5S Evaluation

5S Evaluation

Uploaded by

Chin Kok SoonCopyright:

Available Formats

5S Evaluation

5S Evaluation

Uploaded by

Chin Kok SoonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

5S Evaluation

5S Evaluation

Uploaded by

Chin Kok SoonCopyright:

Available Formats

5S-Lean Audit Checklist--Manufacturing

Evaluator:

Department/Level

Overall Score

Class Teacher

Class Teacher

Class Teacher Score

Date Performed: 0 1 2 3 4 5

Sort: Are there any un-needed, unidentified items in the area?

1

Comments on # 1:

Straighten: Do the items, stationeries, materials that are needed have conveniently

located, visually designated homes? When not in use, are they returned to their

2 homes?

Comments on # 2:

Shine: Are the stationeries, subject corners, floors, walls, windows and all items in the

3 area clean, free from clutter and properly maintained? Is it dust free? Labeled?

Comments on # 3:

Standardize: Team has established and documented standards on sort, straighten,

and shine (checklist). Are current standards being followed, reviewed and improved

4 upon?

Comments on # 4:

Sustain: Have Sort-Straighten-Shine-Standardize been fully implemented and

5 functioning well? Are past checklist posted and used for improvement?

Comments on # 5:

Visual Controls: Are visual aids in use, up to date and effective in telling how the area

6 is performing, what problems are occurring and what improvements are being made?

Comments on # 6:

Safety: Are safe work practices in place and being followed? (Wiring, cable, sockets)

7

Comments on # 7:

Standard Work: Do Standard Work and Work Instructions exist for the area? Are

8 they posted, in use, followed, understood, and updated regularly?

Comments on # 8:

Quality: Are quality control concepts in place? Is there evidence of defect tracking or

other process recording? Are checklist posted? Are defects addressed, not passed

9 on?

Comments on #11:

Material Flow: Are necessities (Cleaning and Art Supplies) replenished when they

are needed, where they are needed in the quantities needed, and presented to the

10 Person-In-Charge as needed with smooth flow?

Comments on # 12:

Employee Engagement: Are team members actively participating in continuous

11 improvement efforts (5S team, idea boards, stairs, walls, toilet)

Comments on # 14:

Overall Comments:

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

You might also like

- MANG EUGENIO VENTURA Activity PhilosophyDocument1 pageMANG EUGENIO VENTURA Activity PhilosophyReizel Jane Pascua20% (5)

- HNC Assignment Brief TemplateDocument2 pagesHNC Assignment Brief Templatenbasson2No ratings yet

- MG408 CW1 The Business Report Assignment Brief Template 2021-22Document7 pagesMG408 CW1 The Business Report Assignment Brief Template 2021-22MdSarowar HossainNo ratings yet

- 5S-Lean Audit Checklist - Manufacturing: Comments On # 1Document1 page5S-Lean Audit Checklist - Manufacturing: Comments On # 1Chin Kok SoonNo ratings yet

- 5S Audit Form (Draft) 12-10-09 Rev4 NLDocument4 pages5S Audit Form (Draft) 12-10-09 Rev4 NLvigneshNo ratings yet

- Marketing Plan 4ps Kotler TemplateDocument16 pagesMarketing Plan 4ps Kotler TemplateEva LianNo ratings yet

- Guidelines For Synopsis & Dissertation-DefenseDocument10 pagesGuidelines For Synopsis & Dissertation-DefenseRajni KumariNo ratings yet

- Anjali Kain Mba 3 SEM Marketing Research: Submitted To Mr. Razi Ur RahimDocument11 pagesAnjali Kain Mba 3 SEM Marketing Research: Submitted To Mr. Razi Ur RahimKain AnjaliNo ratings yet

- English 1Document40 pagesEnglish 1Raúl ArellanoNo ratings yet

- SWPO Analysis ModelDocument21 pagesSWPO Analysis ModelhkwillchanNo ratings yet

- Guidelines For Academic and Administrative AuditDocument3 pagesGuidelines For Academic and Administrative AuditAmandeep VermaNo ratings yet

