Bauxite Technical Note

Bauxite Technical Note

Uploaded by

Biju SebastianCopyright:

Available Formats

Bauxite Technical Note

Bauxite Technical Note

Uploaded by

Biju SebastianOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Bauxite Technical Note

Bauxite Technical Note

Uploaded by

Biju SebastianCopyright:

Available Formats

Bauxite

Technical Note

What is bauxite?

Bauxite is a rock formed by the weathering of aluminium rich rocks that have been

severely leached of silica and other soluble materials in a wet tropical or subtropical

climate.

Hence, the major deposits are generally close to the surface. Bauxite is the worlds principal source of aluminium and can vary

Bauxite is a mixture of aluminium minerals, clay minerals, and from a very soft earth to a very hard rock. It can occur as red-

insoluble materials. Three aluminium minerals can occur in yellow compacted earth (both friable and re-cemented), small

bauxite: gibbsite, boehmite and diaspore. red round pebbles (pisolites), or large pale (pink, white, buff)

hard stones (see below left).

Physical forms of bauxite

Bauxite is usually classified according to its intended commercial

application: abrasive, cement, chemical, metallurgical and

refractory. Approximately 85% of the worlds bauxite production

is metallurgical bauxite and the alumina is extracted from the

bauxite in a refinery using a wet chemical caustic soda leach

process known as the Bayer process. The alumina is then

converted to aluminium metal via electrolysis in a smelter using

the energy-intensive Hall-Heroult process.

Bauxite formation

Pisolitic Pisolitic Bauxite forms from the breakdown of clays when large amounts

of rainfall leach away the more mobile elements in the host rock

leaving the relatively immobile aluminium with some silicon,

iron and titanium. Because climatic conditions play an important

role in the formation of the deposits, they can be very extensive

and are found on almost every continent. The largest known

economic resources occur in Guinea and Australia, followed by

Brazil, Vietnam and Jamaica. Indonesia, India, Guyana, China and

Greece make up the remainder of the top 10 countries.

Earthy Hard rock

Right Solutions Right Partner

alsglobal.com Geochemistry Technical Note 1

There are two types of bauxite deposits. Both are a result of transformed to bauxite through lateritic weathering. Often the

chemical weathering: partially or fully transformed clays (bauxite) were washed into

and accumulated in eroded limestone cavities where further

1. Lateritic

These are the silicate bauxites formed in situ from weathering transformation occurred. Karstic bauxites are usually diaspore

of various aluminous silicate rocks such as granite, gneiss, deposits and occur predominantly in Europe, the Middle East,

basalt, syenite, and shale. They are found mostly in tropical and China and Jamaica.

temperate regions and occur primarily on plateau surfaces and They are generally smaller, poorer quality and have more complex

hill slopes. Most are residual accumulations from which most mineralogy (high processing costs) than lateritic deposits.

other constituents of the parent rock, other than alumina, have Most bauxite mines produce Direct Shipping Ore (DSO) bauxite

been leached. Lateritic bauxites consist mostly of gibbsite or a as they require no processing before being sent to a refinery.

mixture of gibbsite and boehmite. About 90% of bauxite is of However, some bauxites require some form of screening (either

lateritic origin. wet or dry) to remove the fine grained material to improve

2. Karstic the grade and/or handleability. These deposits usually have a

These are the carbonate bauxites that occur above carbonate rocks beneficiation plant that washes the bauxite and sends the high

(limestone and dolomite). They form when dispersed clay layers silica fines (kaolinite and/or quartz) to a tailings dam prior to ship

in the limestone are concentrated as the enclosing limestones loading the bauxite.

gradually dissolved during chemical weathering. The clays are

Global distribution of bauxite

Karstic bauxite

Lateritic bauxite

Annual mine production

Worldwide bauxite mine production for 2015, by major producing

countries Principal mineral components

90 of bauxite

80

70

The three main aluminium minerals are:

Gibbsite

60

Boehmite

50

Diaspore

Mt

40

30

The other minerals are impurities and include:

Kaolinite (clay)

20

10

Quartz

0

Haematite and Goethite (iron oxides)

Anatase and Rutile (titanium dioxide).

r

a

ala l

ia

Gu a

Jam a

a

za ia

Su tan

Gr e

Gu ce

ne a

Vi la

do m

sia

i

he

az

e

ali

in

di

aic

Ve an

am

ys

Ka uss

a

na

ee

in

ne

zu

In

Ch

Ot

Br

str

y

kh

rin

et

R

Au

In

Right Solutions Right Partner

2 alsglobal.com

Find

us on What is Bauxite?

