MC-1300 Marathon Cutting Plotter: Maintenance Manual

MC-1300 Marathon Cutting Plotter: Maintenance Manual

Uploaded by

gass2Copyright:

Available Formats

MC-1300 Marathon Cutting Plotter: Maintenance Manual

MC-1300 Marathon Cutting Plotter: Maintenance Manual

Uploaded by

gass2Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

MC-1300 Marathon Cutting Plotter: Maintenance Manual

MC-1300 Marathon Cutting Plotter: Maintenance Manual

Uploaded by

gass2Copyright:

Available Formats

Maintenance Manual

MC-1300 Marathon Cutting Plotter

MUTOH EUROPE N.V. AP-74040, Rev. 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

2 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

COPYRIGHT NOTICE

COPYRIGHT © 2002 Mutoh Europe N.V. all rights reserved.

This document may not be reproduced by means, in whole or in part, without written permission of the

copyright owner.

This document is furnished to support the Mutoh MC-1300 Marathon Cutting Plotter. In consideration of the

furnishing of the information contained in this document, the party to whom it is given assumes its custody

and control and agrees to the following :

1) The information herein contained is given in confidence, and any part thereof shall not be copied or

reproduced without written consent of Mutoh Europe N.V.

2) This document or the contents herein under no circumstances shall be used in the manufacture or

reproduction of the article shown and delivery of this document shall not constitute any right or license to

do so.

FCC WARNING

This equipment complies with the requirements for a class A computing device in the FCC rules, part 15,

subpart J.

Operation of this device in a residential area may interfere with television reception or operation of utilities.

Cutters generate weak radio signals and may interfere with television reception and utilities. If the cutter

does interfere with radio or television, try the following :

· Change the direction of your radio and TV reception antenna or feeder.

· Change the direction of the cutter.

· Move either the cutter or the receiving antenna so that there is more distance between them.

· Be sure the cutter and the receiving antenna are on separate power lines.

.

3 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

4 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

Table of Contents

1. SPECIFICATIONS...........................................................9

2. SYSTEM BLOCK DIAGRAM......................................11

3. INTERFACES. ...............................................................13

3.1. Serial interface RS-232C (standard).................................................................................... 13

3.1.1. RS232C pin configuration............................................................................................ 14

3.1.2. Serial cable configuration. ........................................................................................... 14

3.2. Centronics interface (standard). .......................................................................................... 15

3.2.1. Centronics interface Pin configuration. ........................................................................ 15

4. TROUBLESHOOTING. ................................................17

4.1. Recoverable errors.............................................................................................................. 17

4.2. Unrecoverable errors. ......................................................................................................... 17

4.3. Problem symptoms and suggested actions. ......................................................................... 18

4.3.1. Processor errors. .......................................................................................................... 18

4.3.2. X-Y Servo errors. ........................................................................................................ 19

4.3.3. Cutting head errors. ..................................................................................................... 20

4.3.4. Other errors. ................................................................................................................ 21

4.4. Problem isolation................................................................................................................ 22

4.5. Rollfeed Errors. .................................................................................................................. 24

5. SPECIALISED DIAGNOSTICS. ..................................25

5.1. Diagnostics overview. ........................................................................................................ 25

5.2. Diagnostics mode : ............................................................................................................. 28

5.2.1. Diagnostics 1 : ............................................................................................................. 29

5.2.2. Diagnostics 2 : ............................................................................................................. 32

5.2.3. Diagnostics 3 : ............................................................................................................. 33

5.2.4. Diagnostics 4. .............................................................................................................. 35

5.2.5. Diagnostics 5. .............................................................................................................. 37

5.2.6. Diagnostics 6. .............................................................................................................. 39

5.2.7. Adjust. 7. ..................................................................................................................... 40

5.2.8. Adjust. 8. ..................................................................................................................... 43

5.2.9. Adjust. 9. ..................................................................................................................... 46

5.2.10. Adjust. 10. ................................................................................................................. 52

6. PARTS REPLACEMENT AND ADJUSTMENTS......53

6.1. Maintenance access table for parts replacement. ................................................................. 53

6.2. Mechanical parts. ............................................................................................................... 54

6.2.1. Cover left : removal and installation. ........................................................................... 54

6.2.2. Cover right : removal and installation. ......................................................................... 55

6.2.3. Transparent cover assy : removal and installation. ....................................................... 56

6.2.4. PCB box : open and close. ........................................................................................... 57

6.2.5. Y-rail cover : removal and installation. ........................................................................ 58

