ET150 y Prototipo PSA PDF

ET150 y Prototipo PSA PDF

Uploaded by

carzanteCopyright:

Available Formats

ET150 y Prototipo PSA PDF

ET150 y Prototipo PSA PDF

Uploaded by

carzanteOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

ET150 y Prototipo PSA PDF

ET150 y Prototipo PSA PDF

Uploaded by

carzanteCopyright:

Available Formats

Proceedings of Solar Forum 2001

Solar Energy: The Power to Choose

April 21-25, 2001, Washington, DC

EUROTROUGH DESIGN ISSUES AND PROTOTYPE TESTING AT PSA

Eckhard Lüpfert, Michael Geyer Wolfgang Schiel

Deutsches Zentrum für Luft- und Raumfahrt e.V. Schlaich Bergermann und Partner (SBP)

Plataforma Solar de Almería (PSA) Hohenzollernstr. 1

Apartado 39 · E-04200 Tabernas, Spain · D-70178 Stuttgart, Germany

Phone: +34 950 387906 Phone: +49 711 6487120

E.LUEPFERT@DLR.DE W.SCHIEL@SBP.DE

Antonio Esteban, Rafael Osuna Eduardo Zarza Paul Nava

INABENSA, División Taller CIEMAT-PSA Flabeg Solar International

c/Manuel Velasco Pando 7 Plataforma Solar de Almería Mühlengasse 7

E-41007 Sevilla, Spain E-04200 Tabernas, Spain · D-50667 Köln, Germany

Phone: +34 95 493 6111 Phone: +34 950 387931 Phone: +49 221 925 970-0

ROSUNA@INABENSA.ABENGOA.COM EDUARDO.ZARZA@PSA.ES PAUL.NAVA@FLABEG.COM

ABSTRACT LUZ collectors LS-2 and LS-3 in California.

A parabolic trough collector has been developed for The work targeted collector development for a wide

various applications in the 200-400°C temperature range in range of applications in the 200-400°C-temperature range

solar fields up to the hundreds Megawatts range. in solar fields up to the hundreds Megawatts range:

The design of a new support structure of the collector • Solar thermal electricity generation in co-generation

included concept studies, wind tunnel measurements, finite plants

elements method (FEM) analyses and resulted in a • Solar thermal process heat applications in a wide range

structure with a central framework element. This torque of process steam

box design will have lower weight and less deformation of • Solar thermal sea-water desalination in MED

the collector structure than the other designs considered. processes

Therefore it will be possible in future to connect more

collector elements on one drive which results in reduced

total number of drives and interconnecting pipes, thus STATE OF THE ART

reducing the installation cost and thermal losses. In terms The successful parabolic trough design in the 80s has

of the degree of material usage further weight reduction been implemented in the Californian SEGS plants by LUZ,

will be possible. The presented design has a significant and the collectors still operate for grid-connected electricity

potential for cost reduction, the most important goal of the production. The operating companies have worked

EUROTROUGH project. The prototype has been set-up and thoroughly on improvement of operation and maintenance

is under testing at PSA (Plataforma Solar de Almería) for (Cohen et al., 1999). Features of the different collector

its thermal and mechanical properties. types in terms of performance and durability became

obvious.

The main characteristics of these collectors however

INTRODUCTION establish the minimum requirements for a new generation

Parabolic trough collectors have been the key element of parabolic trough collectors.

in the commercial application of concentrating solar Key elements of the existing technology are:

thermal power plants in California. Although other • support structure: steel frame-work structure with

concentrators promise higher concentration factors and central torque tube or double V-trusses

higher system efficiencies the parabolic trough will • drive: gear drive, hydraulic drive

continue paving the way for concentrating solar power. • tracking control: clock controlled, sun-sensor

