Appendix 2-6 Process Flow Diagrams With Heat and Material Balances, Plant Performance

Appendix 2-6 Process Flow Diagrams With Heat and Material Balances, Plant Performance

Uploaded by

Peter GeorgeCopyright:

Available Formats

Appendix 2-6 Process Flow Diagrams With Heat and Material Balances, Plant Performance

Appendix 2-6 Process Flow Diagrams With Heat and Material Balances, Plant Performance

Uploaded by

Peter GeorgeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Appendix 2-6 Process Flow Diagrams With Heat and Material Balances, Plant Performance

Appendix 2-6 Process Flow Diagrams With Heat and Material Balances, Plant Performance

Uploaded by

Peter GeorgeCopyright:

Available Formats

APPENDIX 2-6

PROCESS FLOW DIAGRAMS WITH HEAT AND MATERIAL BALANCES,

PLANT PERFORMANCE

Avenal Energy AFC

APPENDIX 2-6

PROCESS FLOW DIAGRAMS, HEAT & MATERIAL BALANCES AND PLANT PERFORMANCE

1.0 PROCESS FLOW DIAGRAMS

Two process flow diagrams depict the conceptual power plant design: A3DV00-1-ME-8-FD-1

and shows the power block, and A3DV00-1-ME-8-FD-2 shows the balance of plant, which

includes the auxiliary cooling water system and the water storage and treatment systems.

2.0 HEAT & MATERIAL BALANCES AND PLANT PERFORMANCE

Six operating cases are summarized in Table 2.3-5, Heat and Material Balance Case

Descriptions. Heat and material balances at the different operating conditions, each at three CTG

loads (100%, 75% and 50%) are presented in Tables 2-6-1 through 2-6-12. The predicted

performance data for full load, 75% load, and 50% load were also calculated for different

ambient temperatures and are shown in Tables for Case 1 through Case 12.

The stream numbers on the heat and material balances correspond to numbered diamonds on the

process flow diagrams.

12/12/07 2-6-1 Avenal Energy Project

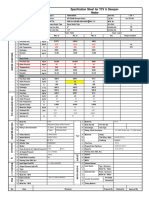

Client: Federal Power King's County, LLC Contract : A3DV

Location: Avenal, CA Revision : B

Project: Avenal Energy Project Date : 11-Jul-07

Equipment: 2 x GE7FA x 2 Fired HRSGs x 1 RH STG By: G. Wadman

Unit 1 Checked:

Approved:

Heat and Material Balance

Table 2.6-1

HEAT AND MATERIAL BALANCE CASE: 101NGF1

AMBIENT CONDITIONS: 101 F Dry Bulb / 23% RH

CTG LOAD: 100%

STG STATUS: ON

DUCT BURNER STATUS: ON

CTG CHILLER STATUS: ON

Stream Flow, kpph Temp. Pressure Enthalpy

NOTES

No Description Per Train Unit Total F psia Btu/lbm

B1 HP Boiler Drum Continuous Blowdown 8.2 -- 635 1,983 670 Note 1

B2 IP Boiler Drum Continuous Blowdown 0.0 -- 481 570 465 Note 1

C1 Condensate from Condenser -- 1,792.7 142 149 110

C2 Condensate to Feed Water Preheater 935.0 -- 142 149 110

C3 Feed Water to LP Drum 935.0 -- 293 103 262

C4 Feed Water from LP Drum to HP/IP BFW Pump 893.6 -- 330 103 301

C5 IP Feed Water Pump Bleed 53.1 -- 332 579 302

C6 HP Feed Water Pump Discharge 840.6 -- 335 2,375 306

C7 HP Feed Water to HP Superheater Attemperator 0.0 -- 332 579 302

C8 IP Feed Water to Reheat Superheater Attemperator 14.0 -- 335 2,375 306

C9 IP BFW to GT Fuel Heating 38.7 475 570 459

C10 IP BFW from GT Fuel Heating 38.7 135 103 103

D1 Demineralized Water Makeup to Condenser -- 16.4 59 40 27

G1 Combustion Turbine Inlet Air 3,558.0 -- 101 14.51 --

G2 Combustion Turbine Chilled Inlet Air 3,550.0 -- 48 14.37 --

G3 Combustion Turbine Exhaust 3,628.0 -- 1,119 15.11 --

G4 HRSG Exhaust Flow after Duct Burners 3,653.0 -- 1,496 15.04 --

G5 HRSG Stack Exit 3,653.0 -- 195 14.51 --

F1 Natural Gas to Combustion Turbine 78.2 -- 60 365 --

F2 Heated Natural Gas to Combustion Turbine 78.2 -- 365 360 --

F3 Natural Gas to Duct Burner 24.5 -- 60 365 --

S1 HRSG HP Superheater Exit 832.4 -- 1,055 1,911 1,512

S2 HRSG Hot Reheater Exit 835.6 -- 1,048 539 1,546

S3 HRSG IP Superheater Exit 0.4 -- 1,117 570 1,583

S4 HRSG LP Superheater Exit 41.4 -- 565 102 1,312

S5 Cold Reheat to HRSG from STG / HP Letdown 821.3 -- 732 570 1,371

S6 Mixed RH Steam into HRSG Reheater 821.6 -- 732 570 1,371

S7 HP STG Throttle Steam -- 1,664.9 1,049 1,837 1,510

S8 STG HP Exhaust as Cold Reheat -- 1,642.5 738 589 1,373

S9 Hot Reheat Steam into STG -- 1,671.2 1,042 511 1,543

S10 LP Superheated Steam into STG -- 82.7 557 100 1,308

S11 STG LP Exhaust Steam to Condenser -- 1,773.0 141 2.95 1,088

W1 Condensate from GT Chiller Coil 8.2 -- 48 14.51 16

W2 Cold Closed Loop CW -- 4,060.0 126 90 -- Note 6

W3 Hot Closed Loop CW -- 4,060.0 139 80 -- Note 6

Performance Summary Units Per Train Per Unit NOTES

CTG Natural Gas Heat Input (LHV) MMBtu/hr 1,618 3,236

HRSG Duct Burner Heat Input (LHV) MMBtu/hr 507.0 1,014.0

Gas Turbine Gross Output kW 172,398 344,796

Steam Turbine Gross Output kW -- 290,818

Gross Power Output kW -- 635,614

Gross Plant Heat Rate (LHV) Btu / kWh -- 6,686

Gross Plant Heat Rate (HHV) Btu / kWh -- 7,413

Total Auxiliary Loads + TXFR Loss kW -- 35,604

Net Power kW -- 600,010

Net Plant Heat Rate (LHV) Btu / kWh -- 7,083

Net Plant Heat Rate (HHV) Btu / kWh -- 7,853

Notes:

1. HRSG HP Blowdown is 1% and is cascaded from HP to IP Drum and IP Blowdown is 1% from IP Drum to Boiler Blowdown Tank (These are included as losses in the mass balance)

2. CTG data based on GTMaster model for GE 7421FA.

3. HRSG data based on GTMaster model.

4. STG data based on GTMaster model with assumed 26 inch last stage blade length in LP turbine.

5. Fuel gas heating value based on 20,694 Btu/lbm-LHV (48,134 kJ/kg-LHV) and 22,945 Btu/lbm-HHV (53,370 kJ/kg-HHV) referenced to 77 F (25C)

6. Assumed Closed Cooling Water Duty: 45 mmBtu/hr

7. Refer to Avenal Energy Project PFDs for a schematic representation of the above streams.

8. The above heat and material balance is an estimate and not a guarantee. All values are subject to change pending detailed design development.

D:\My Documents\Archives\Avenal\Process\Cycle Design\Avenal H&MB RevB

Client: Federal Power King's County, LLC Contract : A3DV

Location: Avenal, CA Revision : B

Project: Avenal Energy Project Date : 11-Jul-07

Equipment: 2 x GE7FA x 2 Fired HRSGs x 1 RH STG By: G. Wadman

Unit 1 Checked:

Approved:

