RMF005600408 PDF

RMF005600408 PDF

Uploaded by

Kasyrem KasremCopyright:

Available Formats

RMF005600408 PDF

RMF005600408 PDF

Uploaded by

Kasyrem KasremOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

RMF005600408 PDF

RMF005600408 PDF

Uploaded by

Kasyrem KasremCopyright:

Available Formats

INVESTIGACION REVISTA MEXICANA DE FISICA 56 (4) 317322 AGOSTO 2010

Universal testing machine for mechanical properties of thin materials

E. Huerta , J.E. Corona, and A.I. Oliva

Centro de Investigacion y de Estudios Avanzados del Instituto Politecnico Nacional,

Unidad Merida, Departamento de Fsica Aplicada,

Apartado Postal 73-Cordemex, 97310 Merida Yucatan, Mexico,

e-mail: microsco@mda.cinvestav.mx

F. Aviles

Centro de Investigacion Cientfica de Yucatan A.C., Unidad de Materiales,

Calle 43 No. 130 Col. Chuburna de Hidalgo, 97200, Merida Yucatan Mexico.

J. Gonzalez-Hernandez

Centro de Investigacion en Materiales Avanzados, S.C.,

Av. Miguel de Cervantes 120 Complejo Industrial Chihuahua, 31109 Chihuahua, Chihuahua, Mexico.

Recibido el 26 de marzo de 2010; aceptado el 8 de junio de 2010

In this work, the design, construction, calibration and compliance measurement of a universal testing machine for tension tests of materials in

film geometry are presented. A commercial load cell of 220 N and sensitivity of 1.2345 mV/V is used to measure the applied load. Material

strain is measured by movement of the crosshead displacement of the machine with a digital indicator with 0.001 mm resolution and 25 mm

maximum displacement, connected to a PC through an interface. Mechanical strain is achieved by an electric high precision stepper motor

capable to obtain displacement velocities as low as 0.001 mm/s. The stress-strain data acquired with a GPIB interface are saved as a file

with a home-made program developed in LabView 7.0. Measurements of the elastic modulus and yield point of a commercial polymer film

(500 HN Kapton) were used to validate the performance of the testing machine. The obtained mechanical properties are in good agreement

with the mean values reported by the supplier and with the values obtained from a commercial machine, taking into account the limitations

of thin film testing and experimental conditions.

Keywords: Universal testing machine; elastic modulus; thin films; compliance.

En este trabajo se discute el diseno, la construccion, la calibracion y la medicion de la complianza de una maquina universal para pruebas

de tension de materiales en geometra de pelicula. La carga aplicada es medida con una celda de carga comercial de 220 N y sensitividad de

1.2345 mV/V. La elongacion de la muestra es medida a traves del desplazamiento del cabezal de la maquina con un indicador de caratula

digital con resolucion de 0.001 mm y desplazamiento maximo de 25 mm, conectada a una PC a traves de una interfase de puerto serial. La

deformacion mecanica es conseguida con un motor a pasos de alta precision capaz de conseguir velocidades tan bajas como 0.001 mm/s. Los

datos adquiridos a traves de una interfase GPIB en tiempo real son guardados en un archivo usando un programa de diseno propio desarrollado

en LabView 7.0. El modulo de elasticidad y el punto de fluencia medidos en una pelicula polimerica comercial (Kapton 500 HN) fueron

utilizados para evaluar el desempeno de la maquina construida. Los valores de las propiedades mecanicas obtenidas muestran buen acuerdo

con los valores reportados por el proveedor y con los resultados obtenidos con una maquina comercial, considerando la geometra de capa

delgada.

Descriptores: Maquina universal de pruebas; modulo de elasticidad; capas delgadas; complianza.

PACS: 07.10.Pz; 62.20.de; 81.05.Bx; 81.70.Bt

1. Introduction textiles [3] and paper-like displays [4-5]. These electronic

devices are normally subjected to high external stresses and

New methodologies to measure the physical properties of large strains due to the flexible material used as substrate [6].

thin films are currently required. Particularly, reported me- As it is well known, the film properties can be quite different

chanical properties of materials at these dimensions are cur- from the bulk properties [7]. Thus, knowledge of the me-

rently controversial in the scientific literature. Thus, it is chanical properties of nanostructured materials is essential to

necessary to propose techniques for determining mechanical obtain functional and reliable electronic devices. Different

properties of thin films, such as elastic modulus, Poisons ra- methods have been proposed to investigate the mechanical

tio and strength. Properties of materials at micro and nano- properties of these thin materials. The most common meth-

scale are of considerable interest because of the unique prop- ods are based on X-ray diffraction [8], interferometry [9] and

erties associated with small volumes. These unique proper- most recently, nanoindentation [10-11]. These methods often

ties are increasing the importance of thin films and nanostruc- require sophisticated instrumentation and do not compel with

tured materials used in several technological applications. At the conventional definition of mechanical properties, which

present, flexible electronics onto polymer substrates [1-2] are are defined in terms of conventional tensile testing. In bulk

being developed for many applications, such as electronic geometry, the mechanical properties are commonly obtained

318 E. HUERTA, J.E. CORONA, A.I. OLIVA, F. AVILES, AND J. GONZALEZ-HERNANDEZ

As is shown in Fig. 1, the testing machine is composed

of five main parts:

i) the main frame,

ii) the drive system,

iii) the movable crosshead,

iv) the load cell, and

v) the digital indicator.

