004 Annexure D Job Safety SAnalysis JSA

004 Annexure D Job Safety SAnalysis JSA

Uploaded by

Avoor KhanCopyright:

Available Formats

004 Annexure D Job Safety SAnalysis JSA

004 Annexure D Job Safety SAnalysis JSA

Uploaded by

Avoor KhanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

004 Annexure D Job Safety SAnalysis JSA

004 Annexure D Job Safety SAnalysis JSA

Uploaded by

Avoor KhanCopyright:

Available Formats

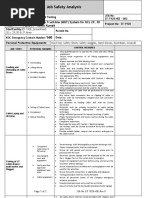

YNGL TRANSFORMER 302A, 100MVA, 115kV/13.

8kV

LV BUSHING&GASKETS REPLACEMENT

JSA FOR REPAIRING OF POWER

TRANSFORMER

Basic Job Sequence

1. Transformer Leak

checking/Nitrogen filling

Potential Hazard

Falling/Tripping

Control Measure

Provide cylinder trolley to secure nitrogen cylinders.

Ensure proper wind up of hoses and housekeeping at

work site.

Ensure the equipments/tools to be used for gas filling

are in good condition and suitable for the pressure

rating of the system.

Ensure that all testing equipments are calibrated and

stamped with calibration certificates.

No one is allowed to work or strike on equipment while

it is under pressure.

Full body harness must be worn at all times and

secure 100% tie off while the activity is ongoing to

prevent fall incident from heights.

2. Dry Air Testing

Over Pressure

Scaffold shall be inspected, certified and tagged

according to procedures and guidelines by a

competent scaffold inspector.

Ensure the equipments/tools to be used for air test

(such as hoses, pump, pressure gauges etc) are free

Responsible Person

YNGL TRANSFORMER 302A, 100MVA, 115kV/13.8kV

LV BUSHING&GASKETS REPLACEMENT

JSA FOR REPAIRING OF POWER

TRANSFORMER

Basic Job Sequence

3. Vacuum Drying

Filling & circulation of oil

Potential Hazard

Fire

Electrocution

Control Measure

from any defect and suitable for the pressure rating of

the system.

Provide whip lash arrestor for hose connections

Barricade the area where activity is to be carried out.

Post warning signs.

Use only tools for intended purpose

All tools/ equipment should be inspected and monthly

color coded.

Make sure internal pressure in the transformer is at

zero gauges before opening manhole cover and

starting air flow into the transformer.

Ensure the equipments/tools to be used for vacuum

testing are free from any defect and suitable for the

pressure rating of the system.

Provide whip lash for hose connections

Provide GCFI using vacuum pump/ and filtration

machine.

Provide fire extinguisher in work area.

Ensure all electrical connection is in good condition no

damage and used 125volts and 380 & 480 volts power

for supply of the equipment.

Always shut off pump motor before opening or closing

Responsible Person

YNGL TRANSFORMER 302A, 100MVA, 115kV/13.8kV

LV BUSHING&GASKETS REPLACEMENT

JSA FOR REPAIRING OF POWER

TRANSFORMER

Basic Job Sequence

4. Insulation test

Prepared by:

HSE Officer

Potential Hazard

Electrocution

Control Measure

Responsible Person

valves to prevent equipment damage and injuries.

Make sure all electrical connection is in good condition

prior to start the job.

Only trained and competent person will be allowed to

execute work during testing.

Reviewed by:

HSE Manager

Responsible Person:

Approved by:

Electrical Engineer

Project Manager

Note: Detailed JSA will be submitted after performing the initial transformer assessment.