Considering this importance a European consortium has controlled

developed the next generation of a parabolic trough • reflector panels: parabolic mirrors, from glass or metal

collector basing on the long experience of operation of sheets

Copyright © 2001 by ASME

• absorber tubes (heat collection element = HCE): with these experiments. Horizontal forces and pitching moments

evacuated glass envelope have been evaluated for different wind speed and direction,

• fluid: mineral oil, synthetic oil, water/steam different collector positions in the field and various

The components depend in part on the application, elevations of the collector. The evaluation of the wind

especially on the temperature range. tunnel measurements confirmed that the solar collector

The EuroTrough project consortium gained through field of a full size plant could be divided into three

the thorough research on the existing parabolic trough different wind loading zones: The shadowed inner field

collector designs an elaborate basis for the important area with approximately 95% of the total Solar Collector

design phase. Elements (SCE), the transient area (close to the edges of

the field) with about 2.5% and the high wind loaded edges

and rim areas where about 2.5% of the total SCE are

EUROTROUGH DESIGN CONCEPT located. Due to these different wind loads the collector

The concept of the EUROTROUGH collector is basing structure is designed in accordance to these different wind

on the boundary conditions mentioned above. Key zones. A solar collector field will have three different types

characteristics are given in table 1. of collector structures (a high wind loaded, a medium wind

loaded and a regular structure) depending on where the

TABLE 1: EUROTROUGH CHARACTERISTICS SCE is located in the field. The cost of a complete Solar

Collector Field will be dictated by the cost of the regular

layout parabolic trough collector SCE located in the shadowed field area. Due to this result

support structure steel frame work, pre-galvanized, the next step in finalizing the design was concentrated on

three variants; light weight, low the SCE structure in the shadowed field area.

torsion

collector length 12 m per element;

100 - 150 m collector length

drive hydraulic drive measuring

segment

max. wind speed operation: 14 m/s, stow: 40 m/s

tracking control clock + sun sensor, <2 mrad

parabola y = x2/4f with f = 1.71 m

aperture width 5.8 m

reflector 4 glass facets

absorber tube evacuated glass envelope, UVAC® or

other, application dependent

fluid oil, steam, application dependent

cost < 200 Euro/m2

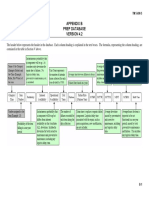

Major effort was put on the design of the metallic Figure 1: Experimental set-up of the wind tunnel test. Cp

collector support structure of the concentrator. Apart from values have been measured at different positions of the

survival of the structure, the stiffness of the collector is collector element, different locations in the field and

important to keep up collector performance with wind- various pitching angles of the SCE as well as different wind

loads during operation. This has been examined from two directions.

aspects:

• wind tunnel experiments for determination of the

forces and moments 2. Structural Analysis

• Finite Element Method calculations (FEM) to Detailed FEM investigations on the structural behavior

determine collector deformation and estimate under different load cases (dead load, wind loads under

losses (spillage of radiation due to wind). different pitching angles of the collector and different wind

directions) for different designs were performed for

1. Wind Tunnel Evaluation obtaining results on the expected deformation of the

In a first step detailed wind tunnel tests have been structure under different operation conditions. From these

conducted for getting a reliable database for the expected results the expected optical performance of the new

wind loads at different locations in the collector field. collector design was derived. A lot of effort was spent on

Figure 1 shows the experimental set up of the wind tunnel evaluating the optical performance of the new collector

test. Bending and torsion forces have been determined in design:

Copyright © 2001 by ASME

80 16

70 14

60 12

50 10

wind speed (m/s)

LS-3 average twist of SCE on wind

spillage in %

40 8

ET4 average twist of SCE on wind

ET6 average twist of SCE on wind

30 spillage losses due to twisting 6

5 m/s

20 4

LS-3

10 2

ET-4

0 0

0 2 4 6 8 10 12 14 16 18 20

Twist in mrad

Figure 2: Analysis of angular twist and radiation spillage as result of wind load on the Solar Collector Assembly for

EuroTrough collector with 100 and 150 m (ET4, ET6), and the reference collector (LS-3).