The testing machine is mainly made of stainless steel, except-

ing some frictional elements like the gears, which were made

of bronze.

The main frame includes the rectangular base where the

gearbox is placed, the fixed crosshead and the two vertical

F IGURE 1. 3D view of the universal testing machine. parallel columns. The drive system includes a stepper motor

with variable speed. The gearbox is formed by a worm shaft,

through tensile testing, and there exists different commercial and two worm gears, which moves the two drive screws. The

machines for characterization of bulk materials [12-15]. Ten- movable crosshead is integrated by the bottom grip, two con-

sile testing is an effective way to investigate the mechanical ical fastener tools with internal thread and an adjustable con-

properties of materials and it is a well established technique ical ring. The conical fastener tools provide stabilization to

for bulk sample characterization. However, tensile testing is the movable crosshead when moving along the drive screws.

not easily implemented for micro and nano-structured mate- The load cell used is a LCC-HTC-50 dual stud cell from Load

rials due to the small dimensions of the specimen. At present, Cell Central Co. [19] which withstands a 220 N maximum

there exist these testing machines for materials in film geom- load with a sensitivity of 1.2345 mV/V. The load cell can be

etry [16-18] but they are expensive and its flexibility to make used for tension or compression testing, it is located on the

modifications is limited. In this work, the design, construc- upper side of the frame and supports the upper grip. The dig-

tion, calibration and compliance determination of a universal ital indicator measures the crosshead displacement and con-

testing machine, specially designed for tensile tests of mate- sists of a digital micrometer from Starret [20] with 0.001 mm

rials in film geometry is discussed. Our universal testing ma- of resolution, which is connected with an RS232 interface to

chine is designed to produce small deformations at low veloc- a personal computer to acquire data.

ities and, consequently, high resolution. The testing machine To achieve high resolution in the measurements, the

is sensitive to small loads and permits to obtain the stress- device includes a stepper motor used to control both ve-

strain curves for materials in film geometry. Elastic modu- locity and torque. The drive system achieves displace-

lus, yield point, and maximum stress can be obtained from ments as small as 0.001 mm and velocities between 0.001

samples of up to about 10 cm length. An important feature and 0.1 mm/s. Two stainless-steel grips (one fixed to the load

of this device is the simplicity to exchange components ac-

cording to the user requirements: the low cost, low machine

compliance and the high resolution obtained. This machine

can also be adapted for compression testing with appropriate

samples and grips. However, compression testing will not be

addressed in this work.

2. Design and construction

The testing machine was designed to determine the stress-

strain curves of thin materials such as polymers and par-

ticularly metallic films deposited onto polymeric substrates.

Figure 1 shows a 3D illustration of the designed device

with 15 cm wide, 55 cm length and 45 cm high as total di-

mensions. The equipment is capable of analyzing samples up

to 10 cm of length. The mechanical design minimizes effects F IGURE 2. Photograph of the universal testing machine. The dif-

of load introduction in the main frame, drive screws, and the ferent components shown in Fig. 1 such as the drive system, load

relative movement between the movable crosshead and the cell, electronic indicator, movable crosshead and stepper motor can

drive screws. be observed.

Rev. Mex. Fs. 56 (4) (2010) 317322

UNIVERSAL TESTING MACHINE FOR MECHANICAL PROPERTIES OF THIN MATERIALS 319

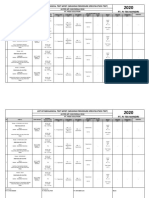

3.1. Calibration and data acquisition

The calibration of the load cell was conducted by collecting

data of different known applied loads (weights) and measur-

ing its corresponding output voltage.

Calibration measurements were conducted by steps over

a range of 0 to 12 N with an elapsed-time of 1 min between

each calibrated load in order to avoid hysteretic effects; i.e,

the voltage returns to cero value after removing the load. A

series of calibrated loads were applied in increasing order.

The output voltage of the load cell was captured through

a high-resolution programmable voltmeter HP 3458A. Fig-

ure 3 shows the obtained linear behavior between the ap-

plied load (P) and the output voltage (V) as obtained from

the load cell. The equation describing this relationship can

be expressed by:

F IGURE 3. Calibration curve showing the relation between applied

P = 12.8366V 0.06574 (1)

load and the voltage response of the load cell.

where the applied load P is given in Newtons and the output

voltage V in milivolts.