You might also like

- JHA For Electrical Works - Rev. 01.Document16 pagesJHA For Electrical Works - Rev. 01.SreekumarNo ratings yet

- Jsa - Cable TerminationDocument4 pagesJsa - Cable TerminationSantos Rex73% (15)

- JSA For Service MaintenanceDocument8 pagesJSA For Service Maintenancemohamed yasinNo ratings yet

- JSA For Cable Tray Installation-Reviewed by CBREDocument10 pagesJSA For Cable Tray Installation-Reviewed by CBREPrakash Tiwari88% (8)

- JSA For WrappingDocument6 pagesJSA For WrappingMohammed Minhaj75% (4)

- Jsa. Cable Laying and TerminationDocument10 pagesJsa. Cable Laying and TerminationMon Trang Nguyễn100% (3)

- JSA - Electrical Testing - Circuit Breaker Field TestDocument4 pagesJSA - Electrical Testing - Circuit Breaker Field TestTawfik Mohamed Abu Zaid0% (1)

- JSA-Manual Lifting of MaterialsDocument3 pagesJSA-Manual Lifting of Materialsfrancis_e_tan80% (5)

- JSA Transformer Installations, Testing, Commissioning.Document6 pagesJSA Transformer Installations, Testing, Commissioning.Kiran Bhatt86% (7)

- JSA For Scaffolding and Shed ErectionDocument1 pageJSA For Scaffolding and Shed ErectionAnonymous voA5Tb0No ratings yet

- JSA FOR HT LT Panel - Transformer InstallationDocument2 pagesJSA FOR HT LT Panel - Transformer Installationwahyu nugroho75% (8)

- JHA - Installation of Pipe & Support For Fire Protection 1Document7 pagesJHA - Installation of Pipe & Support For Fire Protection 1Ralph Castillo100% (2)

- Prequalification QuestionnairDocument28 pagesPrequalification QuestionnairAvoor KhanNo ratings yet

- Jsa Cable TerminationDocument4 pagesJsa Cable TerminationSyed Yousuf Ali100% (1)

- Jsa For Drilling.Document3 pagesJsa For Drilling.Belsyah Nofriyan83% (6)

- Job Safety Analysis Sheet: Electrical IsolationDocument1 pageJob Safety Analysis Sheet: Electrical IsolationLal Dhwoj67% (3)

- 6.chain Pulley BlockDocument2 pages6.chain Pulley BlockFrancis Vinoj75% (4)

- MS Welding in Confined SpaceDocument12 pagesMS Welding in Confined Spacemithun dutta100% (1)

- ADCO Interview Quesiton and AnswerDocument5 pagesADCO Interview Quesiton and AnswerAmal Jagadi100% (2)

- Job Safety Analysis Sheet: Operation Concrete Batching PlantDocument2 pagesJob Safety Analysis Sheet: Operation Concrete Batching Plantzabiulla88% (8)

- JSA For Civil Work Activity Including Installation of Shuttering, Rebar, Formwork, Concrete Work, and Backfilling ActivityDocument12 pagesJSA For Civil Work Activity Including Installation of Shuttering, Rebar, Formwork, Concrete Work, and Backfilling Activitybagas prakoso100% (1)

- Job Safety Analysis - Overhead Power LinesDocument2 pagesJob Safety Analysis - Overhead Power Linesrenee100% (4)

- JSA Transformer InstallationDocument1 pageJSA Transformer Installationpushpanath reddyNo ratings yet

- Petrofac: Job Safety AnalysisDocument3 pagesPetrofac: Job Safety AnalysisMon Trang Nguyễn100% (6)

- JSA Installation of Equipment For Electrical and InstrumentDocument3 pagesJSA Installation of Equipment For Electrical and InstrumentHong Hai Pham83% (6)

- JSA E&I 10.electrical Instrument Panels RemovalDocument3 pagesJSA E&I 10.electrical Instrument Panels RemovalAmy100% (2)

- Jsa - Earthing SystemDocument4 pagesJsa - Earthing SystemAkash Shukla80% (5)

- JSA Cable LayingDocument2 pagesJSA Cable Layingnishanth100% (2)

- Mie Hse Jha 004 - Installation of TransformerDocument5 pagesMie Hse Jha 004 - Installation of TransformerLuqman Osman67% (6)

- Grounding System Jsa 2008Document4 pagesGrounding System Jsa 2008Aldrin100% (5)

- JSA Cable DisconnectedDocument4 pagesJSA Cable Disconnectedwendypost730% (1)

- Job Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteDocument5 pagesJob Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteM M PRADHANNo ratings yet

- Jsa-Ht & LT Panel InstallationDocument1 pageJsa-Ht & LT Panel Installationpushpanath reddy100% (2)

