0 ratings0% found this document useful (0 votes)

119 viewsF 655

F 655

Uploaded by

Michael Haiseoffshore

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

F 655

F 655

Uploaded by

Michael Haise0 ratings0% found this document useful (0 votes)

119 views1 pageoffshore

Original Title

f655

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

offshore

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

119 views1 pageF 655

F 655

Uploaded by

Michael Haiseoffshore

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 1

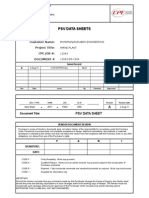

Peck & Hale),

INSTALLATION

PROCEDURE

FOR

F655

BREECH BASE (RAISED) DECK SOCKET

INSTALLATION INSTRUCTIONS:

STEP 1: DECK LINES

‘Shipyard is to lay out intersecting lines on the deck which locate the center line of the deck socket

‘opening ralative to the center lines of the I.S.O. container comer casting openings.

STEP 2: POSITIONING

Socket to be positioned over deck lines described in STEP 1 above.

: SUPPORTS AND STIFFENERS

Shipyards to supply supports, stiffeners, and reinforcing plates to sult ship structure with adequate

installation and construction to satisfy appropriate classification society requirements.

STEP 4: PREPARATION

Socket, deck plates, and base plates are to be properly prepared and cleaned before welding,

‘STEP 5: PREHEAT

Socket to be preheated to 100°C -150°C. Retard cooling after welding

‘STEP 6: WELDING

‘Weld with 70,000 P-S.1. low hydrogen rod equal to A.W.S. E7018. Moisture content to be

controlled per recommended A.W.S. storage and reconditioned procedures.

STEP 7: CLASSIFICATION SOCIETY APPROVAL

‘Shipyard to obtain appropriate classification society approval on specific welding procedures.

STEP

DECK LINES

TOP VIEW (SEE STEPS 1-2) SIDE VIEW (SEE STEPS 3-7)

180 DIVISION AVE., WEST SAYVILLE, NEW YORK 11796 ~ TEL. (516) 589-2510, 1-800-448-7925 ~ FAX (516) 589-2925,

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5986)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1112)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (898)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (932)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (619)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (546)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (357)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (831)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (477)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (275)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (425)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2272)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (99)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (125)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (270)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (232)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (235)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (75)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Heat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SideDocument1 pageHeat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SideMichael HaiseNo ratings yet

- Hydrotest Acceptance Questionnaire & Resources: Questions To AskDocument2 pagesHydrotest Acceptance Questionnaire & Resources: Questions To AskMichael HaiseNo ratings yet

- Pump (English) TemplateDocument1 pagePump (English) TemplateMichael Haise100% (1)

- CalculationsDocument6 pagesCalculationsMichael Haise100% (1)

- Desuperheater Boiler Feed Water RequirementDocument2 pagesDesuperheater Boiler Feed Water RequirementMichael HaiseNo ratings yet

- Vessel Sizing Calculation Data Sheets: Customer Name: Project Title: Cpe Job #: Document #Document13 pagesVessel Sizing Calculation Data Sheets: Customer Name: Project Title: Cpe Job #: Document #Michael HaiseNo ratings yet

- Wind LoadDocument2 pagesWind LoadMichael Haise100% (1)

- Vessel Data Sheet: Design CriteriaDocument8 pagesVessel Data Sheet: Design CriteriaMichael HaiseNo ratings yet

- API TablesDocument72 pagesAPI TablesMichael HaiseNo ratings yet

- Intermediate Head Weld StressDocument1 pageIntermediate Head Weld StressMichael HaiseNo ratings yet

- PSVsDocument8 pagesPSVsMichael HaiseNo ratings yet

- Basic Pipe AnalysisDocument29 pagesBasic Pipe AnalysisMichael HaiseNo ratings yet

- Saddle CalculationDocument7 pagesSaddle CalculationMichael HaiseNo ratings yet

- 88K Condensate Storage Tank 146.75 OD X 100ftDocument11,238 pages88K Condensate Storage Tank 146.75 OD X 100ftMichael HaiseNo ratings yet

- Mechanical Calcualtions: Date: 3/28/2006 By: MH Checked: ApprovedDocument1 pageMechanical Calcualtions: Date: 3/28/2006 By: MH Checked: ApprovedMichael HaiseNo ratings yet

- Inputs Inputs: Top TriangleDocument4 pagesInputs Inputs: Top TriangleMichael HaiseNo ratings yet

- Spreader Bar Plus Free BodyDocument17 pagesSpreader Bar Plus Free BodyMichael HaiseNo ratings yet