Guide To Battery Management

Guide To Battery Management

Uploaded by

joonimCopyright:

Available Formats

Guide To Battery Management

Guide To Battery Management

Uploaded by

joonimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Guide To Battery Management

Guide To Battery Management

Uploaded by

joonimCopyright:

Available Formats

Astrosyn

Guide to Battery Management

Astrosyn International Technology Ltd

Lawtronics Division,

The Old Courthouse, New Rd Ave,

Chatham, Kent, ME4 6BE, England

Tel +44 (0) 1634 815175

Fax +44(0) 1634 826552

www.astrosyn.com

Astrosyn

GUIDE TO BATTERY MANAGEMENT

Introduction

Our standard range of battery chargers caters for sealed

lead acid, nickel cadmium and nickel metal hydride

battery types. Each cell type has certain advantages,

and the decision which to use in a particular application

may depend on economic considerations as much as

technical desirability. A compromise is often needed.

Characteristic

SLA

NiCd

NiMH

Energy Density (Wh/kg)

30

40

60

Volts/cell (nominal)

2.0

1.2

1.2

Operating cycles (typical)

500

1000

800

Self discharge (%/month)

3%

30%

30%

Equivalent series resistance

low

very low

medium

Operating temperature (o C)

5 to 35

10 to 45

10 to 40

Maximum charge rate

0.25C

2C

1C

Charge method

CV

CC

CC

Memory effect

No

Yes

Yes

To prevent overcharging,

accurate charge termination

is achieved by using proven

techniques. In addition,

intelligent chargers have to

accommodate the erratic

characteristics of abused,

unformed or old cells, as well

as the effects of protection

circuitry and variations in

operating temperature and

contact resistance.

Generally the problems are

not as pronounced in the

constant voltage charging of

sealed lead acid cells

compared with constant

current charging of nickel

cadmium and nickel metal

hydride cells charged at

higher C rates.

Battery Charging

The operating life of all rechargeable batteries is determined by

four major factors:

Rate of discharge

Depth of discharge

Operating and ambient temperature

Charging technique: constant voltage (CV) or constant

current (CC).

The first three are determined by the

equipment designer, but if the incorrect

charging technique is adopted, the

benefit of good design is minimised,

resulting in battery service life and

performance being significantly

degraded.

With all types of cells, it is only possible

to achieve optimum performance when

operating within the correct

management of charge and discharge

characteristics.

SLA Battery

Charging

Sealed lead acid batteries

require current limited

constant voltage charging.

Cells should not be charged

in less than four or five hours

for optimum life (C/4 rate).

Accurate charge voltage

control is essential.

The charger model is

determined by the following

application parameters:

Charge time

required

Cyclic or standby

operation

Operating

temperature

Astrosyn International Technology Ltd

Lawtronics Division, The Old Courthouse, New Rd Ave, Chatham, Kent, ME4 6BE, England

Tel +44 (0) 1634 815175 Fax +44 (0) 1634 826552 www.astrosyn.com

GUIDE TO BATTERY MANAGEMENT

Initial current limit

Permissible overcharge

Manufacturers of SLA batteries recommend constant voltage

current limited charging either from a basic single voltage taper

charger or a multistage charger.

Standby Application

Astrosyn

If the battery is fully or

deeply discharged, a

multistage charger initially

generates a small forming

current to restore the battery

to 1.75V/cell (e.g. 10.5V in a

12V battery), before

increasing the bulk current

to the maximum design

limit. The battery voltage

then rises towards the limit

of 2.45V/cell (14.7V), and the

current starts to decay.

When the battery voltage

limit is achieved, the charger

voltage reduces to 2.25V/cell

(13.5V), and the current

continues to fall to a trickle.

Full battery capacity is

recovered when the trickle

current falls to 0.01C Amps.

Where the SLA application is for standby use and the battery is

seldom required to deliver power a single stage current limited

float charger preset to 2.25V/cell at normal temperatures is

adequate. At this potential, the battery will not overcharge and

may remain connected indefinitely without incurring damage.

The trickle current continues

to decay until the natural

maintenance level of

approximately 0.001C Amps

is reached.

Standby and Cyclic Application

The battery can remain

connected to the charger in

this state continuously.