5 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.2.6. Grid cover : removal and installation. .......................................................................... 59

6.2.7. Cutting head : removal and installation. ....................................................................... 60

6.2.8. Grid rollers : removal and installation. ......................................................................... 61

6.2.9. Y-drive belt (long) : removal and installation. .............................................................. 62

6.2.10. Pressure roller pressure adjustment. ........................................................................... 66

6.3. Electrical parts.................................................................................................................... 67

6.3.1. Main PC board : removal and installation. ................................................................... 67

6.3.2. EEPROM initialisation and replacement. ..................................................................... 69

6.3.3. Power supply board : removal and installation. ............................................................ 70

6.3.4. Terminal board : removal and installation. ................................................................... 71

6.3.5. Keyboard : removal and installation............................................................................. 72

6.3.6. X-motor and drive belt : removal and installation......................................................... 73

6.3.7. Y–motor and drive belt : removal and installation. ....................................................... 74

6.3.8. Head flex cable : removal and installation.................................................................... 75

6.3.9. Paper sensors : removal and installation....................................................................... 76

6.3.10. Transparent cover sensor : removal and installation. .................................................. 77

6.3.11. Pressure roller UP/DOWN sensor : removal and installation. ..................................... 78

6.3.12. Fan motors : removal and installation......................................................................... 79

6.3.13. Stocker home position sensor : removal and installation............................................. 80

6.3.14. Stocker motor : removal and installation. ................................................................... 81

6.4. Rollfeed Parts. .................................................................................................................... 83

6.4.1. Remarks. ..................................................................................................................... 83

6.4.2. Removing the Gear Cover............................................................................................ 84

6.4.3. Removing the PCB cover............................................................................................. 85

6.4.4. Replacing the gear motor assembly.............................................................................. 86

6.4.5. Replacing the rollfeed PCB.......................................................................................... 88

6.4.6. Replacing a photo sensor in the front- or rear guidebar. ............................................... 89

6.4.7. Replacing a photo sensor in the front- or rear gear cover.............................................. 90

7. JIG TOOL LIST..............................................................91

7.1. Jig tool list.......................................................................................................................... 91

7.2. Special glue. ....................................................................................................................... 91

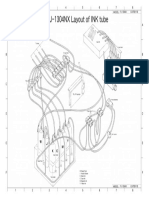

8. PLOTTERBODY AND ROLLFEED. ...........................93

9. PARTS LIST PLOTTERBODY ....................................95

9.1. Platen and alignment (MY-23342)...................................................................................... 95

9.2. Right cover and keyboard assy (MY-23539)....................................................................... 96

9.3. Cover left assy (MY-23540). .............................................................................................. 97

9.4. Transparent cover assy (MY-23306)................................................................................... 98

9.5. Stocker assy (MY-32244). .................................................................................................. 99

9.6. PCB box (MY-23001). ..................................................................................................... 100

9.7. Penhead flex cable assy (MY-23571)................................................................................ 101

9.8. Pressure roller UP/DOWN assy (MY-23024/MY-23029). ................................................ 102

9.9. X-motor assy (EY-10001). ............................................................................................... 104

9.10. X-rail assy (MY-2316-10400)......................................................................................... 105

6 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

9.11. Y-motor assy (EY-10011)............................................................................................... 106

9.12. Y-rail assy (MY-2316-10401 and MY-23313). ............................................................... 107

9.13. Y-axis drive belt assy (MY-23350). ................................................................................ 108

9.14. Y-drive pulley assy and mounting bracket (MY-47657).................................................. 109

9.15. Y-axis return pulley assy (MY-23075)............................................................................ 110

9.16. Pressure roller assy (MY-10402/10403).......................................................................... 111

9.17. End plates (MY-23010). ................................................................................................. 113

9.18. Penhead parts (MY-23864)............................................................................................. 115

9.19. Stocker base assy (MY-23013). ...................................................................................... 116

10. PART LIST ROLLFEED SYSTEM. .........................119

7 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

8 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

1. SPECIFICATIONS.

Model MC-1300 Marathon Cutting Plotter

Max. Media Width 1400 mm (Roll & Sheet)

Min Media Width 900 mm

Max. Cutting Width 1200 mm

Max. Cutting Area (repeatable) 1200 mm x 12 m

Max. Addressable Cut Length 50 m

Max. Media Thickness 1 mm

Max. Roll Media Weight 65 kg

Max. Roll Diameter 300 mm

Roll Media Core 76 mm (3”)

