Construction Notes: General: Concrete Work: Reinforcement Notes

Construction Notes: General: Concrete Work: Reinforcement Notes

Uploaded by

eddieCopyright:

Available Formats

Construction Notes: General: Concrete Work: Reinforcement Notes

Construction Notes: General: Concrete Work: Reinforcement Notes

Uploaded by

eddieOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Construction Notes: General: Concrete Work: Reinforcement Notes

Construction Notes: General: Concrete Work: Reinforcement Notes

Uploaded by

eddieCopyright:

Available Formats

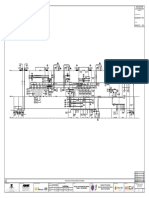

REPUBLIC OF THE PHILIPPINES

DEPARTMENT OF PUBLIC WORKS

AND HIGHWAYS

OFFICE OF THE BUILDING OFFICIAL

CONSTRUCTION NOTES CEBU CITY

RECOMMENDING APPROVAL:

HEAD CIVIL/STRUC'L. SECTION DATE

APPROVED:

BUILDING OFFICIAL DATE

CONCRETE WORK :

GENERAL : REINFORCEMENT NOTES :

1. CONCRETE QUALITY SHALL BE AS FOLLOWS :

1. THESE DRAWINGS ARE TO BE READ IN CONJUNCTION WITH ALL ALL REINFORCING BARS SHALL CONFORM TO ASTM A615 DEFORMED STEEL.

OTHER RELEVANT DRAWINGS AND SPECIFICATIONS AND WITH SUCH ALL BARS SHALL BE GRADE 40 fc' (MPa) Max. Agg. (mm) MAX W/C

WRITTEN INSTRUCTIONS AS MAY BE ISSUED DURING THE COURSE

OF THE CONTRACT. PILE CAPS CONCRETE 24.1 20 0.57

2. ALL DISCREPANCIES SHALL BE REFERRED TO THE CLIENT FOR

RESOLUTION BEFORE PROCEEDING. WHERE CONFLICT ARISES BETWEEN PRECAST CONCRETE PILES 34.5 20 0.57

THE SPECIFICATIONS AND NOTES AND/OR DRAWINGS, IN 1. COVER TO REINFORCEMENT

PRINCIPLE THE NOTES AND DRAWINGS SHALL TAKE PRECEDENCE OVER SHALL BE : Fc' - MINIMUM 28-DAY CHARACTERISTIC CONCRETE COMPRESSIVE STRENGTH

THE SPECIFICATIONS UNO. ALL DIMENSIONS RELEVANT TO SETTING OUT ALL SURFACES

Max Agg. - MAXIMUM AGGREGATE SIZE

AND OFF-SITE WORK SHALL BE VERIFIED BEFORE CONSTRUCTION IS

COMMENCED. THESE DRAWINGS SHALL NOT BE SCALED. Max W/C - MAXIMUM WATER - CEMENT RATIO

PRECAST CONCRETE 50 MM (ALL FACES)

3. WORKMANSHIP AND MATERIALS ARE TO BE IN ACCORDANCE 2. CEMENT SHALL CONFORM TO ASTM C150, TYPE 1.

PILE CAPS 100 MM (BOTTOM), 75 MM (TOP & SIDES)

WITH THE SPECIFICATIONS. ALL CONCRETE INCLUDING SLABS ON GROUND, SHALL BE VIBRATED. IF NECESSARY

2. USE NECESSARY BAR CHAIRS, SUPPORT AND SPACERS BARS TO PLACE PROVIDE ADDITIONAL TAMPING IN THE COVER ZONE. DEEP SECTIONS SHALL BE

STEEL IN ITS CORRECT POSITION DURING CONCRETING. REVIBRATED PRIOR TO FINAL FINISHING TO REDUCE THE EFFECTS OF PLASTIC SETTLEMENT.

DESIGN CRITERIA : 3. ALL REINFORCEMENT SHALL BE AS SHOWN ON THE DRAWINGS, 3. ALL CONCRETE SHALL BE CURED BY KEEPING EXPOSED SURFACES CONTINUOUSLY WET FOR

DESIGN LOADINGS IS BASED ON PLAN PROVIDED BY MEKA BETON 7 DAYS AFTER POURING.