This linear behavior confirms the information provided

by the manufacturer and permits to obtain a relationship to

be used into the program as a transduction signal.

According to the supplier, the load cell can support maxi-

mum loads of 220 N, but it is not desirable to reach this limit

given that supplier guarantees a linear deviation of 0.15% at

full load.

The data acquisition system uses a GPIB interface of Na-

tional instruments to control the applied excitation voltage

of the power supply and to collect the corresponding output

voltage of the voltmeter. The GPIB interface is controlled

with a home-made program developed in Labview 7.0. Fig-

F IGURE 4. Frontal panel of the program developed in LabView. ure 4 shows the frontal panel of the implemented program

The program permits to control the excitation voltage and acquire and the different parameters used to obtain the stress-strain

the applied force and the displacement. curve. The designed program permits to select the acquisition

time, step-time, and the excitation voltage for the load cell,

cell and the other on the movable crosshead) are used to hold

and requires the length, width, and thickness of samples as

the samples. The grips were designed with smooth surfaces

entries. The force-displacement and stress-strain curves are

to avoid damage to the soft and thin samples. Each grip is

plotted in real time during testing. Using this program, pa-

composed by a fixed part and a movable plate joined with

rameters as data acquisition time, displacement, and applied

two screws to uniformly press the samples. This holding sys-

force can be captured and saved in real time for subsequent

tem avoids sliding between sample and grips during tensile

analysis.

tests. The design of this universal testing machine permits

the interchange of the different parts such as the load cell,

grips and drive screws, in order to extend the user require- 3.2. Machine compliance determination

ments. Figure 2 shows a photograph of the universal testing

machine. Stress-strain data are captured and saved in a data In mechanical testing of materials, when a strain gage or an

file through a GPIB interface controlled with a home-made in-situ element cannot be used to measure the real material

protocol programmed in LabView 7.0. strain, it is customary to use the machine crosshead displace-

ment to measure the applied strain. Measurements conducted

3. Performance by crosshead displacement need to be calibrated by taking

into account the machine compliance Cm . In order to cali-

In order to determine the performance of the proposed test- brate the machine compliance (Cm =1/km = /P, where km

ing machine, following the work done to calibrate the load is the stiffness constant, the crosshead displacement, and

cell, the methodology used to obtain the compliance of the P the applied load), a specific experiment was conducted by

machine, and the data acquisition are discussed. tensile testing by using a stiff metallic sample (as compared

Rev. Mex. Fs. 56 (4) (2010) 317322

320 E. HUERTA, J.E. CORONA, A.I. OLIVA, F. AVILES, AND J. GONZALEZ-HERNANDEZ

F IGURE 7. Six stress-strain curves obtained from the Kapton foil

F IGURE 5. Rigidities obtained from the universal testing machine through our home-made machine, showing the elastic and plastic

to calculate the total and material compliances. zone of the polymer.

F IGURE 8. Stress-strain curves for Kapton samples obtained with

a Shimadzu testing machine under similar conditions than Fig. 7.

F IGURE 6. Displacement of the movable crosshead vs. time during

a tensile test.

with soft materials). Compliance was obtained through ten- CT = Cm + CAl (2)

sile testing by using aluminum samples with 35 mm gage

lenght, 4.2 mm wide and 0.46 mm thick. The tensile test was Figure 5 shows load-displacement curves for the analyzed

done by applying loads from 0 to 140 N, limited by the ca- sample measured by the machine-crosshead and strain gage

pacity of the load cell. Strain was measured simultaneously (simultaneously). The values of the compliances (inverse

by the machine crosshead displacement and by a commer- of the load-displacement slopes) measured by both meth-

cial strain gage (Vishay ED-DY-062AK-350) bonded to the ods are CAl =0.43 m/N and CT =0.59 m/N. According to

mid-part of the sample. The strain gage was connected to Eq. (2), the measured values yield a machine compliance of

a Vishay model P3 strain indicator to record the gage sig- Cm =0.16 m/N. As it will be further discussed in connection

nal. Half bridge configuration was used in order to minimize with experiments on Kapton, the compliance of our machine

temperature effects. The total compliance measured by the is significantly low, confirming that our universal testing ma-

crosshead displacement (CT ) is a sum of the compliance of chine is appropriated to obtain mechanical properties of ma-

the analyzed material (CAl ) and the compliance of the ma- terials with low modulus, thin films, and polymers.

chine (Cm ), simulating a series spring system. Since CT and The machine compliance value is constant and needs to

CAl are measured during the experiment, the next relation be considered to determine the real value of the elastic mod-

can determine the machine compliance: ulus of a material under test, if the crosshead displacement