Heat and Material Balance

Table 2.6-2

HEAT AND MATERIAL BALANCE CASE: 101NGU1

AMBIENT CONDITIONS: 101 F Dry Bulb / 23% RH

CTG LOAD: 100%

STG STATUS: ON

DUCT BURNER STATUS: OFF

CTG CHILLER STATUS: ON

Stream Flow, kpph Temp. Pressure Enthalpy

NOTES

No Description Per Train Unit Total F psia Btu/lbm

B1 HP Boiler Drum Continuous Blowdown 4.6 -- 559 1,125 561 Note 1

B2 IP Boiler Drum Continuous Blowdown 0.3 -- 433 353 411 Note 1

C1 Condensate from Condenser -- 1,140.1 129 100 97

C2 Condensate to Feed Water Preheater 656.0 -- 140 100 108

C3 Feed Water to LP Drum 617.3 -- 301 76 271

C4 Feed Water from LP Drum to HP/IP BFW Pump 545.5 -- 308 76 278

C5 IP Feed Water Pump Bleed 79.9 -- 309 508 279

C6 HP Feed Water Pump Discharge 465.6 -- 315 2,678 286

C7 HP Feed Water to HP Superheater Attemperator 0.0 -- 309 508 279

C8 IP Feed Water to Reheat Superheater Attemperator 0.0 -- 315 2,678 286

C9 IP BFW to GT Fuel Heating 47.3 417 353 394

C10 IP BFW from GT Fuel Heating 47.3 135 76 103

D1 Demineralized Water Makeup to Condenser -- 9.9 59 40 27

G1 Combustion Turbine Inlet Air 3,558.0 -- 101 14.51 --

G2 Combustion Turbine Chilled Inlet Air 3,550.0 -- 48 14.37 --

G3 Combustion Turbine Exhaust 3,628.0 -- 1,119 15.06 --

G4 HRSG Exhaust Flow after Duct Burners 3,628.0 -- 1,026 14.99 --

G5 HRSG Stack Exit 3,628.0 -- 207 14.51 --

F1 Natural Gas to Combustion Turbine 78.2 -- 60 365 --

F2 Heated Natural Gas to Combustion Turbine 78.2 -- 365 360 --

F3 Natural Gas to Duct Burner 0.0 -- 60 365 --

S1 HRSG HP Superheater Exit 461.0 -- 1,054 1,081 1,535

S2 HRSG Hot Reheater Exit 487.0 -- 1,048 317 1,552

S3 HRSG IP Superheater Exit 32.4 -- 596 336 1,310

S4 HRSG LP Superheater Exit 71.8 -- 513 72 1,288

S5 Cold Reheat to HRSG from STG / HP Letdown 454.7 -- 753 336 1,395

S6 Mixed RH Steam into HRSG Reheater 487.0 -- 742 336 1,389

S7 HP STG Throttle Steam -- 921.9 1,049 1,040 1,533

S8 STG HP Exhaust as Cold Reheat -- 909.4 759 346 1,397

S9 Hot Reheat Steam into STG -- 974.1 1,041 300 1,549

S10 LP Superheated Steam into STG -- 143.6 503 64 1,284

S11 STG LP Exhaust Steam to Condenser -- 1,128.2 127 2.05 1,095

W1 Condensate from GT Chiller Coil 8.2 -- 48 14.51 16

W2 Cold Closed Loop CW -- 4,060.0 126 90 -- Note 6

W3 Hot Closed Loop CW -- 4,060.0 139 80 -- Note 6

Performance Summary Units Per Train Per Unit NOTES

CTG Natural Gas Heat Input (LHV) MMBtu/hr 1,619 3,238

HRSG Duct Burner Heat Input (LHV) MMBtu/hr 0.0 0.0

Gas Turbine Gross Output kW 172,772 345,544

Steam Turbine Gross Output kW -- 171,608

Gross Power Output kW -- 517,152

Gross Plant Heat Rate (LHV) Btu / kWh -- 6,262

Gross Plant Heat Rate (HHV) Btu / kWh -- 6,943

Total Auxiliary Loads + TXFR Loss kW -- 33,433

Net Power kW -- 483,719

Net Plant Heat Rate (LHV) Btu / kWh -- 6,694

Net Plant Heat Rate (HHV) Btu / kWh -- 7,423

Notes:

1. HRSG HP Blowdown is 1% and is cascaded from HP to IP Drum and IP Blowdown is 1% from IP Drum to Boiler Blowdown Tank (These are included as losses in the mass balance)

2. CTG data based on GTMaster model for GE 7421FA.

3. HRSG data based on GTMaster model.

4. STG data based on GTMaster model with assumed 26 inch last stage blade length in LP turbine.

5. Fuel gas heating value based on 20,694 Btu/lbm-LHV (48,134 kJ/kg-LHV) and 22,945 Btu/lbm-HHV (53,370 kJ/kg-HHV) referenced to 77 F (25C)

6. Assumed Closed Cooling Water Duty: 45 mmBtu/hr

7. Refer to Avenal Energy Project PFDs for a schematic representation of the above streams.

8. The above heat and material balance is an estimate and not a guarantee. All values are subject to change pending detailed design development.

D:\My Documents\Archives\Avenal\Process\Cycle Design\Avenal H&MB RevB

Client: Federal Power King's County, LLC Contract : A3DV

Location: Avenal, CA Revision : B

Project: Avenal Energy Project Date : 11-Jul-07

Equipment: 2 x GE7FA x 2 Fired HRSGs x 1 RH STG By: G. Wadman

Unit 1 Checked:

Approved:

Heat and Material Balance

Table 2.6-3

HEAT AND MATERIAL BALANCE CASE: 101NGU2

AMBIENT CONDITIONS: 101 F Dry Bulb / 23% RH

CTG LOAD: 75%

STG STATUS: ON

DUCT BURNER STATUS: OFF

CTG CHILLER STATUS: OFF

Stream Flow, kpph Temp. Pressure Enthalpy

NOTES

No Description Per Train Unit Total F psia Btu/lbm

B1 HP Boiler Drum Continuous Blowdown 3.4 -- 537 936 532 Note 1

B2 IP Boiler Drum Continuous Blowdown 0.2 -- 415 293 392 Note 1

C1 Condensate from Condenser -- 930.1 125 77 93

C2 Condensate to Feed Water Preheater 551.0 -- 140 77 108

C3 Feed Water to LP Drum 500.7 -- 280 59 249

C4 Feed Water from LP Drum to HP/IP BFW Pump 452.0 -- 292 59 261

C5 IP Feed Water Pump Bleed 64.6 -- 293 520 262

C6 HP Feed Water Pump Discharge 387.4 -- 299 2,693 269

C7 HP Feed Water to HP Superheater Attemperator 0.0 -- 293 520 262

C8 IP Feed Water to Reheat Superheater Attemperator 5.0 -- 299 2,693 269

C9 IP BFW to GT Fuel Heating 35.6 403 293 378

C10 IP BFW from GT Fuel Heating 35.6 135 59 103

D1 Demineralized Water Makeup to Condenser -- 7.2 59 40 27

G1 Combustion Turbine Inlet Air 2,641.6 -- 101 14.51 --

G2 Combustion Turbine Chilled Inlet Air 2,641.6 -- 101 14.40 --

G3 Combustion Turbine Exhaust 2,697.4 -- 1,192 14.84 --

G4 HRSG Exhaust Flow after Duct Burners 2,697.4 -- 1,014 14.78 --

G5 HRSG Stack Exit 2,697.4 -- 189 14.51 --

F1 Natural Gas to Combustion Turbine 55.8 -- 60 365 --

F2 Heated Natural Gas to Combustion Turbine 55.8 -- 365 360 --

F3 Natural Gas to Duct Burner 0.0 -- 60 365 --

S1 HRSG HP Superheater Exit 384.0 -- 1,055 904 1,540

S2 HRSG Hot Reheater Exit 407.5 -- 1,048 265 1,553

S3 HRSG IP Superheater Exit 23.7 -- 595 281 1,313

S4 HRSG LP Superheater Exit 48.7 -- 500 57 1,284

S5 Cold Reheat to HRSG from STG / HP Letdown 378.8 -- 756 281 1,399

S6 Mixed RH Steam into HRSG Reheater 402.5 -- 746 281 1,394

S7 HP STG Throttle Steam -- 768.0 1,050 870 1,538

S8 STG HP Exhaust as Cold Reheat -- 757.5 761 290 1,401

S9 Hot Reheat Steam into STG -- 815.0 1,042 251 1,550

S10 LP Superheated Steam into STG -- 97.5 491 52 1,280

S11 STG LP Exhaust Steam to Condenser -- 921.2 122 1.81 1,099

W1 Condensate from GT Chiller Coil 0.0 -- -- -- --

W2 Cold Closed Loop CW -- 4,060.0 126 90 -- Note 6

W3 Hot Closed Loop CW -- 4,060.0 139 80 -- Note 6

Performance Summary Units Per Train Per Unit NOTES

CTG Natural Gas Heat Input (LHV) MMBtu/hr 1,154 2,308

HRSG Duct Burner Heat Input (LHV) MMBtu/hr 0.0 0.0

Gas Turbine Gross Output kW 107,183 214,366

Steam Turbine Gross Output kW -- 141,494

Gross Power Output kW -- 355,860

Gross Plant Heat Rate (LHV) Btu / kWh -- 6,485

Gross Plant Heat Rate (HHV) Btu / kWh -- 7,191

Total Auxiliary Loads + TXFR Loss kW -- 13,104

Net Power kW -- 342,756

Net Plant Heat Rate (LHV) Btu / kWh -- 6,733

Net Plant Heat Rate (HHV) Btu / kWh -- 7,466

Notes:

1. HRSG HP Blowdown is 1% and is cascaded from HP to IP Drum and IP Blowdown is 1% from IP Drum to Boiler Blowdown Tank (These are included as losses in the mass balance)

2. CTG data based on GTMaster model for GE 7421FA.

3. HRSG data based on GTMaster model.

4. STG data based on GTMaster model with assumed 26 inch last stage blade length in LP turbine.

5. Fuel gas heating value based on 20,694 Btu/lbm-LHV (48,134 kJ/kg-LHV) and 22,945 Btu/lbm-HHV (53,370 kJ/kg-HHV) referenced to 77 F (25C)

6. Assumed Closed Cooling Water Duty: 45 mmBtu/hr

7. Refer to Avenal Energy Project PFDs for a schematic representation of the above streams.

8. The above heat and material balance is an estimate and not a guarantee. All values are subject to change pending detailed design development.