4. REINFORCEMENT IN SLABS MUST BE PLACED IN ACCORDANCE WITH THE

SANTRALLERI DRAWINGS. COGS AND HOOKS TO BE STANDARD IN ACCORDANCE WITH ACI318 AS 4. CONSTRUCTION JOINTS SHALL BE PROPERLY FORMED AND USED WHERE SHOWN ON THE

SHOWN ON DRAWINGS. PLAN. CONSTRUCTION JOINTS SHALL BE INTENTIONALLY ROUGHENED BY ANY APPROVED MEANS

TO EXPOSE AGGREGATE.

SPLICING AND ANCHORAGE LENGTH SCHEDULE : 5. CONCRETE EPOXY BOND SHALL BE PROVIDED ON THE CONTACT SURFACE OF THE PRE-CAST

AND CAST-IN-PLACE CONCRETE. EPOXY BONDING TO BE USED SHALL HAVE WRITTEN APPROVAL

MIN. LAP SPLICE BY THE ENGINEER.

BAR ANCHORAGE STANDARD LAP SPLICES

UNIT LENGTH OF COL

FORMWORK : DIAMETER LENGTH HOOK (m)

(m)

WEIGHT REINFORCEMENT

6. ROUGHEN SURFACE OF PRECAST MEMBERS IN CONTACT WITH NEW CONCRETE.

TENSION BAR COMP. BAR INDIVIDUAL BARS

(mm) (m) (kg/m)

FORMWORK SHALL NOT BE STRIPPED UNTIL THE CONCRETE STRENGTH 90 DEG 180 DEG 133 DEG TOP BAR BOT BAR TOP BAR BOT BAR W/ TIES W/ SPIRAL

IS SUFFICIENT TO SUPPORT THE LOADS WITHOUT EXCESSIVE 10 mm 0.60 0.10 0.13 0.10 0.42 0.30 0.42 0.30 0.617 0.30 0.30

DISTORTION OR CRACKING. NOT WITHSTANDING THIS REQUIREMENT 12 mm 0.60 0.14 0.16 0.12 0.42 0.30 0.42 0.30 0.889 0.30 0.30

HOWEVER, THE FOLLOWING MINIMUM STRIPPING TIMES SHALL APPLY. 16 mm 0.60 0.22 0.18 0.14 0.73 0.52 0.87 0.62 1.580 0.52 0.47 DRIVEN PILE INSTALLATION :

20 mm 0.60 0.30 0.20 0.20 1.10 0.78 0.90 0.65 2.469 0.65 0.58

WALL FORMS 4 DAYS (MIN) 25 mm 0.68 0.40 0.28 0.26 1.40 1.00 1.40 1.00 3.858 0.80 0.73 1. ALL PILES SHALL BE HANDLED, PITCHED AND DRIVEN IN ACCORDANCE

SLAB SIDES > 1000 DEEP 4 DAYS (MIN) 28 mm 0.86 0.48 0.38 1.76 1.26 1.53 1.09 4.840 0.90 0.82 WITH THE SPECIFICATION.

SLAB SIDES < 1000 DEEP 3 DAYS (MIN) 32 mm 1.12 0.56 0.43 2.31 1.65 1.74 1.24 6.327 1.03 0.93

SUSPENDED SLABS SOFFITS 7 DAYS (MIN) 2. PILES SHALL BE DRIVEN TO ACHIEVE THE MINIMUM EMBEDMENT REQUIRED

36 mm 1.38 0.61 0.48 2.95 2.10 2.00 1.40 8.000 1.20 1.05

FOR A NOMINATED CAPACITY OF 27 TONS AND SHALL BE DETERMINED USING

PRECAST CONCRETE ENGINEERING NEWS FORMULA IF DRIVEN USING PILE HAMMER & FROM GAUGE

NOTES :

PROVIDE ALL EXPOSED EDGES AND CORNERS WITH 20mm CHAMFERS READING IF USING PUSH-PILE DRIVING METHOD.