- Gantt ChartDocument5 pagesGantt ChartRana AtifNo ratings yet

- Isttm Guidelines For Student Project Documentation ReportDocument12 pagesIsttm Guidelines For Student Project Documentation ReportChaitanya DevNo ratings yet

- RONNIE IPCRF Personnel Tracking FormDocument35 pagesRONNIE IPCRF Personnel Tracking FormRonnie Francisco TejanoNo ratings yet

- Office Performance Commitment and Review Form (OPCRF) : Olgrethil L. CamongayDocument10 pagesOffice Performance Commitment and Review Form (OPCRF) : Olgrethil L. CamongayOlgrethil CamongayNo ratings yet

- Des Conway - The Event Managers Bible, How To Plan and Deliver An EventDocument329 pagesDes Conway - The Event Managers Bible, How To Plan and Deliver An EventRodrigo de Mendoza y PérezNo ratings yet

- Act 248 Innkeepers Act 1952Document10 pagesAct 248 Innkeepers Act 1952Adam Haida & CoNo ratings yet

- AnnotationDocument55 pagesAnnotationLarracas CristineNo ratings yet

- 2 - ESBM - LEVEL of Practice5Document3 pages2 - ESBM - LEVEL of Practice5QUEENIE BUTALIDNo ratings yet

- Academic AuditDocument14 pagesAcademic AuditSudheer AyazNo ratings yet

- Housekeeping LayoutDocument21 pagesHousekeeping LayoutANURADHANo ratings yet

- 03 Indzara Small Business Product Catalog v1 3Document18 pages03 Indzara Small Business Product Catalog v1 3vijay sainiNo ratings yet

- Maintenance Check List 8160Document80 pagesMaintenance Check List 8160tshewangNo ratings yet

- MBA Project Guidelines - 18-1Document17 pagesMBA Project Guidelines - 18-1Vikeel ReddyNo ratings yet

- IBM Event Management Best PracticesDocument458 pagesIBM Event Management Best Practiceskomal_42k100% (1)

- Academic Audit FormatDocument8 pagesAcademic Audit FormatUma Shankar YaligarNo ratings yet

- ResearchMethods Poster Ver 0.6 PDFDocument1 pageResearchMethods Poster Ver 0.6 PDFMohamed Saad BajjouNo ratings yet

- Security Guide For IBM I V6.1: Front CoverDocument426 pagesSecurity Guide For IBM I V6.1: Front Covervaltech20086605No ratings yet

- MS KPI Trend - Management System Compliance - November 2023Document1 pageMS KPI Trend - Management System Compliance - November 2023DUSTIN AYEN KERBY DEALOLANo ratings yet

- Budget Manning 2022 V01Document13 pagesBudget Manning 2022 V01Marnhy SNo ratings yet

- Training Need Identification Form: HR Receipt DateDocument3 pagesTraining Need Identification Form: HR Receipt DateAmit SinghNo ratings yet

- Interview SkillsDocument25 pagesInterview SkillsPradeep YuvarajNo ratings yet

- Action Plan TemplateDocument2 pagesAction Plan TemplateAgnes Asuncion VelascoNo ratings yet

- TR F & B Services NC IIDocument79 pagesTR F & B Services NC IIMarites AblogNo ratings yet

- Pilot Test QuestionnaireDocument6 pagesPilot Test QuestionnaireNoraz ZyzahNo ratings yet

- School - Financial ModelDocument104 pagesSchool - Financial ModelAisar UddinNo ratings yet

- Form For Employees-Upto Dy Managers Performance Appraisals 2009 - 2010Document5 pagesForm For Employees-Upto Dy Managers Performance Appraisals 2009 - 2010Ashok KumarNo ratings yet

- 8007 Event Planning WorksheetDocument5 pages8007 Event Planning WorksheetErwin HidayatNo ratings yet

- Training Request Form OriginalDocument2 pagesTraining Request Form OriginalGlynish MacapiaNo ratings yet