Rev. Mex. Fs. 56 (4) (2010) 317322

UNIVERSAL TESTING MACHINE FOR MECHANICAL PROPERTIES OF THIN MATERIALS 321

is used to measure strain. To determine the real elastic mod- point for Kapton as provided by the supplier are 2.5 GPa and

ulus (E) of a material under axial tension it is necessary to 69 MPa at 3% of strain [23], respectively. The small differ-

take into account the machine compliance. This can be done ences measured by our testing machine (9 and 11%) can be

using a spring-in-series system. The elastic modulus as deter- due to the difference in the geometry of the samples used by

mined with the machine crosshead displacement (ET ) needs the manufacturer (dog-bone), according to the ASTM D-882-

to be corrected to obtain the real modulus E, by the rela- 91 standard, and the different test velocity (10 mm/s) used.

tion [21,22]: In order to compare our results, Fig. 8 shows results of four

ET similar samples of Kapton tested in a commercial Shimadzu

E= Cm ET A

(3) machine model AGI-100, with a load cell of 500 N, using a

1 L crosshead speed of 0.01 mm/s. From results, the elastic mod-

where Cm is the measured machine compliance, A the sec- ulus and the yield point were estimated in 2.6 0.2 GPa and

tional area, and L the gage length. 55.4 1.2 MPa, respectively. Thus, although the values are

somewhat similar, it is very difficult to obtain the same values

4. Results and validation than those reported by the supplier, if different test conditions

are used.

A commercial polymer, 500 HN Kapton, was initially used It is known that thickness and specimen length can af-

as a benchmarking specimen by its well-known properties fect the stress-strain curves of materials, especially those in

reported by the DuPont Co. supplier [23]. Tensile tests film geometry [24]. Different test conditions can cause vari-

were conducted using rectangular geometries of Kapton films ations on the measurements of mechanical properties of the

of 40 mm length, 5 mm wide and 0.125 mm thick. The gage polymers. For example, notorious effects in the plastic zone

length of the samples was always 20 mm. The displacement due to the testing velocity have been reported in ref [25]. In

velocity of the movable crosshead during tensile experiments several reports [26,27] the analyzed samples deviate from the

was maintained at 0.01 mm/s in all cases. size and geometries required by the ASTM standards, and

sometimes the different values measured of certain mechani-

Figure 6 shows a plot of the displacement of the mov-

cal properties can not be comparable. Thus, testing of micro

able crosshead vs. time, where high stability can be observed

and nano-materials demands to establish new standards and

when it moves along the drive screw with the sample gripped.

fix the test conditions, size and, geometry of the samples, to

From Fig. 6, a constant behavior of the velocity and very low

obtain reproducible mechanical properties.

mechanical noise during the crosshead displacement is ev-

ident. Therefore, the movement of the movable crosshead

5. Conclusions

does not have additional effects, such as vibrations or speed

changes that could affect the tensile tests. The design, construction, calibration and compliance mea-

surement of a universal testing machine for tensile tests on

Figure 7 shows a group of six superimposed stress-strain thin and soft materials were discussed. The design has the

curves as obtained from different samples of the Kapton foil. capability to obtain displacement as small as 0.001 mm and

The six curves are difficult to visualize given their high re- maximum loads of 220 N. The estimated compliance ma-

producibility. From this figure, it can be observed that Kap- chine value was 0.16 m/N as measured with a stiff mate-

ton has a linear elastic behavior below 1.8% strain. The total rial. The mechanical properties of a 500HN Kapton polymer

strain applied to the samples was always 24%, which is far film were measured and compared with the mean values re-

from the ultimate strain reported by the supplier (72%). This ported by the supplier as well as independent testing using a

high strain can not be achieved by our machine giving the commercial testing machine. The corrected average elastic

mechanical limits of the device. modulus and the yield point of Kapton film determined with

In Fig. 7, the initial slope of the curve (elastic zone) cor- our home-made testing machine were 2.7 GPa, and 61.0 MPa.

responds to the elastic modulus. The value of the real elastic This elastic modulus value was corrected in about 1.1% for

modulus (E) calculated from the different stress-strain curves the case of Kapton, and represents a slight difference as com-

and corrected through Eq. 3 were estimated in 2.7 0.1 GPa pared with the mean values reported by the supplier; and is

as mean value. This value is 1.1% larger than the ET value also in reasonable agreement with the values obtained with

measured from the stress-strain curves directly obtained from the Shimadzu machine. The performance and low compli-

the machine. The low dispersion of data affirms the high re- ance value of our testing machine indicate that it is appro-

producibility of the measurements inducted on Kapton foils. priate to obtain reliable mechanical properties of compliant

