Performance Analysis of A Plate Heat Exchanger and Its Comparison With Double Pipe Exchanger PDF

Performance Analysis of A Plate Heat Exchanger and Its Comparison With Double Pipe Exchanger PDF

Uploaded by

esatjournalsCopyright:

Available Formats

Performance Analysis of A Plate Heat Exchanger and Its Comparison With Double Pipe Exchanger PDF

Performance Analysis of A Plate Heat Exchanger and Its Comparison With Double Pipe Exchanger PDF

Uploaded by

esatjournalsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Performance Analysis of A Plate Heat Exchanger and Its Comparison With Double Pipe Exchanger PDF

Performance Analysis of A Plate Heat Exchanger and Its Comparison With Double Pipe Exchanger PDF

Uploaded by

esatjournalsCopyright:

Available Formats

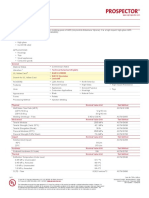

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

PERFORMANCE ANALYSIS OF A PLATE HEAT EXCHANGER AND

ITS COMPARISON WITH DOUBLE PIPE EXCHANGER

Anunay Sanganal1

1

B.E. Student, Department of Mechanical Engineering, K.J. Somaiya College of Engineering, Maharashtra, India

Abstract

The primary focus of this paper is to evaluate the performance of a Plate type heat exchanger. The evaluation is carried out for

namely two heat transfer parameters, heat transfer coefficient and heat exchanger effectiveness for varying Reynolds number of

hot and cold fluids. From the experimental values of inlet and outlet temperatures measured, the above two parameters were

calculated.

The analytical approach for calculation is illustrated for one sample reading. The heat transfer coefficient and heat exchanger

effectiveness was seen to increase with increasing Reynolds number of both the fluids. A PHE belongs to the family of compact

plate heat exchangers. Therefore, the secondary objective was to compare the PHE with conventional heat exchanger i.e. Double

pipe. The comparison was done on the basis of area required for a given temperature drop and heat transfer capacity. The

numerical values of areas obtained confirmed that a PHE requires the least space for operation.

Keywords: Plate heat exchanger, Reynolds number, heat transfer coefficient, effectiveness, compact

--------------------------------------------------------------------***---------------------------------------------------------------------1. INTRODUCTION

Plate heat exchangers were introduced in the 1930s mainly

for the food industries because of their ease of cleaning and

their design reached maturity in the 1960s with the

development of more effective plate geometries, assemblies,

and improved gasket materials. The range of possible

applications has widened considerably and, at present, under

specific and appropriate conditions, overlaps and

successfully competes in areas historically considered to be

the domain of tubular heat exchangers. Therefore, they can

be used as an alternative to tube-and-shell type heat

exchangers for low-and medium-pressure liquid to-liquid

heat transfer applications.

To successfully incorporate a PHE, we need to have an

understanding of the variation of a PHEs heat transfer

characteristics with respect to changes in its input

parameters. An attempt has been made in this paper to than

end. Also, to demonstrate the space saving capability of a

PHE, we determined the area required by a Plate heat

exchanger, a double pipe heat exchanger for achieving the

same temperature drop and heat transfer capacity.

2. EXPERIMENTATION

For experimentation, a working model of PHE with 9 plates

was put on a test setup. The plates used were made of

Stainless 3016L having a thermal conductivity (K) 16.2

W/mK. The plate dimensions are, 395 x 122 mm the

channel diameter is 32 mm and the plate thickness is 0.5

mm.The actual effective area of the PHE as specified by

the manufacturer is 0.303751 m2. The chevron angle () of

the plates employed is 65 w.r.t the vertical. The gasket used

is of Nitrile Butadiene with a temperature range of30 to 80

C. The temperatures and flow rates were measured by

alcohol thermometer and rotameter respectively. Water was

used as both the cold and hot fluid and the source of hot

fluid was an electric heater. The cold fluid was obtained

from the city mains. CPVC pipes were used to convey the

fluids having a maximum permissible temperature of 80 C.

Fig -1: Disassembled view of PHE

_______________________________________________________________________________________

Volume: 05 Issue: 06 | Jun-2016, Available @ http://ijret.esatjournals.org

437

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

3. OBSERVATIONS AND CALCULATIONS

As mentioned in the experimental procedure we recorded

temperatures for different flow rates of the hot stream

keeping the cold stream flow rate constant.

