Efwe 2 e 4 GF 1 W 3

Efwe 2 e 4 GF 1 W 3

Uploaded by

BALACHANDAR SCopyright:

Available Formats

Efwe 2 e 4 GF 1 W 3

Efwe 2 e 4 GF 1 W 3

Uploaded by

BALACHANDAR SOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Efwe 2 e 4 GF 1 W 3

Efwe 2 e 4 GF 1 W 3

Uploaded by

BALACHANDAR SCopyright:

Available Formats

CONTROL PLAN

Prototype Prelaunch Production Key contact / Phone Date ( Orig) Date ( Rev)

Mr. F. Khan 24-12.-04 09.12.16

Control plan Number- Tractor Assembly / Post Painting 05944- 281115

Customer Engineering Approval / Date ( if reqd )

Partnumber / latest change level :- Core team -

TR 510 FK / RS / AM / RP

Part name / Description :- Supplier / PartApproval / Date Customer Quality Approval / Date( if reqd )

Demasking & Greasing

Supplier / Plant Supplier code Other Approval / Date( if reqd ) Other Approval / Date ( if reqd )

M & M LTD., ID / F005

Characteristics Methods

Product / Process

Process Name / Operation Machine Device ./ Special Evaluation measurement

Part process number No Product Process Specification / Sample Control method Reaction Plan

Description Jig Tools For Mfg Char. Class technique

Tolerance

Complete tightening of all

10 Hand hole cover tightening 10.1 - Visual. 1 100% Self certification Retight

bolts

Unloading thehand brake

Unloading pf Hand Brake 10.2 Visual. 1 100% Self certification As per SOP

and hang on stand

complete demasking of all

20 Demasking - 20.1 - - - Visual. 1 100% Self certification Demask all points completely as per Sop

points

All grease points should be completely

30 Rear m/c Area greasing 30.1 - - - Visual. 1 100% Self certification Apply grease properly as per SOP.

greased and clean.

Re orientate grease gun properly and grease all

30.2 - - - - Visual. 1 100% Self certification

points .

Elgi Grease

till the grease is

pump &

Greasing at the points given All grease points should be completely seen coming out

40 Pneumatic 40.1 - - Visual. 1 100% Self certification Apply grease properly as per SOP.

in SOP greased and clean. from the

Cylinder

respective point

(100X1200mm)

Quantified

Quantified dispensor for Re orientate grease gun properly and grease all

dispensor for 40.2 - - Auto cutoff Visual. 1 100% Self certification

Front Axle points .

Front Axle

40.3 No of stroke for turn buckle 8 strokes Visual. 1 100% Self certification Apply the grease using 8 strokes

BR

No of stroke for Antifriction

- 40.4 - - 18 strokes Visual. 1 100% Self certification Apply the grease using 18 strokes.

Bearing

MKM model VTU

oil 12 litter in /

Oil Dispensing

50 VTU oil filling

Unit

60.1 Use of correct bill of material - <SC> tractor and regular dispensing unit - 100% Calibration record Fill up as per SOP

model 11.5

letter/tractor

Oil Dispensing

60 Air cleaner oil filling 50.1 Correct oil quantity - 0.5 L dispensing unit - 100% Calibration record Fill up as per SOP

Unit

Oil Dispensing

70 Transmission oil level Filling 70.1 Ensure Oil at between Min- Max of dipstick - - - Visual 1 100% self certification by cell member Record in history card & keep tractor aside

Unit

BS

DATE C.L. CHANGE APPD. BY DATE C.L. CHANGE APPD. BY

09.12.16 BS OIB Oil Qty revised to 35.5 from 35 Ltr & Stand by grease dispensing system FK

AFB Grease Strokes increased from 10 to 18 to eliminate the chances of noise from