The yield point (Y ) was determined as the stress obtained materials in thin and soft materials. Our testing machine per-

at 3% of the deformation (Y ) as shown in Fig. 7. The mits to interchange different elements according to the user

mean value of this parameter estimated in 61.01.0 MPa. requirements. An additional advantage of our testing ma-

The stress obtained at 24 % strain was ranged from 146.1 chine is the lower cost and smaller size compared to other

to 149.3 MPa, with an average of 147.61.0 MPa. For com- commercial machines. Future efforts will address the use of

parison, the mean values of the elastic modulus and the yield this equipment to obtain the mechanical properties of thin

Rev. Mex. Fs. 56 (4) (2010) 317322

322 E. HUERTA, J.E. CORONA, A.I. OLIVA, F. AVILES, AND J. GONZALEZ-HERNANDEZ

metallic films (pure and alloys) with different nano-thickness Acknowledgements

deposited on polymeric substrates.

Authors recognize the technical assistance of Gaspar Euan

and Oswaldo Gomez. This work was financially supported

by CONACYT - Mexico through project F1-54173.

. Doctoral student at CIMAV-Chihuahua, Mexico 15. S. Bergs and F. Sweden, US Patent 6148676 (2000).

1. C.T. Huang. C.L. Shen, C.F. Tang, and S.H. Chang, Sensors & 16. A.V. Sergueeva, J. Zhou, B.E. Meacham and D.J. Branagan,

Actuators A 141 (2008) 396. Mater. Sci. Eng. A 526 (2008) 79.

2. S.A. Wilson, R.P.J. Jourdain, and Q. Zhang, Mat. Sci. Eng. R 17. K. Yang et al., Acta Mater. 58 (2010) 967.

56 (2007) 1.

18. O. Kulyasova, R.K. Islamgaliev, B. Mingler, and M. Zehet-

3. E. Bonderove and S. Wagner, IEEE Electr. Dev. Lett. 25 (2004) bauer. Mat. Sci. Eng. A 503 (2009) 176.

295.

19. Load Cells, Dual Stud Load Cell Tension/Compression Model:

4. J. Rogers, Science 291 (2001) 1502.

LCC-HTC, http://www.800loadcel.com.

5. Y. Chen et al., Nature 423 (2003) 136.

20. Starret, Athol, MA, and US, Catalog No. 31B (2007) 192.

6. F. Macionczyk and W. Bruckner, J. Appl. Phys. 86 (1999) 4922.

21. U. Ramamurty and A. Paul. Acta Mater. 52 (2004) 869.

7. A.I. Oliva Arias, F. Lopez Garduza, and V. Sosa, Ingeniera 10

(2006) 57. 22. N. Huber and Ch. Tsakmakis, J. Mater. Res. 13 (1998) 1650.

8. P. Goudeau et al., Thin Solid Films 49 (2001) 398. 23. DuPont, Circleville, OH, and US, Technical Data Sheet (1999)

9. W.N. Sharpe Jr., B. Yuan, and R.L. Edwards, J. Microelec- 1.

tromech Syst. 6 (1997) 193. 24. Y.H. Zhao et al., Scripta Mater. 59 (2008) 627.

10. CS. Oh, H.J. Lee, S.G. Ko, S.W. Kim, and H.G. Ahn. Sensors 25. Handbook of Polymer Testing, Edited by R. Brown (Rapra

& Actuators A 117 (2005) 151 Technology, Shrewsbury, Shropshire SY4 4NR, UK. 2002). p.

11. R. Saha and W.D. Nix, Acta Mater. 56 (2008) 1399. 97

12. P.C. Lehning Jr, US Patent 3203232 (1965). 26. K.M. Youssef, R.O. Scattergood, K.L. Murty, J.A. Horton, and

13. W.T. Gloor, US Patent 3323357 (1967). C.C. Koch. Appl. Phys. Lett. 87 (2005) 091904.

14. R.J. Simonelli, US Patent 5913246 (1999). 27. Y.H. Zhao et al., Adv. Mater. 18 (2006) 2494.

Rev. Mex. Fs. 56 (4) (2010) 317322

You might also like

- 360 Degree Conveyor Belt PDFDocument4 pages360 Degree Conveyor Belt PDFUpendra BingundiNo ratings yet

- IRC 24-2010 Ammendment (Nov-17)Document3 pagesIRC 24-2010 Ammendment (Nov-17)avisek_basuNo ratings yet

- ASM - Tensile TestingDocument283 pagesASM - Tensile TestingSanthosh Nair83% (6)

- Sist en 12317 2 2010Document9 pagesSist en 12317 2 2010Dinesh PrasharNo ratings yet

- Manual Controls C807Document40 pagesManual Controls C807Felipe Aguilar Rivera100% (1)

- Follow To Writing-Calculating HysterisDocument6 pagesFollow To Writing-Calculating HysterisĐào Thanh PhongNo ratings yet