Bauxite The aluminium minerals

mineralogy Gibbsite - Al(OH)3 or Al2O3.3H2O

Commonly referred to as tri-hydrate due to the three lots of water.

The mineralogy is very important

The three OH bonds are relatively weak and require the lowest

as it dictates the refining conditions

refining temperature to break them, typically 143C -150C.

that must be used and has a

large bearing on the economics Boehmite - AlO(OH) or Al2O3.H2O

of processing bauxite. Alumina Commonly referred to as monohydrate due to the single water.

refineries are usually classified as The single OH bond is much stronger than the three bonds in

either high temperature (>240C) or low temperature (~143C - gibbsite and requires a higher refining temperature to break it,

150C). typically 240-260C

Pure gibbsite or mixed gibbsite and boehmite deposits with a Diaspore - AlO(OH) or Al2O3.H2O

low boehmite content are usually sent to low temperature Has the same composition as boehmite but is denser and harder

refineries. However, once the deposit has more than about 6% due to a different crystal form.

boehmite, then it must be sent to a high temperature refinery Diaspore requires the highest refining temperatures to process,

due to economics. typically +260C.

Metallurgical extraction The Alumina Refinery

Bauxite is converted to alumina in a refinery through a continuous 3. Precipitation forming alumina crystals

four stage Bayer process involving: The liquor is further cooled to allow the alumina to be deposited

1. Digestion dissolving the bauxites alumina content in solid form as alumina hydrate crystals. Crystal growth is

Finely ground bauxite is mixed with recycled hot caustic soda assisted by seeding the liquor with previously precipitated fine

solution under pressure. This dissolves the alumina content of the grained alumina crystals. The finished mix of crystals is settled

bauxite and the solution is then cooled in a series of flash tanks. from the liquor stream and separated. The spent liquor is returned

to Digestion where is it re-heated, fresh caustic soda added and

2. Clarification settling out and separating undissolved

then used to dissolve more bauxite as it starts another circuit on

impurities

its continuous journey around the plant.

The undissolved impurities are allowed to settle as a fine mud

in thickening tanks. The caustic soda is recovered by washing 4. Calcination high temperature drying of alumina

this bauxite residue (red mud) through several stages before the The hydrate crystals are washed and calcined at temperatures

pumping the red mud to waste storage dams. The solution of exceeding 1000C. This forms the dry white aluminium oxide

alumina in caustic soda (the liquor) is further clarified by filtration powder, alumina, which is cooled and conveyed to storage sheds.

with the aid of lime. (Source: Queensland Alumina Limited pamphlet)

The impurities bauxite often result in a high concentration of iron in the liquor

and consequently leads to a high iron content in the precipitated

The impurities are often more important to consider than the alumina as there is insufficient seed to enable the reprecipitation

alumina grade because of their detrimental effect. Silica is the of the iron. The two main iron oxides are haematite and goethite.

most commercially important impurity in bauxite as generally Haematite

the more silica in the bauxite, the higher the amount of caustic Iron oxide - Fe2O3

soda consumed in the refining process and the higher the loss of

Goethite

alumina to the red mud tailings in the desilication product (DSP).

Iron hydroxy-oxide - FeO(OH)

The two main sources of silica in bauxite are kaolinite and quartz.

Can contain some Al2O3

Kaolinite When fine grained, it can be associated with slow or poor

Kaolin - Al2Si2O5(OH)4 or Al2O3.2SiO2.2H2O settling of red muds.

100% reacts (dissolves) in both low and high temperature Anatase and Rutile - TiO2

refineries Associated with scaling inside refining equipment which

Quartz reduces plant efficiency and increases maintenance costs.

Silicon dioxide - SiO2 Can increase caustic usage in high temperature plants

Reacts (dissolves) at temperatures above 200C Essentially, they remain insoluble and end up in the red mud.

