-Roof Tanks - Oil & Gas JournalIlze Lorena Priego AhumadaNo ratings yet

- Mitusha: Corrosion of Base Metals in ContactDocument1 pageMitusha: Corrosion of Base Metals in ContactAVINASHRAJNo ratings yet

- Apco Vacuum Reliefair Inlet Valves Avr 1500 PDFDocument8 pagesApco Vacuum Reliefair Inlet Valves Avr 1500 PDFTanmoy Dutta100% (1)

- Corrosion of Plastics and Composites in Chemical EnvironmentsDocument7 pagesCorrosion of Plastics and Composites in Chemical EnvironmentsRizky AnandaNo ratings yet

- Chemical Resistance GuideDocument35 pagesChemical Resistance GuideAGPNo ratings yet

- Sodium Hypochlorite: General Information For The ConsumerDocument31 pagesSodium Hypochlorite: General Information For The ConsumerMarco Franco0% (1)

- Elastopipe A Flexible Piping SystemDocument2 pagesElastopipe A Flexible Piping SystemRuano StumpfNo ratings yet

- Chemline Plastics Chemical Resistance GuideDocument36 pagesChemline Plastics Chemical Resistance GuidezazaNo ratings yet

- TDS - Emaco S88 PlusDocument2 pagesTDS - Emaco S88 PlusVenkata RaoNo ratings yet

- CI Sodium Hypochlorite Compatibility ChartDocument1 pageCI Sodium Hypochlorite Compatibility ChartastromoNo ratings yet

- Review of Cansolv SO Scrubbing System's First Commercial Operations in The Oil Refining IndustryDocument17 pagesReview of Cansolv SO Scrubbing System's First Commercial Operations in The Oil Refining Industryrogerh44No ratings yet

- AEGIS Ammonia AnalyzerDocument73 pagesAEGIS Ammonia Analyzeraku katalistNo ratings yet

- N 40 Tech 11 25 08Document2 pagesN 40 Tech 11 25 08hiker.fcb2009No ratings yet

- Watter Hammer HobasDocument35 pagesWatter Hammer HobasAnonymous 87xpkIJ6CFNo ratings yet

- VJ CatalogueDocument196 pagesVJ CatalogueShane HancockNo ratings yet

- Datasheet-Saf-2507-En-V2021-03-05 18 - 06 Version 1Document19 pagesDatasheet-Saf-2507-En-V2021-03-05 18 - 06 Version 1aap aapNo ratings yet

- Us 4058649Document6 pagesUs 4058649yigitilgazNo ratings yet

- Derakane Momentum 470 300 Epoxy Vinyl Ester ResinDocument14 pagesDerakane Momentum 470 300 Epoxy Vinyl Ester ResinKaren Elias Villegas50% (2)

- 2014, Experiments and Modelling of Two-Phase Transient Flow During Pipeline Depressurization of CO2 With Various N2 CompositionsDocument10 pages2014, Experiments and Modelling of Two-Phase Transient Flow During Pipeline Depressurization of CO2 With Various N2 CompositionsCO2 NIDFNo ratings yet

- PPXV An Elegant and Fast Method To Predict The Slow Crack Growth Behaviour of High Density Polyethylene Pipe MaterialsDocument7 pagesPPXV An Elegant and Fast Method To Predict The Slow Crack Growth Behaviour of High Density Polyethylene Pipe MaterialsMehboob ulHaqNo ratings yet

- Decomposition of NaOClDocument10 pagesDecomposition of NaOClswongNo ratings yet

- CFRP Pipe Repair - How To Ensure SuccessDocument7 pagesCFRP Pipe Repair - How To Ensure SuccessTS WongNo ratings yet

- Reichold, Corrosion Guide 12.15.2010Document45 pagesReichold, Corrosion Guide 12.15.2010Pradeep Srivastava100% (1)

- Engate Breakaway Manual TécnicoDocument21 pagesEngate Breakaway Manual Técnicolima_almeida5865100% (1)

- PN01SA0B03Document5 pagesPN01SA0B03Julian GaleanoNo ratings yet

- Case Study Bicine Formation Amine UnitDocument14 pagesCase Study Bicine Formation Amine Unitmahesh070No ratings yet

- Melamine Formaldehyde Curing Studies andDocument7 pagesMelamine Formaldehyde Curing Studies andtahera aqeelNo ratings yet

- De Scaling Plate Heat ExchangersDocument2 pagesDe Scaling Plate Heat ExchangersKiran DuggarajuNo ratings yet

- Ignition of SilaneDocument98 pagesIgnition of SilanechujiyoNo ratings yet

- Total Requirements PDFDocument7 pagesTotal Requirements PDFsmrndrdasNo ratings yet