For the first set of observations, the cold stream flow rate

was kept at the following value.

= 2.3 LPM

The apparatus mentioned above was arranged in a way

described below.

The corrugated plates with gaskets were compressed

between two end plates with the help of four

compression bolts.

The holes in the plates form cylindrical channels which

are directly connected to flow lines.

The hot and cold fluid flows through the channels

formed due to corrugations on the plates.

The plates are arranged such that the hot and cold fluid

flow in alternate channels with the help of gaskets.

The hot fluid from the heater flows via the C-PVC pipe

into the upper right inlet and flows out of the lower

right outlet.

The cold fluid from the tap flows via the C-PVC pipe

into the lower left inlet and flows out of the upper left

outlet.

The above arrangement allows the fluids to flow in

counter flow in a single pass.

A rotameter is used to measure the mass flow rates of

the hot fluid while a beaker-stopwatch arrangement was

used to measure the mass flow rate of the cold fluid.

The temperature of the fluids was measured using 4

alcohol thermometers connected to the inlet and outlet

ports.

The procedure of the experimentation for achieving the

above was as follows

Hot fluid flow rate was measured using a rotameter.

Cold fluid flow rate was measured using a graduated

beaker and a stop watch.

The first set of observations were taken by keeping the

flow rate of cold fluid constant at a certain value and

the hot fluid flow rate was varied.

For the second set of observations, the hot fluid flow

rate was varied for a different value of cold fluid flow

rate,

The fluid flow rates were varied by using a ball valve.

For each combination of hot and cold fluid flow rates,

all the four temperatures, Thi, Tho, Tci, Tco were noted

down using the alcohol thermometers.

Before taking the temperature readings, the apparatus

was kept undisturbed for at least 10 minutes after

setting the fluid flow rates for achieving steady state

conditions.

Fig -2: PHE in working

Table -1: Observation table 1

C

29.7

29.7

29.7

29.7

C

38.8

38.5

38.2

37.8

C

53

49

45.6

43.5

C

41

39

38

37

LPM

2.3

2.3

2.3

2.3

LPM

2.3

3

3.4

4.4

29.7

37

42

36.5

2.3

For the second set of observations, the cold stream flow rate

was kept at the following value.

= 3.4 LPM

Table -2: Observation table 2

C

29

29

29

29

29

C

36

37.2

36.1

35.9

36.2

C

52.5

48.5

45.2

42.5

42.2

C

38.5

36

36.2

35.5

36

LPM

3.4

3.4

3.4

3.4

3.4

LPM

2.3

3

3.4

4.4

5

Heat transfer coefficient and effectiveness calculationHeat rejected by hot fluid,

Q H = mh cp (THI THO )

_______________________________________________________________________________________

Volume: 05 Issue: 06 | Jun-2016, Available @ http://ijret.esatjournals.org

438

IJRET: International Journal of Research in Engineering and Technology

Heat accepted by cold fluid,

Q C = mC cp (TCO TCI )

The Q H and Q C ideally should be same but due to physical

irreversibilties they are not equal. Therefore for calculation

purposes, the averages of the two are taken.

Q avg =

Q C+Q H

2

Now, the area required by Double pipe HE and Shell & tube

HE to achieve the same temperature drop as attained by

PHE is found out. The formulas and relations to find out the

area were referred from the book on Heat Exchangers by

SadicKakac, HongtanLui and AnchasaPramuanjaroenkij.

Area requirement for Double pipe HEDimensions of a commercially available double pipe heat

exchanger have been found out. For that purpose, a set of

dimensions for the diameters of inside and outside tubes are

assumed from the TEMA standards. Also, the inside tube

was assumed to have fins and the required fin dimensions

were also taken from TEMA standards. They are as follows-

The heat transfer is given by the following equation,

Q avg = UA[LMTD]

Where actual effective area of the plate as specified by

the manufacturer (A) =0.303751 m2 and [LMTD] is given

by,

LMTD =

eISSN: 2319-1163 | pISSN: 2321-7308

i e

ln i

e

Shell

ID

Tube

OD

Tube

wall

Tube

ID

Fin

height

(mm)

(mm)

(mm)

(mm)

(mm)

DS

DO

DI

HF

NF

114

48.3

40.94

25.4

36

3.68

Max. no.

of fins

The material of the double pipes was taken to be the same as

that of the PHE i.e. Stainless Steel 3016L having a thermal

conductivity of 16.2 W/mk. The length was calculated for

the temperatures and fluid flowrate values from the last

reading of observation table 1.