- Journal FABRICATIONOFWEARTESTINGMACHINEDocument7 pagesJournal FABRICATIONOFWEARTESTINGMACHINEAmar JabarNo ratings yet

- 978_3_031_32511_3_92Document13 pages978_3_031_32511_3_92Antoni Clares GarciaNo ratings yet

- 基于压电驱动的大行程高负载精密平移台技术研究 荣雪媛Document97 pages基于压电驱动的大行程高负载精密平移台技术研究 荣雪媛weizhixing518No ratings yet

- Virtual Instrumentation For Measurement of Strain Using Thin Film Strain Gauge SensorsDocument9 pagesVirtual Instrumentation For Measurement of Strain Using Thin Film Strain Gauge SensorsIAEME PublicationNo ratings yet

- Design and Fabrication of X-Y Gantry Mechanism Using Python A ReviewDocument6 pagesDesign and Fabrication of X-Y Gantry Mechanism Using Python A ReviewIJRASETPublicationsNo ratings yet

- Micromachines 13 01071 v2Document9 pagesMicromachines 13 01071 v2morteza13950102No ratings yet

- Trends in Hardness TestingDocument3 pagesTrends in Hardness TestingipraoNo ratings yet

- PlagDocument49 pagesPlagpranali.21stNo ratings yet

- PlagDocument46 pagesPlagpranali.21stNo ratings yet

- NDT2012 2a2 PDFDocument12 pagesNDT2012 2a2 PDFIvan MauricioNo ratings yet

- Article SDEMPED07 FinalDocument7 pagesArticle SDEMPED07 FinalShadNo ratings yet

- Metals: Feeling Machine For Process Monitoring of Turning Hybrid Solid ComponentsDocument12 pagesMetals: Feeling Machine For Process Monitoring of Turning Hybrid Solid ComponentsahmadNo ratings yet

- 1.1 Patent ResearchDocument18 pages1.1 Patent Researchapi-405430997No ratings yet

- Version Final PublicadaDocument13 pagesVersion Final Publicadaelarab29No ratings yet

- Development of A Measuring Sensory System Based OnDocument10 pagesDevelopment of A Measuring Sensory System Based OnNathanael Basana HisarNo ratings yet

- Mechatronics: Dongwoo Kang, Kihyun Kim, Dongmin Kim, Jongyoup Shim, Dae-Gab Gweon, Jaehwa JeongDocument9 pagesMechatronics: Dongwoo Kang, Kihyun Kim, Dongmin Kim, Jongyoup Shim, Dae-Gab Gweon, Jaehwa JeongMAHESH VNo ratings yet

- SM Lab Manual Part 1-1Document78 pagesSM Lab Manual Part 1-1Uneeb RamzanNo ratings yet

- 43 Electronics-10-01429-V2Document30 pages43 Electronics-10-01429-V2Triwiyanto TriwiyantoNo ratings yet

- A1-203 Macrographic InsulationDocument12 pagesA1-203 Macrographic Insulationnasrun nasrunNo ratings yet

- A Note On A Numerically Controlled Precision System For Sheet Metal Bending TestsDocument5 pagesA Note On A Numerically Controlled Precision System For Sheet Metal Bending TestsPourya NouryNo ratings yet

- Pig Pipe DetailsDocument8 pagesPig Pipe DetailsSUBHOMOYNo ratings yet

- Equotip Piccolo Portable Hardness TesterDocument4 pagesEquotip Piccolo Portable Hardness Testersolrac4371100% (1)

- Plag DDocument33 pagesPlag Dpranali.21stNo ratings yet

- Electrical Inspection and Autometed Robot For Electrical Transmission Line InspectionDocument5 pagesElectrical Inspection and Autometed Robot For Electrical Transmission Line InspectionIJRASETPublicationsNo ratings yet

- Image Processing Safety Assessment Ferrer2013Document6 pagesImage Processing Safety Assessment Ferrer2013Utsa RashiqueNo ratings yet

- IJCRT2306900Document7 pagesIJCRT2306900Shanu KumarNo ratings yet

- 2018 - Kiran Kumar - IOP - Conf. - Ser. - Mater. - Sci. - Eng. - 376 - 012110Document7 pages2018 - Kiran Kumar - IOP - Conf. - Ser. - Mater. - Sci. - Eng. - 376 - 012110Eri SukocoNo ratings yet

- Bolt 1Document10 pagesBolt 1Shawn WaltzNo ratings yet

- Novel - Virtual - Seismic - Assessment - of - A - MV - Primary - Switchgear - Based - On - The - New - IEC-TS 62271-210Document6 pagesNovel - Virtual - Seismic - Assessment - of - A - MV - Primary - Switchgear - Based - On - The - New - IEC-TS 62271-210Alexandre MandettaNo ratings yet

