Shell Heat Transfer Oil S2

Shell Heat Transfer Oil S2

Uploaded by

Mudabbir Shan AhmedCopyright:

Available Formats

Shell Heat Transfer Oil S2

Shell Heat Transfer Oil S2

Uploaded by

Mudabbir Shan AhmedOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Shell Heat Transfer Oil S2

Shell Heat Transfer Oil S2

Uploaded by

Mudabbir Shan AhmedCopyright:

Available Formats

Technical Data Sheet

Previous Name: Shell Thermia B

Shell Heat Transfer Oil S2 Reliable Performance

High Performance Heat Transfer Fluid

Shell Heat Transfer Oil S2 is based on carefully selected, highly refined mineral oils chosen for their ability to provide

superior performance in indirect closed fluid heat transfer systems.

Performance, Features & Benefits Main Applications

Extended maintenance intervals

Shell Heat Transfer Oil S2 is based on carefully selected highly

refined mineral oils and resists oil cracking, oxidation and

thickening. This provides extended oil life, provided efficient

fluid heating and good pump circulation is ensured, such that

Enclosed circulated heat transfer systems for industrial

applications such as process industry, chemical plants, textile

film temperatures on the heater surface do not exceed the producers etc. and in household equipment such as oil filled

limits below. radiators.

System efficiency Shell Heat Transfer Oil S2 can be used in high temperature

Low viscosity enables excellent fluidity and heat transfer over a continuous heat transfer equipment with the following

wide temperature range. Shell Heat Transfer Oil S2 also has application limits:

a low vapour pressure so resists cracking. This minimises the

formation of volatile decomposition products; these would

Max. film temperature : 320C

require recovery via expansion chamber and condensate Max. bulk temperature : 300C

collector. Specifications, Approvals & Recommendations

Wear protection Classified as ISO 6743-12 Family Q

Shell Heat Transfer Oil S2 is non-corrosive and has high

solvency this reduces deposit formation by holding oxidation

Meets DIN 51522 requirements

For a full listing of equipment approvals and recommendations,

products in solution and keeping internal surfaces of heat

please consult your local Shell Technical Helpdesk.

exchangers clean.

Typical Physical Characteristics

Properties Method Shell Heat Transfer Oil S2

Density @20 C0

kg/m 3 ISO 12185 857

Flash Point (PMCC) 0

C ISO 2719 208

Flash Point (COC) 0

C ISO 2592 220

Pour Point 0

C ISO 3016 -12

Kinematic Viscosity @400C mm2/s ISO 3104 29

Kinematic Viscosity @1000C mm2/s ISO 3104 5.1

Kinematic Viscosity @2000C mm2/s ISO 3104 1.4

Initial Boiling Point 0

C ASTM D2887 >330

Autoignition temperature 0

C DIN 51794 332

Neutralisation Value mg KOH/g ASTM D974 <0.2

Ash (Oxide) % m/m ISO 6245 <0.01

Page 1 of 2 Shell Heat Transfer Oil S2, v 1.2 18.07.2014.08.45

Properties Method Shell Heat Transfer Oil S2

Carbon Residue (Conradson) % m/m ISO 10370 <0.01

0

Copper Corrosion (3 hrs/100 C) ISO 2160 Class 1

Coefficient of Thermal Expansion 1/0C 0.0008

These characteristics are typical of current production. Whilst future production will conform to Shell's specification, variations in

these characteristics may occur.

Health, Safety & Environment

Health and Safety

Shell Heat Transfer Oil S2 is unlikely to present any significant health or safety hazard when properly used in the recommended

application and good standards of personal hygiene are maintained.

Avoid contact with skin. Use impervious gloves with used oil. After skin contact, wash immediately with soap and water.

Guidance on Health and Safety is available on the appropriate Material Safety Data Sheet, which can be obtained from

http://www.epc.shell.com/

Protect the Environment

Take used oil to an authorised collection point. Do not discharge into drains, soil or water.

Additional Information

Advice

The life of Shell Heat Transfer Oil S2 depends on the design and usage of the system. If the system is well designed and not

subjected to abnormal workloads, the life can be for many years.

It is important to monitor oil condition regularly as rates of change in physical characteristics are more significant than actual

values. The properties that should be monitored are viscosity, acidity, flash point (open and closed) and insolubles content.

Advice on applications not covered here may be obtained from your Shell representative.