= THI TCO

= THO TCI

We get the heat transfer coefficient by the following

equation,

1

1

1

t

=

+

+

U hC hH K

The Hot fluid is assumed to flow from the inside tube and

cold fluid through the annular space.

Q avg = UO A O ()

Where outside pipe area =

AssuminghC = hH ,

1.5453 103 = 48.3 103 5.8539

= 1739.72

1 2 t

= +

U h K

ln

1

=

+

+

I

2

Now, effectiveness is given by,

=

Q avg

Q max

Where inside pipe area = ,by substituting the

values we get,

Where is given by,

Q max = m Cp

min

1.1797 1

= 2.46 104 +

+

1739.72

(THI TCI )

The above calculations were done for two readings which

had the same flow rate for cold and hot fluid for the ease of

calculations as their Reynolds number would be equal. The

results are tabulated as follows

Kg/s

0.03833

3

0.0567

Kg/s

0.03833

3

0.0567

Kw

1.693

U

W/m2.k

439.12

h

W/m2.k

890.31

1.910

4

775.22

5

1588.45

5

Consider the above equation as (1)

For inner pipeReynolds number is given by,

0.452

7

0.496

7

Where velocity is given by,

= 2

4

_______________________________________________________________________________________

Volume: 05 Issue: 06 | Jun-2016, Available @ http://ijret.esatjournals.org

439

IJRET: International Journal of Research in Engineering and Technology

Taking properties of water at an average temperature of hot

inlet and outlet TH=39.5 C

Density () = 992.5 Kg/m3

Viscosity () = 0.000663

Prandtl Number (Pr

) = 4.39

Thermal conductivity = 0.631 W/mK

eISSN: 2319-1163 | pISSN: 2321-7308

Now the hydraulic diameter for annular space is given by,

=

Where,

=

We get,

2 2

4

= 7.551 103 2

= 0.06375 /

And

And

= 3907.01

= + + 2

Hence the flow is turbulent and the heat transfer will be

governed by the empirical relation given byPetukhovKirillov which gives the value of Nusselt Number as,

= 2.338

2

Nu =

1 + 8.7( )0.5 ( 1)

2

Where = (1.58 ln 3.28)

Substituting, we get

= 0.0129

And also

= /

= 0.005103

= 3907.01

Hence we get Reynolds number as,

= 4.39

= 87.88

We get,

Hence the flow is laminar and the heat transfer will be

governed by the empirical relation given by Sieder and Tate.

= 0.01044

And Nusselt Number as

= 1.86(

= 28.595

Now Nusselt Number is also given by,

=

Where,

4

Equivalent diameter = = = 0.04094

Thermal conductivity = 0.631 W/mK

1/3

)

Here the Length (L) is unknown. Substituting other

parameters by taking properties of water at an average

temperature of cold inlet and outlet Tc=33.35 C

Density () = 994.59 Kg/m3

Viscosity () = 0.000745

Prandtl Number (Pr

) = 4.7246

Thermal conductivity = 0.6239 W/mK

We get,

Hence substituting we get, heat transfer coefficient at inlet

as,

125.212

1

= 440.64 W/ . k

Now,

For outer pipeReynolds number is given by,

=

Where

_______________________________________________________________________________________

Volume: 05 Issue: 06 | Jun-2016, Available @ http://ijret.esatjournals.org

440

IJRET: International Journal of Research in Engineering and Technology

= + 2 = 1.84

Hence = 0.164

0.0164 3.254

= 1/3

0.631

125 .212

eISSN: 2319-1163 | pISSN: 2321-7308

[5]. TambeShahanwaj K, Pandhare Nitin T, Bardeskar

Santosh J, Khandekar S.B Experimental investigation of

performance of plate heat exchanger for water as working

fluid in International journal of research in Engineering

and Technology (IJRET) Volume: 04 Issue: 03 published

March-2015.

BIOGRAPHIE

1/3

Substituting the values of heat transfer coefficient of both

inlet and outlet in equation 1, we get the value of Length (L)

as

Anunay Sanganl, BE Student, Dept. of

Mechanical Engineering, K.JSomaiya

College of Engineering.