D:\My Documents\Archives\Avenal\Process\Cycle Design\Avenal H&MB RevB

Client: Federal Power King's County, LLC Contract : A3DV

Location: Avenal, CA Revision : B

Project: Avenal Energy Project Date : 11-Jul-07

Equipment: 2 x GE7FA x 2 Fired HRSGs x 1 RH STG By: G. Wadman

Unit 1 Checked:

Approved:

Heat and Material Balance

Table 2.6-4

HEAT AND MATERIAL BALANCE CASE: 101NGU3

AMBIENT CONDITIONS: 101 F Dry Bulb / 23% RH

CTG LOAD: 50%

STG STATUS: ON

DUCT BURNER STATUS: OFF

CTG CHILLER STATUS: OFF

Stream Flow, kpph Temp. Pressure Enthalpy

NOTES

No Description Per Train Unit Total F psia Btu/lbm

B1 HP Boiler Drum Continuous Blowdown 2.7 -- 523 834 516 Note 1

B2 IP Boiler Drum Continuous Blowdown 0.2 -- 400 248 376 Note 1

C1 Condensate from Condenser -- 780.5 122 62 90

C2 Condensate to Feed Water Preheater 475.6 -- 140 62 108

C3 Feed Water to LP Drum 419.6 -- 267 49 236

C4 Feed Water from LP Drum to HP/IP BFW Pump 380.9 -- 280 49 249

C5 IP Feed Water Pump Bleed 50.6 -- 281 516 250

C6 HP Feed Water Pump Discharge 330.2 -- 289 2,701 258

C7 HP Feed Water to HP Superheater Attemperator 0.0 -- 281 516 250

C8 IP Feed Water to Reheat Superheater Attemperator 0.0 -- 289 2,701 258

C9 IP BFW to GT Fuel Heating 29.4 390 248 364

C10 IP BFW from GT Fuel Heating 29.4 135 49 103

D1 Demineralized Water Makeup to Condenser -- 5.9 59 40 27

G1 Combustion Turbine Inlet Air 2,189.1 -- 101 14.51 --

G2 Combustion Turbine Chilled Inlet Air 2,189.1 -- 101 14.43 --

G3 Combustion Turbine Exhaust 2,232.7 -- 1,200 14.74 --

G4 HRSG Exhaust Flow after Duct Burners 2,232.7 -- 1,008 14.69 --

G5 HRSG Stack Exit 2,232.7 -- 180 14.51 --

F1 Natural Gas to Combustion Turbine 43.6 -- 60 365 --

F2 Heated Natural Gas to Combustion Turbine 43.6 -- 365 360 --

F3 Natural Gas to Duct Burner 0.0 -- 60 365 --

S1 HRSG HP Superheater Exit 327.5 -- 1,055 809 1,542

S2 HRSG Hot Reheater Exit 343.9 -- 1,039 223 1,549

S3 HRSG IP Superheater Exit 21.0 -- 586 237 1,312

S4 HRSG LP Superheater Exit 38.7 -- 491 47 1,280

S5 Cold Reheat to HRSG from STG / HP Letdown 322.9 -- 753 238 1,400

S6 Mixed RH Steam into HRSG Reheater 343.9 -- 743 238 1,394

S7 HP STG Throttle Steam -- 655.1 1,051 780 1,541

S8 STG HP Exhaust as Cold Reheat -- 645.8 759 245 1,402

S9 Hot Reheat Steam into STG -- 687.8 1,032 212 1,546

S10 LP Superheated Steam into STG -- 77.5 482 44 1,276

S11 STG LP Exhaust Steam to Condenser -- 773.1 119 1.65 1,101

W1 Condensate from GT Chiller Coil 0.0 -- -- -- --

W2 Cold Closed Loop CW -- 4,060.0 126 90 -- Note 6

W3 Hot Closed Loop CW -- 4,060.0 139 80 -- Note 6

Performance Summary Units Per Train Per Unit NOTES

CTG Natural Gas Heat Input (LHV) MMBtu/hr 903 1,806

HRSG Duct Burner Heat Input (LHV) MMBtu/hr 0.0 0.0

Gas Turbine Gross Output kW 72,058 144,116

Steam Turbine Gross Output kW -- 118,339

Gross Power Output kW -- 262,455

Gross Plant Heat Rate (LHV) Btu / kWh -- 6,881

Gross Plant Heat Rate (HHV) Btu / kWh -- 7,629

Total Auxiliary Loads + TXFR Loss kW -- 12,165

Net Power kW -- 250,290

Net Plant Heat Rate (LHV) Btu / kWh -- 7,215

Net Plant Heat Rate (HHV) Btu / kWh -- 8,000

Notes:

1. HRSG HP Blowdown is 1% and is cascaded from HP to IP Drum and IP Blowdown is 1% from IP Drum to Boiler Blowdown Tank (These are included as losses in the mass balance)

2. CTG data based on GTMaster model for GE 7421FA.

3. HRSG data based on GTMaster model.

4. STG data based on GTMaster model with assumed 26 inch last stage blade length in LP turbine.

5. Fuel gas heating value based on 20,694 Btu/lbm-LHV (48,134 kJ/kg-LHV) and 22,945 Btu/lbm-HHV (53,370 kJ/kg-HHV) referenced to 77 F (25C)

6. Assumed Closed Cooling Water Duty: 45 mmBtu/hr

7. Refer to Avenal Energy Project PFDs for a schematic representation of the above streams.

8. The above heat and material balance is an estimate and not a guarantee. All values are subject to change pending detailed design development.

D:\My Documents\Archives\Avenal\Process\Cycle Design\Avenal H&MB RevB

Client: Federal Power King's County, LLC Contract : A3DV

Location: Avenal, CA Revision : B

Project: Avenal Energy Project Date : 11-Jul-07

Equipment: 2 x GE7FA x 2 Fired HRSGs x 1 RH STG By: G. Wadman

Unit 1 Checked:

Approved:

Heat and Material Balance

Table 2.6-5

HEAT AND MATERIAL BALANCE CASE: 63NGF1

AMBIENT CONDITIONS: 63 F Dry Bulb / 53% RH

CTG LOAD: 100%

STG STATUS: ON

DUCT BURNER STATUS: ON

CTG CHILLER STATUS: ON

Stream Flow, kpph Temp. Pressure Enthalpy

NOTES

No Description Per Train Unit Total F psia Btu/lbm

B1 HP Boiler Drum Continuous Blowdown 7.5 -- 622 1,816 650 Note 1

B2 IP Boiler Drum Continuous Blowdown 0.1 -- 472 525 455 Note 1

C1 Condensate from Condenser -- 1,637.1 105 153 73

C2 Condensate to Feed Water Preheater 1,075.3 -- 140 153 108

C3 Feed Water to LP Drum 858.5 -- 274 93 243

C4 Feed Water from LP Drum to HP/IP BFW Pump 825.4 -- 323 93 294

C5 IP Feed Water Pump Bleed 58.9 -- 324 564 295

C6 HP Feed Water Pump Discharge 766.5 -- 328 2,463 299

C7 HP Feed Water to HP Superheater Attemperator 0.0 -- 324 564 295

C8 IP Feed Water to Reheat Superheater Attemperator 12.8 -- 328 2,463 299

C9 IP BFW to GT Fuel Heating 40.0 465 525 447

C10 IP BFW from GT Fuel Heating 40.0 135 93 103

D1 Demineralized Water Makeup to Condenser -- 15.1 59 40 27

G1 Combustion Turbine Inlet Air 3,552.0 -- 63 14.51 --

G2 Combustion Turbine Chilled Inlet Air 3,552.0 -- 48 14.37 --

G3 Combustion Turbine Exhaust 3,630.0 -- 1,119 15.10 --

G4 HRSG Exhaust Flow after Duct Burners 3,650.0 -- 1,409 15.03 --

G5 HRSG Stack Exit 3,650.0 -- 185 14.51 --

F1 Natural Gas to Combustion Turbine 78.2 -- 60 365 --

F2 Heated Natural Gas to Combustion Turbine 78.2 -- 365 360 --

F3 Natural Gas to Duct Burner 19.8 -- 60 365 --

S1 HRSG HP Superheater Exit 759.0 -- 1,055 1,749 1,517

S2 HRSG Hot Reheater Exit 767.7 -- 1,048 496 1,547

S3 HRSG IP Superheater Exit 6.2 -- 954 524 1,495

S4 HRSG LP Superheater Exit 33.1 -- 565 93 1,312

S5 Cold Reheat to HRSG from STG / HP Letdown 748.8 -- 735 524 1,375

S6 Mixed RH Steam into HRSG Reheater 754.9 -- 737 524 1,376

S7 HP STG Throttle Steam -- 1,517.9 1,049 1,681 1,515

S8 STG HP Exhaust as Cold Reheat -- 1,497.5 741 542 1,378

S9 Hot Reheat Steam into STG -- 1,535.4 1,042 470 1,544

S10 LP Superheated Steam into STG -- 66.3 556 91 1,308

S11 STG LP Exhaust Steam to Condenser -- 1,619.0 103 1.04 1,074

W1 Condensate from GT Chiller Coil 0.0 -- -- -- --

W2 Cold Closed Loop CW -- 4,060.0 88 90 -- Note 6

W3 Hot Closed Loop CW -- 4,060.0 101 80 -- Note 6

Performance Summary Units Per Train Per Unit NOTES

CTG Natural Gas Heat Input (LHV) MMBtu/hr 1,618 3,236

HRSG Duct Burner Heat Input (LHV) MMBtu/hr 409.7 819.4

Gas Turbine Gross Output kW 172,486 344,972

Steam Turbine Gross Output kW -- 273,325

Gross Power Output kW -- 618,297

Gross Plant Heat Rate (LHV) Btu / kWh -- 6,559

Gross Plant Heat Rate (HHV) Btu / kWh -- 7,272

Total Auxiliary Loads + TXFR Loss kW -- 18,276

Net Power kW -- 600,021

Net Plant Heat Rate (LHV) Btu / kWh -- 6,758

Net Plant Heat Rate (HHV) Btu / kWh -- 7,494

Notes:

1. HRSG HP Blowdown is 1% and is cascaded from HP to IP Drum and IP Blowdown is 1% from IP Drum to Boiler Blowdown Tank (These are included as losses in the mass balance)

2. CTG data based on GTMaster model for GE 7421FA.

3. HRSG data based on GTMaster model.

4. STG data based on GTMaster model with assumed 26 inch last stage blade length in LP turbine.

5. Fuel gas heating value based on 20,694 Btu/lbm-LHV (48,134 kJ/kg-LHV) and 22,945 Btu/lbm-HHV (53,370 kJ/kg-HHV) referenced to 77 F (25C)

6. Assumed Closed Cooling Water Duty: 45 mmBtu/hr

7. Refer to Avenal Energy Project PFDs for a schematic representation of the above streams.

8. The above heat and material balance is an estimate and not a guarantee. All values are subject to change pending detailed design development.