Page 2 of 2 Shell Heat Transfer Oil S2, v 1.2 18.07.2014.08.45

You might also like

- Compressor Oils: DIN 51506 VDL (Only For 32, 46, 68, 100, 150) DIN 51506 VBL (Only For 150-M, 220, 320, 460)Document2 pagesCompressor Oils: DIN 51506 VDL (Only For 32, 46, 68, 100, 150) DIN 51506 VBL (Only For 150-M, 220, 320, 460)Majed Dawa100% (2)

- HiTEC 343 MSDSDocument6 pagesHiTEC 343 MSDSMehmet PetronolNo ratings yet

- Mobil ATF 333Document2 pagesMobil ATF 333ppanagos5664No ratings yet

- Customer Technical Guide: Customer: Palmiye Corap Teks - San.Tic - Ltd.StiDocument71 pagesCustomer Technical Guide: Customer: Palmiye Corap Teks - San.Tic - Ltd.StiMudabbir Shan Ahmed100% (1)

- Shell Risella X 420: Specifications, Approvals & RecommendationsDocument2 pagesShell Risella X 420: Specifications, Approvals & RecommendationsHUM CIREBON DFLTS100% (1)

- Xaerus Product CatalogueDocument4 pagesXaerus Product CatalogueBurhan AdnanNo ratings yet

- Comparison ThermalDocument1 pageComparison ThermalABDUL REHMAN PIPRANINo ratings yet

- Lubricantes LSCDocument22 pagesLubricantes LSCAndres PozoNo ratings yet

- LZ 7077 Pds PDFDocument4 pagesLZ 7077 Pds PDFNadia SalemNo ratings yet

- Ficha Infenium P5096Document2 pagesFicha Infenium P5096yonaathan diaz100% (1)

- Evaluation of Hydrocarbon Heat Transfer Fluids: Standard Guide ForDocument3 pagesEvaluation of Hydrocarbon Heat Transfer Fluids: Standard Guide ForahmedNo ratings yet

- Gear Lubrication 3Document9 pagesGear Lubrication 3rashm006ranjan100% (1)

- GOM Majors EquivalentsPO Aug 2009 FINALDocument3 pagesGOM Majors EquivalentsPO Aug 2009 FINALArif HanifNo ratings yet

- Pub Role Additives v4 LODocument20 pagesPub Role Additives v4 LOTudor RatiuNo ratings yet

- APE Core Group 1 Sell SheetDocument1 pageAPE Core Group 1 Sell Sheetbig2yaNo ratings yet

- LUB OILS NOHAB W25 W25SG W25DF 9193911800eDocument2 pagesLUB OILS NOHAB W25 W25SG W25DF 9193911800eLIVIA100% (2)

- Oloa 10501: High Overbased Calcium SulfonateDocument1 pageOloa 10501: High Overbased Calcium SulfonateAtman FozdarNo ratings yet

- Product Information Navigo 6 So: DescriptionDocument2 pagesProduct Information Navigo 6 So: DescriptionCOMITYNo ratings yet

- Global DHD 1Document15 pagesGlobal DHD 1sanbao72No ratings yet

- Bell Lubricants European EnglishDocument16 pagesBell Lubricants European EnglishStroia Constantin MariusNo ratings yet

- GulfSea Power MDO Series PDFDocument2 pagesGulfSea Power MDO Series PDFObydur RahmanNo ratings yet

- HiTEC-2571 PDS Premium R&O TurbineDocument2 pagesHiTEC-2571 PDS Premium R&O TurbineJeremias UtreraNo ratings yet

- Caterpillar Elevated Copper Levels in Used Oil SamplesDocument3 pagesCaterpillar Elevated Copper Levels in Used Oil SamplesAnonymous Xi0dqd2No ratings yet

- Shell Turbo T46 PDFDocument2 pagesShell Turbo T46 PDFdionisio emilio reyes jimenezNo ratings yet

- CASE STUDY 2 - SteelDocument19 pagesCASE STUDY 2 - SteelAnkit UjjwalNo ratings yet

- Petro Canada Lubricants Handbook 2012 English PDFDocument212 pagesPetro Canada Lubricants Handbook 2012 English PDFsoumya ghoshNo ratings yet

- HiTEC 521F PDS Antiwear HydraulicDocument2 pagesHiTEC 521F PDS Antiwear HydraulicJeremias Utrera100% (1)