09.11.16 BR

the sleeve FK

15.10.2015 BQ SOP Revised for offline greasing of tie rod FK

01.07.15 BP Regual oil filling quantity reduced from 12 liters to 11.6 Liters FK

30.06.15 BO Use of IOCL (MTRAC 30) Oil in place of EP90 Oil for 255 DI model(ER15C0003077 ) FK

Total Transmission oil quantity reduction by 3.6 lit.from H1 OIB

19.05.15 BN

models(ER15C0003108 ) FK

TO : Trainee Officer ; IN : Inspector; SL : Shift Leader; CL : Cell Leader

Format No :- TQM 15

You might also like

- Service Manual: © MARCH 2016, Mercury Marine. All Rights Reserved. 90-8M0107213Document94 pagesService Manual: © MARCH 2016, Mercury Marine. All Rights Reserved. 90-8M0107213fabianoNo ratings yet

- Doblò 1.9 Diesel Code - Wiring Diagram E7010Document3 pagesDoblò 1.9 Diesel Code - Wiring Diagram E7010Serg RonkNo ratings yet

- Mercedes 722.3 722.4 Transmission PartsDocument6 pagesMercedes 722.3 722.4 Transmission PartsKhalid KhassawnehNo ratings yet

- SPC FormatDocument2 pagesSPC FormatRaajha MunibathiranNo ratings yet

- Effective Problem SolvingDocument1 pageEffective Problem Solvingmuthuswamy77No ratings yet

- Alpha Drives: Vendor RatingDocument10 pagesAlpha Drives: Vendor Ratingdaniel_sasikumarNo ratings yet

- F-PD-01 Process Flow DiagramDocument1 pageF-PD-01 Process Flow DiagramTrivesh SharmaNo ratings yet

- Vendor Rating ExampleDocument4 pagesVendor Rating ExampleRohit SoniNo ratings yet

- DS-05-02 R0 Objectieve & TargetsDocument20 pagesDS-05-02 R0 Objectieve & TargetsDhinakaranNo ratings yet

- Lorenz Shaping-02Document1 pageLorenz Shaping-02Azhar ImamNo ratings yet

- Sidhi Alcast: Machine Maintenance RecordDocument1 pageSidhi Alcast: Machine Maintenance Recordpulkit gargNo ratings yet

- Vendor Supplier RatingDocument3 pagesVendor Supplier RatingSandip TambeNo ratings yet

- Tool Life Monitoring RecordDocument4 pagesTool Life Monitoring RecordMani ManishNo ratings yet

- AQL For SafemateDocument1 pageAQL For SafemateEkklesia Bema PrasyantiNo ratings yet

- RD ASW 22 Masterlist of APQPDocument1 pageRD ASW 22 Masterlist of APQPom cncNo ratings yet

- Quality Performance of SupplierDocument1 pageQuality Performance of Suppliershobha shelarNo ratings yet

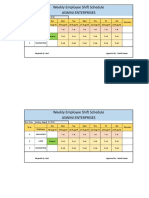

- Weekly Employee Shift Schedule Aswini Enterprises: 1 Adalarasu 2 Ajith 3 MarimuthuDocument10 pagesWeekly Employee Shift Schedule Aswini Enterprises: 1 Adalarasu 2 Ajith 3 Marimuthuom cncNo ratings yet

- Escalation Level E 0: Escalation Process - Status ReportDocument1 pageEscalation Level E 0: Escalation Process - Status ReportSudhagarNo ratings yet

- FT 35 DC D10447340A Process SheetDocument7 pagesFT 35 DC D10447340A Process SheetSuraj RawatNo ratings yet

- Toaz - Info Red Bin Analysis Procedure PRDocument4 pagesToaz - Info Red Bin Analysis Procedure PRRohit QualityNo ratings yet

- Agreement Between Alpha & Disposafe Health and Life CareDocument2 pagesAgreement Between Alpha & Disposafe Health and Life CarePrakash RathodNo ratings yet

- Internal Rejection LevelDocument1 pageInternal Rejection LevelISO CERTIFICATION-ROHSNo ratings yet