Computer modeling of the optical performance was 12 (150m) is feasible. This decreases the total number of

done with ray tracing of the structure deformed due to required drives for a collector field as well as the number

bending and twisting, evaluation of tracking error, of interconnecting pipes and will have a positive impact on

deformation and misalignment of the absorber tube. the total collector cost.

Different operating wind velocities from 3 to 14 m/s The actual EUROTROUGH collector support structure

(causes different induced twisting moments on the design is shown in figure 3. It is composed of a rectangular

structure) were investigated in order to estimate the torque box with mirror support arms. The rotational axis is

influence of a windier site on optical system performance. in the center of gravity, a few millimeters above the torque

For comparing the obtained results with the data and box.

experience gained in the US and on the Plataforma Solar de The central element of the box design is a 12-m long

Almería with other collector designs the same FEM steel space-frame structure having a squared cross section

analysis was also performed for those structures. Three that holds the support arms for the parabolic mirror facets.

design variants have been worked out and compared to The torque box is much simpler than the LS-3 space frame

each other by detailed FEM calculations, and cost structure. The box is built out of only 4 different steel parts.

approximates. This will lead to an easy manufacturing and will decrease

required efforts and thus cost for assembling and erection

on site. Transportation requirements have been optimized

RESULTS for maximum packing.

Based on these studies a so-called torque-box design The design comprises mirror supports that make use of

has been selected as the most promising concept. The the glass facets as static structural element, but at the same

torque-box design proves to allow less deformation of the time reduce the forces onto the glass sheets by a factor of

collector structure due to dead weight and wind loading three. This promises less glass breakage with highest wind

than the other designs. This reduces torsion and bending of speeds.

the structure during operation and results in increased Due to an improved design of the drive pylon the Solar

optical performance and wind resistance. An extension of Collector Assembly could be mounted on an inclined site

the number of SCEs per drive unit from today 8 (100m) to (3%). Thus cost for site preparation will be reduced.

Copyright © 2001 by ASME

The accuracy of the concentrator is achieved by a

combination of prefabrication with jig mounting on site.

The majority of the structural parts is produced with steel

construction tolerances. The accuracy for the mirror

supports is introduced with 6 drillings in each of the

cantilever arms. Two of them serve for positioning and

keep available for later alignments. The other four holes

are used for the mirror support brackets and define the

position of the parabola with a relatively simple erection

jig.

An important objective was the cost reduction of

parabolic trough collectors. The weight of the steel

structure has been reduced about 14% as compared to the

available design of the LS-3 collector. Additional cost

reduction in the order of another 10 % is assumed by

reduction of the variety of parts and by more compact

transport. Series production cost of the total collector

installation below 200 Euro(€) per square meter of aperture

is anticipated.

PROTOTYPE TESTING AT PSA

The construction and workshop drawings have been

Figure 3: Sketch of the EUROTROUGH collector torque-box finished and the first prototype collector has been mounted

design: Central element is a steel construction which in a strong version (for high wind load) at PSA, see figures

absorbs torsion and bending forces. The reflector panels 4 and 5. The collector is set-up in east-west direction and

are supported with attached arms, using a type of fixation with careful temperature sensor installation for improved

to reduce breakage. testing capabilities. Due to budget limitations only half a

collector (drive pylon with collector elements to one side

One of the objectives of the design was weight only) has been prepared (figure 5).

reduction as compared to the LS-3 collector structure. The

following table shows weight figures for the EuroTrough

Collector Element:

TABLE 2: EUROTROUGH SOLAR COLLECTOR

ELEMENT WEIGHTS:

EuroTrough Collector strong “field”

Component SCE SCE

Glass mirrors kg 747 747

HCE (incl. oil) kg 73 73

Torque box kg 597 597

End Plates kg 186 130

Cantilever Arms kg 384 231

HCE supports kg 113 90

Torque Transfer kg 32 32 Figure 4: View of the EUROTROUGH support structure

Total weight steel structure only kg 1,312 1,080 taken during mirror assembly.