- Hotel Training Needs Assessment PDFDocument7 pagesHotel Training Needs Assessment PDFshobhitkaliaNo ratings yet

- Training Calendar 2019Document3 pagesTraining Calendar 2019Chaudhary RanvijayNo ratings yet

- HR - Manual - ToshaliDocument43 pagesHR - Manual - ToshaliVikas SharmaNo ratings yet

- Training Manager Tools - 2018Document48 pagesTraining Manager Tools - 2018haiNo ratings yet

- Draft Audit Program - Teacher WorkloadDocument6 pagesDraft Audit Program - Teacher WorkloadMaria CharessaNo ratings yet

- 5S Audit Checklist Template1Document4 pages5S Audit Checklist Template1Mohamed Ali SalemNo ratings yet

- Research MethodologyDocument14 pagesResearch MethodologyMariana Ulfah HoesnyNo ratings yet

- HandbookDocument17 pagesHandbookerayNo ratings yet

- Training Employees: Read Unit 7 of Your TextDocument34 pagesTraining Employees: Read Unit 7 of Your TextGrace VersoniNo ratings yet

- C02 Advics North India Private LTD.,: Performance Register From 01/10/2018 To 31/10/2018Document3 pagesC02 Advics North India Private LTD.,: Performance Register From 01/10/2018 To 31/10/2018Rohit SoniNo ratings yet

- Training Performance AppraisalDocument4 pagesTraining Performance AppraisalJohnson FernandezNo ratings yet

- Vaishali - Officer & Above KPI 2022Document5 pagesVaishali - Officer & Above KPI 2022Deepak JhaNo ratings yet

- BC HRMA - HR Metrics Interpretation GuideDocument30 pagesBC HRMA - HR Metrics Interpretation GuideManidip GangulyNo ratings yet

- Strategy and Strategic Management: David Campbell, David Edgar & George StonehouseDocument14 pagesStrategy and Strategic Management: David Campbell, David Edgar & George StonehouseRabiya MalikNo ratings yet

- GM - Project Time ManagementDocument35 pagesGM - Project Time ManagementinesNo ratings yet

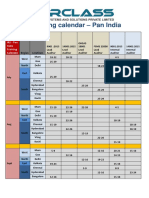

- IRS - Pan India Training CalenderDocument2 pagesIRS - Pan India Training CalenderShankar RajNo ratings yet

- Training FeedbackDocument1 pageTraining Feedbackc_b1964No ratings yet

- Facility Officer JD PSDocument5 pagesFacility Officer JD PSJamie MallanNo ratings yet

- AppraisalDocument6 pagesAppraisalPoulami DeNo ratings yet

- 5S Audit FormDocument6 pages5S Audit Formentrancemattingcart.1No ratings yet

- 5S For WCDocument3 pages5S For WCChokri AouinaNo ratings yet

- FD2 Social Studies Assignment Guideline Sept 2017Document2 pagesFD2 Social Studies Assignment Guideline Sept 2017Chin Kok SoonNo ratings yet

- Evaluation For Teachers' Training - June 2016 Not at All Neutral Yes! OverallDocument2 pagesEvaluation For Teachers' Training - June 2016 Not at All Neutral Yes! OverallChin Kok SoonNo ratings yet

- Children's Rights Lesson PlansDocument2 pagesChildren's Rights Lesson PlansChin Kok SoonNo ratings yet

- Respiration Form 3Document21 pagesRespiration Form 3Chin Kok SoonNo ratings yet

- Lesson Plan - Light, Reflection and RefractionDocument1 pageLesson Plan - Light, Reflection and RefractionChin Kok SoonNo ratings yet

- World Through Our Senses (All Sensory Organs)Document48 pagesWorld Through Our Senses (All Sensory Organs)Chin Kok Soon100% (3)

- GMC 20patiala PDFDocument2 pagesGMC 20patiala PDFMARSHMALLOW GAMINGNo ratings yet

- GameBased Learning and Gamification For EducationDocument224 pagesGameBased Learning and Gamification For EducationJaime Melero JuárezNo ratings yet