- PUR-F-SPR - Supplier Performance RatingDocument4 pagesPUR-F-SPR - Supplier Performance RatingRajkumar PrajapatiNo ratings yet

- FMEA Machine Shop As On 31-10-2022Document1 pageFMEA Machine Shop As On 31-10-2022raghbirNo ratings yet

- Actual Sampling PlanDocument2 pagesActual Sampling PlanAtlasLiu100% (1)

- QMS Cross Audit 18Document4 pagesQMS Cross Audit 18rajesh sharmaNo ratings yet

- 6.2.1 Quality ObjectivesDocument1 page6.2.1 Quality ObjectivesPrakash kumarTripathiNo ratings yet

- D-6 Safety Management Plan 2017Document1 pageD-6 Safety Management Plan 2017Ravikant PandeyNo ratings yet

- Quality System ProcedureDocument3 pagesQuality System ProcedureSubrat barikNo ratings yet

- Qav Observation Closer Sheet FormatDocument1 pageQav Observation Closer Sheet FormatDEVENDERNo ratings yet

- Non Confirmity Closer Method-1Document1 pageNon Confirmity Closer Method-1aslamNo ratings yet

- Sampling PlanDocument1 pageSampling PlanHasnaoui AsmaaNo ratings yet

- 704.F05Daily Production, Rejection ReportDocument4 pages704.F05Daily Production, Rejection ReportRAJESH DHOKALENo ratings yet

- Date: 17.12.2018: 1) 100% Gauge Inspection To Be Carried by Plug Gauge During Final InspectionDocument3 pagesDate: 17.12.2018: 1) 100% Gauge Inspection To Be Carried by Plug Gauge During Final InspectionmuthuselvanNo ratings yet

- PFD Excercise SheetDocument1 pagePFD Excercise SheetRaajha MunibathiranNo ratings yet

- Supplier RatingDocument7 pagesSupplier RatingAarm IndiaNo ratings yet

- Surface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODDocument7 pagesSurface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODBALACHANDAR SNo ratings yet

- Nipfrg-Cqe002 4M Change RegulationDocument10 pagesNipfrg-Cqe002 4M Change RegulationRalph Jason AlvarezNo ratings yet

- 06 Chemical WIDocument1 page06 Chemical WIOMKAR BHAVLENo ratings yet

- MFG Process Audit ReportDocument1 pageMFG Process Audit ReportBASAVA ENGINEERINGNo ratings yet

- RFL, Ismaila Rohtak Supplier Performance Rating: Month: Jan-2015Document6 pagesRFL, Ismaila Rohtak Supplier Performance Rating: Month: Jan-2015Vikas KashyapNo ratings yet

- DS-09-01 R0 Communication During ChangeDocument1 pageDS-09-01 R0 Communication During ChangeDhinakaranNo ratings yet

- Skill MatrixxDocument11 pagesSkill MatrixxNikhil SirNo ratings yet

- Rohtas Fasteners Pvt. LTD.: Defect Matrix-Bolt Cylinder Head SR. Ok Part Defect Reject Part ImageDocument4 pagesRohtas Fasteners Pvt. LTD.: Defect Matrix-Bolt Cylinder Head SR. Ok Part Defect Reject Part ImageVandana MehraNo ratings yet

- PDIR Review PlanDocument1 pagePDIR Review Plankumar QANo ratings yet

- A) Social and Psychological Work EnvironmentDocument4 pagesA) Social and Psychological Work EnvironmentSagar DaundNo ratings yet

- Top 3 Rejections: Rejected Qty Rej %Document1 pageTop 3 Rejections: Rejected Qty Rej %om cncNo ratings yet

- Contingency Plan 2017-2018Document1 pageContingency Plan 2017-2018Suraj RawatNo ratings yet