1. ACI SECTION 12.4 STATES THAT:

OR FILLETS U.N.O. DEVELOPMENT LENGTH OF INDIVIDUAL BARS WITHIN A BUNDLE IN TENSION OR COMPRESSION SHALL BE 3. DRIVING RECORD SHALL BE TAKEN FOR ALL PILES.

THAT FOR THE INDIVIDUAL BAR. INCREASED 20 PERCENT FOR THREE-BAR BUNDLE AND 33 PERCENT

FOR FOUR-BAR BUNDLE. 4. ENSURE PILE TOPS REMAIN SAFE DURING CONSTRUCTION.

FOUNDATION NOTES : 2. FOR COLUMNS AT ANY LEVEL NO MORE THAN ALTERNATE BARS SHOULD BE SPLICED NOT MORE

THAN 33% OF THE BARS SHALL BE SPLICED WITHIN THE REQUIRED LAP LENGTH MINIMUM DISTANCE

5. UNDERTAKE AN AS CONSTRUCTED SURVEY, WHICH

IDENTIFIES TRUE VERSUS THEORETICAL PILE POSITIONS AND PILE LENGTHS.

THE DESIGN OF FOUNDATIONS ARE BASED ON THE FINAL BETWEEN TWO ADJACENT BAR SPLICES SHALL BE 600MM.

REPORT ON THE OFF-SHORE SOIL DRILLING FOR THE PROPOSED

3. TOP BARS ARE HORIZONTAL BARS WITH MORE THAN 300 MM DEPTH OF CONRETE CAST BELOW

PIER AND RECLAMATION PREPARED BY ACCREDITED GEOTECHNICAL

ENGINEERING COMPANY

THE REINFORCEMENT. BACKFILLING WORK :

1. BACKFILLING SHALL BE DONE AT EVERY 300mm LIFTS AND COMPACTED

4. AS MUCH AS POSSIBLE SPLICES SUBJECTED TO TENSILE STRESSES ARE DISCOURAGE. THESE

SHOULD BE AVOIDED OR PROVIDED WITH STANDARD HOOKS. ACCORDING TO ASTM D-698 WITH MINIMUM MDD 95% OF OPTIMUM.

ONLY APPLICABLE ABOVE WATER LEVEL.

2. BACKFILL MATERIALS SHALL CONFORM TO ITEM 104 OF DPWH

SPECIFICATIONS FOR PUBLIC WORKS AND HIGHWAYS 2013 EDITION,

VOLUME II.

3. BACKFILLING AT THE PROPOSED AREA FOR RECLAMATION (FOR FUTURE DEVT.)

ARE NOT INCLUDED IN THIS WORK AND CONSIDERED IN FUTURE CONSTRUCTION.

4. A 75mm BACKFILL ALLOWANCE SHALL BE PROVIDED ABOVE THE FINISH

GRADE LEVEL TO COMPENSATE THE EXPECTED 75mm SETTLEMENT OF

BACKFILL MATERIALS.

DRAFTED BY:

FROM THE OFFICE OF: SEAL PROJECT TITLE: #1014 PROJECT OWNER: SHEET CONTENTS: THIS DRAWING IS ISSUED FOR: SHEET NO.

FL

AS BUILT ESTIMATE

DATE:

PRC NO.: DATE: 21 AUGUST 2018 BIDDING FABRICATION

67949 10-12-93

ERWIN J. PONCE PTR NO.: DATE:

BATCHING PLANT FOUNDATION CEBU LINK JOINT VENTURE (CLJV) AS SHOWN

REVISION

-

BUILDING PERMIT

CONSTRUCTION

OWNER'S APPROVAL

PRESENTATION

S01

CIVIL ENGINEER 16932226 01-04-2018

PLACE: TIN:

IMPORTANT: ALL MEASUREMENTS ARE TO BE VERIFIED ON SITE BY THE CONTRACTOR. ALL DISCREPANCIES

ARE TO BE IMMEDIATELY REPORTED TO THE DESIGNER. THIS DRAWING ACTING AS AN INSTRUMENT OF SERVICES

S02

ADDRESS: POB., LILOAN, CEBU LOCATION: SRP, CEBU CITY ADDRESS: 10F INSULAR LIFE BLDG., AYALA BUSINESS PARK, CEBU CITY IS THE INTELLECTUAL PROPERTY OF THE ARCHITECT AND CANNOT BE REPRODUCED WITHOUT THEIR WRITTEN CONSENT.