The maximum charge voltage recommended by most battery

manufacturers is 2.45V/cell with a maximum in-rush current of

0.25C Amps. This limits the safe charge time to approximately 5

hours to reach 90% capacity. Exceeding the voltage or current limit

is detrimental to battery life. Some SLA manufacturers permit a

larger in-rush current, but the additional cost of the enhanced

charger may not be acceptable.

If a single stage charger set at 2.45V/cell remains connected to a

battery, the high residual value of trickle current causes

overcharge which cannot be absorbed into cells. The excess

energy is dissipated as heat, resulting in reduced operating life and

performance. Reduction in cell voltage to the float value of 2.25V

minimises the overcharge current to a safe, sustainable level, at the

cost of increased charge time.

Optimum fast charging is obtained by combining the cyclic and

standby modes in a multistage managed charger with a re-forming

mode for initial recovery.

In summary, the multistage

SLA charging process

sequence is:

Step 1

Forming current until

discharged cell voltage rises

to 1.75V/cell.

Astrosyn International Technology Ltd

Lawtronics Division, The Old Courthouse, New Rd Ave, Chatham, Kent, ME4 6BE, England

Tel +44 (0) 1634 815175 Fax +44 (0) 1634 826552 www.astrosyn.com

Astrosyn

GUIDE TO BATTERY MANAGEMENT

Step 2

Voltage Depression

Memory Effect

Bulk charge to 2.45V/cell (approximately 80% returned capacity).

Step 3

Continuous trickle charge at 2.25V/cell, reaching 90% of capacity

after 5-6 hours.

SLA Battery Charge Time

The approximate charge time for an SLA battery in good condition

and not over-discharged can be calculated as:

Time (h) = (Battery Ah Capacity / Max Charger Current A) + 2h

One effect of continual

overcharge and high

temperature operation is

voltage depression. The

voltage of each cell in the

battery pack may be reduced

by up to 150mV reducing

useful operating hours

significantly.

This is a more probable

reason for loss of capacity

NiCd and NiMH Battery Charging

Standard Charge

For many applications using NiCd and NiMH batteries, a standard

overnight constant current charge for a period of 14 hours is

suitable. This equates to a rate of C/10, where C is the Ampere hour

capacity of the cell. Extended constant current charge at the C/10

rate has little effect on the overall performance or operating life of

NiCd and NiMH batteries. It is however good practice to

discontinue the charge within 24 hours to minimise long term

effects, particularly when using NiMH cells.

If accelerated fast charge is required at rates of typically C/5 to 2C,

the correct management of the charge characteristic is vital to

prevent battery damage.

than the near mythical

"memory effect", which is

only apparent after a cell has

been subjected to precise

repetitive shallow cycling.

Both voltage depression and

memory effect can be

removed by a controlled

conditioning discharge to a

known end point voltage.

NiCd and NiMH Battery Charge Time

The approximate charge time for NiCd and NiMH batteries in good

condition and not over-discharged can be calculated as:

Time (h) = (Battery Ah Capacity / Max Charger Current A) + 20%

Astrosyn International Technology Ltd

Lawtronics Division, The Old Courthouse, New Rd Ave, Chatham, Kent, ME4 6BE, England

Tel +44 (0) 1634 815175 Fax +44 (0) 1634 826552 www.astrosyn.com

You might also like

- Touran FuseboxDocument16 pagesTouran FuseboxRiki Nurzaman75% (4)

- Charging Information For Lead Acid Batteries - Battery UniversityDocument92 pagesCharging Information For Lead Acid Batteries - Battery UniversityarthurNo ratings yet

- Lead-X Tech Manual PDFDocument20 pagesLead-X Tech Manual PDFgenial72No ratings yet

- Battery CalculationsDocument6 pagesBattery CalculationsMandip Pokharel100% (1)

- Battery Sizing Calculation Methodology: Ieee STD 485 (1997, R2003) IEEE STD 1115 (2000, R2005)Document7 pagesBattery Sizing Calculation Methodology: Ieee STD 485 (1997, R2003) IEEE STD 1115 (2000, R2005)Thirumal100% (1)

- Scottishpower 14 FullDocument4 pagesScottishpower 14 FullSaurabh SinghNo ratings yet

- Ek Kaynak LM2576Document19 pagesEk Kaynak LM2576Şakir BayramNo ratings yet

- Battery Test Procedures 1997Document7 pagesBattery Test Procedures 1997Tara P. PradhanNo ratings yet