- Additiv 730 Additiv 830 (For Engine Oil) TdsDocument2 pagesAdditiv 730 Additiv 830 (For Engine Oil) TdsahmetNo ratings yet

- Product CatalogueDocument8 pagesProduct CatalogueD Wahyu BawonoNo ratings yet

- Gulf Lubricants Brief ProfileDocument10 pagesGulf Lubricants Brief Profileatripathi2009100% (1)

- Oloa 11000: Ashless Succinimide DispersantDocument1 pageOloa 11000: Ashless Succinimide DispersantAtman FozdarNo ratings yet

- Hitec 8799b PdsDocument2 pagesHitec 8799b PdsahmetNo ratings yet

- Shell Omala BrochureDocument2 pagesShell Omala BrochurehuseynseymenNo ratings yet

- Lubrizol360 Webinar - Predicting High-Temperature Performance in Motorcycle Engine Oils - Z124Document49 pagesLubrizol360 Webinar - Predicting High-Temperature Performance in Motorcycle Engine Oils - Z124tiến thử huỳnhNo ratings yet

- Engine Oil 15W 40 PDFDocument2 pagesEngine Oil 15W 40 PDFAngela Jackson100% (1)

- Deutz Gas Engine 0199-99-2105-5 BulletinDocument6 pagesDeutz Gas Engine 0199-99-2105-5 BulletinalexanderNo ratings yet

- The Most Common Worldwide-Were Introduced in The Early 1940s. Lithium Complex GreasesDocument14 pagesThe Most Common Worldwide-Were Introduced in The Early 1940s. Lithium Complex GreasesKiran DuggarajuNo ratings yet

- Glenda Melanie Lub - ChartDocument7 pagesGlenda Melanie Lub - ChartAndrei ZahaNo ratings yet

- Gulf Marine Corporate Presentation Ppt2009 07Document22 pagesGulf Marine Corporate Presentation Ppt2009 07Philippe BoileauNo ratings yet

- Gear OilsDocument3 pagesGear OilsPurchase ZenoilNo ratings yet

- Brake FluidsDocument4 pagesBrake FluidsPhuc DcNo ratings yet

- Why Brake Fluid It Is ImportantDocument5 pagesWhy Brake Fluid It Is ImportantengrsurifNo ratings yet

- GulfSea de Compressor Oil SeriesDocument2 pagesGulfSea de Compressor Oil SeriesObydur RahmanNo ratings yet

- Lubricant GlossaryDocument8 pagesLubricant GlossaryAli KhanNo ratings yet

- FUCHS LUBRITECH Product RangeDocument76 pagesFUCHS LUBRITECH Product RangeBurak GüleşNo ratings yet

- Hitec 9490 PDFDocument2 pagesHitec 9490 PDFPranit More Arabian Petroleum LimitedNo ratings yet

- Tech Trol Gold Synthetic LubricantDocument2 pagesTech Trol Gold Synthetic LubricantAzhar1109No ratings yet

- Oloa 4994CDocument2 pagesOloa 4994Csafindit50% (2)

- PETROVOLL BROCHURE FINAL (May2016) PDFDocument50 pagesPETROVOLL BROCHURE FINAL (May2016) PDFAbir MazumderNo ratings yet

- Surface Vehicle Information: Engine CoolantsDocument20 pagesSurface Vehicle Information: Engine CoolantsJOSE ANDRES OCHOA ORELLANANo ratings yet

- Dewmare Marine Oil 4040Document1 pageDewmare Marine Oil 4040ednsmnNo ratings yet

- The Next Generation Gas Engine Oil Mobil Pegasus 1005Document46 pagesThe Next Generation Gas Engine Oil Mobil Pegasus 1005Sandeep100% (1)

- ASTM D6158-16 Standard Specification For Mineral Hydraulic OilsDocument14 pagesASTM D6158-16 Standard Specification For Mineral Hydraulic OilsROMAY MERECIASNo ratings yet

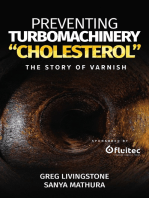

- Preventing Turbomachinery "Cholesterol": The Story of VarnishFrom EverandPreventing Turbomachinery "Cholesterol": The Story of VarnishNo ratings yet