0% reacts in low temperature refineries and a portion reacts Organic Carbon

in high temperature refineries. The percentage depends on Organic matter is broken down as part of the Bayer process

refinery conditions. and forms sodium oxalate.

The iron oxides essentially pass through the refinery process Increases operating costs by reducing plant efficiency and

unchanged. They either remain insoluble or react and reprecipitate lowers alumina purity. Alternatively increases capital cost by

and end up in the red mud. However, very low levels of iron in adding an organic removal facility, e.g. oxalate plant.

Right Solutions Right Partner

alsglobal.com Technical Note 3

Drilling and sampling of bauxite deposits

As bauxite deposits are usually extensive, relatively thin (most average <10m thick) and

close to the surface, drilling is usually a series of shallow vertical holes set out on a regular

grid. It would be rare for drill holes to exceed 50m depth with drilling at most deposits being

much shallower than this. Consequently, sample intervals are small with sub metre sampling

being common. Sample sizes are also small meaning that little or no sample preparation is

required at the drill site other than splitting of the larger intervals down to the appropriate

subsample size, usually a couple of kilograms to be sent to the laboratory for analysis.

Sample preparation and analytical methods at the laboratory

Once at the laboratory, sample preparation for DSO bauxites is (aluminium-silica compounds or 3[Na2O.Al2O3.2SiO2.2H2O]Na2X).

usually limited to drying, weighing, crushing, sub-sampling and The total amount of alumina that is extractable in solution from

grinding the sample to less than 75 microns. For bauxites that are bauxite in the Bayer process is called the Total Available Alumina

subject to beneficiation, the laboratory preparation will include a (TAA). It is made up of two parts:

screening step as well as additional drying and weighing steps

THA Trihydrate Alumina. This is the alumina that is

and the calculation of a percentage yield.

extracted in a low temperature refinery.

Although bauxite comprises a mixture of minerals, the industry- MHA Monohydrate Alumina. This is the extra alumina that

standard analytical method for reporting the composition is by will be extracted in a high temperature plant.

elemental analysis, expressed as metal oxides. This analysis

The relationship can be simply expressed as TAA = THA + MHA

is usually determined by X-Ray Fluorescence Spectrometry

(XRF). In addition, Loss on Ignition (LOI) is also measured by Similarly, not all of the SiO2 (silica) present in the bauxite causes

Thermogravimetric Analyzer (TGA). This determines the loss caustic soda loss in the Bayer process. The part of total silica which

of mass due to volatiles that are driven off when the sample reacts with caustic soda and forms sodalite complex through

is heated from 105C to 1000C (i.e. after the removal of free sodium silicate route is termed as Reactive Silica. Thus, the non-

moisture). reacting component of total silica with caustic soda is also known

as Non-Reactive Silica.

The sum of the major oxides (Al2O3, SiO2, Fe2O3 and TiO2) and LOI

usually sum to greater than 99% for bauxites. Trace elements In a low temperature refinery, reactive silica = kaolinite. In a high

make up the remaining percentage. temperature refinery, reactive silica = kaolinite + partial quartz.

Bauxite = Al2O3 + SiO2 + Fe2O3 + TiO2 + LOI + trace elements In addition to XRF and TGA LOI analysis, ALS also offers additional

characterisation methods such as organic carbon, reactive silica

The major oxides reported are usually referred to as Total

and available alumina analysis (see the table below). However,

Al2O3, Total SiO2, etc. However, this information by itself can be

when requesting an available alumina and/or reactive silica from

misleading as several minerals can contribute to each oxide

the laboratory, it is important to understand if the bauxite being

value. For example:

tested will be going to a high or low temperature refinery as the

Total Al2O3 - gibbsite, boehmite, diaspore + clay minerals digestion temperature for the analysis needs to be specified.

(kaolinite)

ALS can also provide TGA loss of mass at multiple temperatures to

Total SiO2 - clay minerals (kaolinite), quartz assist in confirmation of various mineral phases.

Not all of the Al2O3 (alumina) is available for making aluminium Multi-screen sizing to determine the optimum screen size for

as some is in the clays and is lost in the Bayer process to the DSP recovery and subsequent wet beneficiation are also available.