D:\My Documents\Archives\Avenal\Process\Cycle Design\Avenal H&MB RevB

Client: Federal Power King's County, LLC Contract : A3DV

Location: Avenal, CA Revision : B

Project: Avenal Energy Project Date : 11-Jul-07

Equipment: 2 x GE7FA x 2 Fired HRSGs x 1 RH STG By: G. Wadman

Unit 1 Checked:

Approved:

Heat and Material Balance

Table 2.6-6

HEAT AND MATERIAL BALANCE CASE: 63NGU1

AMBIENT CONDITIONS: 63 F Dry Bulb / 53% RH

CTG LOAD: 100%

STG STATUS: ON

DUCT BURNER STATUS: OFF

CTG CHILLER STATUS: ON

Stream Flow, kpph Temp. Pressure Enthalpy

NOTES

No Description Per Train Unit Total F psia Btu/lbm

B1 HP Boiler Drum Continuous Blowdown 4.6 -- 559 1,124 561 Note 1

B2 IP Boiler Drum Continuous Blowdown 0.3 -- 433 353 411 Note 1

C1 Condensate from Condenser -- 1,130.3 106 104 74

C2 Condensate to Feed Water Preheater 740.5 -- 140 104 108

C3 Feed Water to LP Drum 612.5 -- 292 59 261

C4 Feed Water from LP Drum to HP/IP BFW Pump 545.5 -- 307 74 277

C5 IP Feed Water Pump Bleed 80.1 -- 308 506 277

C6 HP Feed Water Pump Discharge 465.4 -- 314 2,676 284

C7 HP Feed Water to HP Superheater Attemperator 0.0 -- 308 506 277

C8 IP Feed Water to Reheat Superheater Attemperator 0.0 -- 314 2,676 284

C9 IP BFW to GT Fuel Heating 47.4 417 353 394

C10 IP BFW from GT Fuel Heating 47.4 135 74 103

D1 Demineralized Water Makeup to Condenser -- 9.9 59 40 27

G1 Combustion Turbine Inlet Air 3,552.0 -- 63 14.51 --

G2 Combustion Turbine Chilled Inlet Air 3,552.0 -- 48 14.37 --

G3 Combustion Turbine Exhaust 3,630.0 -- 1,119 15.06 --

G4 HRSG Exhaust Flow after Duct Burners 3,630.0 -- 1,025 14.99 --

G5 HRSG Stack Exit 3,630.0 -- 199 14.51 --

F1 Natural Gas to Combustion Turbine 78.2 -- 60 365 --

F2 Heated Natural Gas to Combustion Turbine 78.2 -- 365 360 --

F3 Natural Gas to Duct Burner 0.0 -- 60 365 --

S1 HRSG HP Superheater Exit 460.8 -- 1,054 1,081 1,535

S2 HRSG Hot Reheater Exit 486.9 -- 1,048 316 1,552

S3 HRSG IP Superheater Exit 32.3 -- 597 336 1,310

S4 HRSG LP Superheater Exit 67.0 -- 516 71 1,290

S5 Cold Reheat to HRSG from STG / HP Letdown 454.6 -- 753 336 1,395

S6 Mixed RH Steam into HRSG Reheater 486.9 -- 742 336 1,389

S7 HP STG Throttle Steam -- 921.7 1,049 1,039 1,533

S8 STG HP Exhaust as Cold Reheat -- 909.1 758 346 1,397

S9 Hot Reheat Steam into STG -- 973.7 1,041 300 1,548

S10 LP Superheated Steam into STG -- 134.1 506 63 1,286

S11 STG LP Exhaust Steam to Condenser -- 1,118.3 103 1.05 1,080

W1 Condensate from GT Chiller Coil 0.0 -- -- -- --

W2 Cold Closed Loop CW -- 4,060.0 88 90 -- Note 6

W3 Hot Closed Loop CW -- 4,060.0 101 80 -- Note 6

Performance Summary Units Per Train Per Unit NOTES

CTG Natural Gas Heat Input (LHV) MMBtu/hr 1,619 3,238

HRSG Duct Burner Heat Input (LHV) MMBtu/hr 0.0 0.0

Gas Turbine Gross Output kW 172,791 345,582

Steam Turbine Gross Output kW -- 176,074

Gross Power Output kW -- 521,656

Gross Plant Heat Rate (LHV) Btu / kWh -- 6,207

Gross Plant Heat Rate (HHV) Btu / kWh -- 6,882

Total Auxiliary Loads + TXFR Loss kW -- 15,171

Net Power kW -- 506,485

Net Plant Heat Rate (LHV) Btu / kWh -- 6,393

Net Plant Heat Rate (HHV) Btu / kWh -- 7,088

Notes:

1. HRSG HP Blowdown is 1% and is cascaded from HP to IP Drum and IP Blowdown is 1% from IP Drum to Boiler Blowdown Tank (These are included as losses in the mass balance)

2. CTG data based on GTMaster model for GE 7421FA.

3. HRSG data based on GTMaster model.

4. STG data based on GTMaster model with assumed 26 inch last stage blade length in LP turbine.

5. Fuel gas heating value based on 20,694 Btu/lbm-LHV (48,134 kJ/kg-LHV) and 22,945 Btu/lbm-HHV (53,370 kJ/kg-HHV) referenced to 77 F (25C)

6. Assumed Closed Cooling Water Duty: 45 mmBtu/hr

7. Refer to Avenal Energy Project PFDs for a schematic representation of the above streams.

8. The above heat and material balance is an estimate and not a guarantee. All values are subject to change pending detailed design development.

D:\My Documents\Archives\Avenal\Process\Cycle Design\Avenal H&MB RevB

Client: Federal Power King's County, LLC Contract : A3DV

Location: Avenal, CA Revision : B

Project: Avenal Energy Project Date : 11-Jul-07

Equipment: 2 x GE7FA x 2 Fired HRSGs x 1 RH STG By: G. Wadman

Unit 1 Checked:

Approved:

Heat and Material Balance

Table 2.6-7

HEAT AND MATERIAL BALANCE CASE: 63NGU2

AMBIENT CONDITIONS: 63 F Dry Bulb / 53% RH

CTG LOAD: 75%

STG STATUS: ON

DUCT BURNER STATUS: OFF

CTG CHILLER STATUS: OFF

Stream Flow, kpph Temp. Pressure Enthalpy

NOTES

No Description Per Train Unit Total F psia Btu/lbm

B1 HP Boiler Drum Continuous Blowdown 3.6 -- 542 976 539 Note 1

B2 IP Boiler Drum Continuous Blowdown 0.3 -- 419 306 396 Note 1

C1 Condensate from Condenser -- 968.5 105 85 73

C2 Condensate to Feed Water Preheater 648.0 -- 140 85 108

C3 Feed Water to LP Drum 523.5 -- 276 61 245

C4 Feed Water from LP Drum to HP/IP BFW Pump 473.6 -- 294 61 264

C5 IP Feed Water Pump Bleed 69.8 -- 295 514 265

C6 HP Feed Water Pump Discharge 403.8 -- 302 2,689 271

C7 HP Feed Water to HP Superheater Attemperator 0.0 -- 295 514 265

C8 IP Feed Water to Reheat Superheater Attemperator 4.7 -- 302 2,689 271

C9 IP BFW to GT Fuel Heating 39.3 405 306 381

C10 IP BFW from GT Fuel Heating 39.3 135 61 103

D1 Demineralized Water Makeup to Condenser -- 7.8 59 40 27

G1 Combustion Turbine Inlet Air 2,849.4 -- 63 14.51 --

G2 Combustion Turbine Chilled Inlet Air 2,849.4 -- 63 14.40 --

G3 Combustion Turbine Exhaust 2,911.5 -- 1,170 14.88 --

G4 HRSG Exhaust Flow after Duct Burners 2,911.5 -- 1,017 14.82 --

G5 HRSG Stack Exit 2,911.5 -- 186 14.51 --

F1 Natural Gas to Combustion Turbine 62.1 -- 60 365 --

F2 Heated Natural Gas to Combustion Turbine 62.1 -- 365 360 --

F3 Natural Gas to Duct Burner 0.0 -- 60 365 --

S1 HRSG HP Superheater Exit 400.2 -- 1,055 942 1,539

S2 HRSG Hot Reheater Exit 425.0 -- 1,048 276 1,553

S3 HRSG IP Superheater Exit 25.5 -- 595 293 1,313

S4 HRSG LP Superheater Exit 49.9 -- 506 59 1,286

S5 Cold Reheat to HRSG from STG / HP Letdown 394.8 -- 755 293 1,398

S6 Mixed RH Steam into HRSG Reheater 420.3 -- 745 293 1,393

S7 HP STG Throttle Steam -- 800.4 1,050 906 1,537

S8 STG HP Exhaust as Cold Reheat -- 789.5 761 302 1,401

S9 Hot Reheat Steam into STG -- 850.0 1,042 262 1,550

S10 LP Superheated Steam into STG -- 99.7 497 54 1,282

S11 STG LP Exhaust Steam to Condenser -- 958.9 103 1.03 1,082

W1 Condensate from GT Chiller Coil 0.0 -- -- -- --

W2 Cold Closed Loop CW -- 4,060.0 88 90 -- Note 6

W3 Hot Closed Loop CW -- 4,060.0 101 80 -- Note 6

Performance Summary Units Per Train Per Unit NOTES

CTG Natural Gas Heat Input (LHV) MMBtu/hr 1,285 2,569

HRSG Duct Burner Heat Input (LHV) MMBtu/hr 0.0 0.0

Gas Turbine Gross Output kW 125,277 250,554

Steam Turbine Gross Output kW -- 152,281

Gross Power Output kW -- 402,835

Gross Plant Heat Rate (LHV) Btu / kWh -- 6,378

Gross Plant Heat Rate (HHV) Btu / kWh -- 7,072

Total Auxiliary Loads + TXFR Loss kW -- 11,377

Net Power kW -- 391,458

Net Plant Heat Rate (LHV) Btu / kWh -- 6,563

Net Plant Heat Rate (HHV) Btu / kWh -- 7,277

Notes:

1. HRSG HP Blowdown is 1% and is cascaded from HP to IP Drum and IP Blowdown is 1% from IP Drum to Boiler Blowdown Tank (These are included as losses in the mass balance)

2. CTG data based on GTMaster model for GE 7421FA.

3. HRSG data based on GTMaster model.

4. STG data based on GTMaster model with assumed 26 inch last stage blade length in LP turbine.

5. Fuel gas heating value based on 20,694 Btu/lbm-LHV (48,134 kJ/kg-LHV) and 22,945 Btu/lbm-HHV (53,370 kJ/kg-HHV) referenced to 77 F (25C)

6. Assumed Closed Cooling Water Duty: 45 mmBtu/hr

7. Refer to Avenal Energy Project PFDs for a schematic representation of the above streams.

8. The above heat and material balance is an estimate and not a guarantee. All values are subject to change pending detailed design development.

D:\My Documents\Archives\Avenal\Process\Cycle Design\Avenal H&MB RevB

Client: Federal Power King's County, LLC Contract : A3DV

Location: Avenal, CA Revision : B

Project: Avenal Energy Project Date : 11-Jul-07

Equipment: 2 x GE7FA x 2 Fired HRSGs x 1 RH STG By: G. Wadman

Unit 1 Checked:

Approved:

Heat and Material Balance

Table 2.6-8

HEAT AND MATERIAL BALANCE CASE: 63NGU3

AMBIENT CONDITIONS: 63 F Dry Bulb / 53% RH

CTG LOAD: 50%

STG STATUS: ON

DUCT BURNER STATUS: OFF

CTG CHILLER STATUS: OFF

Stream Flow, kpph Temp. Pressure Enthalpy

NOTES

No Description Per Train Unit Total F psia Btu/lbm

B1 HP Boiler Drum Continuous Blowdown 2.9 -- 524 839 516 Note 1

B2 IP Boiler Drum Continuous Blowdown 0.2 -- 404 258 379 Note 1

C1 Condensate from Condenser -- 808.2 106 68 74

C2 Condensate to Feed Water Preheater 550.0 -- 140 68 108

C3 Feed Water to LP Drum 436.2 -- 262 50 231

C4 Feed Water from LP Drum to HP/IP BFW Pump 398.4 -- 281 50 250

C5 IP Feed Water Pump Bleed 53.1 -- 282 516 252

C6 HP Feed Water Pump Discharge 345.3 -- 290 2,699 259

C7 HP Feed Water to HP Superheater Attemperator 0.0 -- 282 516 252

C8 IP Feed Water to Reheat Superheater Attemperator 0.0 -- 290 2,699 259

C9 IP BFW to GT Fuel Heating 32.1 392 258 366

C10 IP BFW from GT Fuel Heating 32.1 135 50 103

D1 Demineralized Water Makeup to Condenser -- 6.2 59 40 27

G1 Combustion Turbine Inlet Air 2,288.7 -- 63 14.51 --

G2 Combustion Turbine Chilled Inlet Air 2,288.7 -- 63 14.43 --

G3 Combustion Turbine Exhaust 2,336.8 -- 1,200 14.76 --

G4 HRSG Exhaust Flow after Duct Burners 2,336.8 -- 1,012 14.71 --

G5 HRSG Stack Exit 2,336.8 -- 176 14.51 --

F1 Natural Gas to Combustion Turbine 48.1 -- 60 365 --

F2 Heated Natural Gas to Combustion Turbine 48.1 -- 365 360 --

F3 Natural Gas to Duct Burner 0.0 -- 60 365 --

S1 HRSG HP Superheater Exit 342.4 -- 1,055 811 1,542

S2 HRSG Hot Reheater Exit 358.5 -- 1,042 233 1,551

S3 HRSG IP Superheater Exit 20.8 -- 591 248 1,314

S4 HRSG LP Superheater Exit 37.8 -- 493 49 1,281

S5 Cold Reheat to HRSG from STG / HP Letdown 337.7 -- 754 248 1,399

S6 Mixed RH Steam into HRSG Reheater 358.5 -- 744 248 1,394

S7 HP STG Throttle Steam -- 684.8 1,050 780 1,541

S8 STG HP Exhaust as Cold Reheat -- 675.4 759 255 1,402

S9 Hot Reheat Steam into STG -- 717.1 1,036 221 1,548

S10 LP Superheated Steam into STG -- 75.5 485 45 1,277

S11 STG LP Exhaust Steam to Condenser -- 800.5 103 1.04 1,084

W1 Condensate from GT Chiller Coil 0.0 -- -- -- --

W2 Cold Closed Loop CW -- 4,060.0 88 90 -- Note 6

W3 Hot Closed Loop CW -- 4,060.0 101 80 -- Note 6

Performance Summary Units Per Train Per Unit NOTES

CTG Natural Gas Heat Input (LHV) MMBtu/hr 996 1,992

HRSG Duct Burner Heat Input (LHV) MMBtu/hr 0.0 0.0

Gas Turbine Gross Output kW 84,286 168,572

Steam Turbine Gross Output kW -- 127,583

Gross Power Output kW -- 296,155

Gross Plant Heat Rate (LHV) Btu / kWh -- 6,725

Gross Plant Heat Rate (HHV) Btu / kWh -- 7,456

Total Auxiliary Loads + TXFR Loss kW -- 9,873

Net Power kW -- 286,282

Net Plant Heat Rate (LHV) Btu / kWh -- 6,957

Net Plant Heat Rate (HHV) Btu / kWh -- 7,713

Notes:

1. HRSG HP Blowdown is 1% and is cascaded from HP to IP Drum and IP Blowdown is 1% from IP Drum to Boiler Blowdown Tank (These are included as losses in the mass balance)

2. CTG data based on GTMaster model for GE 7421FA.

3. HRSG data based on GTMaster model.

4. STG data based on GTMaster model with assumed 26 inch last stage blade length in LP turbine.

5. Fuel gas heating value based on 20,694 Btu/lbm-LHV (48,134 kJ/kg-LHV) and 22,945 Btu/lbm-HHV (53,370 kJ/kg-HHV) referenced to 77 F (25C)

6. Assumed Closed Cooling Water Duty: 45 mmBtu/hr

7. Refer to Avenal Energy Project PFDs for a schematic representation of the above streams.

8. The above heat and material balance is an estimate and not a guarantee. All values are subject to change pending detailed design development.

D:\My Documents\Archives\Avenal\Process\Cycle Design\Avenal H&MB RevB

Client: Federal Power King's County, LLC Contract : A3DV

Location: Avenal, CA Revision : B

Project: Avenal Energy Project Date : 11-Jul-07

Equipment: 2 x GE7FA x 2 Fired HRSGs x 1 RH STG By: G. Wadman

Unit 1 Checked:

Approved:

Heat and Material Balance

Table 2.6-9

HEAT AND MATERIAL BALANCE CASE: 32NGF1

AMBIENT CONDITIONS: 32 F Dry Bulb / 79% RH

CTG LOAD: 100%

STG STATUS: ON

DUCT BURNER STATUS: ON

CTG CHILLER STATUS: OFF

Stream Flow, kpph Temp. Pressure Enthalpy

NOTES

No Description Per Train Unit Total F psia Btu/lbm

B1 HP Boiler Drum Continuous Blowdown 7.0 -- 612 1,685 634 Note 1

B2 IP Boiler Drum Continuous Blowdown 0.1 -- 465 489 447 Note 1

C1 Condensate from Condenser -- 1,542.9 105 143 73

C2 Condensate to Feed Water Preheater 1,009.9 -- 140 143 108

C3 Feed Water to LP Drum 814.2 -- 280 90 249

C4 Feed Water from LP Drum to HP/IP BFW Pump 769.5 -- 320 90 291

C5 IP Feed Water Pump Bleed 60.7 -- 322 554 292

C6 HP Feed Water Pump Discharge 708.8 -- 326 2,528 296

C7 HP Feed Water to HP Superheater Attemperator 0.0 -- 322 554 292

C8 IP Feed Water to Reheat Superheater Attemperator 4.8 -- 326 2,528 296

C9 IP BFW to GT Fuel Heating 42.7 455 489 436

C10 IP BFW from GT Fuel Heating 42.7 135 90 103

D1 Demineralized Water Makeup to Condenser -- 14.3 59 40 27

G1 Combustion Turbine Inlet Air 3,662.0 -- 32 14.51 --

G2 Combustion Turbine Chilled Inlet Air 3,662.0 -- 32 14.37 --

G3 Combustion Turbine Exhaust 3,743.0 -- 1,108 15.12 --

G4 HRSG Exhaust Flow after Duct Burners 3,759.0 -- 1,324 15.05 --

G5 HRSG Stack Exit 3,759.0 -- 189 14.51 --

F1 Natural Gas to Combustion Turbine 80.9 -- 60 365 --

F2 Heated Natural Gas to Combustion Turbine 80.9 -- 365 360 --

F3 Natural Gas to Duct Burner 15.5 -- 60 365 --

S1 HRSG HP Superheater Exit 701.8 -- 1,054 1,621 1,520

S2 HRSG Hot Reheater Exit 710.2 -- 1,048 459 1,548

S3 HRSG IP Superheater Exit 13.1 -- 807 486 1,417

S4 HRSG LP Superheater Exit 44.7 -- 556 89 1,308

S5 Cold Reheat to HRSG from STG / HP Letdown 692.3 -- 736 486 1,378

S6 Mixed RH Steam into HRSG Reheater 705.4 -- 737 486 1,379

S7 HP STG Throttle Steam -- 1,403.5 1,048 1,558 1,518

S8 STG HP Exhaust as Cold Reheat -- 1,384.6 742 502 1,380

S9 Hot Reheat Steam into STG -- 1,420.4 1,042 436 1,545

S10 LP Superheated Steam into STG -- 89.4 548 86 1,304

S11 STG LP Exhaust Steam to Condenser -- 1,525.8 103 1.04 1,075

W1 Condensate from GT Chiller Coil 0.0 -- -- -- --

W2 Cold Closed Loop CW -- 4,060.0 57 90 -- Note 6

W3 Hot Closed Loop CW -- 4,060.0 70 80 -- Note 6

Performance Summary Units Per Train Per Unit NOTES

CTG Natural Gas Heat Input (LHV) MMBtu/hr 1,673 3,346

HRSG Duct Burner Heat Input (LHV) MMBtu/hr 321.3 642.6

Gas Turbine Gross Output kW 179,501 359,002

Steam Turbine Gross Output kW -- 254,690

Gross Power Output kW -- 613,692

Gross Plant Heat Rate (LHV) Btu / kWh -- 6,500

Gross Plant Heat Rate (HHV) Btu / kWh -- 7,207

Total Auxiliary Loads + TXFR Loss kW -- 13,684

Net Power kW -- 600,008

Net Plant Heat Rate (LHV) Btu / kWh -- 6,648

Net Plant Heat Rate (HHV) Btu / kWh -- 7,371

Notes:

1. HRSG HP Blowdown is 1% and is cascaded from HP to IP Drum and IP Blowdown is 1% from IP Drum to Boiler Blowdown Tank (These are included as losses in the mass balance)

2. CTG data based on GTMaster model for GE 7421FA.

3. HRSG data based on GTMaster model.

4. STG data based on GTMaster model with assumed 26 inch last stage blade length in LP turbine.

5. Fuel gas heating value based on 20,694 Btu/lbm-LHV (48,134 kJ/kg-LHV) and 22,945 Btu/lbm-HHV (53,370 kJ/kg-HHV) referenced to 77 F (25C)

6. Assumed Closed Cooling Water Duty: 45 mmBtu/hr

7. Refer to Avenal Energy Project PFDs for a schematic representation of the above streams.

8. The above heat and material balance is an estimate and not a guarantee. All values are subject to change pending detailed design development.

D:\My Documents\Archives\Avenal\Process\Cycle Design\Avenal H&MB RevB

Client: Federal Power King's County, LLC Contract : A3DV

Location: Avenal, CA Revision : B

Project: Avenal Energy Project Date : 11-Jul-07

Equipment: 2 x GE7FA x 2 Fired HRSGs x 1 RH STG By: G. Wadman

Unit 1 Checked:

Approved:

Heat and Material Balance

Table 2.6-10

HEAT AND MATERIAL BALANCE CASE: 32NGU1

AMBIENT CONDITIONS: 32 F Dry Bulb / 79% RH

CTG LOAD: 100%

STG STATUS: ON

DUCT BURNER STATUS: OFF

CTG CHILLER STATUS: OFF

Stream Flow, kpph Temp. Pressure Enthalpy

NOTES

No Description Per Train Unit Total F psia Btu/lbm

B1 HP Boiler Drum Continuous Blowdown 4.7 -- 560 1,132 562 Note 1

B2 IP Boiler Drum Continuous Blowdown 0.3 -- 434 358 412 Note 1

C1 Condensate from Condenser -- 1,150.1 107 106 75

C2 Condensate to Feed Water Preheater 749.5 -- 140 106 108

C3 Feed Water to LP Drum 623.9 -- 294 76 264

C4 Feed Water from LP Drum to HP/IP BFW Pump 553.8 -- 308 76 278

C5 IP Feed Water Pump Bleed 83.3 -- 309 501 279

C6 HP Feed Water Pump Discharge 470.6 -- 315 2,676 285

C7 HP Feed Water to HP Superheater Attemperator 0.0 -- 309 501 279

C8 IP Feed Water to Reheat Superheater Attemperator 0.0 -- 315 2,676 285

C9 IP BFW to GT Fuel Heating 48.8 418 358 394

C10 IP BFW from GT Fuel Heating 48.8 135 76 103

D1 Demineralized Water Makeup to Condenser -- 10.0 59 40 27

G1 Combustion Turbine Inlet Air 3,662.0 -- 32 14.51 --

G2 Combustion Turbine Chilled Inlet Air 3,662.0 -- 32 14.37 --

G3 Combustion Turbine Exhaust 3,743.0 -- 1,108 15.09 --

G4 HRSG Exhaust Flow after Duct Burners 3,743.0 -- 1,017 15.02 --

G5 HRSG Stack Exit 3,743.0 -- 201 14.51 --

F1 Natural Gas to Combustion Turbine 80.9 -- 60 365 --

F2 Heated Natural Gas to Combustion Turbine 80.9 -- 365 360 --

F3 Natural Gas to Duct Burner 0.0 -- 60 365 --

S1 HRSG HP Superheater Exit 465.9 -- 1,043 1,089 1,528

S2 HRSG Hot Reheater Exit 493.6 -- 1,038 320 1,546

S3 HRSG IP Superheater Exit 34.1 -- 592 339 1,307

S4 HRSG LP Superheater Exit 70.1 -- 516 72 1,290

S5 Cold Reheat to HRSG from STG / HP Letdown 459.6 -- 744 339 1,390

S6 Mixed RH Steam into HRSG Reheater 493.6 -- 733 339 1,384

S7 HP STG Throttle Steam -- 931.8 1,039 1,047 1,527

S8 STG HP Exhaust as Cold Reheat -- 919.1 749 349 1,392

S9 Hot Reheat Steam into STG -- 987.3 1,031 303 1,543

S10 LP Superheated Steam into STG -- 140.2 507 64 1,286

S11 STG LP Exhaust Steam to Condenser -- 1,138.1 104 1.07 1,077

W1 Condensate from GT Chiller Coil 0.0 -- -- -- --

W2 Cold Closed Loop CW -- 4,060.0 57 90 -- Note 6

W3 Hot Closed Loop CW -- 4,060.0 70 80 -- Note 6

Performance Summary Units Per Train Per Unit NOTES

CTG Natural Gas Heat Input (LHV) MMBtu/hr 1,674 3,348

HRSG Duct Burner Heat Input (LHV) MMBtu/hr 0.0 0.0

Gas Turbine Gross Output kW 179,753 359,506

Steam Turbine Gross Output kW -- 177,672

Gross Power Output kW -- 537,178

Gross Plant Heat Rate (LHV) Btu / kWh -- 6,232

Gross Plant Heat Rate (HHV) Btu / kWh -- 6,910

Total Auxiliary Loads + TXFR Loss kW -- 11,689

Net Power kW -- 525,489

Net Plant Heat Rate (LHV) Btu / kWh -- 6,371

Net Plant Heat Rate (HHV) Btu / kWh -- 7,064

Notes:

1. HRSG HP Blowdown is 1% and is cascaded from HP to IP Drum and IP Blowdown is 1% from IP Drum to Boiler Blowdown Tank (These are included as losses in the mass balance)

2. CTG data based on GTMaster model for GE 7421FA.

3. HRSG data based on GTMaster model.

4. STG data based on GTMaster model with assumed 26 inch last stage blade length in LP turbine.

5. Fuel gas heating value based on 20,694 Btu/lbm-LHV (48,134 kJ/kg-LHV) and 22,945 Btu/lbm-HHV (53,370 kJ/kg-HHV) referenced to 77 F (25C)

6. Assumed Closed Cooling Water Duty: 45 mmBtu/hr

7. Refer to Avenal Energy Project PFDs for a schematic representation of the above streams.

8. The above heat and material balance is an estimate and not a guarantee. All values are subject to change pending detailed design development.