- JSA For Installation of Precast SlabDocument4 pagesJSA For Installation of Precast Slabyc safety100% (4)

- Method Statement For The Installation of TransformerDocument11 pagesMethod Statement For The Installation of TransformerShaikh Ahamed100% (3)

- MV Cables Data Sheet - SampleDocument5 pagesMV Cables Data Sheet - SampleAvoor KhanNo ratings yet

- Project Management PQQ Part ADocument7 pagesProject Management PQQ Part AAvoor KhanNo ratings yet

- JSA FOR Fixing of Light FittingsDocument1 pageJSA FOR Fixing of Light Fittingswahyu nugroho100% (3)

- JSA Earthpit Construction GeneralDocument4 pagesJSA Earthpit Construction Generalmukka88No ratings yet

- Installation of Pannel JSADocument6 pagesInstallation of Pannel JSAOFFSHORE OFFSITENo ratings yet

- Ultratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSADocument5 pagesUltratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSATFattah100% (1)

- JSA Cable Tray Erection On Pipe RackDocument7 pagesJSA Cable Tray Erection On Pipe RacknishanthNo ratings yet

- EEEPL - JSA Light Fitting ErectionDocument6 pagesEEEPL - JSA Light Fitting ErectionnishanthNo ratings yet

- JSA For Electrical ActivitiesDocument14 pagesJSA For Electrical Activitiesdrparihary100% (4)

- JHA For Installation of Boiler AccessoriesDocument2 pagesJHA For Installation of Boiler Accessoriesperquino oasan100% (3)

- PTW JHA Electrical Wiring Installation Work at Air Dryer RoomDocument4 pagesPTW JHA Electrical Wiring Installation Work at Air Dryer RoomPHH9834No ratings yet

- Jsa Installing BracketDocument3 pagesJsa Installing BracketHow Chin Engineering Sdn Bhd100% (1)

- Jsa For Brick WorkDocument4 pagesJsa For Brick WorkSushil Kumar YadavNo ratings yet

- Jsa For Camera & Fire Alarm InstallationDocument5 pagesJsa For Camera & Fire Alarm InstallationSushil Kumar YadavNo ratings yet

- Facility/Plant Location: Description of Work: Contractor:: PCD Project: Water Treatment Facilities - 3Document8 pagesFacility/Plant Location: Description of Work: Contractor:: PCD Project: Water Treatment Facilities - 3AldrinNo ratings yet

- JHA 08 On Erection of Roofing SheetsDocument3 pagesJHA 08 On Erection of Roofing SheetsAkhilesh Kumar100% (1)

- JSA For Screeding With MeshDocument4 pagesJSA For Screeding With MeshMohammed Minhaj100% (1)

- JSA FOR Shakthi ElectricalDocument8 pagesJSA FOR Shakthi Electricalwahyu nugroho100% (1)

- Jha - Transformer Installation PDFDocument6 pagesJha - Transformer Installation PDFperquino oasan0% (1)

- Job Hazard Analysis ON Erection of High Mast Lighting SystemDocument5 pagesJob Hazard Analysis ON Erection of High Mast Lighting SystemKiran Bhatt100% (5)

- PTA-JSA-001-Mobilization Deployment of Manpower & Beginning of The JobDocument3 pagesPTA-JSA-001-Mobilization Deployment of Manpower & Beginning of The JobSaiyad RiyazaliNo ratings yet

- JSA Hydrant Pipe LineDocument7 pagesJSA Hydrant Pipe Lineakshay pradeep100% (1)

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocument5 pagesThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh KumarNo ratings yet

- JHA General Maintenance Activity PDFDocument5 pagesJHA General Maintenance Activity PDFdede SinbadNo ratings yet

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- HIRA-Shaft Cable Tray N Cable InstallationDocument2 pagesHIRA-Shaft Cable Tray N Cable InstallationDivakar Dhande100% (2)

- Leak Test Procedure InstrumentDocument10 pagesLeak Test Procedure InstrumentNAVANEETH100% (1)