ANALYTES & RANGES (%) DESCRIPTION CODE

Al2O3 0.01-100 MgO 0.01-40 SrO 0.01-1.5

BaO 0.01-10 MnO 0.01-31 TiO2 0.01-30 ME-XRF13n

CaO 0.01-40 Na2O 0.01-503 V2O5 0.01-8 (normalised)

Fused disc XRF

Cr2O3 0.01-10 PxO5 0.01-23 Zn 0.01-106 ME-XRF13u

Fe2O3 0.01-100 SiO2 0.05-100 ZrO2 0.01-1.5 (un-normalised)

K2O 0.001-6.3 SO3 0.01-12.5 Total 0.01-110

Furnace or OA-GRA05x

Loss on Ignition

Thermogravimetric Analyser (TGA) ME-GRA05

Total Organic Carbon (Non Carbonate Carbon) TOC by Combustion Furnace C-IR17

Microwave digestion, chemical ME-LICP01

Reactive Silica and Available Alumina

separation/ICP-AES analysis# ME-LICP02

#

Digestion temperature, caustic strength and sample/caustic weight ratio to be specified by client

Technical note compiled by John Bower, OBK Consulting Pty Ltd

Right Solutions Right Partner

4 alsglobal.com

Find

us on What is Bauxite?

You might also like

- Use of Lip BumpersDocument21 pagesUse of Lip BumpersDr. Amir MoradiNo ratings yet

- Sustainable Bauxite Mining Guidelines 2022Document94 pagesSustainable Bauxite Mining Guidelines 2022Paula Brazuelo100% (2)

- GEOLOGY AND GENESIS OF THE CENTRAL AFRICAN COPPERBELT ORE DEPOSITS-Lecture 8 NotesDocument4 pagesGEOLOGY AND GENESIS OF THE CENTRAL AFRICAN COPPERBELT ORE DEPOSITS-Lecture 8 NotesPumulo MukubeNo ratings yet

- 01 IronDocument21 pages01 IronvhinzsanguinaryNo ratings yet

- Boq Specification For The Roof Deck SheetingDocument3 pagesBoq Specification For The Roof Deck SheetingAmudhalingam LingamNo ratings yet

- BauxiteDocument31 pagesBauxiteRenesha100% (5)

- What Is Bauxite?: Mineral RockDocument13 pagesWhat Is Bauxite?: Mineral RockRenesha100% (2)

- Bauxite DepositsDocument25 pagesBauxite DepositsLara CharisseNo ratings yet

- FT GTW Ipoh Kinta Limestone Excursion Guides Final 2dec2019 AAPG EAGEDocument12 pagesFT GTW Ipoh Kinta Limestone Excursion Guides Final 2dec2019 AAPG EAGERichard OonNo ratings yet

- Bauxite and Mining Exploration Info PDFDocument2 pagesBauxite and Mining Exploration Info PDFtandrianieNo ratings yet

- CHROMITEDocument5 pagesCHROMITETayyab FiazNo ratings yet

- A Review Study On The Extraction of Nickel From Its OresDocument44 pagesA Review Study On The Extraction of Nickel From Its OresAqila AbizardNo ratings yet

- Tanzania Pilot Study On Natural Resources in Tanzania (Coal, Iron, Nickel, Gold, Gemstone and Gypsum)Document121 pagesTanzania Pilot Study On Natural Resources in Tanzania (Coal, Iron, Nickel, Gold, Gemstone and Gypsum)Daniel KadasoNo ratings yet

- Iron OreDocument39 pagesIron OreAjay ChauhanNo ratings yet

- Processing Spodumene by Froth Flotation For Lithium ExtractionDocument16 pagesProcessing Spodumene by Froth Flotation For Lithium Extractionnaren_013No ratings yet

- Lime Making Process - A Business Perspective Rev1Document43 pagesLime Making Process - A Business Perspective Rev1Abhishek ChoudharyNo ratings yet

- Nature of Basins in GhanaDocument4 pagesNature of Basins in GhanaAcheampong SamuelNo ratings yet

- Beach Sand Minerals ProcessingDocument10 pagesBeach Sand Minerals ProcessingKrishnan Saravanakumar100% (1)

- ALS Metallurgy - Iron Ore Process DevelopmentDocument8 pagesALS Metallurgy - Iron Ore Process DevelopmentDeepakKumarGorai100% (1)