D:\My Documents\Archives\Avenal\Process\Cycle Design\Avenal H&MB RevB

Client: Federal Power King's County, LLC Contract : A3DV

Location: Avenal, CA Revision : B

Project: Avenal Energy Project Date : 11-Jul-07

Equipment: 2 x GE7FA x 2 Fired HRSGs x 1 RH STG By: G. Wadman

Unit 1 Checked:

Approved:

Heat and Material Balance

Table 2.6-11

HEAT AND MATERIAL BALANCE CASE: 32NGU2

AMBIENT CONDITIONS: 32 F Dry Bulb / 79% RH

CTG LOAD: 75%

STG STATUS: ON

DUCT BURNER STATUS: OFF

CTG CHILLER STATUS: OFF

Stream Flow, kpph Temp. Pressure Enthalpy

NOTES

No Description Per Train Unit Total F psia Btu/lbm

B1 HP Boiler Drum Continuous Blowdown 3.8 -- 545 1,001 543 Note 1

B2 IP Boiler Drum Continuous Blowdown 0.3 -- 421 313 398 Note 1

C1 Condensate from Condenser -- 994.6 107 88 75

C2 Condensate to Feed Water Preheater 655.8 -- 140 88 108

C3 Feed Water to LP Drum 539.0 -- 280 64 249

C4 Feed Water from LP Drum to HP/IP BFW Pump 485.3 -- 297 64 266

C5 IP Feed Water Pump Bleed 71.2 -- 298 512 267

C6 HP Feed Water Pump Discharge 414.0 -- 304 2,687 274

C7 HP Feed Water to HP Superheater Attemperator 0.0 -- 298 512 267

C8 IP Feed Water to Reheat Superheater Attemperator 2.5 -- 304 2,687 274

C9 IP BFW to GT Fuel Heating 41.7 407 313 382

C10 IP BFW from GT Fuel Heating 41.7 135 64 103

D1 Demineralized Water Makeup to Condenser -- 8.2 59 40 27

G1 Combustion Turbine Inlet Air 2,997.3 -- 32 14.51 --

G2 Combustion Turbine Chilled Inlet Air 2,997.3 -- 32 14.41 --

G3 Combustion Turbine Exhaust 3,064.0 -- 1,151 14.92 --

G4 HRSG Exhaust Flow after Duct Burners 3,064.0 -- 1,020 14.86 --

G5 HRSG Stack Exit 3,064.0 -- 189 14.51 --

F1 Natural Gas to Combustion Turbine 66.3 -- 60 365 --

F2 Heated Natural Gas to Combustion Turbine 66.3 -- 365 360 --

F3 Natural Gas to Duct Burner 0.0 -- 60 365 --

S1 HRSG HP Superheater Exit 410.2 -- 1,055 965 1,538

S2 HRSG Hot Reheater Exit 433.8 -- 1,048 282 1,553

S3 HRSG IP Superheater Exit 26.8 -- 595 299 1,312

S4 HRSG LP Superheater Exit 53.8 -- 507 61 1,286

S5 Cold Reheat to HRSG from STG / HP Letdown 404.6 -- 754 299 1,397

S6 Mixed RH Steam into HRSG Reheater 431.3 -- 744 299 1,392

S7 HP STG Throttle Steam -- 820.3 1,050 928 1,537

S8 STG HP Exhaust as Cold Reheat -- 809.1 760 308 1,400

S9 Hot Reheat Steam into STG -- 867.6 1,042 268 1,550

S10 LP Superheated Steam into STG -- 107.5 498 56 1,282

S11 STG LP Exhaust Steam to Condenser -- 984.5 105 1.09 1,082

W1 Condensate from GT Chiller Coil 0.0 -- -- -- --

W2 Cold Closed Loop CW -- 4,060.0 57 90 -- Note 6

W3 Hot Closed Loop CW -- 4,060.0 70 80 -- Note 6

Performance Summary Units Per Train Per Unit NOTES

CTG Natural Gas Heat Input (LHV) MMBtu/hr 1,371 2,742

HRSG Duct Burner Heat Input (LHV) MMBtu/hr 0.0 0.0

Gas Turbine Gross Output kW 136,245 272,490

Steam Turbine Gross Output kW -- 155,819

Gross Power Output kW -- 428,309

Gross Plant Heat Rate (LHV) Btu / kWh -- 6,402

Gross Plant Heat Rate (HHV) Btu / kWh -- 7,098

Total Auxiliary Loads + TXFR Loss kW -- 10,426

Net Power kW -- 417,883

Net Plant Heat Rate (LHV) Btu / kWh -- 6,561

Net Plant Heat Rate (HHV) Btu / kWh -- 7,275

Notes:

1. HRSG HP Blowdown is 1% and is cascaded from HP to IP Drum and IP Blowdown is 1% from IP Drum to Boiler Blowdown Tank (These are included as losses in the mass balance)

2. CTG data based on GTMaster model for GE 7421FA.

3. HRSG data based on GTMaster model.

4. STG data based on GTMaster model with assumed 26 inch last stage blade length in LP turbine.

5. Fuel gas heating value based on 20,694 Btu/lbm-LHV (48,134 kJ/kg-LHV) and 22,945 Btu/lbm-HHV (53,370 kJ/kg-HHV) referenced to 77 F (25C)

6. Assumed Closed Cooling Water Duty: 45 mmBtu/hr

7. Refer to Avenal Energy Project PFDs for a schematic representation of the above streams.

8. The above heat and material balance is an estimate and not a guarantee. All values are subject to change pending detailed design development.

D:\My Documents\Archives\Avenal\Process\Cycle Design\Avenal H&MB RevB

Client: Federal Power King's County, LLC Contract : A3DV

Location: Avenal, CA Revision : B

Project: Avenal Energy Project Date : 11-Jul-07

Equipment: 2 x GE7FA x 2 Fired HRSGs x 1 RH STG By: G. Wadman

Unit 1 Checked:

Approved:

Heat and Material Balance

Table 2.6-12

HEAT AND MATERIAL BALANCE CASE: 32NGU3

AMBIENT CONDITIONS: 32 F Dry Bulb / 79% RH

CTG LOAD: 50%

STG STATUS: ON

DUCT BURNER STATUS: OFF

CTG CHILLER STATUS: OFF

Stream Flow, kpph Temp. Pressure Enthalpy

NOTES

No Description Per Train Unit Total F psia Btu/lbm

B1 HP Boiler Drum Continuous Blowdown 3.0 -- 526 853 519 Note 1

B2 IP Boiler Drum Continuous Blowdown 0.2 -- 406 264 381 Note 1

C1 Condensate from Condenser -- 827.7 107 70 75

C2 Condensate to Feed Water Preheater 558.9 -- 140 70 108

C3 Feed Water to LP Drum 447.8 -- 264 52 233

C4 Feed Water from LP Drum to HP/IP BFW Pump 408.5 -- 283 52 252

C5 IP Feed Water Pump Bleed 55.4 -- 284 515 253

C6 HP Feed Water Pump Discharge 353.1 -- 291 2,698 261

C7 HP Feed Water to HP Superheater Attemperator 0.0 -- 284 515 253

C8 IP Feed Water to Reheat Superheater Attemperator 0.0 -- 291 2,698 261

C9 IP BFW to GT Fuel Heating 33.9 393 264 367

C10 IP BFW from GT Fuel Heating 33.9 135 52 103

D1 Demineralized Water Makeup to Condenser -- 6.4 59 40 27

G1 Combustion Turbine Inlet Air 2,362.2 -- 32 14.51 --

G2 Combustion Turbine Chilled Inlet Air 2,362.2 -- 32 14.44 --

G3 Combustion Turbine Exhaust 2,413.3 -- 1,195 14.78 --

G4 HRSG Exhaust Flow after Duct Burners 2,413.3 -- 1,014 14.73 --

G5 HRSG Stack Exit 2,413.3 -- 177 14.51 --

F1 Natural Gas to Combustion Turbine 51.1 -- 60 365 --

F2 Heated Natural Gas to Combustion Turbine 51.1 -- 365 360 --

F3 Natural Gas to Duct Burner 0.0 -- 60 365 --

S1 HRSG HP Superheater Exit 350.1 -- 1,055 825 1,542

S2 HRSG Hot Reheater Exit 366.6 -- 1,044 238 1,552

S3 HRSG IP Superheater Exit 21.2 -- 592 253 1,314

S4 HRSG LP Superheater Exit 39.3 -- 495 50 1,281

S5 Cold Reheat to HRSG from STG / HP Letdown 345.4 -- 754 253 1,399

S6 Mixed RH Steam into HRSG Reheater 366.6 -- 744 253 1,394

S7 HP STG Throttle Steam -- 700.2 1,050 793 1,540

S8 STG HP Exhaust as Cold Reheat -- 690.7 759 261 1,402

S9 Hot Reheat Steam into STG -- 733.2 1,037 226 1,548

S10 LP Superheated Steam into STG -- 78.6 486 46 1,278

S11 STG LP Exhaust Steam to Condenser -- 819.8 104 1.07 1,084

W1 Condensate from GT Chiller Coil 0.0 -- -- -- --

W2 Cold Closed Loop CW -- 4,060.0 57 90 -- Note 6

W3 Hot Closed Loop CW -- 4,060.0 70 80 -- Note 6

Performance Summary Units Per Train Per Unit NOTES

CTG Natural Gas Heat Input (LHV) MMBtu/hr 1,057 2,113

HRSG Duct Burner Heat Input (LHV) MMBtu/hr 0.0 0.0

Gas Turbine Gross Output kW 91,624 183,248

Steam Turbine Gross Output kW -- 130,603

Gross Power Output kW -- 313,851

Gross Plant Heat Rate (LHV) Btu / kWh -- 6,734

Gross Plant Heat Rate (HHV) Btu / kWh -- 7,466

Total Auxiliary Loads + TXFR Loss kW -- 9,075

Net Power kW -- 304,776

Net Plant Heat Rate (LHV) Btu / kWh -- 6,934

Net Plant Heat Rate (HHV) Btu / kWh -- 7,688

Notes:

1. HRSG HP Blowdown is 1% and is cascaded from HP to IP Drum and IP Blowdown is 1% from IP Drum to Boiler Blowdown Tank (These are included as losses in the mass balance)

2. CTG data based on GTMaster model for GE 7421FA.

3. HRSG data based on GTMaster model.

4. STG data based on GTMaster model with assumed 26 inch last stage blade length in LP turbine.

5. Fuel gas heating value based on 20,694 Btu/lbm-LHV (48,134 kJ/kg-LHV) and 22,945 Btu/lbm-HHV (53,370 kJ/kg-HHV) referenced to 77 F (25C)

6. Assumed Closed Cooling Water Duty: 45 mmBtu/hr

7. Refer to Avenal Energy Project PFDs for a schematic representation of the above streams.

8. The above heat and material balance is an estimate and not a guarantee. All values are subject to change pending detailed design development.