1.1797

1

= 2.46 104 +

+

1739.72

440.64 125.212

Solving for unknown L, we get

= 59.2416

The area of heat transfer for the standard diametrical

dimensions and the above calculated length is,

= ( + 2 )

= 1 59.2416 ( 0.0483 + 2 36 0.0254 )

= 117.33 2

This is the area required by a standard Double pipe heat

exchanger to attain the same temperature drop and heat

transfer capacity. The area required by the Plate type heat

exchanger is 0.303751 m2.

4. CONCLUSION

From this experimentation, the heat transfer coefficient and

effectiveness were calculated. From the values it can be seen

that the heat transfer coefficient increases as both the hot

and cold fluid Reynolds number increases. Also, from the

calculation of area required for double pipe heat exchanger,

it can be seen that it requires far more area than Plate type

heat exchanger to achieve same temperature drop and heat

transfer capacity.

REFERENCES

[1]. Book on Heat Exchangers by SadicKakac,

HongtanLui and AnchasaPramuanjaroenkij.

[2]. Er. R.K. Rajput, Heat and Mass Transfer, S. Chand &

Company LTD., Ram Nagar, New Delhi-110055.

[3]. T.S. Khan, M.S. Khan, Ming-C. Chyu, Z.H. Ayub,

Experimental investigation of single phase convective heat

transfer coefficient in a corrugated plate heat exchanger for

multiple plate configurations in Elsevier published on 22nd

January 2010 online.

[4]. Abdullah Yildiz, MustafaAliErsz Theoretical and

experimental thermo dynamic analyses of a chevron type

heatexchanger in Elsevier published on 28th October 2014

online.

_______________________________________________________________________________________

Volume: 05 Issue: 06 | Jun-2016, Available @ http://ijret.esatjournals.org

441

You might also like

- Gerald Burns Solid State PhysicsDocument9 pagesGerald Burns Solid State PhysicsPranjul Yadav33% (6)

- Direct Fired Vapor Absorption ChillerDocument40 pagesDirect Fired Vapor Absorption ChillerObayomi KennyNo ratings yet

- Catalogo Schneider - MedicionDocument266 pagesCatalogo Schneider - MedicionGerardo Zambrano Ovalle100% (1)

- Optimization of Shell and Tube Heat ExchangerDocument29 pagesOptimization of Shell and Tube Heat ExchangerAna QuintanaNo ratings yet

- Table of Content: Lab Report SOLTEQ Concentric Tube Heat Exchanger Unit (HE:104-PD)Document46 pagesTable of Content: Lab Report SOLTEQ Concentric Tube Heat Exchanger Unit (HE:104-PD)iwe1234100% (3)

- Examples of Friction in Everyday LifeDocument2 pagesExamples of Friction in Everyday LifeVidya MuthukrishnanNo ratings yet

- Design 2-Pass Shell and Tube Heat ExchangerDocument20 pagesDesign 2-Pass Shell and Tube Heat Exchangerazib100% (1)

- Carrier - 39 XT Air HandlingDocument24 pagesCarrier - 39 XT Air HandlingorganicspolybondNo ratings yet

- Heart Lung MachineDocument20 pagesHeart Lung MachineDeepak DennisonNo ratings yet

- EVI (Enhance Vapour Injection) Scroll COMPRESSORSDocument10 pagesEVI (Enhance Vapour Injection) Scroll COMPRESSORSambuenaflorNo ratings yet

- 5 Pink PC19Document2 pages5 Pink PC19Amín AC100% (1)

- Catalog of Vortex (Tianjin China.)Document23 pagesCatalog of Vortex (Tianjin China.)Waqas JawaidNo ratings yet

- Troubleshooting A Plate Heat Exchanger - CPE Systems IncDocument7 pagesTroubleshooting A Plate Heat Exchanger - CPE Systems Incrajmohan_kNo ratings yet

- Air HeatersDocument34 pagesAir HeatersNaveen KamatNo ratings yet

- API 70 R1 UV Spares - V1Document1 pageAPI 70 R1 UV Spares - V1Malik MentuNo ratings yet

- Mech3005 Lab1112 Fancoil PDFDocument5 pagesMech3005 Lab1112 Fancoil PDFbilal almelegy100% (1)

- Biodiesel 36244Document110 pagesBiodiesel 36244api-3802837100% (1)