Specific weight steel only kg/m² 19.0 15.6

Total weight kg 2,132 1,900

incl. mirrors and HCE

Specific weight kg/m² kg/m² 30.9 27.5

Copyright © 2001 by ASME

ACKNOWLEDGMENTS

Financial support of the European Commission (JOR3

CT98 0231) and the consortium partners is gratefully

acknowledged.

The presented work has been performed by the

EUROTROUGH consortium partners Instalaciones Abengoa,

S.A. (INABENSA), Schlaich Bergermann und Partner

(SBP), Fichtner Solar GmbH, FLABEG Solar

International, Deutsches Zentrum für Luft- und Raumfahrt

e.V. (DLR), Centro de Investigaciones Energéticas,

Medioambientales y Tecnológicas (CIEMAT), and Centre

for Renewable Energy Sources (CRES).

Figure 5: The EUROTROUGH collector prototype tested at

PSA has currently four, later six collector elements to one

side of the hydraulic drive. REFERENCES

Cohen, G., Kearney, D., Price, H. (1999) “Performance

The test program for the prototype includes initial history and future costs of parabolic trough solar

thermal performance tests with synthetic oil up to 390°C. electric systems”, 9th Int. Symposium on Solar Thermal

Further tests aim at optical and mechanical evaluation of Concentrating Technologies, Odeillo, France, June

the collector. 1998, J. Phys . IV France 9 PR3 pp. 169-179.

Esteban, A.; Lüpfert, E. (2001) “Final Report EuroTrough

project JOR3-CT98-0231”, public version.

OUTLOOK Pilkington Solar (1996) “Status Report on Solar Thermal

As wind influence is highly transient and difficult to Power Plants - Experience, Prospects and

measure with the thermal output, stress and acceleration Recommendations to Overcome Market Barriers of

sensors as well as angular encoders on several pylons are Parabolic Trough Collector Power Plant Technology.”

foreseen. Cologne 1996. ISBN 3-9804901-0-6.

Additional outcome from the prototype development

phase goes towards economic fabrication technologies for

mass production.

Performance data from the testing and other recent

project information will be available in Internet

(www.eurotrough.com).

Basing on the current design with lower cost and

higher performance of the parabolic trough collector, a next

step towards better competition of solar power with

conventional fossil technologies has been achieved.

Like in other European project work on trough

collectors, e.g. direct steam generation, the project aims at

further cost reduction and market penetration for near term

future.

Worldwide interest in solar thermal technology is the

driving force for the ongoing work on the parabolic trough

collector design. The design is available for interested

license takers. The main challenges for the EUROTROUGH

technology are electricity generation, and process heat in a

wide temperature range, including desalination.

Copyright © 2001 by ASME

You might also like

- Mechanical Engineering Design Criteria PDFDocument44 pagesMechanical Engineering Design Criteria PDFadca100% (1)

- Solar BikeDocument16 pagesSolar BikeRobi Sixer Axial0% (1)

- Ar 1167Document7 pagesAr 1167tarun_aseriNo ratings yet

- Junchang 2008Document8 pagesJunchang 2008samruddhi davkarNo ratings yet

- Diseño y Construcción de Un Prototipo de Colector Solar Parabólico Tipo Disco Con Sistema de Seguimiento SolarDocument14 pagesDiseño y Construcción de Un Prototipo de Colector Solar Parabólico Tipo Disco Con Sistema de Seguimiento Solarandrea.lopezNo ratings yet

- Solarpaces Fresnel 9 2002Document11 pagesSolarpaces Fresnel 9 2002piranna7400No ratings yet