- Gold Ore Processing PlantDocument4 pagesGold Ore Processing Plantjafer2000No ratings yet

- High-Magnesia Portland CementsDocument12 pagesHigh-Magnesia Portland CementsyinglvNo ratings yet

- Analysis of Lead OreDocument17 pagesAnalysis of Lead OrePutoy ItoyNo ratings yet

- BauxiteDocument5 pagesBauxiteJohn-Paul MollineauxNo ratings yet

- Ni-Co Laterites - A Deposit Model by USGSDocument12 pagesNi-Co Laterites - A Deposit Model by USGSAhmad AshariNo ratings yet

- Safe Shipment of Nickel OreDocument5 pagesSafe Shipment of Nickel OreNelson GuoNo ratings yet

- Geology and Geochemistry Bauxite in TanzsniaDocument13 pagesGeology and Geochemistry Bauxite in TanzsniaRonnyAsidoNo ratings yet

- Iron Ore Fines Presentation 2009 PDFDocument37 pagesIron Ore Fines Presentation 2009 PDFKalai Selvan100% (1)

- Mike Jolley - President Director PT Rio Tinto IndonesiaDocument24 pagesMike Jolley - President Director PT Rio Tinto IndonesiaAhmad AshariNo ratings yet

- Ilmenite - An Ore of Titanium - Uses and PropertiesDocument5 pagesIlmenite - An Ore of Titanium - Uses and PropertieswessilissaNo ratings yet

- Coking Coal IndexDocument12 pagesCoking Coal IndexZaidan EffendieNo ratings yet

- 09162014114959monograph ChromiteDocument162 pages09162014114959monograph ChromiteRahul MishraNo ratings yet

- A Case Study of Different Limestone During Quick Lime and Slaked-Lime Production PDFDocument7 pagesA Case Study of Different Limestone During Quick Lime and Slaked-Lime Production PDFGuglielmo CancelliNo ratings yet

- Classification MaceralDocument26 pagesClassification MaceralTeguh PratamaNo ratings yet

- Galaxy Resources ReportDocument28 pagesGalaxy Resources Reportokeydokey01No ratings yet

- High Pressure Acid Leaching of A Refractory Lateritic Nickel OreDocument10 pagesHigh Pressure Acid Leaching of A Refractory Lateritic Nickel OreFabian MansillaNo ratings yet

- Iron Sand ProcessingDocument17 pagesIron Sand ProcessingTomi PurwonoNo ratings yet

- Aluminium AssignmentDocument4 pagesAluminium AssignmentangellaNo ratings yet

- Recovery of Gold Using Gravity Concentration The Hemlo ExperienceDocument14 pagesRecovery of Gold Using Gravity Concentration The Hemlo Experienceboanerges wino pattyNo ratings yet

- Ophiolite: Pseudostratigraphy and Definition Research Groups and Assemblages Formation and EmplacementDocument7 pagesOphiolite: Pseudostratigraphy and Definition Research Groups and Assemblages Formation and Emplacementpaulo de carvalhoNo ratings yet

- Coal ZimbDocument22 pagesCoal ZimbDavid KatemaunzangaNo ratings yet

- ISO 5997-1984 Chrome Ore Determination of SilicaDocument7 pagesISO 5997-1984 Chrome Ore Determination of SilicaArijit dasguptaNo ratings yet

- 3 Mine Revenue and Costs - 1Document24 pages3 Mine Revenue and Costs - 1Fred Ferraz100% (1)

- Ekstraksi Mineral Galena DARMADocument17 pagesEkstraksi Mineral Galena DARMAChisya Ayu PuspitaweniNo ratings yet

- Limestone GeochemistryDocument11 pagesLimestone GeochemistryJohn S. Armstrong-Altrin100% (1)

- Extraction and Beneficiation of Ores and Minerals PDFDocument2 pagesExtraction and Beneficiation of Ores and Minerals PDFFredNo ratings yet

- Characterization of Alluvial Gold BearingDocument15 pagesCharacterization of Alluvial Gold BearingAntonioNo ratings yet

- Harmful Constituents of CementDocument1 pageHarmful Constituents of CementProsenjit GhoshNo ratings yet