- Ev Unit6Document30 pagesEv Unit6ashuamair7No ratings yet

- Basic Battery Princeple Avition CourseDocument17 pagesBasic Battery Princeple Avition CourseabyNo ratings yet

- Three Stage Battery Charge SLA PDFDocument18 pagesThree Stage Battery Charge SLA PDFzigoto_2n0% (1)

- Harging EAD CID: Learn How To Optimize Charging Conditions To Extend Service LifeDocument4 pagesHarging EAD CID: Learn How To Optimize Charging Conditions To Extend Service LifebigsloNo ratings yet

- Care and Maintenance of Lead-Acid BatteriesDocument11 pagesCare and Maintenance of Lead-Acid BatteriesBalakrishnan Pedda GovindierNo ratings yet

- Panasonic NiMH ChargeMethodsDocument2 pagesPanasonic NiMH ChargeMethodsMarcio M GuedesNo ratings yet

- Ni-Cd Battery Maintenance ManualDocument18 pagesNi-Cd Battery Maintenance Manualhathanhchinh2279No ratings yet

- Ex 2. To Acquaint With The Charging Methods of Batteries and Calculation of Their Life CycleDocument23 pagesEx 2. To Acquaint With The Charging Methods of Batteries and Calculation of Their Life CycleKunal TanwarNo ratings yet

- 2022 ... Pocket Battery Manual - HengmingDocument16 pages2022 ... Pocket Battery Manual - HengmingProfesional19No ratings yet

- Acceptation de ChargeDocument14 pagesAcceptation de ChargebenaliNo ratings yet

- 504pet23 PDFDocument9 pages504pet23 PDFsickdogNo ratings yet

- Uninterruptible Power Supply Battery Acceptance/Capacity Test ProcedureDocument9 pagesUninterruptible Power Supply Battery Acceptance/Capacity Test Proceduresjaveeds2003No ratings yet

- Manual of Ni-Cd Pocket Type BatteryDocument17 pagesManual of Ni-Cd Pocket Type BatteryCasanova FernandoNo ratings yet

- Battery Management GuideDocument10 pagesBattery Management GuideR.S. Kumaraswamy100% (1)

- User Manual Gn-EnglishDocument17 pagesUser Manual Gn-EnglishMinh Chí NguyễnNo ratings yet

- CZC7 Automatic Charger: Operating InstructionDocument10 pagesCZC7 Automatic Charger: Operating InstructionJavier VillelaNo ratings yet

- Tutorial BatteryChargersDocument3 pagesTutorial BatteryChargersManuelNo ratings yet

- s65 Instruction Manual v2.0Document29 pagess65 Instruction Manual v2.0Julian COULETNo ratings yet

- DC Power Supply in Medium Voltage Electrical Distribution SystemDocument8 pagesDC Power Supply in Medium Voltage Electrical Distribution SystemLowell Estrella-SchneiderNo ratings yet

- Battery Testing: Keysight TechnologiesDocument10 pagesBattery Testing: Keysight Technologieswahlgren9483No ratings yet

- 3A Battery Charger PDFDocument6 pages3A Battery Charger PDFRamazan ÖzenNo ratings yet

- Battery ChargingDocument9 pagesBattery Chargingtaiwong167No ratings yet

- BatteriesDocument83 pagesBatteriesShubham DawleNo ratings yet

- Battery Charging Guide - 6 VoltDocument5 pagesBattery Charging Guide - 6 VoltKidus DawitNo ratings yet

- Battery Charge - Discharge BattconDocument5 pagesBattery Charge - Discharge BattconmatarakiNo ratings yet

- 1.7 Handling Manual enDocument4 pages1.7 Handling Manual eningridNo ratings yet

- General Information On Sealed Nickel Cadmium BatteriesDocument9 pagesGeneral Information On Sealed Nickel Cadmium BatteriesB.Kailash Krishna PrasadNo ratings yet

- Automotive Electrical & ElectronicsDocument83 pagesAutomotive Electrical & ElectronicsSathya NarayananNo ratings yet

- SIS-Preventive Maintenance For BatteriesDocument2 pagesSIS-Preventive Maintenance For BatteriesmkNo ratings yet

- Battery Sizing - Open ElectricalDocument7 pagesBattery Sizing - Open Electricalhn_317No ratings yet