- 2Document10 pages2NamanMishraNo ratings yet

- Finite Element Analysis of 450T Eot CranDocument8 pagesFinite Element Analysis of 450T Eot CranAmith PaulNo ratings yet

- Utm PDFDocument5 pagesUtm PDFaybi pearlNo ratings yet

- DownloadDocument7 pagesDownloadMartinoNo ratings yet

- X-Ray For Packed ColumnsDocument6 pagesX-Ray For Packed ColumnsAkk KolNo ratings yet

- Qiang Liu and Weiming GaiDocument6 pagesQiang Liu and Weiming GaiMarimuthu VijayanNo ratings yet

- Proceq Metal Hardness Catalog - 81053502EDocument8 pagesProceq Metal Hardness Catalog - 81053502EramalingamNo ratings yet

- 2022 - YANG - A Novel Intelligent Fault Diagnosis Method of Rolling Bearings...Document11 pages2022 - YANG - A Novel Intelligent Fault Diagnosis Method of Rolling Bearings...igorbassoNo ratings yet

- INSPECTION CONVEYOR ppt-2-1Document15 pagesINSPECTION CONVEYOR ppt-2-1A/4041 /Haridoss.SNo ratings yet

- Utm Manual 1Document16 pagesUtm Manual 1JhEan LoUiseNo ratings yet

- Inner and Outer Races Bearing Damage Detection Using Low-Cost Fault Detecting SensorsDocument5 pagesInner and Outer Races Bearing Damage Detection Using Low-Cost Fault Detecting SensorsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Robotic Non-Destructive InspectionDocument8 pagesRobotic Non-Destructive InspectionFadhli AzinnuddinNo ratings yet

- UMT Catalog 2009Document156 pagesUMT Catalog 2009Thuron Charlize100% (1)

- Duroline - M Instruction Manual - MT12-00Document20 pagesDuroline - M Instruction Manual - MT12-00Paulo Castro Da SilvaNo ratings yet

- Ballistic Penetration of Steel Plates - Borvik Et AlDocument9 pagesBallistic Penetration of Steel Plates - Borvik Et AlJoydeep DeNo ratings yet

- Optimal Design, Fabrication, and Control of An Micropositioning Stage Driven by Electromagnetic ActuatorsDocument14 pagesOptimal Design, Fabrication, and Control of An Micropositioning Stage Driven by Electromagnetic ActuatorspopescuNo ratings yet

- ExposiciónDocument11 pagesExposiciónKEVINNo ratings yet

- C372MDocument2 pagesC372Mmiloud_flittiNo ratings yet

- Real-Time Seam Penetration Identification in Arc Welding Based On Fusion of Sound, Voltage and Spectrum SignalsDocument12 pagesReal-Time Seam Penetration Identification in Arc Welding Based On Fusion of Sound, Voltage and Spectrum Signalsgino andradeNo ratings yet

- Explorer: Untethered Real-Time Gas Main Assessment Robot SystemDocument6 pagesExplorer: Untethered Real-Time Gas Main Assessment Robot SystemSweta DeyNo ratings yet

- Leeb - Mjerenje TvrdoćeDocument12 pagesLeeb - Mjerenje TvrdoćedragoslavNo ratings yet

- SF2023Document7 pagesSF2023Phước Bùi TháiNo ratings yet

- Piezoelectric-Sensored Sustainable Pads For Smart Railway Traffic and TrackDocument10 pagesPiezoelectric-Sensored Sustainable Pads For Smart Railway Traffic and TrackOficina técnica HermacastiNo ratings yet

- 02 396 Zwicki PI EDocument4 pages02 396 Zwicki PI EUsman HameedNo ratings yet

- Research Regarding Uniaxial Tensile Strength of Nylon Woven Fabrics, Coated and Uncoated With SiliconeDocument11 pagesResearch Regarding Uniaxial Tensile Strength of Nylon Woven Fabrics, Coated and Uncoated With SiliconeSimulation CAENo ratings yet

- Earthquake Simulations of Large Scale Structures Using Opensees Software On Grid and High Performance Computing in IndiaDocument4 pagesEarthquake Simulations of Large Scale Structures Using Opensees Software On Grid and High Performance Computing in Indiasofiane9500No ratings yet

- Evaluation of The Materials Damage in Gas TurbineDocument9 pagesEvaluation of The Materials Damage in Gas TurbineThanapaet RittirutNo ratings yet

- New Sensors and Processing ChainFrom EverandNew Sensors and Processing ChainJean-Hugh ThomasNo ratings yet

- Applied Metrology for Manufacturing EngineeringFrom EverandApplied Metrology for Manufacturing EngineeringRating: 5 out of 5 stars5/5 (1)

