0 ratings0% found this document useful (0 votes)

Review Questions To Attempt

Review Questions To Attempt

Uploaded by

Fish de PaieThis document contains 4 review questions about quality control and control charts. It discusses key concepts of control charts like their construction and interpretation. Control charts are used to monitor processes over time and determine if the process is in or out of control. An example is given monitoring checkout times at a supermarket using mean and range control charts. The data shows 6 samples, and the question asks to determine control limits for the charts and if the process is in or control. Another question provides data on the fillweights of toothpaste tubes over 24 samples, and asks to calculate control limits, draw the X-bar and R charts, and comment on the process variability.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

Review Questions To Attempt

Review Questions To Attempt

Uploaded by

Fish de Paie0 ratings0% found this document useful (0 votes)

This document contains 4 review questions about quality control and control charts. It discusses key concepts of control charts like their construction and interpretation. Control charts are used to monitor processes over time and determine if the process is in or out of control. An example is given monitoring checkout times at a supermarket using mean and range control charts. The data shows 6 samples, and the question asks to determine control limits for the charts and if the process is in or control. Another question provides data on the fillweights of toothpaste tubes over 24 samples, and asks to calculate control limits, draw the X-bar and R charts, and comment on the process variability.

Original Description:

Operations management

Original Title

Review Questions to Attempt

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document contains 4 review questions about quality control and control charts. It discusses key concepts of control charts like their construction and interpretation. Control charts are used to monitor processes over time and determine if the process is in or out of control. An example is given monitoring checkout times at a supermarket using mean and range control charts. The data shows 6 samples, and the question asks to determine control limits for the charts and if the process is in or control. Another question provides data on the fillweights of toothpaste tubes over 24 samples, and asks to calculate control limits, draw the X-bar and R charts, and comment on the process variability.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

Review Questions To Attempt

Review Questions To Attempt

Uploaded by

Fish de PaieThis document contains 4 review questions about quality control and control charts. It discusses key concepts of control charts like their construction and interpretation. Control charts are used to monitor processes over time and determine if the process is in or out of control. An example is given monitoring checkout times at a supermarket using mean and range control charts. The data shows 6 samples, and the question asks to determine control limits for the charts and if the process is in or control. Another question provides data on the fillweights of toothpaste tubes over 24 samples, and asks to calculate control limits, draw the X-bar and R charts, and comment on the process variability.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1/ 2

CHAPTER 10: REVIEW QUESTIONS QUALITY CONTROL

1. What are the key concepts that underlie the construction and interpretation of control charts?

2. What is the purpose of a control chart?

3. Checkout time at a supermarket is monitored using a mean and a range chart. Six samples of

n = 20 observations have been obtained and the sample means

and ranges computed:

Sample Mean Range Sample Mean Range

1 3.06 .42 4 3.13 .46

2 3.15 .50 5 3.06 .46

3 3.11 .41 6 3.09 .45

a. Using the factors in Table 10.3, determine upper and lower limits for mean and range

charts.

b. Is the process in control?

QUESTION 4

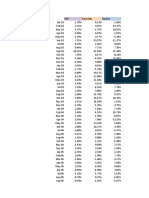

The table below shows the fillweights of toothpaste tubes on a filling machine. The time between samples is

20 minutes; 24 samples are taken during the 8-hour production shift. The samples are of size n=4.

Table: Data on fillweight of Toothpaste Tubes

Sample Fillweight (gms)

1 22.1 21.9 21.7 22.0

2 22.0 22.2 21.7 21.6

3 22.2 21.9 22.0 22.0

4 21.6 22.2 22.3 22.0

5 22.2 21.9 22.1 22.4

6 22.2 22.2 21.9 22.3

7 22.2 22.2 22.1 21.8

8 22.0 22.0 22.0 22.1

9 21.9 22.2 21.7 21.5

10 22.2 21.8 21.8 22.2

11 21.9 21.7 22.5 22.0

12 22.3 22.0 21.9 21.8

13 21.8 22.2 22.2 21.7

14 22.0 21.9 22.1 22.1

15 22.2 21.9 22.1 22.2

16 22.2 21.9 22.1 22.1

17 22.2 21.9 21.9 22.0

18 21.9 22.0 22.0 21.8

19 22.2 22.2 21.8 21.8

20 22.1 22.1 22.0 21.7

21 21.5 21.7 21.9 21.9

22 21.8 21.8 21.7 21.5

23 21.5 21.9 21.7 21.8

24 21.5 21.6 21.7 21.7

a. Calculate both the X-bar chart and R-chart control limits.

b. Draw both charts and plot the above data.

c. Comment on the process variability.