Drive Mechanism Friction

Cutting Principle Drag Knife

Mechanical Resolution 0.005 mm

Accuracy 0.15 % of distance moved

Repeatability 0.25 mm/m

Number of Pressure Rollers 3

Knives 30° / 45° / 60°

Speed 100 – 1000 mm/s (*)

Acceleration 4G (Tool up/down)

Tool Up / Tool Dow Cycles Max. 40/s

Pressure Range 20 – 500 g

Interface (Standard) RS-232 / Centronics

Input Buffer (Standard) 1Mb

Input Buffer (Optional) 4Mb

Stand Included

Roll Support System Included

Graphic Language MH-GL/2 (HP-GL/2 Compatible) / MC-GL

Configurable Origin Yes

Offset Adjustment Yes (semi-automatic)

Auto Sheet-Off Function Yes (Tool 8)

Replot Function Yes

(*) = When working with the rollfeed system, use a maximum speed of 400 mm/s.

9 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

10 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

2. SYSTEM BLOCK DIAGRAM.

11 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

12 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

3. INTERFACES.

3.1. Serial interface RS-232C (standard).

1) Baud rate (software selectable)

- 19200 bps

- 9600 bps

- 4800 bps

- 2400 bps

- 1200 bps

2) Data length (software selectable)

- 7 bits

- 8 bits

3) Stop bits (software selectable)

- 1 bit

- 2 bits

4) Parity (software selectable)

- Odd

- Even

- None

5) Error detection

- Parity error

- Framing error

- Overrun error

6) External connector

- DB-25S (equivalent)

7) RS-232C Driver / Receiver IC

- Driver : 75188 (TI, +/- 12V power supply)

- Receiver 75189A

13 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

3.1.1. RS232C pin configuration.

Pin# Signal Abbr. Signal direction

1 Frame ground FG -

2 Transmit data TXD OUT

3 Receive data RXD IN

4 Request to send RTS OUT

5 Clear to send CTS IN

6 Data set ready DSR IN

7 Signal ground SG -

8 Carrier detect CD IN

9 ® 14 Not used

15 Transmitter signal element timing ST IN

16 Not used

17 Receiver signal element timing RT IN

18 Data terminal ready DTR OUT

19 Not used

20 Data terminal ready DTR OUT

21 ® 25 Not used

3.1.2. Serial cable configuration.

1) 9 pins ® 25 pins connector :

2) 25 pins ® 9 pins connector :

14 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

3.2. Centronics interface (standard).

- Uni-directional (Receiving only)

- Data length : 8 bit parallel

- Signal level : TTL

- Transmission distance : maximum 5 m

3.2.1. Centronics interface Pin configuration.

Pin# Signal Signal Direction

1 Strobe Strobe input IN

2®9 DATA 1 ® 8 Parallel data input IN

10 ACK* Acknowledge output OUT

11 BUSY Busy OUT

12 PAPER END Paper end OUT

13 SELECTED Selected OUT

16 SG Signal ground -

17 FG Frame ground -

18 HIGH High level OUT

19 ® 30 SG Signal ground -

31 - Not used -

32 FAULT Error OUT

33 SG Signal ground -

Note :

Other pins are put in NC (no contact) status.

Asterix (*) indicates negative logic.

15 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

16 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

4. TROUBLESHOOTING.

In general 2 different types of error messages may occur :

4.1. Recoverable errors.

Recoverable errors are mostly related to communication problems or user mistakes.

These kind of errors can appear while the machine is working or sometimes it makes the machine stop but

starts again when error is corrected.

4.2. Unrecoverable errors.

Unrecoverable errors make the machine stop.

To clear the error message, the machine needs to be powered OFF and ON again. (Wait +/- 10 seconds

between power OFF / ON).

17 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

4.3. Problem symptoms and suggested actions.

4.3.1. Processor errors.

MESSAGES POSSIBLE CAUSE SUGGESTED ACTIONS

Watch dog activated Poor connection between main Check cable and connection.

Bus trap error and terminal board.

Address trap error Check pins and position of

CPU illegal instruction Bad EPROM’s. EPROM and EEPROM.

encountered Reinstall EPROM and EEPROM.

Zero division error Bad EEPROM.

Interrupt failure Replace mainboard.

Microprocessor 1010 error Mainboard defective.

Microprocessor 1111 error

CPU failure

Mainboard must be 50Mhz !!

Static RAM error

Dynamic RAM error

EPROM checksum error EPROM data is changed. Replace EPROM set.

This machine does not match the

EEPROM set KROM data is changed.