- Tips Coal Sampling and Analysis StandardsDocument123 pagesTips Coal Sampling and Analysis StandardsEE OPN1TTPS100% (1)

- Washing Equipment Introduction 2020 PDFDocument62 pagesWashing Equipment Introduction 2020 PDFJohn Tesfamariam100% (2)

- FeldsparDocument11 pagesFeldsparمحمد حسينNo ratings yet

- NI43-101 La Plata Oct 2017 Master 20171026 FINAL1 PDFDocument322 pagesNI43-101 La Plata Oct 2017 Master 20171026 FINAL1 PDFHassan ChiribogaNo ratings yet

- The Future of Ferrochrome Production in ZimbabweDocument4 pagesThe Future of Ferrochrome Production in ZimbabweFadzai FunguraNo ratings yet

- Factors Affecting The Quality of Quicklime (Cao) : From Mining To Manufacturing To UsageDocument14 pagesFactors Affecting The Quality of Quicklime (Cao) : From Mining To Manufacturing To UsageDaniel Vargas CeliNo ratings yet

- Hydaulic MiningDocument9 pagesHydaulic MiningSatya Prakash SuryavanshiNo ratings yet

- Indonesian Coal ReportDocument6 pagesIndonesian Coal ReportSoundar rajanNo ratings yet

- Industrial MineralsDocument43 pagesIndustrial MineralsadisatriowicaksonoNo ratings yet

- 2023 Semi Annual Report of Huayou CobaltDocument262 pages2023 Semi Annual Report of Huayou CobaltHilman DarojatNo ratings yet

- BauxiteDocument18 pagesBauxitejulianusginting00No ratings yet

- Dealing With Nickel Cobalt Laterite Deposit Complexity Mick Elias September 2019 1Document32 pagesDealing With Nickel Cobalt Laterite Deposit Complexity Mick Elias September 2019 1rezaard100% (1)

- ChromiteDocument16 pagesChromitebvhanji100% (2)

- Current Business Models in LithiumDocument68 pagesCurrent Business Models in LithiumyaklyNo ratings yet

- The Department of Mining and Geology: WWW - Portal.dmg - Kerala.gov - inDocument19 pagesThe Department of Mining and Geology: WWW - Portal.dmg - Kerala.gov - inBiju SebastianNo ratings yet

- Deogiri-583112, Sandur, Bellary, Karnataka.: (ML No. 2580 & ML No. 2581)Document30 pagesDeogiri-583112, Sandur, Bellary, Karnataka.: (ML No. 2580 & ML No. 2581)Biju SebastianNo ratings yet

- No Longer Just A Hole in The Ground: The Adaptive Re-Use of Resource Depleted QuarriesDocument19 pagesNo Longer Just A Hole in The Ground: The Adaptive Re-Use of Resource Depleted QuarriesBiju SebastianNo ratings yet

- SummaryDocument35 pagesSummaryBiju SebastianNo ratings yet

- Plakkat Granites JudgementDocument17 pagesPlakkat Granites JudgementBiju SebastianNo ratings yet

- Supreme Court Judgement 4352 2014 Judgement 02-Aug-2017Document114 pagesSupreme Court Judgement 4352 2014 Judgement 02-Aug-2017Kishore ChaudharyNo ratings yet

- Display PDF - PHP PDFDocument32 pagesDisplay PDF - PHP PDFBiju SebastianNo ratings yet

- 2018 11 1501 14662 Judgement 03-Jul-2019Document203 pages2018 11 1501 14662 Judgement 03-Jul-2019Biju Sebastian100% (1)

- Kerala Protection of River Banks - Rules, 2002Document17 pagesKerala Protection of River Banks - Rules, 2002Biju SebastianNo ratings yet

- Display PDF - PHP PDFDocument32 pagesDisplay PDF - PHP PDFBiju SebastianNo ratings yet

- RQP List PDFDocument23 pagesRQP List PDFBiju SebastianNo ratings yet

- RQP List PDFDocument23 pagesRQP List PDFBiju SebastianNo ratings yet

- Black Women Mothering and Protest in 19th Century American Society Journal Article With Notes ColumnDocument5 pagesBlack Women Mothering and Protest in 19th Century American Society Journal Article With Notes Columnapi-260339450No ratings yet