MANDAUE CITY 129-167-593

You might also like

- Counseling Case Conceptualization Andrews FinalDocument11 pagesCounseling Case Conceptualization Andrews Finalapi-269876030100% (2)

- Covered Court PlanDocument13 pagesCovered Court PlanJohn Leonne100% (3)

- SAMPLE Complete Set of Plan - Single - Storey PDFDocument8 pagesSAMPLE Complete Set of Plan - Single - Storey PDFKyla Joy Jimenez100% (1)

- 9.design Plans and SpecificationsDocument15 pages9.design Plans and SpecificationsJoshua DayritNo ratings yet

- 2 Storey PlanDocument21 pages2 Storey Plan誰 も100% (5)

- Proposed 2 Storey Residential BLDG - BT3 1 PDFDocument13 pagesProposed 2 Storey Residential BLDG - BT3 1 PDFJaybenz Jazon100% (3)

- HVAC - Equipment ScheduleDocument1 pageHVAC - Equipment ScheduleRommel Dela SernaNo ratings yet

- Illustrated Notes-Form One and Two NotesDocument131 pagesIllustrated Notes-Form One and Two NotesDi'genius Neshmentation100% (3)

- Final Proj Floor PlanDocument1 pageFinal Proj Floor PlankbgainsanNo ratings yet

- Ce 39 Final ProjectDocument9 pagesCe 39 Final ProjectkbgainsanNo ratings yet

- Pedestal ScheduleDocument1 pagePedestal ScheduleeddieNo ratings yet

- A1-Archt'l Plan Toreno-02.12.2020 PDFDocument1 pageA1-Archt'l Plan Toreno-02.12.2020 PDFWilbert ReuyanNo ratings yet

- Wash Area Lavatory DetailDocument1 pageWash Area Lavatory DetailMark Gil DorosanNo ratings yet

- ARCH264 - R7: A2-1 Rear Elevation A2-2 Left-Side ElevationDocument1 pageARCH264 - R7: A2-1 Rear Elevation A2-2 Left-Side Elevationreynesmarygen9No ratings yet

- Kaya MeDocument1 pageKaya MeluciojrruizNo ratings yet

- Service Apartel Building Structural Plan - Edited PDFDocument17 pagesService Apartel Building Structural Plan - Edited PDFHeliosNo ratings yet

- Fourth To Sixt and SectionDocument1 pageFourth To Sixt and SectionAshley Villarico AbanganNo ratings yet

- Plate 1Document1 pagePlate 1kbgainsanNo ratings yet

- Proposed New Cebu City Medical Center A-02: Lower Ground - Masonry ActivitiesDocument1 pageProposed New Cebu City Medical Center A-02: Lower Ground - Masonry ActivitiesJing AytonaNo ratings yet

- Plate 2 Floor PlanDocument1 pagePlate 2 Floor PlankbgainsanNo ratings yet

- 03 Paref - e - Mech - Ece PDFDocument5 pages03 Paref - e - Mech - Ece PDFRomeo PedranoNo ratings yet

- HVAC - Standard Detail - BDocument1 pageHVAC - Standard Detail - BRommel Dela Serna100% (1)

- SECRET BASE-me 01Document1 pageSECRET BASE-me 01luciojrruizNo ratings yet

- Perspective: Site Development Plan Vicinity MapDocument1 pagePerspective: Site Development Plan Vicinity MapDrei SupremoNo ratings yet

- A B C D: Proposed Three-Storey BuildingDocument1 pageA B C D: Proposed Three-Storey BuildingAngelo AmarNo ratings yet

- Hvac - Schematic - CHWPDocument1 pageHvac - Schematic - CHWPRommel Dela SernaNo ratings yet

- Hvac - Schematic - VentDocument1 pageHvac - Schematic - VentRommel Dela SernaNo ratings yet