- Writing Task 1 - Mixed ChartsDocument5 pagesWriting Task 1 - Mixed ChartsKim DungNo ratings yet

- 1.1 Sample Question - AMCAT ENGLISH COMPREHENSION PDFDocument5 pages1.1 Sample Question - AMCAT ENGLISH COMPREHENSION PDFCrazy Nerd100% (1)

- Toolbox Business Coaching KitDocument18 pagesToolbox Business Coaching KittaeBo50% (6)

- First World War 1917-1918Document13 pagesFirst World War 1917-1918Ismar HadzicNo ratings yet

- Interview MemoDocument2 pagesInterview Memoapi-254060442No ratings yet

- Another LP WeeblyDocument14 pagesAnother LP Weeblyapi-396517404No ratings yet

- CV Maths TeacherDocument2 pagesCV Maths TeacherknlsinhaNo ratings yet

- Instructional Text: How To Make A Banana MilkshakeDocument4 pagesInstructional Text: How To Make A Banana MilkshakeKeziaNo ratings yet

- Setting Sail With The 7 HabitsDocument18 pagesSetting Sail With The 7 Habitsretaniautami93No ratings yet

- Moment of Pride Nineteen Successful UPSC Candidates Make SPIPA ProudDocument2 pagesMoment of Pride Nineteen Successful UPSC Candidates Make SPIPA ProudGajendraPatelNo ratings yet

- Jackie Lagus Portfolio 2Document18 pagesJackie Lagus Portfolio 2api-260742623No ratings yet

- 0580 w14 Ms 42Document7 pages0580 w14 Ms 42Haider AliNo ratings yet

- q3 w4 Answer SheetDocument1 pageq3 w4 Answer SheetDivina LacapNo ratings yet

- National Employability Enhancement Mission (NEEM) FAQ'sDocument2 pagesNational Employability Enhancement Mission (NEEM) FAQ'sRohan ShettyNo ratings yet

- CookingDocument32 pagesCookingNightNo ratings yet

- Watertown City School District - Budget ResultsDocument3 pagesWatertown City School District - Budget ResultsNewzjunkyNo ratings yet

- SBTE Kerala: State Board of Technical Education Kerala Provisional Admission Ticket - April 2021Document2 pagesSBTE Kerala: State Board of Technical Education Kerala Provisional Admission Ticket - April 2021Adarsh SooryaNo ratings yet

- Ap Lang ArgumentDocument7 pagesAp Lang Argumentapi-280982802No ratings yet

- PGBM133 Assessment 2021 22 Summer Term v1Document7 pagesPGBM133 Assessment 2021 22 Summer Term v1mehakjaanii55555No ratings yet

- MPA 509 Khursheed YusufDocument25 pagesMPA 509 Khursheed YusufMuhammad Irfan ZafarNo ratings yet

- JJJDocument100 pagesJJJDeninda Dwi PutriNo ratings yet

- I. Objectives: School Grade Level Teacher Learning Areas Science Teaching Dates and Period QuarterDocument3 pagesI. Objectives: School Grade Level Teacher Learning Areas Science Teaching Dates and Period QuarterR-Yel Labrador BaguioNo ratings yet

- CRISTINA - Results Based Performance Management SystemDocument70 pagesCRISTINA - Results Based Performance Management Systemmariane tabugonNo ratings yet

- CrimeDocument2 pagesCrimefffNo ratings yet

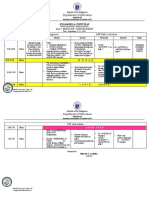

- Department of Education: Learning Area Am Daily ActivitiesDocument2 pagesDepartment of Education: Learning Area Am Daily ActivitiesMeg Calapit LapidaNo ratings yet

- HelpAge IndiaDocument6 pagesHelpAge IndiaPranay NarayaniNo ratings yet

- Profile of Asoke Nath, M.SC, Ph.D.,M.C.ADocument10 pagesProfile of Asoke Nath, M.SC, Ph.D.,M.C.AHappy RajputNo ratings yet