- Plant OperatorDocument10 pagesPlant Operatoryasir aliNo ratings yet

- Job Plan: Lead Craft Condition For Work Crafts Department Craft QTYDocument3 pagesJob Plan: Lead Craft Condition For Work Crafts Department Craft QTYMohsin YasinNo ratings yet

- INS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1Document7 pagesINS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1jayhuacat7743100% (4)

- Outcome 1 Tutorial 1 - Plant Operations: UNIT 47: Engineering Plant TechnologyDocument6 pagesOutcome 1 Tutorial 1 - Plant Operations: UNIT 47: Engineering Plant TechnologyHakiimuddin ShaariNo ratings yet

- Zone 1, 2, 21, 22 - Group IIB+H - Aluminium Junction Boxes - IP 66 / 67Document22 pagesZone 1, 2, 21, 22 - Group IIB+H - Aluminium Junction Boxes - IP 66 / 67Avoor Khan100% (1)

- Pod 4999168985-DHLDocument1 pagePod 4999168985-DHLAvoor KhanNo ratings yet

- Copper Penn-Crimps Telecommunication Lugs - Type Bblu-2Tc: 2 Hole Long Barrel Lugs For 8 Stranded Thru 2000 MCMDocument2 pagesCopper Penn-Crimps Telecommunication Lugs - Type Bblu-2Tc: 2 Hole Long Barrel Lugs For 8 Stranded Thru 2000 MCMAvoor KhanNo ratings yet

- Temp Access FormDocument1 pageTemp Access FormAvoor KhanNo ratings yet

- Pod 4999168985-DHLDocument1 pagePod 4999168985-DHLAvoor KhanNo ratings yet

- 004 - 60a THN3362SS - 10103091SH109 Data SheetsDocument2 pages004 - 60a THN3362SS - 10103091SH109 Data SheetsAvoor KhanNo ratings yet

- Model 4 MCC Buckets - D Selector Guide - Schneider Price ListDocument3 pagesModel 4 MCC Buckets - D Selector Guide - Schneider Price ListAvoor KhanNo ratings yet

- HEX Lugs Price ListDocument10 pagesHEX Lugs Price ListAvoor KhanNo ratings yet

- QUO-02553-X9Y3: Customer Information ليمعلا تامولعمDocument2 pagesQUO-02553-X9Y3: Customer Information ليمعلا تامولعمAvoor KhanNo ratings yet

- Code of EthicsDocument7 pagesCode of EthicsAvoor KhanNo ratings yet

- Annexure - Equipments ListDocument3 pagesAnnexure - Equipments ListAvoor KhanNo ratings yet

- Staffing by Ward May 2015Document1 pageStaffing by Ward May 2015Avoor KhanNo ratings yet

- TPE (Web) - MinDocument16 pagesTPE (Web) - MinAvoor KhanNo ratings yet

- SP0504R01Document8 pagesSP0504R01Avoor KhanNo ratings yet

- Phenix 650-2P Portable AC Dielectric Test Set Phenix 6502P 650 2P 650-2P - TEquipmentDocument3 pagesPhenix 650-2P Portable AC Dielectric Test Set Phenix 6502P 650 2P 650-2P - TEquipmentAvoor KhanNo ratings yet

- 026 Subcontracting Plan ModelDocument10 pages026 Subcontracting Plan ModelAvoor KhanNo ratings yet

- Pre-Qualification Submittal FOR Testing and Pre-Commissioning of Electrical SystemsDocument1 pagePre-Qualification Submittal FOR Testing and Pre-Commissioning of Electrical SystemsAvoor KhanNo ratings yet

- Items Delivered: Cleveland Bridge Steel Company LTDDocument1 pageItems Delivered: Cleveland Bridge Steel Company LTDAvoor KhanNo ratings yet

- Shell Diala Product Family Brochure LowDocument4 pagesShell Diala Product Family Brochure LowAvoor KhanNo ratings yet

- 012 Sbplan Sample Appendix91Document6 pages012 Sbplan Sample Appendix91Avoor KhanNo ratings yet

- Course ListDocument2 pagesCourse ListAvoor KhanNo ratings yet

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocument1 pageJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C Paulose100% (1)

- Installation of Spiral DuctsDocument15 pagesInstallation of Spiral DuctsAnandu AshokanNo ratings yet