- Jaye 3Document1 pageJaye 3Quijano, “Jinja” Junrey C.No ratings yet

- Plate 7 ElectricalDocument2 pagesPlate 7 ElectricalkbgainsanNo ratings yet

- Maghaway PDF Final1Document10 pagesMaghaway PDF Final1Jet ToledoNo ratings yet

- Telephone, FTTH and Wireless Access Point Riser Diagram: A Proposed Two-Strorey ResidenceDocument7 pagesTelephone, FTTH and Wireless Access Point Riser Diagram: A Proposed Two-Strorey ResidenceShena Mae BugasNo ratings yet

- Interior Perspective: Land Use & ZoningDocument1 pageInterior Perspective: Land Use & ZoningLady Mae BrigoliNo ratings yet

- Structural - Pit Os S1Document1 pageStructural - Pit Os S1Kurt jan Bacon DamandamanNo ratings yet

- LUVAR BTECH-STRUCTURAL-ModelDocument1 pageLUVAR BTECH-STRUCTURAL-Modelreynesmarygen9No ratings yet

- Plate 3 ElevationDocument1 pagePlate 3 ElevationkbgainsanNo ratings yet

- Mompong Beach Resort-R1 PDFDocument1 pageMompong Beach Resort-R1 PDFDonato Henry LacbayoNo ratings yet

- Marajaw Guest House 1-St2Document1 pageMarajaw Guest House 1-St2Mike Durero LitangNo ratings yet

- QF08Document1 pageQF08pis.engineering007No ratings yet

- PLA1 Layout1Document1 pagePLA1 Layout1Danzel C DayondonNo ratings yet

- General Notes: Abbrevations: Symbols: Fire Protection:: Schedule of Equipments Vicinity MapDocument12 pagesGeneral Notes: Abbrevations: Symbols: Fire Protection:: Schedule of Equipments Vicinity MapHelios100% (1)

- Basement To ThirdDocument1 pageBasement To ThirdAshley Villarico AbanganNo ratings yet

- Notes:: Recommended ApprovalDocument1 pageNotes:: Recommended ApprovalJhon SabinoNo ratings yet

- Final Proj Sheet 2Document1 pageFinal Proj Sheet 2kbgainsanNo ratings yet

- ROYAL CEBU ESTATES HOUSE Sept 11 2022 PAGE A1Document1 pageROYAL CEBU ESTATES HOUSE Sept 11 2022 PAGE A1Gio CordovaNo ratings yet

- Typ. 2Nd and 3Rd Floor Framing Plan: E I K C A F B G D J HDocument1 pageTyp. 2Nd and 3Rd Floor Framing Plan: E I K C A F B G D J HSherly PocotNo ratings yet

- CAD A1 - MergedDocument5 pagesCAD A1 - Merged21-07543No ratings yet

- Front Elevation Left - Side Elevation: Ronnie Chris E. Animo Proposed Warehouse Dmi Medical Supply IncDocument1 pageFront Elevation Left - Side Elevation: Ronnie Chris E. Animo Proposed Warehouse Dmi Medical Supply Inckayl mamolangNo ratings yet

- M-108B - 21ST Floor Mvac PlanDocument1 pageM-108B - 21ST Floor Mvac PlanJaime Antonio RoselloNo ratings yet

- C:/Users/LADY/Desktop/Untitled - PNG: Interior PerspectiveDocument1 pageC:/Users/LADY/Desktop/Untitled - PNG: Interior PerspectiveBrigoli AlexanderNo ratings yet

- 2022 10 19 Odessa Grantville-A0Document1 page2022 10 19 Odessa Grantville-A0Mary Gen ReynesNo ratings yet

- Ground Floor Plan Second Floor Plan: A B C A B CDocument1 pageGround Floor Plan Second Floor Plan: A B C A B CNick Operario JrNo ratings yet

- Glaston R03Document21 pagesGlaston R03Pinoy Showbiz FilesNo ratings yet

- Tandag A 101Document1 pageTandag A 101Mdrrmo San MiguelNo ratings yet

- Foundation P L A N: E I K C F A B G J D HDocument1 pageFoundation P L A N: E I K C F A B G J D HSherly PocotNo ratings yet