- Essae 8.03.23Document4 pagesEssae 8.03.23Parthiban DNo ratings yet

- Blow Packaging India LTD: List of Approved SuppliersDocument3 pagesBlow Packaging India LTD: List of Approved Suppliersvishvendan100% (1)

- 2.PFD & PQCS-18293-KVT-9000Document3 pages2.PFD & PQCS-18293-KVT-9000RS MANIKANDANNo ratings yet

- Process Map-NewDocument1 pageProcess Map-NewqualityNo ratings yet

- Control Plan Ingersol RandDocument2 pagesControl Plan Ingersol Randrgrao85No ratings yet

- Quality Evaluation, Problem and Follow Up Results Pdca FormatDocument1 pageQuality Evaluation, Problem and Follow Up Results Pdca FormatPk Nimiwal100% (1)

- List of Competent AuditorsDocument1 pageList of Competent AuditorsRohtash fastnerNo ratings yet

- Sr. No. Hours 1 Apr-21 2 May-21 3 Jun-21 4 Jul-21 5 Aug-21 6 Sep-21 7 Oct-21 8 Nov-21 9 Dec-21 10 Jan-22 11 Feb-22Document5 pagesSr. No. Hours 1 Apr-21 2 May-21 3 Jun-21 4 Jul-21 5 Aug-21 6 Sep-21 7 Oct-21 8 Nov-21 9 Dec-21 10 Jan-22 11 Feb-22Prakash kumarTripathiNo ratings yet

- Life Cycle AnalysisDocument2 pagesLife Cycle Analysis1170100669 Jatoth Naveen KumarNo ratings yet

- Document Change Request: To Be Filled by Requester (Attached Copy If Required)Document1 pageDocument Change Request: To Be Filled by Requester (Attached Copy If Required)Shahbaz AhmedNo ratings yet

- Control Plan m6 Flange NutDocument8 pagesControl Plan m6 Flange NutRANANo ratings yet

- Breakdown Hrs FormatDocument3 pagesBreakdown Hrs FormatnishantNo ratings yet

- Aj D-Prod-01 Preventive Maintenace PlanDocument5 pagesAj D-Prod-01 Preventive Maintenace PlanMANAGEMENT REPRESENTATIVENo ratings yet

- Rohtas Fasteners Pvt. LTD.: Supplier / In-Plant Quality Problem Analysis and Countermeasure Sheet (5-Rule)Document4 pagesRohtas Fasteners Pvt. LTD.: Supplier / In-Plant Quality Problem Analysis and Countermeasure Sheet (5-Rule)Rohtash fastnerNo ratings yet

- Control Plan TWIN ANCHORDocument5 pagesControl Plan TWIN ANCHORMURALIDHRANo ratings yet

- Ewfcxdsavdx3egfqwdswxcvrbgfcf Gbvevf BvcsxawcevDocument3 pagesEwfcxdsavdx3egfqwdswxcvrbgfcf Gbvevf BvcsxawcevBALACHANDAR SNo ratings yet

- Price ListDocument3 pagesPrice ListBALACHANDAR SNo ratings yet

- JyfhtdydhrsdjfjckDocument6 pagesJyfhtdydhrsdjfjckBALACHANDAR SNo ratings yet

- khgjhfjfjvjvjhvjDocument11 pageskhgjhfjfjvjvjhvjBALACHANDAR SNo ratings yet

- AlagDocument31 pagesAlagBALACHANDAR SNo ratings yet

- Step 4: Overall InspectionDocument8 pagesStep 4: Overall InspectionBALACHANDAR SNo ratings yet

- OS For Domain B 3mu The Killer Virus!Document5 pagesOS For Domain B 3mu The Killer Virus!BALACHANDAR SNo ratings yet

- Level 4 Level 3 Level 2 Level 1 Skill Levels: Concept of Skill-UpDocument1 pageLevel 4 Level 3 Level 2 Level 1 Skill Levels: Concept of Skill-UpBALACHANDAR SNo ratings yet