Kanji checksum error

EEPROM error EEPROM data is changed. Perform INIT 1

EEPROM missing or defect

Perform INIT 2.

Replace EEPROM

Extended RAM error Poor extended RAM connection. Check connection.

Bad extended RAM. Replace extended RAM.

18 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

4.3.2. X-Y Servo errors.

MESSAGES POSSIBLE CAUSE SUGGESTED ACTIONS

Out sync X Defective motor / encoder. Replace motor / encoder.

Out sync Y

X servo failure Loose drive pulley. Fix pulley or replace motor /

Y servo failure encoder.

Over current X Failure in drive circuit.

Over current Y Replace main PC board.

Encoder fail X Poor connection of motor /

Encoder fail Y encoder. Check cables and connections.

Encoder failure moving coil

X or Y encoder connector is Too much friction in X or Y axis. Check X or Y movement.

disconnected

Cable broken. Replace cable.

Over load X

Over load Y

Obstacle. Remove obstacle.

Driver failure

19 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

4.3.3. Cutting head errors.

MESSAGE POSSIBLE CAUSE SUGGESTED ACTIONS

Position timeout moving coil Nose piece of knife holder not Check knife holder.

Over current moving coil fixed.

Over force moving coil Check blade depth.

A/D failure moving coil Blade is too far out.

Check connections or replace

Head flex cable bad or poor head flex cable.

connection.

Replace cutting head.

Bad cutting head.

Replace main PC board.

Failure in drive circuit.

20 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

4.3.4. Other errors.

MESSAGES POSSIBLE CAUSE SUGGESTED ACTIONS

Power failure Defective power supply (P/S). Check power cord.

Pen change error

Defective mainboard . Check wall outlet.

Bad installed pen in stocker. Check fuse on P/S.

Penchange need to be aligned. Check Led on P/S.

Replace mainboard.

Load pens / knife holders

correctly.

21 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

4.4. Problem isolation.

PROBLEM DESCRIPTION POSSIBLE CAUSE SUGGESTED ACTIONS

System is dead : Defective power supply (P/S). Check power cord.

- No movement Defective mainboard. Check wall outlet.

- No LCD display

Check fuse on P/S.

Check LED on P/S.

Replace mainboard.

LCD display, but no movement Defective EPROM’s. Replace EPROM’s.

of motors and cutting head.

Defective EEPROM. Replace EEPROM.

Defective mainboard. Replace mainboard.

Check cable connections.

Plotter powers ON, head Transparent cover is not closed. Close the cover.

UP/DOWN initialises but no

movement of motors. Transparent cover switch Check or replace cover switch.

defective.

Plotter does not shuffle media. Pressure roller lever is not down. Lower the lever.

Bad lever sensor. Check the lever sensor.

Both media sensors are not Load media properly.

covered.

Clean or replace media sensors.

Media sensors dusty or bad.

Illegal mainboard revision Mainboard version is not Use correct mainboard.

(message). compatible.

Wrong mainboard (message). Wrong mainboard is used. Use correct mainboard.

Plotter has shuffled media but Plotter is off-line. Put plotter in on-line.

does not respond to data.

Interface cable not connected or Check interface cable.

bad.

Check plotter driver.

Wrong plotter driver.

Check interface parameters.

Wrong interface parameters.

Check port or replace mainboard.

Bad interface port.

Plotter is responding to data, Wrong interface parameters. Check interface parameters.

but error messages appear on

LCD display. Wrong cable configuration. Check interface cable.

22 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

PROBLEM DESCRIPTION POSSIBLE CAUSE SUGGESTED ACTIONS

Plotter is cutting but quality is Blade worn or broken. Replace blade.

not acceptable.

Blade is not turning smooth. Check or replace knife holder.

Offset is not correct. Perform offset procedure.

Blade is too far out. Adjust knife depth.

Cutting force is too high. Reduce cutting force.

Cutting mat worn Replace cutting mat.

Wrong plotter driver. Select correct plotter driver.

Play on cutting head. Check or replace cutting head.

Drive belt tension not correct. Check or adjust belt tensions.

X or Y motor defective. Replace X or Y motor.

Media tracking problems. Media is not loaded straight in the Load media as described in the

machine. User’s Guide.

Media skews during cutting or

loading. Grid rolls are dirty. Clean grid rollers.

Grid rollers or pressure rollers Replace grid rollers or pressure

worn. rollers.

Speed or acceleration too high. Decrease :

- cutting speed

Pressure roller (pressure not - pen / UP speed

correct).