- Job Safety AnalysisDocument35 pagesJob Safety AnalysisSuraj PantNo ratings yet

- JSA - Backfilling at The Side of Retaining WallDocument2 pagesJSA - Backfilling at The Side of Retaining WallNFRNNo ratings yet

- JSA-Uplift Load On Test Pile - REV 0Document7 pagesJSA-Uplift Load On Test Pile - REV 0Sanjay Kumar Ghadai33% (3)

- Job Safety Analysis: Cladding WorkDocument22 pagesJob Safety Analysis: Cladding WorkAldian MuftiNo ratings yet

- JSA For Cutting, Grinding and Welding in AtmosphereDocument21 pagesJSA For Cutting, Grinding and Welding in AtmosphereThái Đạo Phạm Lê100% (1)

- Nithin ResumeDocument5 pagesNithin ResumeBenjamin GonzalezNo ratings yet

- Short Service Employee Program (Sse) - ProcedureDocument11 pagesShort Service Employee Program (Sse) - ProcedureBenson CherianNo ratings yet

- JSA - Erection Boiler Install (SFILEDocument35 pagesJSA - Erection Boiler Install (SFILEHilman Nugraha100% (1)

- JSA - Hydro-Testing of Pipe & EquipmentDocument1 pageJSA - Hydro-Testing of Pipe & EquipmentRajuNo ratings yet

- JSA Vehicle Entry in CCRDocument2 pagesJSA Vehicle Entry in CCRAliNo ratings yet

- 4.cutting Grinding WeldingDocument5 pages4.cutting Grinding WeldingMohammad Fazal KhanNo ratings yet

- JSA - FlowBackLoop - Choke ChangeDocument2 pagesJSA - FlowBackLoop - Choke ChangeAmur Al-rumhiNo ratings yet

- PLTMG Dumai 15Mw Analisa Keselamatan Kerja (Akk) Job Safety Analysis (Jsa)Document3 pagesPLTMG Dumai 15Mw Analisa Keselamatan Kerja (Akk) Job Safety Analysis (Jsa)Ikhbal NasutionNo ratings yet

- Health Safety Environment WorkshopDocument3 pagesHealth Safety Environment WorkshopJoan MilokNo ratings yet

- Chapter 1 Part 3 CKB 30103 Ind Safety and Health Rev 0Document14 pagesChapter 1 Part 3 CKB 30103 Ind Safety and Health Rev 0amirul ashrafNo ratings yet

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingRyan100% (1)

- Residual Risk Level Step & Activities Hazard, Env. Aspect Risk, Env. Impacts Resiko DanDocument1 pageResidual Risk Level Step & Activities Hazard, Env. Aspect Risk, Env. Impacts Resiko DanIwan RayaNo ratings yet

- Jsa EctDocument6 pagesJsa EctIkhbal NasutionNo ratings yet

- JSA-03 ConcreteDocument2 pagesJSA-03 ConcreteSujith KSNo ratings yet

- 003-JSA Pipe Loading and OffloadingDocument8 pages003-JSA Pipe Loading and OffloadingMoaatazz NouisriNo ratings yet

- Work Method Statement: Activity Wms For Mivan Modification WorkDocument6 pagesWork Method Statement: Activity Wms For Mivan Modification WorkamolNo ratings yet

- JSA For Cleaning Exchanger Channel Head by High Pressure Water JettingDocument17 pagesJSA For Cleaning Exchanger Channel Head by High Pressure Water JettingThái Đạo Phạm LêNo ratings yet

- Release Sheet: BGC Steel Site Safety ManualDocument94 pagesRelease Sheet: BGC Steel Site Safety Manualjacobpm2010No ratings yet

- 002-JSA RoW Opening and Marking FinalDocument6 pages002-JSA RoW Opening and Marking FinalMoaatazz NouisriNo ratings yet

- Shailesh Job Safety Analysis in Steel Manufacturing Unit and Recommendations To Improve The Work Safety EnvironmentDocument21 pagesShailesh Job Safety Analysis in Steel Manufacturing Unit and Recommendations To Improve The Work Safety EnvironmentNandini RajNo ratings yet