- ElectrolysisDocument11 pagesElectrolysisMahmudul Hassan ShuvoNo ratings yet

- 1968 - Feher - The Supercritical Thermodynamic Power CycleDocument6 pages1968 - Feher - The Supercritical Thermodynamic Power CycleDilipNo ratings yet

- Modelling and Numerical Simulation of Solar Powered Vapor Absorption Refrigeration System For Hot Areas of Ethiopia in Case of AfarDocument36 pagesModelling and Numerical Simulation of Solar Powered Vapor Absorption Refrigeration System For Hot Areas of Ethiopia in Case of AfarEmnet AbNo ratings yet

- Hitachi S-4700 InstructionsDocument19 pagesHitachi S-4700 InstructionssuperheoNo ratings yet

- Heat Exchanger (H&C)Document133 pagesHeat Exchanger (H&C)hwang2No ratings yet

- Tubular Drag Conveyor Brochure WWDocument8 pagesTubular Drag Conveyor Brochure WWsamvendanNo ratings yet

- Cooling Tower. Application - TreybalDocument81 pagesCooling Tower. Application - TreybalMarx CesarNo ratings yet

- GCC Law Exam 2014Document8 pagesGCC Law Exam 2014Mulalo Magidimisa0% (1)

- Minimizing Fan Energy CostsDocument9 pagesMinimizing Fan Energy Costsmemep1No ratings yet

- Steam Absorption ChillerDocument3 pagesSteam Absorption ChillerAbd AbdulNo ratings yet

- Application of CHEMCADDocument11 pagesApplication of CHEMCADAlbertIvanoAndreanNo ratings yet

- 99 Examples of Pneumatic ApplicationsDocument120 pages99 Examples of Pneumatic ApplicationsluizNo ratings yet

- Heat Transfer DoeDocument32 pagesHeat Transfer DoeArt RmbdNo ratings yet

- Tri Sector Rotary Air APHDocument2 pagesTri Sector Rotary Air APHthehinduNo ratings yet

- IT10 BrochureDocument5 pagesIT10 BrochureMarlon Pierre de Haas100% (1)

- Quotation to 1000LPH Milk、Yogurt Production LineDocument7 pagesQuotation to 1000LPH Milk、Yogurt Production LineZoran PetrovNo ratings yet

- Hitungan Volume Pompa EbaraDocument6 pagesHitungan Volume Pompa EbaraApriliyanto Rahadi PradanaNo ratings yet

- CH 5 Heat Exchanger Design MethodsDocument30 pagesCH 5 Heat Exchanger Design Methodsapi-3765936100% (1)

- Evaporative Cooling WhitepaperDocument6 pagesEvaporative Cooling WhitepaperArun CherianNo ratings yet

- Evaporator DesignDocument1 pageEvaporator DesignNaqqash SajidNo ratings yet

- Efficient Use of SteamDocument31 pagesEfficient Use of SteamHn Nayak100% (1)

- Comparison of Refrigerants R410a and R404aDocument99 pagesComparison of Refrigerants R410a and R404aLuis CarlosNo ratings yet

- Assignment - Types of Heat ExchangersDocument4 pagesAssignment - Types of Heat ExchangersFully YoursNo ratings yet

- Shell and Tube Heat ExchangerDocument12 pagesShell and Tube Heat ExchangerZi ChingNo ratings yet

- SABROE Heat Pump Programme SB-4106r GB120dpiDocument2 pagesSABROE Heat Pump Programme SB-4106r GB120dpiBASEM NOMAN ALI MOHAMMEDNo ratings yet

- Static Pressure in HVAC Systems BOACDocument32 pagesStatic Pressure in HVAC Systems BOACKesava DhoniNo ratings yet

- How Steam Trap WorkDocument40 pagesHow Steam Trap Workdeny prasyamtyo100% (1)

- NETZSCH General BrochureDocument19 pagesNETZSCH General BrochureAnonymous T7zEN6iLHNo ratings yet

- Contherm Max Scraped Surface Heat ExchangerDocument2 pagesContherm Max Scraped Surface Heat ExchangerManoj Kumar LalNo ratings yet

- Mechanical Workshop ReportDocument4 pagesMechanical Workshop ReportHumaid Al-'AmrieNo ratings yet