- Sustainability Awareness Behavior Based Safety Industrial Fire HandlingDocument1 pageSustainability Awareness Behavior Based Safety Industrial Fire HandlingBALACHANDAR SNo ratings yet

- Name of Applicant: Personal DetailsDocument4 pagesName of Applicant: Personal DetailsBALACHANDAR SNo ratings yet

- MQS/TPM/3S/1S2S Audit Sheet-Office/F/04 Rev. No.: 00 Rev. Date: 10th April'2013 1Document1 pageMQS/TPM/3S/1S2S Audit Sheet-Office/F/04 Rev. No.: 00 Rev. Date: 10th April'2013 1BALACHANDAR SNo ratings yet

- 3S' Score Board - PU: Total Plant Level ScoreDocument1 page3S' Score Board - PU: Total Plant Level ScoreBALACHANDAR SNo ratings yet

- Audit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50Document1 pageAudit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50BALACHANDAR SNo ratings yet

- MVML/TPM/3S Audit Sheet-Shop Floor/f/03: Rev. No.: 01 Rev. Date: 12th Nov'2014Document5 pagesMVML/TPM/3S Audit Sheet-Shop Floor/f/03: Rev. No.: 01 Rev. Date: 12th Nov'2014BALACHANDAR SNo ratings yet

- PU / Shop Zone Area Description Zone Leader's Name: 3 'S' Zones Details - PlantDocument1 pagePU / Shop Zone Area Description Zone Leader's Name: 3 'S' Zones Details - PlantBALACHANDAR SNo ratings yet

- 3S' Score Board - PlantDocument1 page3S' Score Board - PlantBALACHANDAR SNo ratings yet

- MVML/TPM/3S Audit Sheet-Shop Floor/f/03Document1 pageMVML/TPM/3S Audit Sheet-Shop Floor/f/03BALACHANDAR SNo ratings yet

- 3S - Audit Sheet (Shopfloor) : MQS/TPM/3S/3S Audit Sheet-Shop Floor/f/05 Rev. No.: 00 Rev. Date: 10th April'2013 1Document1 page3S - Audit Sheet (Shopfloor) : MQS/TPM/3S/3S Audit Sheet-Shop Floor/f/05 Rev. No.: 00 Rev. Date: 10th April'2013 1BALACHANDAR SNo ratings yet

- Key Benefits Summary (1S 2S 3S) : F - (FY &month) SR - No. Description BenefitsDocument1 pageKey Benefits Summary (1S 2S 3S) : F - (FY &month) SR - No. Description BenefitsBALACHANDAR SNo ratings yet

- Improvement Sheet (1S 2S 3S)Document1 pageImprovement Sheet (1S 2S 3S)BALACHANDAR SNo ratings yet

- This Moment Is Real and Valuable Give More Than You Take Build Trust by Giving Trust If We Did Good We Will Get GoodDocument1 pageThis Moment Is Real and Valuable Give More Than You Take Build Trust by Giving Trust If We Did Good We Will Get GoodBALACHANDAR SNo ratings yet

- 1S 2S - Audit Sheet (Shopfloor) : MQS/TPM/3S/1S2S Audit Sheet-Shop Floor/f/03 Rev. No.: 00 Rev. Date: 10th April'2013 1Document1 page1S 2S - Audit Sheet (Shopfloor) : MQS/TPM/3S/1S2S Audit Sheet-Shop Floor/f/03 Rev. No.: 00 Rev. Date: 10th April'2013 1BALACHANDAR SNo ratings yet

- Fluid Power Technology: Faculty of Engineering Technology Universiti Malaysia PahangDocument21 pagesFluid Power Technology: Faculty of Engineering Technology Universiti Malaysia PahangAniq AmirahNo ratings yet

- Data Sheet: Air BlowerDocument2 pagesData Sheet: Air BlowerAhmad RifaiNo ratings yet