- Calculation of Optical Efficiency For The First Central Recei - 2015 - Energy PRDocument6 pagesCalculation of Optical Efficiency For The First Central Recei - 2015 - Energy PRpaween saetaeNo ratings yet

- Low Concentration Solar Array Experiment On-Board Proba-2Document6 pagesLow Concentration Solar Array Experiment On-Board Proba-2llmm_088No ratings yet

- Modeling of The Double-Skin Facades For Building Energy Simulations: Radiative and Convective Heat TransferDocument8 pagesModeling of The Double-Skin Facades For Building Energy Simulations: Radiative and Convective Heat TransferThao NguyenNo ratings yet

- Study On Linear Fresnel Reflector PDFDocument9 pagesStudy On Linear Fresnel Reflector PDFPaulFerry100% (1)

- Overview of Solar DesalinationDocument17 pagesOverview of Solar Desalinationalagar krishna kumarNo ratings yet

- (##) Solar Water Purification by Using Thermal MethodDocument83 pages(##) Solar Water Purification by Using Thermal MethodKiruba Shanker88% (8)

- J.renene.2010.06.00320210423 16696 436w02 With Cover Page v2Document8 pagesJ.renene.2010.06.00320210423 16696 436w02 With Cover Page v2AHMED AL MERSNo ratings yet

- Performance Evaluation of Solar Tracking Systems For Power Generation Based On Simulation Analysis: Solar Island ConceptDocument4 pagesPerformance Evaluation of Solar Tracking Systems For Power Generation Based On Simulation Analysis: Solar Island ConceptJoelson PaixãoNo ratings yet

- PERFORDocument12 pagesPERFORHamza MoussaNo ratings yet

- Power Plant EngineeringDocument11 pagesPower Plant Engineeringnickswap100% (1)

- Performance Design Optimization PDFDocument12 pagesPerformance Design Optimization PDFoscop2009No ratings yet

- A Detailed Thermal Model of A Parabolic Trough Collector Receiver PDFDocument9 pagesA Detailed Thermal Model of A Parabolic Trough Collector Receiver PDFAnikilatorBoy100% (1)

- 1 s2.0 S0038092X20308434 MainDocument12 pages1 s2.0 S0038092X20308434 MainZARINo ratings yet

- Floating Solar Chimney Technology: February 2010Document37 pagesFloating Solar Chimney Technology: February 2010Chinna CharanNo ratings yet

- Floating Solar Chimney Technology: Christos D. PapageorgiouDocument21 pagesFloating Solar Chimney Technology: Christos D. PapageorgiouPrabhat SharmaNo ratings yet

- Journal TemplateDocument6 pagesJournal TemplateMuhammad Danial Bin RazaliNo ratings yet

- An End of Service Life Assessment of Pmma Lenses From Veteran Concentrator Photovoltaic SystemsDocument43 pagesAn End of Service Life Assessment of Pmma Lenses From Veteran Concentrator Photovoltaic SystemsIsagani BadajosNo ratings yet

- Light Concrete Shells For Parabolic Trough Collectors - Conceptual Design, Prototype and Proof of Accuracy - ScienceDirectDocument6 pagesLight Concrete Shells For Parabolic Trough Collectors - Conceptual Design, Prototype and Proof of Accuracy - ScienceDirectkoatalkier2No ratings yet

- Determination of Efficiency of Flat-Plate Solar Collectors Using Neural Network ApproachDocument7 pagesDetermination of Efficiency of Flat-Plate Solar Collectors Using Neural Network ApproachOmarZSharafNo ratings yet

- Experimental Investigation On The Feasibility of UDocument10 pagesExperimental Investigation On The Feasibility of UFERNANDO CASTRONo ratings yet

- Volumetric Recievers-A ReviewDocument20 pagesVolumetric Recievers-A ReviewDany ValverdeNo ratings yet