- 11a. Chlor-AlkaliDocument4 pages11a. Chlor-Alkalimuhammad omerNo ratings yet

- Polyethylene (PE) Plastic Pipe, Schedules 40 and 80, Based On Outside DiameterDocument9 pagesPolyethylene (PE) Plastic Pipe, Schedules 40 and 80, Based On Outside DiameterAndres Camilo BenitezNo ratings yet

- H2O2 Hydrogen Peroxide Passivation ProcedureDocument7 pagesH2O2 Hydrogen Peroxide Passivation ProcedureLion TigerNo ratings yet

- FRP Ashland - Different FRP Resin Chemistries For Different Chemical EnvironmentsDocument6 pagesFRP Ashland - Different FRP Resin Chemistries For Different Chemical EnvironmentsHafiz Kamal100% (1)

- Pipe Hangers Supports Seismic BracingDocument5 pagesPipe Hangers Supports Seismic BracingBryan S. AlejandroNo ratings yet

- Ammonium Carbamte P, T - BASFDocument4 pagesAmmonium Carbamte P, T - BASFVinh Do ThanhNo ratings yet

- Pietro FiorentiniDocument6 pagesPietro FiorentiniRadityaA.PerdanaNo ratings yet

- 353.FoamglassAssamblyDocument12 pages353.FoamglassAssamblyCeratita ClarkNo ratings yet

- Pipeline Acronyms and Classifications GuidelineDocument12 pagesPipeline Acronyms and Classifications Guidelinelsaishankar100% (1)

- General and Dilution Ventilation PDFDocument15 pagesGeneral and Dilution Ventilation PDFSeunNo ratings yet

- Derakane - Tech SupportDocument32 pagesDerakane - Tech SupportJainam ShahNo ratings yet

- FRP - Spec For Hypo Storage TanksDocument4 pagesFRP - Spec For Hypo Storage Tanksssureshkar7699100% (1)

- Prodution of Ferrous Sulfate From SteelmakingDocument7 pagesProdution of Ferrous Sulfate From SteelmakinganaazizNo ratings yet

- Understanding and Eliminating Pressure Fluctuations in 2010 Process SafetyDocument6 pagesUnderstanding and Eliminating Pressure Fluctuations in 2010 Process SafetyandriNo ratings yet

- 3LPEDocument48 pages3LPEjangdiniNo ratings yet

- Unlock-Durcomet 100 (CD-4MCu)Document8 pagesUnlock-Durcomet 100 (CD-4MCu)Dimas Pratama PutraNo ratings yet

- Piping FG Smith FiberglassDocument12 pagesPiping FG Smith Fiberglassnader0123100% (1)

- Bete Fog Whitepaper PDFDocument9 pagesBete Fog Whitepaper PDFmalikaNo ratings yet

- Xerxes Above Ground Tanks BrochureDocument16 pagesXerxes Above Ground Tanks Brochurebruno383No ratings yet

- Forest Product Conversion FactorsFrom EverandForest Product Conversion FactorsNo ratings yet

- The Iron Oxides: Structure, Properties, Reactions, Occurrences and UsesFrom EverandThe Iron Oxides: Structure, Properties, Reactions, Occurrences and UsesRating: 5 out of 5 stars5/5 (1)

- Ammonia TankDocument17 pagesAmmonia TankIoana PopescuNo ratings yet

- 42 - Pe-P-Roa07114227006-Me-Dwg-003-01-E - Plan LegaturiDocument1 page42 - Pe-P-Roa07114227006-Me-Dwg-003-01-E - Plan LegaturiIoana PopescuNo ratings yet

- Air Cooled Heat ExchangersDocument6 pagesAir Cooled Heat ExchangersIoana PopescuNo ratings yet

- Stress Analysis of Piping SystemsDocument108 pagesStress Analysis of Piping SystemsShijumon Kp100% (1)

- PSV Calculation Report - Liquid Relief Sizing Case: Const. VarDocument1 pagePSV Calculation Report - Liquid Relief Sizing Case: Const. VarIoana PopescuNo ratings yet

- Cars Air France: Line 2: Etoile - Porte Maillot / Aéroport Paris-Charles de GaulleDocument5 pagesCars Air France: Line 2: Etoile - Porte Maillot / Aéroport Paris-Charles de GaulleIoana PopescuNo ratings yet

- Pump Sizing Calculation: Data FlowrateDocument4 pagesPump Sizing Calculation: Data FlowrateIoana PopescuNo ratings yet

- Flow1 PDFDocument1 pageFlow1 PDFIoana PopescuNo ratings yet

- PSV 6r8 Api - 526lDocument1 pagePSV 6r8 Api - 526lIoana PopescuNo ratings yet

- PSV Data Sheet UnwettedDocument7 pagesPSV Data Sheet UnwettedIoana PopescuNo ratings yet

- Sala Unirii PDFDocument1 pageSala Unirii PDFIoana PopescuNo ratings yet

- PSV Data Sheet WettedDocument7 pagesPSV Data Sheet WettedIoana PopescuNo ratings yet