- CEL PROJECTDocument17 pagesCEL PROJECTCHAITANYA KULKARNINo ratings yet

- A Complete Guide To Battery ChargingDocument4 pagesA Complete Guide To Battery ChargingAman SinghNo ratings yet

- Battery Charger: Rechargeable Battery Electric Current Voltage CurrentDocument12 pagesBattery Charger: Rechargeable Battery Electric Current Voltage CurrentRonaldNo ratings yet

- Battery Charging TutorialDocument3 pagesBattery Charging TutorialPaul Cortes OlivosNo ratings yet

- A Guide To Battery ChargingDocument7 pagesA Guide To Battery ChargingRohit BhogleNo ratings yet

- Battery Charging Guide - 2 VoltDocument4 pagesBattery Charging Guide - 2 VoltR.ArumugamNo ratings yet

- Automotive Electrical and Electronics EngineeringDocument5 pagesAutomotive Electrical and Electronics EngineeringKarthik SwaminathanNo ratings yet

- T105RE TrojanRE Data SheetsDocument2 pagesT105RE TrojanRE Data SheetsMtech ServSolNo ratings yet

- VRLA BatteryDocument23 pagesVRLA BatteryAlexander Mccormick100% (1)

- Battery HandbookDocument7 pagesBattery Handbookcheguevara2010100% (1)

- 2021 - 4.0 Storage For EVs - UploadDocument44 pages2021 - 4.0 Storage For EVs - Uploadsahilparveenyadav12345No ratings yet

- Nergie-: Diesel Engine Starting Batteries Guide and WorksheetDocument7 pagesNergie-: Diesel Engine Starting Batteries Guide and WorksheetAlexander OngNo ratings yet

- Application Note 68 December 1996:, LTC and LT Are Registered Trademarks of Linear Technology CorporationDocument36 pagesApplication Note 68 December 1996:, LTC and LT Are Registered Trademarks of Linear Technology CorporationHahdNo ratings yet

- Lead Acid Battery Charger Circuits - Homemade Circuit ProjectsDocument25 pagesLead Acid Battery Charger Circuits - Homemade Circuit ProjectsDhe KencoesNo ratings yet

- IntroductionDocument8 pagesIntroductionmanuNo ratings yet

- Samsung 2600mah ICR18650-26CDocument17 pagesSamsung 2600mah ICR18650-26CStreet_skNo ratings yet

- CB2410AC Manual PDFDocument4 pagesCB2410AC Manual PDFdinhvuNo ratings yet

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- A Case Study for a Single-Phase Inverter Photovoltaic System of a Three-Bedroom Apartment Located in Alexandria, Egypt: building industry, #0From EverandA Case Study for a Single-Phase Inverter Photovoltaic System of a Three-Bedroom Apartment Located in Alexandria, Egypt: building industry, #0No ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Static-Inverter 1.0: A Complete Design Process to Convert D.C. to A.C. Electricity Using the Astable-MultivibratorFrom EverandStatic-Inverter 1.0: A Complete Design Process to Convert D.C. to A.C. Electricity Using the Astable-MultivibratorNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

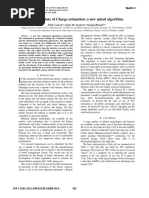

- On Battery State of Charge Estimation - A New Mixed Algorithm PDFDocument6 pagesOn Battery State of Charge Estimation - A New Mixed Algorithm PDFjoonimNo ratings yet

- Some Tips For Charging From USB Sources-Pt2Document4 pagesSome Tips For Charging From USB Sources-Pt2joonimNo ratings yet

- Li-Ion Battery Emulation Circuit by Microcontroller PDFDocument3 pagesLi-Ion Battery Emulation Circuit by Microcontroller PDFjoonimNo ratings yet

- Advanced Power Converters For More Electric Aircraft ApplicationsDocument6 pagesAdvanced Power Converters For More Electric Aircraft ApplicationsjoonimNo ratings yet

- Lm317 Regulated Battery Charger Circuit - Electronic CircuitsDocument10 pagesLm317 Regulated Battery Charger Circuit - Electronic CircuitsjoonimNo ratings yet

- Servo Motors and Its ApplicationsDocument19 pagesServo Motors and Its ApplicationsjoonimNo ratings yet