- SECRET BASE-me 02Document1 pageSECRET BASE-me 02luciojrruizNo ratings yet

- m2-02 Stair Fireman's Lift Pressurization-1351m2-03-1Document1 pagem2-02 Stair Fireman's Lift Pressurization-1351m2-03-1Darwin LimNo ratings yet

- Perspective: Site Development PlanDocument1 pagePerspective: Site Development Planwilson coNo ratings yet

- Section Detail 19: Stair Footing 17Document1 pageSection Detail 19: Stair Footing 17Jhon SabinoNo ratings yet

- Beam DetailDocument1 pageBeam DetailkbgainsanNo ratings yet

- S-7.1 Proposed Five Storey Pension House: Republic of The PhilippinesDocument1 pageS-7.1 Proposed Five Storey Pension House: Republic of The PhilippinesChristian BartiquelNo ratings yet

- QF09Document1 pageQF09pis.engineering007No ratings yet

- Project:: Panguil Bay Bridge ProjectDocument4 pagesProject:: Panguil Bay Bridge ProjecteddieNo ratings yet

- Pile Driving 400x400mm X 10m DepthDocument2 pagesPile Driving 400x400mm X 10m DeptheddieNo ratings yet

- Submission of Package 1 - Part 3 14 Abutment Piles and ILM Yard Piles - Rev.1Document3 pagesSubmission of Package 1 - Part 3 14 Abutment Piles and ILM Yard Piles - Rev.1eddieNo ratings yet

- Ground Floor Plan (Redmarks)Document1 pageGround Floor Plan (Redmarks)eddieNo ratings yet

- Package 2 Part 1 Design DrawingsDocument45 pagesPackage 2 Part 1 Design DrawingseddieNo ratings yet

- D220-Ew-Cljv-Shd-410016-C Earthworks - Shp.causeway 1 Cross Sections-Sheet 6 of 27Document1 pageD220-Ew-Cljv-Shd-410016-C Earthworks - Shp.causeway 1 Cross Sections-Sheet 6 of 27eddieNo ratings yet

- Department of Public Works and Highways: Roads Management Cluster Ii (Multilateral) UpmoDocument24 pagesDepartment of Public Works and Highways: Roads Management Cluster Ii (Multilateral) UpmoeddieNo ratings yet

- Package 2 Part 1 Design DrawingsDocument45 pagesPackage 2 Part 1 Design DrawingseddieNo ratings yet

- Project 7Document327 pagesProject 7eddieNo ratings yet

- Kitchen Basics: Planning and TrendsDocument58 pagesKitchen Basics: Planning and TrendseddieNo ratings yet

- Architectural Working DrawingsDocument52 pagesArchitectural Working DrawingseddieNo ratings yet

- Sequence of Civil WorkDocument33 pagesSequence of Civil WorkDevendra Potdar100% (6)

- Summary For Pre-Cast Yard 5.6 Tons Railing (102 Meters) Rebars Concrete FormworksDocument4 pagesSummary For Pre-Cast Yard 5.6 Tons Railing (102 Meters) Rebars Concrete FormworkseddieNo ratings yet

- Pre Cast YardDocument2 pagesPre Cast YardeddieNo ratings yet

- Tw-cljv-456397-Precast Yard at Cordova Causeway 1-Reinforcement of Soil-ADocument1 pageTw-cljv-456397-Precast Yard at Cordova Causeway 1-Reinforcement of Soil-AeddieNo ratings yet

- Overtime SlipDocument1 pageOvertime SlipeddieNo ratings yet

- 7X7-TR8 InstallGuide E PDFDocument2 pages7X7-TR8 InstallGuide E PDFAirton BarrosNo ratings yet

- Department of Education Schools Division of Camarines SurDocument5 pagesDepartment of Education Schools Division of Camarines SurDayAnne Dela Vega PasibeNo ratings yet

- ppc2 CH 2Document68 pagesppc2 CH 2mich abiNo ratings yet

- Especificaciones HP 3508Document3 pagesEspecificaciones HP 3508spider blackNo ratings yet