- TE Lab Manual 2011Document47 pagesTE Lab Manual 2011gash287No ratings yet

- Heat RecoveryDocument2 pagesHeat RecoveryRohmat SetiawanNo ratings yet

- Condenser Product ManualDocument24 pagesCondenser Product ManualAdnanNo ratings yet

- 14 Shell & Tube ExchangerDocument9 pages14 Shell & Tube ExchangerEdwin AldrinNo ratings yet

- ASRMSFIELD Concentric Tube Heat Exchanger - 2024Document7 pagesASRMSFIELD Concentric Tube Heat Exchanger - 2024lekhethokhalametsaneNo ratings yet

- Concentric Tube Heat Exchanger ReportDocument19 pagesConcentric Tube Heat Exchanger Reportillyzl100% (1)

- Che245 Lab Report Solteq Concentric Tube Heat Exchanger UnitDocument10 pagesChe245 Lab Report Solteq Concentric Tube Heat Exchanger UnitSyafiq Sabran HasnanNo ratings yet

- CHE245 Lab Report SOLTEQ Concentric TubeDocument46 pagesCHE245 Lab Report SOLTEQ Concentric TubeVuyiseka maqukwanaNo ratings yet

- Shell and Tube Heat ExchangerDocument15 pagesShell and Tube Heat Exchangerishaqabubakar2019No ratings yet

- Lab 4 Manual - Heat ExchangerDocument11 pagesLab 4 Manual - Heat ExchangerVinoth K VelauthamNo ratings yet

- Concentric Heat ExchangerDocument35 pagesConcentric Heat Exchangerafiqahanuwar0% (1)

- Lab 5 Heat ExchangerDocument13 pagesLab 5 Heat ExchangerNur Syuhaidah100% (1)

- Concentric Tube Heat ExchangersDocument8 pagesConcentric Tube Heat ExchangersHazryNo ratings yet

- PTE 3 Week Study ScheduleDocument3 pagesPTE 3 Week Study ScheduleesatjournalsNo ratings yet

- Analysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFDocument4 pagesAnalysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFesatjournalsNo ratings yet

- Analysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFDocument7 pagesAnalysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFesatjournalsNo ratings yet

- Analysis of Cylindrical Shell Structure With Varying Parameters PDFDocument6 pagesAnalysis of Cylindrical Shell Structure With Varying Parameters PDFesatjournalsNo ratings yet

- A Review Paper On Smart Health Care System Using Internet of ThingsDocument5 pagesA Review Paper On Smart Health Care System Using Internet of ThingsesatjournalsNo ratings yet

- A Review Paper On Smart Health Care System Using Internet of ThingsDocument5 pagesA Review Paper On Smart Health Care System Using Internet of ThingsesatjournalsNo ratings yet

- A Study and Survey On Various Progressive Duplicate Detection MechanismsDocument3 pagesA Study and Survey On Various Progressive Duplicate Detection MechanismsesatjournalsNo ratings yet

- A Study and Survey On Various Progressive Duplicate Detection MechanismsDocument3 pagesA Study and Survey On Various Progressive Duplicate Detection MechanismsesatjournalsNo ratings yet

- A Servey On Wireless Mesh Networking ModuleDocument5 pagesA Servey On Wireless Mesh Networking ModuleesatjournalsNo ratings yet

- A Review On Fake Biometric Detection System For Various ApplicationsDocument4 pagesA Review On Fake Biometric Detection System For Various ApplicationsesatjournalsNo ratings yet

- A Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesDocument9 pagesA Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesesatjournalsNo ratings yet

- A Women Secure Mobile App For Emergency Usage (Go Safe App)Document3 pagesA Women Secure Mobile App For Emergency Usage (Go Safe App)esatjournalsNo ratings yet

- A Survey On Identification of Ranking Fraud For Mobile ApplicationsDocument6 pagesA Survey On Identification of Ranking Fraud For Mobile ApplicationsesatjournalsNo ratings yet

- A Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemDocument8 pagesA Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemesatjournalsNo ratings yet

- Power Generation Using Maglev Windmill PDFDocument6 pagesPower Generation Using Maglev Windmill PDFesatjournalsNo ratings yet

- Pushover Analysis-To Study Seismic Performances of Vertical Irregular Structure PDFDocument4 pagesPushover Analysis-To Study Seismic Performances of Vertical Irregular Structure PDFesatjournalsNo ratings yet