- AMC-servo Drive OverviewDocument28 pagesAMC-servo Drive OverviewjoonimNo ratings yet

- Synthesis of State Variable Controllers For Industrial Servo Drives (Lorenz) 86-08Document6 pagesSynthesis of State Variable Controllers For Industrial Servo Drives (Lorenz) 86-08joonimNo ratings yet

- Battery GuideDocument1 pageBattery GuidejoonimNo ratings yet

- 520L0893 PDFDocument240 pages520L0893 PDFthailanNo ratings yet

- Canadian With 100 KWDocument3 pagesCanadian With 100 KWsourabh purohitNo ratings yet

- From Feedstocks To Final Products: Biomass ConversionDocument4 pagesFrom Feedstocks To Final Products: Biomass ConversionJoshi kartikNo ratings yet

- DTU Wind Energy Report I 46Document73 pagesDTU Wind Energy Report I 46hemal4379No ratings yet

- Manual Sundaya-Apple - 15 PDFDocument1 pageManual Sundaya-Apple - 15 PDFEduSizaNo ratings yet

- Absorber:: Reactions: N O 2no + O 3NO + H O + NoDocument4 pagesAbsorber:: Reactions: N O 2no + O 3NO + H O + NoShivam PandyaNo ratings yet

- Harish SolankiDocument58 pagesHarish Solankiyogesh pandeyNo ratings yet

- IJCRT1803270Document13 pagesIJCRT1803270Chandra Shekhar SahuNo ratings yet

- Introduction To TTL, Its Activities and Future CooperationDocument23 pagesIntroduction To TTL, Its Activities and Future CooperationSaroj GautamNo ratings yet

- 2 Djoko Santoso CCS-CCUS - NZEDocument42 pages2 Djoko Santoso CCS-CCUS - NZEgunawan wibisanaNo ratings yet

- Energy Storage TechnologyDocument12 pagesEnergy Storage Technologyrhodz_24No ratings yet

- 14 - Automated Solar Operated Water PurifierDocument1 page14 - Automated Solar Operated Water PurifierRajesh RamaswamyNo ratings yet

- Power PlantDocument388 pagesPower PlantlvsaruNo ratings yet

- Fyp Report Full FinalDocument74 pagesFyp Report Full FinalMohammad SaleemNo ratings yet

- Certificado de FabricaDocument8 pagesCertificado de FabricaCristian MenesesNo ratings yet

- 02 03 2022 Shift3Document43 pages02 03 2022 Shift3SURAJ MALLAHNo ratings yet

- Advanced Thermally Stable Jet FuelsDocument2 pagesAdvanced Thermally Stable Jet FuelsgeorgecmuNo ratings yet

- Literature Review Solar PVDocument4 pagesLiterature Review Solar PVafmzatvuipwdal100% (1)

- PMFIAS Environment First Vs Second EditionDocument181 pagesPMFIAS Environment First Vs Second Editionchaitanyasktp9414100% (2)

- CompressorDocument22 pagesCompressorSai Krishna Kiran B V100% (2)

- Nios Tma EnglishDocument2 pagesNios Tma EnglishSoham AhluwaliaNo ratings yet

- Presentation RIPDocument26 pagesPresentation RIPAbhishek Prakash SrivastavaNo ratings yet

- Gyser Catalogue 2016Document44 pagesGyser Catalogue 2016Dinesh Durai RajNo ratings yet

- Increased Energy Yield of 50% at Flat Roof - Hanitsch Quaschning PDFDocument4 pagesIncreased Energy Yield of 50% at Flat Roof - Hanitsch Quaschning PDFshibly anastasNo ratings yet

- Add-Bab Xii.3. TPG Gi JenepontoDocument17 pagesAdd-Bab Xii.3. TPG Gi JenepontoPrasetiyo HanantoNo ratings yet

- THESIS Synopsysis NET ZERO ENERGY BUILDING AND HOTELDocument4 pagesTHESIS Synopsysis NET ZERO ENERGY BUILDING AND HOTELKranthikumar PrathiNo ratings yet

- SOLAR ENERGY NilDocument12 pagesSOLAR ENERGY NilBodra NilNo ratings yet

- Report of An Industrial Visit To Reliance Thermal Power Plant, DahanuDocument8 pagesReport of An Industrial Visit To Reliance Thermal Power Plant, DahanuAmeya VirkudNo ratings yet