D:\My Documents\Archives\Avenal\Process\Cycle Design\Avenal H&MB RevB

You might also like

- Free Uniben Post Utme Past Questions and Answers: Instruction40% (5)Free Uniben Post Utme Past Questions and Answers: Instruction5 pages

- Internship Report: Rayalaseema Thermal Power Project100% (3)Internship Report: Rayalaseema Thermal Power Project34 pages

- Objective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpNo ratings yetObjective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate Pump5 pages

- Study of Power Generating System in Captive Power Plant (VSP)No ratings yetStudy of Power Generating System in Captive Power Plant (VSP)32 pages

- Desuper-heater Specification Sheet فناورانNo ratings yetDesuper-heater Specification Sheet فناوران1 page

- PPGJ-PRO-CAL-200 Line Sizing Hot Oil System - 0B Not Print100% (1)PPGJ-PRO-CAL-200 Line Sizing Hot Oil System - 0B Not Print82 pages

- TBL 31 B HA en DC 004 A Safety Valve Design CalculationNo ratings yetTBL 31 B HA en DC 004 A Safety Valve Design Calculation37 pages

- V94.2 Beggenum Experience & Improve Concept For Syngas Application PDFNo ratings yetV94.2 Beggenum Experience & Improve Concept For Syngas Application PDF24 pages

- Data Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)No ratings yetData Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)7 pages

- A1 Boiler Performance, Layouts, PP, L&i & DuctsNo ratings yetA1 Boiler Performance, Layouts, PP, L&i & Ducts305 pages

- Pump: P-101: Aspen Technology Inc. Aspen HYSYS Version 10 Page 1 of 5No ratings yetPump: P-101: Aspen Technology Inc. Aspen HYSYS Version 10 Page 1 of 55 pages

- Dr. Md. Zahurul Haq: Preparatory Training Program For Energy Auditor Certification ExamNo ratings yetDr. Md. Zahurul Haq: Preparatory Training Program For Energy Auditor Certification Exam8 pages

- Nomenclature For Gpsa Engineering Data Book, 12 Ed - Section 9, Heat ExchangersNo ratings yetNomenclature For Gpsa Engineering Data Book, 12 Ed - Section 9, Heat Exchangers8 pages

- Sipat - 660 MW Super Critical Boiler Presentation100% (2)Sipat - 660 MW Super Critical Boiler Presentation55 pages

- Column Relief Loads Calculations 1653386984No ratings yetColumn Relief Loads Calculations 16533869849 pages

- MMTC - Chiller Equipment Schedule - R0-10-08-2023No ratings yetMMTC - Chiller Equipment Schedule - R0-10-08-20238 pages

- 6B - Basic Design For Some Units Used in Steam PlantNo ratings yet6B - Basic Design For Some Units Used in Steam Plant14 pages

- Technical Documentation - Regulation (EU) N. 2281 - 2016 - FOCS2-W-G05 - H-Y SEPR - HTNo ratings yetTechnical Documentation - Regulation (EU) N. 2281 - 2016 - FOCS2-W-G05 - H-Y SEPR - HT10 pages

- Prakiraan Kebutuhan Steam Untuk Operasi 1 Pabrik (Normal Case) Rate Nh3 90 %,urea 100 % (Full Granul)No ratings yetPrakiraan Kebutuhan Steam Untuk Operasi 1 Pabrik (Normal Case) Rate Nh3 90 %,urea 100 % (Full Granul)20 pages

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Resources For Teaching The Historical Documents: American GovernmentNo ratings yetResources For Teaching The Historical Documents: American Government8 pages

- Planning Sheet For Single Science Lessons Lesson Title: Microscopic Organisms, Lesson 3 Cluster: 1 S.L.O: 6-1-06 Grade: 6No ratings yetPlanning Sheet For Single Science Lessons Lesson Title: Microscopic Organisms, Lesson 3 Cluster: 1 S.L.O: 6-1-06 Grade: 63 pages

- TATA Ammonia Plant: Design Features and Operating ExperienceNo ratings yetTATA Ammonia Plant: Design Features and Operating Experience17 pages

- Saudi Arabia Shuqaiq-2 Iwpp Project: ITEM - Basics of Boiler, Turbine and GeneratorNo ratings yetSaudi Arabia Shuqaiq-2 Iwpp Project: ITEM - Basics of Boiler, Turbine and Generator103 pages

- Unit Ii Boilers 2.1BOILER:: 2.2 ComparisonNo ratings yetUnit Ii Boilers 2.1BOILER:: 2.2 Comparison32 pages

- Power Plant Lecture Notes - CHAPTER-3 STEAM GENERATOR: October 2014No ratings yetPower Plant Lecture Notes - CHAPTER-3 STEAM GENERATOR: October 201446 pages

- Heat Balane Diagram & Interface Parameters of An 800 MW Unit.No ratings yetHeat Balane Diagram & Interface Parameters of An 800 MW Unit.4 pages

- Sample Calculations of Boiler Pumps and IDNo ratings yetSample Calculations of Boiler Pumps and ID5 pages

- Final Report For Industrial Training Done at Mukwano Industries100% (2)Final Report For Industrial Training Done at Mukwano Industries62 pages

- How To Validate An Autoclave: Steam Quality TestingNo ratings yetHow To Validate An Autoclave: Steam Quality Testing4 pages

- EMX 11 E H - EN DC 004-en-A-HRSG Guarantees (T212B4 Appendix 4)No ratings yetEMX 11 E H - EN DC 004-en-A-HRSG Guarantees (T212B4 Appendix 4)7 pages

- Free Uniben Post Utme Past Questions and Answers: InstructionFree Uniben Post Utme Past Questions and Answers: Instruction

- Internship Report: Rayalaseema Thermal Power ProjectInternship Report: Rayalaseema Thermal Power Project

- Objective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpObjective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate Pump

- Study of Power Generating System in Captive Power Plant (VSP)Study of Power Generating System in Captive Power Plant (VSP)

- PPGJ-PRO-CAL-200 Line Sizing Hot Oil System - 0B Not PrintPPGJ-PRO-CAL-200 Line Sizing Hot Oil System - 0B Not Print

- TBL 31 B HA en DC 004 A Safety Valve Design CalculationTBL 31 B HA en DC 004 A Safety Valve Design Calculation

- V94.2 Beggenum Experience & Improve Concept For Syngas Application PDFV94.2 Beggenum Experience & Improve Concept For Syngas Application PDF

- Data Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Data Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)

- Pump: P-101: Aspen Technology Inc. Aspen HYSYS Version 10 Page 1 of 5Pump: P-101: Aspen Technology Inc. Aspen HYSYS Version 10 Page 1 of 5

- Dr. Md. Zahurul Haq: Preparatory Training Program For Energy Auditor Certification ExamDr. Md. Zahurul Haq: Preparatory Training Program For Energy Auditor Certification Exam

- Nomenclature For Gpsa Engineering Data Book, 12 Ed - Section 9, Heat ExchangersNomenclature For Gpsa Engineering Data Book, 12 Ed - Section 9, Heat Exchangers

- 6B - Basic Design For Some Units Used in Steam Plant6B - Basic Design For Some Units Used in Steam Plant

- Technical Documentation - Regulation (EU) N. 2281 - 2016 - FOCS2-W-G05 - H-Y SEPR - HTTechnical Documentation - Regulation (EU) N. 2281 - 2016 - FOCS2-W-G05 - H-Y SEPR - HT

- Prakiraan Kebutuhan Steam Untuk Operasi 1 Pabrik (Normal Case) Rate Nh3 90 %,urea 100 % (Full Granul)Prakiraan Kebutuhan Steam Untuk Operasi 1 Pabrik (Normal Case) Rate Nh3 90 %,urea 100 % (Full Granul)

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and Equipment

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and Designers

- Resources For Teaching The Historical Documents: American GovernmentResources For Teaching The Historical Documents: American Government

- Planning Sheet For Single Science Lessons Lesson Title: Microscopic Organisms, Lesson 3 Cluster: 1 S.L.O: 6-1-06 Grade: 6Planning Sheet For Single Science Lessons Lesson Title: Microscopic Organisms, Lesson 3 Cluster: 1 S.L.O: 6-1-06 Grade: 6

- TATA Ammonia Plant: Design Features and Operating ExperienceTATA Ammonia Plant: Design Features and Operating Experience

- Saudi Arabia Shuqaiq-2 Iwpp Project: ITEM - Basics of Boiler, Turbine and GeneratorSaudi Arabia Shuqaiq-2 Iwpp Project: ITEM - Basics of Boiler, Turbine and Generator

- Power Plant Lecture Notes - CHAPTER-3 STEAM GENERATOR: October 2014Power Plant Lecture Notes - CHAPTER-3 STEAM GENERATOR: October 2014

- Heat Balane Diagram & Interface Parameters of An 800 MW Unit.Heat Balane Diagram & Interface Parameters of An 800 MW Unit.

- Final Report For Industrial Training Done at Mukwano IndustriesFinal Report For Industrial Training Done at Mukwano Industries

- How To Validate An Autoclave: Steam Quality TestingHow To Validate An Autoclave: Steam Quality Testing

- EMX 11 E H - EN DC 004-en-A-HRSG Guarantees (T212B4 Appendix 4)EMX 11 E H - EN DC 004-en-A-HRSG Guarantees (T212B4 Appendix 4)