- Ficha Oleo Termico - UnlockedDocument2 pagesFicha Oleo Termico - UnlockedWisard MagalhãesNo ratings yet

- Shell Heat Transfer Oil S2 TDSDocument2 pagesShell Heat Transfer Oil S2 TDSHemanthNo ratings yet

- Shell Heat Transfer Oil S2X TDSDocument2 pagesShell Heat Transfer Oil S2X TDSrudiarto 07No ratings yet

- Shell Thermia B PDFDocument2 pagesShell Thermia B PDFEduardo Dreifus100% (1)

- Shell Heat Transfer Oil S4 X: Performance, Features & BenefitsDocument2 pagesShell Heat Transfer Oil S4 X: Performance, Features & Benefitsrodrigonicolasdiaz1No ratings yet

- Napier Aftermarket ServicesDocument5 pagesNapier Aftermarket ServicesMudabbir Shan AhmedNo ratings yet

- A5e43215508a Sicherheitshinweise Simotics GP SD DP FL En-UsDocument10 pagesA5e43215508a Sicherheitshinweise Simotics GP SD DP FL En-UsMudabbir Shan AhmedNo ratings yet

- Mobil Pegasus™ 1100 Series Mobil Pegasus™ 1100 Series Mobil Pegasus™ 1100 Series Mobil Pegasus™ 1100 SeriesDocument3 pagesMobil Pegasus™ 1100 Series Mobil Pegasus™ 1100 Series Mobil Pegasus™ 1100 Series Mobil Pegasus™ 1100 SeriesMudabbir Shan AhmedNo ratings yet

- Shell Gadus S5 T460 1.5: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S5 T460 1.5: Performance, Features & Benefits Main ApplicationsMudabbir Shan Ahmed100% (1)

- 2014 609 - Mobil SHC 524 Synthetic Hydraulic Oil Success StoryDocument1 page2014 609 - Mobil SHC 524 Synthetic Hydraulic Oil Success StoryMudabbir Shan Ahmed100% (1)

- Exxonmobil and Innio Announce Introduction of Jenbacher N Oil 40 Lubricant For Jenbacher Gas EnginesDocument2 pagesExxonmobil and Innio Announce Introduction of Jenbacher N Oil 40 Lubricant For Jenbacher Gas EnginesMudabbir Shan AhmedNo ratings yet

- Shell Omala S2 G 320: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 320: Performance, Features & BenefitsMudabbir Shan AhmedNo ratings yet

- Shell Mysella S7 N Ultra 40: Performance, Features & BenefitsDocument2 pagesShell Mysella S7 N Ultra 40: Performance, Features & BenefitsMudabbir Shan AhmedNo ratings yet

- Orc English 20180507 PDFDocument8 pagesOrc English 20180507 PDFMudabbir Shan AhmedNo ratings yet

- Orc English 20180507 PDFDocument8 pagesOrc English 20180507 PDFMudabbir Shan AhmedNo ratings yet

- Security 25.0C 3.0Y 50.0R 8-18-2018Document3 pagesSecurity 25.0C 3.0Y 50.0R 8-18-2018Mudabbir Shan AhmedNo ratings yet

- A7CA89 Excel Template Shell and Tube Heat Exchanger Design P1and2 Us UnitsDocument5 pagesA7CA89 Excel Template Shell and Tube Heat Exchanger Design P1and2 Us UnitsMudabbir Shan AhmedNo ratings yet

- Ball ValvesDocument35 pagesBall ValvesMudabbir Shan AhmedNo ratings yet

- ValvesDocument128 pagesValvesMudabbir Shan AhmedNo ratings yet

- Pressure Transmitter For General Industrial Purposes Type MBS 3000 and MBS 3050Document4 pagesPressure Transmitter For General Industrial Purposes Type MBS 3000 and MBS 3050Mudabbir Shan AhmedNo ratings yet

- Emerson Control ValveDocument319 pagesEmerson Control ValveMudabbir Shan Ahmed100% (1)

- 1 s2.0 S245232161930530X MainDocument10 pages1 s2.0 S245232161930530X MainbytestefNo ratings yet

- 2.5.4 Soil CollapseDocument3 pages2.5.4 Soil Collapsecandice2811No ratings yet

- V5-Gan-Gp16 Series: Resilient Seated Gate Valve, Non Rising Stem (Hand Wheel)Document2 pagesV5-Gan-Gp16 Series: Resilient Seated Gate Valve, Non Rising Stem (Hand Wheel)Em Es WeNo ratings yet