- PerfDocument1 pagePerfKasyrem KasremNo ratings yet

- Na FiberDocument35 pagesNa FiberKasyrem KasremNo ratings yet

- JAWWALDocument14 pagesJAWWALKasyrem KasremNo ratings yet

- MOSHELL Commands v14Document63 pagesMOSHELL Commands v14Kasyrem KasremNo ratings yet

- Drive Test Learning:: 2) Types of Drive TestsDocument8 pagesDrive Test Learning:: 2) Types of Drive TestsKasyrem KasremNo ratings yet

- Scientific Typesetting Made Easy: This Is No Mere "Processing" of WordsDocument12 pagesScientific Typesetting Made Easy: This Is No Mere "Processing" of WordsKasyrem KasremNo ratings yet

- Is 2062Document13 pagesIs 2062Sourav Hait57% (7)

- Jis G 3444 - 2010Document17 pagesJis G 3444 - 2010ZSZ GAMINGNo ratings yet

- Design of Engineering Materials: Stress-Strain DiagramDocument32 pagesDesign of Engineering Materials: Stress-Strain DiagramTRNADEWNo ratings yet

- As 1855-2008 Methods For The Determination of Transverse Tensile Properties of Round Steel PipeDocument7 pagesAs 1855-2008 Methods For The Determination of Transverse Tensile Properties of Round Steel PipeSAI Global - APACNo ratings yet

- Rahim 2020 IOP Conf. Ser. Earth Environ. Sci. 476 012058Document12 pagesRahim 2020 IOP Conf. Ser. Earth Environ. Sci. 476 012058casaNo ratings yet

- Fabrication and Fatigue Properties of Dissimilar Steel Functionally Graded Material Structure Through Wire Arc Additive ManufacturingDocument11 pagesFabrication and Fatigue Properties of Dissimilar Steel Functionally Graded Material Structure Through Wire Arc Additive Manufacturinggatese2020No ratings yet

- Astm A 414 - A 414M - 04 - Qtqxnc9bnde0tqDocument3 pagesAstm A 414 - A 414M - 04 - Qtqxnc9bnde0tqEjat ISNo ratings yet

- Data Sheet ASTM A387 Grade 22 2017-04-19Document1 pageData Sheet ASTM A387 Grade 22 2017-04-19Kevin GuoNo ratings yet

- Aço Sa 537 cl1Document23 pagesAço Sa 537 cl1pcorreia68100% (1)

- 9295Document14 pages9295Rathish ViswanathanNo ratings yet

- WAW-1000Y (1000kN) Computer Control Electric-Hydraulic Servo Universal Testing MachineDocument12 pagesWAW-1000Y (1000kN) Computer Control Electric-Hydraulic Servo Universal Testing MachineUbaidNo ratings yet

- Physical Properties of RockDocument35 pagesPhysical Properties of RockErdem Salih SeyfeliNo ratings yet

- Practical Task 2 SomDocument4 pagesPractical Task 2 SomSyfull musicNo ratings yet

- Astm d2519Document4 pagesAstm d2519Anonymous WDTFw8EKNo ratings yet

- 2.3.2.A.SIM TensileTestingDocument9 pages2.3.2.A.SIM TensileTestingBianca Enireb-GaiborNo ratings yet

- IS 1148-1982-Reaffirmed 2004 PDFDocument10 pagesIS 1148-1982-Reaffirmed 2004 PDFNav TalukdarNo ratings yet

- List Mechanical Procedure Qualification Test (API 1104) 2018 (CEPU)Document5 pagesList Mechanical Procedure Qualification Test (API 1104) 2018 (CEPU)Muhammad Iqbal SpNo ratings yet

- Page 37 From API-1104-2016Document1 pagePage 37 From API-1104-2016Riaz AhmadNo ratings yet

- World Pipelines June 2007 - Integrity ManagementDocument55 pagesWorld Pipelines June 2007 - Integrity ManagementShrikant MojeNo ratings yet

- SOM Lab EXP1Document6 pagesSOM Lab EXP1Amisha SharonNo ratings yet

- Lab Sheet Experiment 2-StrengthDocument2 pagesLab Sheet Experiment 2-Strengthfaqhrul0% (1)

- Dma PDFDocument9 pagesDma PDFkrishna saiNo ratings yet

- Prensa Universal ManualDocument20 pagesPrensa Universal ManualMAIKEL ANDRES VINCES MENDOZANo ratings yet

- Impact Testing of Stainless Steel Materials: ICP/CON-04-00633 PreprintDocument10 pagesImpact Testing of Stainless Steel Materials: ICP/CON-04-00633 Preprintbabis1980No ratings yet

- SABITA Manual-13 - 1997Document62 pagesSABITA Manual-13 - 1997Jacques Van HeerdenNo ratings yet

- Rules For Materials and Welding, 2015 PDFDocument287 pagesRules For Materials and Welding, 2015 PDFQuality TeamNo ratings yet