- Cdna102013ac 001Document202 pagesCdna102013ac 001Fernando HoyoNo ratings yet

- Concentrating Solar CollectorDocument21 pagesConcentrating Solar CollectorAthira RajineshNo ratings yet

- The Wind Structure Interaction Analysis and Optimization of - 2015 - Energy ProDocument7 pagesThe Wind Structure Interaction Analysis and Optimization of - 2015 - Energy Propaween saetaeNo ratings yet

- Skills PresentDocument10 pagesSkills Presenteyad mohamadNo ratings yet

- Nanofuids in Solar Thermal CollectorsDocument74 pagesNanofuids in Solar Thermal Collectorssaedpanahrashid2No ratings yet

- A New Dynamic Test Method For Thermal Performance of All-Glass Evacuated Solar Air CollectorsDocument10 pagesA New Dynamic Test Method For Thermal Performance of All-Glass Evacuated Solar Air CollectorsTihomir TanevNo ratings yet

- Evaluation of CPC-collector Designs For Stand-Alone, Roof-Or Wall InstallationDocument10 pagesEvaluation of CPC-collector Designs For Stand-Alone, Roof-Or Wall InstallationPedro Reynaldo MartinezNo ratings yet

- Solar RefrigerationDocument8 pagesSolar RefrigerationPavan HkNo ratings yet

- A Building-Integrated Eolic System For The Exploitation of Wind Energy in Urban AreasDocument6 pagesA Building-Integrated Eolic System For The Exploitation of Wind Energy in Urban AreasrasablackmoreNo ratings yet

- SolarEnergyandPhotovoltaicSystemspublication PDFDocument9 pagesSolarEnergyandPhotovoltaicSystemspublication PDFAnonymous AN2Dd7qjNo ratings yet

- Transient Characterization of Multiple Parabolic Trough Collect 2015 EnergyDocument10 pagesTransient Characterization of Multiple Parabolic Trough Collect 2015 Energypaween saetaeNo ratings yet

- CFD Analysis of Solar Flat Plate CollectorDocument6 pagesCFD Analysis of Solar Flat Plate CollectorDimuthu Prasad WijethungeNo ratings yet

- Simulation Model of at Plate Solar Collector Performance: February 2011Document20 pagesSimulation Model of at Plate Solar Collector Performance: February 2011Meryem BenNo ratings yet

- 2016 - Evaluation of An Integrated Roof Wind Energy System For Urban EnvironmentsDocument12 pages2016 - Evaluation of An Integrated Roof Wind Energy System For Urban EnvironmentsKhoirul BeNo ratings yet

- Solar Thermal Power Technologies: July 2002 ECN-C - 02-062Document50 pagesSolar Thermal Power Technologies: July 2002 ECN-C - 02-062fragriNo ratings yet

- Design and Experimental Validation of A Photovoltaic-Thermal (PVT) Hybrid CollectorDocument8 pagesDesign and Experimental Validation of A Photovoltaic-Thermal (PVT) Hybrid CollectorSuraj SharmaNo ratings yet

- Effect of Slope Tower Angle and Thermal Storage Media On Flexibility Solar Chimney Power Plant Performance (Accepted)Document23 pagesEffect of Slope Tower Angle and Thermal Storage Media On Flexibility Solar Chimney Power Plant Performance (Accepted)Hakim SemaiNo ratings yet

- CHESS Upgrade With Compact Undulator Magnets: Operating Experience and First ResultsDocument5 pagesCHESS Upgrade With Compact Undulator Magnets: Operating Experience and First ResultsBengt HörbergNo ratings yet

- A Study of Solar Chimney Coupled To Spiral Heat Exchanger: March 2016Document7 pagesA Study of Solar Chimney Coupled To Spiral Heat Exchanger: March 2016Amoul DhahriNo ratings yet

- Design and Testing of A Solar Parabolic Concentrating CollectorDocument5 pagesDesign and Testing of A Solar Parabolic Concentrating CollectorAsepta Surya WardhanaNo ratings yet