- Sir Alan Cottrell and The Dislocation Mechanics of FracturingDocument34 pagesSir Alan Cottrell and The Dislocation Mechanics of FracturingGood & GoodNo ratings yet

- BR SPECORDaccesoires V03 en AJKDocument20 pagesBR SPECORDaccesoires V03 en AJKRoy NathanielNo ratings yet

- Effect of Rice Husk and Rice Husk Ash To Properties of BricksDocument7 pagesEffect of Rice Husk and Rice Husk Ash To Properties of BricksPernah SekolahNo ratings yet

- Wire Loss CalculatorDocument6 pagesWire Loss CalculatorAhmed SayedNo ratings yet

- QM 05. Line PipesDocument2 pagesQM 05. Line Pipesmohamed elmasry100% (1)

- Physics Report Band Gap of SemiconductorDocument5 pagesPhysics Report Band Gap of SemiconductorTumzangwanaNo ratings yet

- Intermolecular Forces BackgroundDocument10 pagesIntermolecular Forces BackgroundNicholas DoNo ratings yet

- Astm F754-88 PtfeDocument4 pagesAstm F754-88 PtfeIsabella RomeroNo ratings yet

- Vol. 3 Phosgene 435Document13 pagesVol. 3 Phosgene 435ichsan hakimNo ratings yet

- A Review Paper On Emulsion Polymerization of Vinyl Acetate: Sandeeptripathi, Shahida Anjum, Ashwini SoodDocument26 pagesA Review Paper On Emulsion Polymerization of Vinyl Acetate: Sandeeptripathi, Shahida Anjum, Ashwini Soodbushra shahidNo ratings yet

- Stabilization of Black Cotton Soil Using Fly Ash and GeopolymerDocument4 pagesStabilization of Black Cotton Soil Using Fly Ash and Geopolymerbhaskar pallaNo ratings yet

- Intraplast: Expanding Grout AdmixtureDocument2 pagesIntraplast: Expanding Grout AdmixtureManoj ChhetriNo ratings yet

- ICC ESR-3814 For HIT-RE 500 V3Document47 pagesICC ESR-3814 For HIT-RE 500 V3yessica godoyNo ratings yet

- T800 PDFDocument10 pagesT800 PDFRenato CampoverdeNo ratings yet

- 15eng 3.5 Building Structures - IiiDocument2 pages15eng 3.5 Building Structures - IiiRakeshNo ratings yet

- Gas Cylinder Safety SOP 12 Rev 02Document11 pagesGas Cylinder Safety SOP 12 Rev 02momenNo ratings yet

- Zero Waste Electric Arc Furnace (Eaf) Steelmaking Chaparral Steel Company TargetDocument9 pagesZero Waste Electric Arc Furnace (Eaf) Steelmaking Chaparral Steel Company TargetSaurabh GuptaNo ratings yet

- EDGE Materials Methodology Report v2.2Document42 pagesEDGE Materials Methodology Report v2.2arqjoramirezNo ratings yet

- ALCHEMY The Philosphers Stone by Alchemist NDCDocument3 pagesALCHEMY The Philosphers Stone by Alchemist NDCVladimir VergunNo ratings yet

- AkfixDocument110 pagesAkfixWempy WiryaatmajaNo ratings yet

- 13 - OGV Inner ShroudDocument4 pages13 - OGV Inner ShroudVALDEMIRNo ratings yet

- Chapter 19 Brines and Brine Piping SystemDocument26 pagesChapter 19 Brines and Brine Piping SystemATUL SONAWANE100% (2)

- Me2303 - Design of Machine ElementsDocument14 pagesMe2303 - Design of Machine ElementsGowtham RajNo ratings yet

- Lecture 2 - Water Supply - Distribution SystemDocument69 pagesLecture 2 - Water Supply - Distribution SystemApao, Trixie Ann P.No ratings yet

- Boq YvonneDocument6 pagesBoq Yvonneyvonne bonalesNo ratings yet

- Thompson - 1986-Elastic BucklingDocument5 pagesThompson - 1986-Elastic BucklingAnonymous wWOWz9UnWNo ratings yet

- BOM With DETAILED SOLUTIONDocument33 pagesBOM With DETAILED SOLUTIONShivendrq pratap singNo ratings yet