- Properties of Engineering Materials 2Document12 pagesProperties of Engineering Materials 2Douglas Kufre-Abasi GilbertNo ratings yet

- Nelson Stud Welding 2009Document110 pagesNelson Stud Welding 2009LhenzMorrizNo ratings yet

- Institute of Space Technology: Applied Physics LabDocument18 pagesInstitute of Space Technology: Applied Physics LabFurqan Ali Cheema100% (1)

- Plaxis Advanced Course Hong Kong 2012 PDFDocument449 pagesPlaxis Advanced Course Hong Kong 2012 PDFHà Mập67% (3)

- 058:0160 Chapter 6-Part3 Professor Fred Stern Fall 2018 1Document40 pages058:0160 Chapter 6-Part3 Professor Fred Stern Fall 2018 1muddassir razzaqNo ratings yet

- L16 17 Shell StructuresDocument128 pagesL16 17 Shell StructuresAnand Thomas100% (1)

- On Foundations Under Seismic Loads: Vijay K. PURI and Shamsher PRAKASHDocument11 pagesOn Foundations Under Seismic Loads: Vijay K. PURI and Shamsher PRAKASHkarthikmr85No ratings yet

- DMZ QuizDocument2 pagesDMZ QuizmoaazNo ratings yet

- Lustran® 433: INEOS StyrolutionDocument3 pagesLustran® 433: INEOS StyrolutionJames FaunceNo ratings yet

- Permeability of ConcreteDocument6 pagesPermeability of ConcreteS Praveenkumar100% (1)

- Quantum Numbers Structure 2Document22 pagesQuantum Numbers Structure 2vishalsingh1997No ratings yet

- PS Q2 Week-3a-1Document8 pagesPS Q2 Week-3a-1Faith PacomiosNo ratings yet

- Corona Loss Measurements For The Design Of: Transmission VoltagesDocument8 pagesCorona Loss Measurements For The Design Of: Transmission Voltagesboxeli2281No ratings yet

- Matlab Expo 2021 Teaching Electric Power Systems With Matlab and Simulink EdtDocument25 pagesMatlab Expo 2021 Teaching Electric Power Systems With Matlab and Simulink EdtA Naveen KumarNo ratings yet

- En 13941 OriginalDocument112 pagesEn 13941 Originalboban njagulovićNo ratings yet

- BPSC ME Practice-Questions - SET 1Document29 pagesBPSC ME Practice-Questions - SET 1gaurav singhNo ratings yet

- 01 Semiconductor TheoryDocument32 pages01 Semiconductor TheoryAnmay MishraNo ratings yet

- A540A540MDocument8 pagesA540A540MAlejandro GonzálezNo ratings yet

- Physics Questions Vol-Ii Bernard PDF PDFDocument2 pagesPhysics Questions Vol-Ii Bernard PDF PDFSilva scary svNo ratings yet

- Assignment01 MECH5304 BendFlowDocument2 pagesAssignment01 MECH5304 BendFlowPraveen P JoseNo ratings yet

- Study Materials: Physical Metallurgy of Non - Ferrous Metals & AlloysDocument25 pagesStudy Materials: Physical Metallurgy of Non - Ferrous Metals & AlloysSuvodip ChatterjeeNo ratings yet

- Fem Assignment 2 and 3Document7 pagesFem Assignment 2 and 3Aravind PhoenixNo ratings yet

- TM-CP1-PMT-0070 Att.4 - Strength Calculation For Bellows (Sample)Document13 pagesTM-CP1-PMT-0070 Att.4 - Strength Calculation For Bellows (Sample)jhunkujha11No ratings yet

- LURGI ZIMMER PolyesterPackagingTechnologyDocument12 pagesLURGI ZIMMER PolyesterPackagingTechnologyGeorge Markas100% (1)

- Unit 4 DC MachinesDocument13 pagesUnit 4 DC Machineskumarwaris123No ratings yet

- Lecture Notes On Wind Tunnel TestingDocument277 pagesLecture Notes On Wind Tunnel TestingAseem Taneja100% (2)

- Laser Physics.1Document19 pagesLaser Physics.1Sepatu Lukis Drainbow IVNo ratings yet

- Systematic Review of The Preparation Techniques of Iron Oxide Magnetic NanoparticlesDocument11 pagesSystematic Review of The Preparation Techniques of Iron Oxide Magnetic NanoparticlesSyed Farhan HasanyNo ratings yet