- Validation of CFD Simulation For Flat Plate Solar Energy CollectorDocument5 pagesValidation of CFD Simulation For Flat Plate Solar Energy CollectorcrikalaoNo ratings yet

- EuroTroughPaperZurich2002 FinalDocument8 pagesEuroTroughPaperZurich2002 FinalGonzalo OncalaNo ratings yet

- Teorical MainDocument14 pagesTeorical MainFaryth DazaNo ratings yet

- San Juan Condominium ProjectDocument36 pagesSan Juan Condominium Projectmaria fernanda toro carlosiNo ratings yet

- Chapter 10Document31 pagesChapter 10Satyajit MNo ratings yet

- Pap Kraetzig 02Document16 pagesPap Kraetzig 02ersinNo ratings yet

- Floating Solar PowerDocument37 pagesFloating Solar Powerthomas1313No ratings yet

- A Detailed Thermal Model So A Parabilic Trough Collector Receiver (Sosteris A Kalogirou) 2012 (Paper)Document9 pagesA Detailed Thermal Model So A Parabilic Trough Collector Receiver (Sosteris A Kalogirou) 2012 (Paper)Eirick Wayne Zuñigga De-ItzelNo ratings yet

- 11 Enclosure and InfrastructuresDocument32 pages11 Enclosure and Infrastructuresborisleonovick512No ratings yet

- Hybrid Photovoltaic Thermal PV-T Solar Systems Simulation With Simulink MatlabDocument12 pagesHybrid Photovoltaic Thermal PV-T Solar Systems Simulation With Simulink MatlabnivamNo ratings yet

- 1 s2.0 S0360319913010379 MainDocument9 pages1 s2.0 S0360319913010379 MainveepekayNo ratings yet

- Ices 2023 448Document16 pagesIces 2023 448Andrew GibsonNo ratings yet

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsFrom EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsNo ratings yet

- Radio Control for Model Ships, Boats and AircraftFrom EverandRadio Control for Model Ships, Boats and AircraftRating: 5 out of 5 stars5/5 (1)

- H2 Storage - CostDocument26 pagesH2 Storage - CostcarzanteNo ratings yet

- Tabla Disponibilidad (Alternativa OREDA)Document18 pagesTabla Disponibilidad (Alternativa OREDA)carzanteNo ratings yet

- Manual Cost Analysis Tool V1.0Document54 pagesManual Cost Analysis Tool V1.0carzanteNo ratings yet

- Lahmeyer - Costes de O&MDocument225 pagesLahmeyer - Costes de O&McarzanteNo ratings yet

- Vaccum Pump Vs Steam Ejector AdvantagesDocument6 pagesVaccum Pump Vs Steam Ejector AdvantagescarzanteNo ratings yet

- Wittmann Some Aspects On Parabolic Trough Field Operation PDFDocument9 pagesWittmann Some Aspects On Parabolic Trough Field Operation PDFcarzanteNo ratings yet

- Integrated Solar Power Plants (ISCC)Document13 pagesIntegrated Solar Power Plants (ISCC)carzanteNo ratings yet

- Compressor SpecificationDocument9 pagesCompressor Specificationcarzante100% (1)

- Task 2 Final Report PDFDocument94 pagesTask 2 Final Report PDFcarzanteNo ratings yet

- Aerosols en SolarGISDocument4 pagesAerosols en SolarGIScarzanteNo ratings yet

- Technical Description Steam EnginesDocument6 pagesTechnical Description Steam Enginescarzante100% (1)

- HTF Venting System - MojaveDocument29 pagesHTF Venting System - MojavecarzanteNo ratings yet

- 3 Value Chain MorinDocument14 pages3 Value Chain MorincarzanteNo ratings yet

- HTF DegradationDocument13 pagesHTF DegradationcarzanteNo ratings yet

- Combined Autoclave and Water Purification System Using Solar EnergyDocument3 pagesCombined Autoclave and Water Purification System Using Solar EnergyIJIRSTNo ratings yet