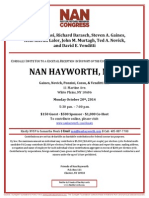

- Cocktail Reception For Nan HayworthDocument2 pagesCocktail Reception For Nan HayworthSunlight FoundationNo ratings yet

- Earth Science Lecture 2 V.2Document39 pagesEarth Science Lecture 2 V.2MieNo ratings yet

- Soal Bhs Inggris Kelas XiDocument7 pagesSoal Bhs Inggris Kelas Xinadhiva guraysNo ratings yet

- Quiz 1-3Document6 pagesQuiz 1-3Ailyn Balmes100% (1)

- Points of Concurrency WS-1Document5 pagesPoints of Concurrency WS-1eebobNo ratings yet

- BMC Resmart Gii Y30t Bipap HumidifierDocument4 pagesBMC Resmart Gii Y30t Bipap HumidifierAtul KhadkeNo ratings yet

- Flavourart SRL: FA1378 - Heaven Juice 7foglie 7 Leaves 4,5 MGDocument9 pagesFlavourart SRL: FA1378 - Heaven Juice 7foglie 7 Leaves 4,5 MGmvp flavorsNo ratings yet

- Rapid P0022 Punj CVS DWG 5100 0095 - 2Document1 pageRapid P0022 Punj CVS DWG 5100 0095 - 2testNo ratings yet

- Name of Document: Compliance To Barangay Full Disclosure PolicyDocument17 pagesName of Document: Compliance To Barangay Full Disclosure PolicyLiza Mae CagampangNo ratings yet

- Relining and Rebasing of Complete DenturesDocument28 pagesRelining and Rebasing of Complete DenturesLely LyNo ratings yet

- SITHCCC001 Use Food Preparation Equipment PDFDocument7 pagesSITHCCC001 Use Food Preparation Equipment PDFavishek raiNo ratings yet

- Product Catalogue 9 - Page 7 EJATNDocument1 pageProduct Catalogue 9 - Page 7 EJATNAndrei Ionut UtaNo ratings yet

- CPD + MakrosomiaDocument6 pagesCPD + MakrosomiaLili SurianiNo ratings yet

- USP 40-61-62 Microbial LimitDocument15 pagesUSP 40-61-62 Microbial LimitScribdTranslationsNo ratings yet

- Human V Frog Blood TeacherDocument8 pagesHuman V Frog Blood TeacherJAYHANNE PSYCHE MONDIANo ratings yet

- 4 Great Methods To Make Graphene at Home, Along With Graphene BasicsDocument12 pages4 Great Methods To Make Graphene at Home, Along With Graphene BasicsNaga RajuNo ratings yet

- Bio Chem Phy Exampro PDFDocument9 pagesBio Chem Phy Exampro PDFshakeel shahulNo ratings yet

- Cyber Resilience Assessment FrameworkDocument21 pagesCyber Resilience Assessment Frameworklava.sky10No ratings yet

- Global Warming: Exercise Ii ReadingDocument4 pagesGlobal Warming: Exercise Ii ReadingfitriNo ratings yet

- Sample Test 1 Reading Test PDFDocument14 pagesSample Test 1 Reading Test PDFKeerthi Kumar M. J.50% (2)

- A. Maternal Adaptation in PregnancyDocument32 pagesA. Maternal Adaptation in PregnancyKeziah TampusNo ratings yet

- Brighter Futures - Orthodontics and Dental TraumaDocument2 pagesBrighter Futures - Orthodontics and Dental TraumaEastma MeiliNo ratings yet

- 150KW 3300V Induction MotorDocument2 pages150KW 3300V Induction MotorManisha KharwarNo ratings yet

- Case Historyand MSE FormatDocument14 pagesCase Historyand MSE FormatOSHMITA BHATTACHARJEE 23223145No ratings yet

- Cardioversion and DefibrillationDocument24 pagesCardioversion and Defibrillationrona-chanNo ratings yet

- CCTV Sub-1Document2 pagesCCTV Sub-1Giovanni TandogNo ratings yet

- Models For Program Planning inDocument52 pagesModels For Program Planning inrazamenesesNo ratings yet