- Dictionar Tehnic Roman Englez A IDocument798 pagesDictionar Tehnic Roman Englez A IIoana PopescuNo ratings yet

- TM 5 3895 358 14 and PDocument1 pageTM 5 3895 358 14 and PIoana PopescuNo ratings yet

- Template - Hold UpDocument1 pageTemplate - Hold UpIoana PopescuNo ratings yet

- Glycol Reboiler - Still Column PDFDocument3 pagesGlycol Reboiler - Still Column PDFIoana PopescuNo ratings yet

- Compressor: 40-K-001: Stream Name 131Document3 pagesCompressor: 40-K-001: Stream Name 131Ioana PopescuNo ratings yet

- Forming, Working and Heat-Treating MetalDocument3 pagesForming, Working and Heat-Treating MetalFaten ChekmanNo ratings yet

- Process Control Seminar TopicsDocument2 pagesProcess Control Seminar TopicslalusebanNo ratings yet

- 8 AS4041 ASME B31 3 Pipe Wall ThicknessDocument12 pages8 AS4041 ASME B31 3 Pipe Wall ThicknessAnggaNo ratings yet

- Logistics InfrastructureDocument5 pagesLogistics InfrastructureTiviz RoobanNo ratings yet

- Marwan Rateb Resume - MBA, PMP, SCRUM, Six Sigma, Lean, ConsultantDocument2 pagesMarwan Rateb Resume - MBA, PMP, SCRUM, Six Sigma, Lean, ConsultantnervousmarkNo ratings yet

- Requirements of A Good PartitionDocument11 pagesRequirements of A Good PartitionShraddha Bahirat100% (1)

- Nano Bubble Technology: A New Way To Sustainable Jeans FinishingDocument2 pagesNano Bubble Technology: A New Way To Sustainable Jeans FinishingElias KhalilNo ratings yet

- Rain Commodities LTD Initiating - CoverageDocument24 pagesRain Commodities LTD Initiating - CoverageCindrella TaraNo ratings yet

- Teerthanker Mahaveer University Moradabad (U.P) - 244001 Tabulation SheetDocument3 pagesTeerthanker Mahaveer University Moradabad (U.P) - 244001 Tabulation SheetMohit RuhalNo ratings yet

- Concrete Protection Materials & TechniquesDocument34 pagesConcrete Protection Materials & TechniquesSasikumar ViswanathanNo ratings yet

- Final Assignment Course: BUS525 (Managerial Economics)Document8 pagesFinal Assignment Course: BUS525 (Managerial Economics)MushfiqNo ratings yet

- Hysa9460 enDocument3 pagesHysa9460 enengpontelliNo ratings yet

- Branding A ProductDocument43 pagesBranding A Productnavya111No ratings yet

- What Is A Composite MaterialDocument12 pagesWhat Is A Composite MaterialGaurav MakwanaNo ratings yet

- NS1 Work Plan Procedure For CW Piping Installation Rev.4Document47 pagesNS1 Work Plan Procedure For CW Piping Installation Rev.4namdq-1No ratings yet

- The Foster Wheeler Gasification Technology For Biofuels: Refuse-Derived Fuel (RDF) Power GenerationDocument17 pagesThe Foster Wheeler Gasification Technology For Biofuels: Refuse-Derived Fuel (RDF) Power Generationib4uNo ratings yet

- 31003Document4 pages31003Elliott RussellNo ratings yet

- Horizontal Bracing Connection Bolted Type - IS800-2007Document55 pagesHorizontal Bracing Connection Bolted Type - IS800-2007Nitesh SinghNo ratings yet

- Typical Analysis: OrangeDocument2 pagesTypical Analysis: Orange146235No ratings yet

- Decopling PointDocument25 pagesDecopling PointHimanshuSinghNo ratings yet

- Die Casting Maintainance PDFDocument32 pagesDie Casting Maintainance PDFgksp100% (1)

- Organe Asamblare PDFDocument7 pagesOrgane Asamblare PDFMazare IonNo ratings yet

- Ews Cat 2006 8000Document2 pagesEws Cat 2006 8000gabrielcarm7938No ratings yet

- Classif AçosDocument7 pagesClassif AçoslavascudoNo ratings yet

- Copper Based Project ReportsDocument2 pagesCopper Based Project ReportseiribooksNo ratings yet

- MSE GeotextileDocument23 pagesMSE GeotextileshumwenjunNo ratings yet

- Project Management and Scrum - A Side by Side ComparisonDocument7 pagesProject Management and Scrum - A Side by Side Comparisonilqbinh9007No ratings yet

- Complete EDM Handbook - 4Document7 pagesComplete EDM Handbook - 4newchap chapNo ratings yet

- Automation of Coronary Stent ManufactureDocument55 pagesAutomation of Coronary Stent ManufactureNeville Lawless100% (1)