You might also like

- Machine Learning Project Problem 1 Jupyter Notebook PDF100% (5)Machine Learning Project Problem 1 Jupyter Notebook PDF85 pages

- Assignment 12 Case Study-Home Style Cookies100% (2)Assignment 12 Case Study-Home Style Cookies3 pages

- Zainul Fahmi TABEL Perhitungaan DAC 1 Dan DAC 2No ratings yetZainul Fahmi TABEL Perhitungaan DAC 1 Dan DAC 21 page

- Wind Speed and Generator Output Data For Calculating A Power Curve For A Wind TurbineNo ratings yetWind Speed and Generator Output Data For Calculating A Power Curve For A Wind Turbine1 page

- 08 11 2023 02 00 To 3 30 PM B Tech Y22 Batch Lateral Entry SeatingNo ratings yet08 11 2023 02 00 To 3 30 PM B Tech Y22 Batch Lateral Entry Seating11 pages

- Statistical Process Control Study: Data Collection: - d2 A2 D4No ratings yetStatistical Process Control Study: Data Collection: - d2 A2 D42 pages

- Compressive and Flexural Test of Mortar PDFNo ratings yetCompressive and Flexural Test of Mortar PDF9 pages

- Curah Hujan Tahunan (CM) Suatu Daerah Dalam 90 TahunNo ratings yetCurah Hujan Tahunan (CM) Suatu Daerah Dalam 90 Tahun8 pages

- 2018 Fluid Mechanics Workbook Key: (By:-Manoj Kumar Gour)No ratings yet2018 Fluid Mechanics Workbook Key: (By:-Manoj Kumar Gour)2 pages

- R9.1.41 Grama Sachivalayam Building Works Status Report (Agriculture Staff)No ratings yetR9.1.41 Grama Sachivalayam Building Works Status Report (Agriculture Staff)2 pages

- 12th + ICS Class Pairing Scheme 2024 All Boards100% (1)12th + ICS Class Pairing Scheme 2024 All Boards36 pages

- Table 7: Solar Radiation and Sunshine Duration in Sudan (: Create PDF in Your Applications With The PdfcrowdNo ratings yetTable 7: Solar Radiation and Sunshine Duration in Sudan (: Create PDF in Your Applications With The Pdfcrowd1 page

- FY - Remedial - Seating Arrangement - 27 Sept 2024No ratings yetFY - Remedial - Seating Arrangement - 27 Sept 20242 pages

- Importance of Teams & Team Building in Current Day Work ContextNo ratings yetImportance of Teams & Team Building in Current Day Work Context9 pages

- Ecommerce in Developing Countries BrazilNo ratings yetEcommerce in Developing Countries Brazil14 pages

- Survival Models: 7.1 The Hazard and Survival FunctionsNo ratings yetSurvival Models: 7.1 The Hazard and Survival Functions34 pages

- Course Outline-Probability and Statistics-Spring 2023No ratings yetCourse Outline-Probability and Statistics-Spring 20233 pages

- Statistics and Probability Module 7: Week 7: Third QuarterNo ratings yetStatistics and Probability Module 7: Week 7: Third Quarter7 pages

- Bootstrapping Techniques in Statistical Analysis and Approaches in R MATH 289No ratings yetBootstrapping Techniques in Statistical Analysis and Approaches in R MATH 28910 pages

- Active Learning Lecture Slides: Chapter 4 ProbabilityNo ratings yetActive Learning Lecture Slides: Chapter 4 Probability15 pages

- Lampiran 24 Hasil Analisis Data Uji Post Hoc (Uji Tukey HSD Dan Uji LSD)No ratings yetLampiran 24 Hasil Analisis Data Uji Post Hoc (Uji Tukey HSD Dan Uji LSD)6 pages

- Lecture: Simultaneous Equation Model (Wooldridge's Book Chapter 16)No ratings yetLecture: Simultaneous Equation Model (Wooldridge's Book Chapter 16)28 pages

- Statistics For Managers Using Microsoft Excel: 5 EditionNo ratings yetStatistics For Managers Using Microsoft Excel: 5 Edition43 pages