- Claas Lexion 470-420 Technical Systems, Hydraulic System PDF ManualDocument222 pagesClaas Lexion 470-420 Technical Systems, Hydraulic System PDF ManualBratislav TomicNo ratings yet

- Idah AirSaperatorDocument8 pagesIdah AirSaperatortranngt2020No ratings yet

- Safety: 22 RecyclerDocument16 pagesSafety: 22 RecyclerSebirad StuhaNo ratings yet

- DTC P0420 Catalyst System Efficiency Below Threshold (Bank 1) Catalyst System Efficiency Below Threshold (Bank 2)Document7 pagesDTC P0420 Catalyst System Efficiency Below Threshold (Bank 1) Catalyst System Efficiency Below Threshold (Bank 2)Malik GINo ratings yet

- REPORT CASE STUDY Group 7 - Ahmad Usairi&Firgina Syakura R - EVE16Document79 pagesREPORT CASE STUDY Group 7 - Ahmad Usairi&Firgina Syakura R - EVE16Muhammad IkhwanNo ratings yet

- MMEA Driving and Vehicle Safety OHS StandardDocument14 pagesMMEA Driving and Vehicle Safety OHS StandardaliNo ratings yet

- Condition: 90 Audi Virtual Cockpit Map Section Displayed Inside The SpeedometerDocument4 pagesCondition: 90 Audi Virtual Cockpit Map Section Displayed Inside The SpeedometerMartsinovskyi MykhaildNo ratings yet

- Inventario BujesDocument4 pagesInventario BujeswrkssiraNo ratings yet

- Literature Review On Hydraulic Braking SystemDocument4 pagesLiterature Review On Hydraulic Braking Systemshjpotpif100% (1)

- Komponen Master Rem Mobil - Google PenelusuranDocument1 pageKomponen Master Rem Mobil - Google PenelusuranD KANCUTZNo ratings yet

- MR20 Type 1Document8 pagesMR20 Type 1Juan HamedeliNo ratings yet

- 2020 Corolla HatchbackDocument24 pages2020 Corolla HatchbackaeroglideNo ratings yet

- E.mc 01Document29 pagesE.mc 01Hasitha B. RathnayakeNo ratings yet

- Plant Protection Equipment: Classification o Spraying TechnologiesDocument20 pagesPlant Protection Equipment: Classification o Spraying Technologiesठाकुर प्रशान्त सिंहNo ratings yet

- U431a - Axle - RearDocument6 pagesU431a - Axle - RearbennieNo ratings yet

- CAT 3126E Disassembly&AssemblyDocument120 pagesCAT 3126E Disassembly&AssemblyMatíasNo ratings yet

- Sierra Designs Flashlight 2 Pitching InstructionsDocument2 pagesSierra Designs Flashlight 2 Pitching InstructionsYanivNo ratings yet

- 16c3001 Com Inb RB 545 545silagepack Final LowDocument20 pages16c3001 Com Inb RB 545 545silagepack Final LowSamuelNo ratings yet

- SM 7Document702 pagesSM 7mohhizbarNo ratings yet

- Report On S/D of Unit#7: 1. TG Bearing-1 Shaft Vibration & Journal Bearing Temperature Bottom L & R Remain HighDocument11 pagesReport On S/D of Unit#7: 1. TG Bearing-1 Shaft Vibration & Journal Bearing Temperature Bottom L & R Remain Higheureka.nitishNo ratings yet

- Cop 1132Document20 pagesCop 1132rolandNo ratings yet

- 6.2 Cem Plan Final Edit2Document36 pages6.2 Cem Plan Final Edit2Jerry SarimoleNo ratings yet

- SSV 7500Document3 pagesSSV 7500hans calderonNo ratings yet

- Dawn 150 Africa (Feb, 2019)Document96 pagesDawn 150 Africa (Feb, 2019)Michaell KingsNo ratings yet

- 4HK1 Manual 3Document37 pages4HK1 Manual 3Imesh SachinthaNo ratings yet