- Renewable PPT Presentation (Every Monday) (Responses)Document1 pageRenewable PPT Presentation (Every Monday) (Responses)gauravpatel5436No ratings yet

- Proton Exchange Membrane (PEM) and Solid Oxide (SOFC) Fuel Cell Based Vehicles-A ReviewDocument5 pagesProton Exchange Membrane (PEM) and Solid Oxide (SOFC) Fuel Cell Based Vehicles-A ReviewSHISHIRNo ratings yet

- SolarDocument9 pagesSolarPablo TrujilloNo ratings yet

- Project PPT For NCRIEDocument17 pagesProject PPT For NCRIE12 Jayesh DhavaleNo ratings yet

- Lorentz PS1800 CS-36-1Document4 pagesLorentz PS1800 CS-36-1SINES FranceNo ratings yet

- Discuss The Processes of The Following PlantsDocument1 pageDiscuss The Processes of The Following PlantsEric John CruzNo ratings yet

- Energy Management Dissertation TopicsDocument7 pagesEnergy Management Dissertation TopicsBuyCollegePaperOnlineUK100% (1)

- MR. GOPAL RATHOD: 999-888-1999: Model Payable After Subsidy System Payable Structure Payable Final PayableDocument1 pageMR. GOPAL RATHOD: 999-888-1999: Model Payable After Subsidy System Payable Structure Payable Final PayableSudesh RewaniNo ratings yet

- Oef 127Document61 pagesOef 127DjousNo ratings yet

- Different Sources of Energy An AssignmentDocument17 pagesDifferent Sources of Energy An Assignmentrex23065No ratings yet

- Tech Musings: Don Lancaster'sDocument6 pagesTech Musings: Don Lancaster'sngaltunokNo ratings yet

- 7th Sem Major ProjectDocument23 pages7th Sem Major ProjectArjun BanerjeeNo ratings yet

- Unit 6 - Bell RingersDocument19 pagesUnit 6 - Bell Ringersluz gilNo ratings yet

- Solar Power: An Eternal Source of EnergyDocument2 pagesSolar Power: An Eternal Source of EnergyBishwajitNo ratings yet

- 2A-2 PHEV TestingDocument17 pages2A-2 PHEV Testingrey1004No ratings yet

- Lecture 10 - Energy Efficiency and Renewable EnergyDocument25 pagesLecture 10 - Energy Efficiency and Renewable EnergyimdhruvgNo ratings yet

- IB Physics: Energy Production (I)Document73 pagesIB Physics: Energy Production (I)Anson CHAUNo ratings yet

- Topic - Renewable Energy in MalaysiaDocument6 pagesTopic - Renewable Energy in MalaysiaRachel NhanamNo ratings yet

- Advances in Wind EnergyDocument66 pagesAdvances in Wind EnergyArshadali Ansari100% (2)

- CMR MetchDocument10 pagesCMR Metchlbhanu408No ratings yet

- Design of Renewable Energy Systems-1Document118 pagesDesign of Renewable Energy Systems-1Sameh Haj AliNo ratings yet

- Windpods BrochureDocument8 pagesWindpods BrochurelhotapNo ratings yet

- Question Bank - ETDocument2 pagesQuestion Bank - ETSOWMI C SNo ratings yet

- LG Chem Resu DatasheetDocument14 pagesLG Chem Resu Datasheetachmad 1900000No ratings yet

- Study On Linear Fresnel Reflector PDFDocument9 pagesStudy On Linear Fresnel Reflector PDFPaulFerry100% (1)

- Sean White CV 10-2012Document2 pagesSean White CV 10-2012DangQuangTrungNo ratings yet

- Passive Solar DesignDocument44 pagesPassive Solar Designnandanthareja100% (1)