- Rizals Birth and GenealogyDocument29 pagesRizals Birth and GenealogyMariel BarnacheaNo ratings yet

- Iapmo 4197 PDFDocument15 pagesIapmo 4197 PDFIvan FlorezNo ratings yet

- CQDF 802Document12 pagesCQDF 802mohammed elmobasherNo ratings yet

- AN ANALYSIS OF DEIXIS USED YULE by Tiur 17810008 & Hasyanty TurnipDocument9 pagesAN ANALYSIS OF DEIXIS USED YULE by Tiur 17810008 & Hasyanty Turnipimelda huraNo ratings yet

- Correlation AnalysisDocument18 pagesCorrelation AnalysissalhotraonlineNo ratings yet

- Tactical Decision Making Process PDFDocument116 pagesTactical Decision Making Process PDFGreg JacksonNo ratings yet

- Reading MidtermDocument11 pagesReading MidtermHồ Như QuỳnhNo ratings yet

- LogDocument27 pagesLogchaaanrikkaNo ratings yet

- Lesson 4 Manicure and PedicureDocument22 pagesLesson 4 Manicure and PedicureMARY JOY VILLARUEL100% (3)

- ACT I Scene 1: Context QuestionsDocument51 pagesACT I Scene 1: Context QuestionsShashwat MishraNo ratings yet

- Mahmoud Mohamed Mady Ali: EmailDocument3 pagesMahmoud Mohamed Mady Ali: Emailkhaled ahnedNo ratings yet

- PAST SIMPLE: Regular: Grammar WorksheetDocument1 pagePAST SIMPLE: Regular: Grammar WorksheetTan Solo Angel ProxzNo ratings yet

- Cable 3 X50Document2 pagesCable 3 X50Jalal AlbadriNo ratings yet

- NURSING RESEARCH I Houserules and SyllabusDocument17 pagesNURSING RESEARCH I Houserules and SyllabusAndrea Asdala SairunaNo ratings yet

- G.R. No. 137296 June 26, 2003 PEOPLE OF THE PHILIPPINES, Plaintiff-Appellee, DIONISIO VICENTE y QUINTO, Accused-AppellantDocument11 pagesG.R. No. 137296 June 26, 2003 PEOPLE OF THE PHILIPPINES, Plaintiff-Appellee, DIONISIO VICENTE y QUINTO, Accused-AppellantAnna Lee Acsibar CarbonilNo ratings yet

- South Sea Bubble Refers To The Speculation Mania That Ruined ManyDocument7 pagesSouth Sea Bubble Refers To The Speculation Mania That Ruined ManyPuneet GargNo ratings yet

- Nursing Care PlanDocument3 pagesNursing Care PlanBhie DizonNo ratings yet

- Module 6 - Engineering Drawings and Plans, Lab. MidtermDocument13 pagesModule 6 - Engineering Drawings and Plans, Lab. MidtermJahara N. CuerdoNo ratings yet

- Himalaya Jyoti by Sri Swami SivanandaDocument81 pagesHimalaya Jyoti by Sri Swami SivanandakartikscribdNo ratings yet

- DLL - Science 6 - Q1 - W1Document6 pagesDLL - Science 6 - Q1 - W1job legionNo ratings yet

- Code of Ethics: Bustamante, Guianne Carlo B. CE195 - C2 CE-4 / 2010100616 April 26, 2014 Engr. Geoffrey CuetoDocument4 pagesCode of Ethics: Bustamante, Guianne Carlo B. CE195 - C2 CE-4 / 2010100616 April 26, 2014 Engr. Geoffrey CuetoGuianne Carlo BustamanteNo ratings yet

- JSD 1Document23 pagesJSD 1Gopala Krishnan CKNo ratings yet

- Busduct Canalis 20 - 1000ADocument288 pagesBusduct Canalis 20 - 1000AAnonymous yugocxnNo ratings yet

- Case2: Liulishuo: AI English TeacherDocument3 pagesCase2: Liulishuo: AI English TeacherSoubhagya DashNo ratings yet