Adjust pressure roller pressure.

Media backing is very slippery.

(Teflon based) Change media type or decrease

speed and acceleration.

Plot is too small or too big. X/Y axis adjust is set incorrectly. Set X/Y adjust to 100%

(User adjustment/Machine

Program step does not match with adjustment)

cutting software.

Change program step.

23 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

4.5. Rollfeed Errors.

Symptom POSSIBLE CAUSE SUGGESTED ACTIONS

Rollfeed does not start rolling Wrong dip-switch setting. Check the dip-switch setting on

UP/OFF after plotted frame is the Rollfeed.

finished.

Incorrect MC-1300 Marathon Check the MC-1300 Marathon

menu setting. Menu setting :

Settings / General Settings /

Rollup Device should be set to

“ACTIVE”.

Bad connection between Rollfeed Check the connections.

and MC-1300 Marathon. Check the ribbon cable for

damage. If damaged, replace the

ribbon cable.

Manual Rollup/RollOff buttons Bad internal connection. Remove the PCB cover. Check

do not work all connections on the Rollfeed

PCB.

PCB failure. Open the PCB-box on the AC.

Replace the Rollfeed Control

PCB.

Rollup/RollOff does not slow Photo sensor failure. Replace the failing photo sensor.

down when the tension bar

passes the first photo sensor or Cover photo sensor failure. Set the dip-switch setting for both

does not stop when the tension the front and rear to ‘OFF’.

bar passes the second photo Restart the MC-1300 Marathon

sensor. and check whether the error

MC-1300 Marathon gives ‘Cover occurs again. If so, the MC-1300

open’ on display, even when all Marathon cover sensor is failing.

the MC-1300 Marathon covers Replace Cover sensor. If this is

are closed. not the case, set the front dip-

switch to ‘ON’ and check when the

error occurs after restart. If so,

replace the front cover photo

sensor. If not, set the rear dip-

switch to ‘ON’. If the error occurs,

replace the rear cover photo

sensor.

24 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

5. SPECIALISED DIAGNOSTICS.

5.1. Diagnostics overview.

Caution :

The specialised diagnostics built into the MC-1300 Marathon cutting plotter, are

designed only for maintenance purposes and may only be used by authorised MUTOH

technicians.

Entering the diagnostic menu’s by non-qualified people may result in damaging the

machine.

There are ten diagnostic pages.

DIAGNOST. 1 :

DIAGNOST. 2 :

DIAGNOST. 3 :

25 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

DIAGNOST. 4 :

DIAGNOST. 5 :

DIAGNOST. 6 :

ADJUST. 7 :

ADJUST. 8 :

26 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

ADJUST. 9 :

ADJUST. 10 :

27 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

5.2. Diagnostics mode :

To activate the Diagnostics mode on your machine, press the [ALIGNMENT], [SETTINGS] and [RESET] key

simultaneously while switching on the power.

Note :

Before you change your settings in the diagnostics mode, it is advised to make a backup

plot of the current user parameters and adjustment values (Please refer to the User’s

Guide).

Press the [EXIT] key to interrupt a diagnostics operation.

You can then scroll through the diagnostics menu by pressing the arrow (cursor) keys.

There are four different keys to select an item in the diagnostics menu :

28 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

5.2.1. Diagnostics 1 :

MEMORY (3) :

SUMCHECK (1) :

· EEPROM (2) : This value is of no importance for maintenance and repair.

· EPROM (3) : CHECKSUM of EPROM is related to the version. The calculated sum should

be equal to the programmed one. If not, the EPROM set has to be replaced.

· KROM (KanjiROM) (4) : The calculated sum should be equal to the programmed one.

DRAM (Dynamic RAM) (3) :

Test of no importance for maintenance and repair.

29 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

EEPROM (4) :

· TESTS (1) : READ (1), WRITE (2), CLEAR (3) are of no importance for maintenance and

repair.

· INIT 1 (3) : Initialises all user parameters to default values.

· INIT 2 (4) : Initialises all adjustment values to default values.

Caution :

After INIT 2, the following adjustments need to be performed :

- X-axis length adjustment (Please refer to 5.2.8. Adjust 8).

- Cutting mat height adjustment (Please refer to 5.2.8. Adjust 8).

- Pen force calibration (Please refer to 5.2.9. Adjust 9).

- Penchange Z (Please refer to 6.3.14 stocker motor : removal and installation)

- Penchange ROT (Please refer to 6.3.14 stocker motor : removal and

installation)

- Penchange Y (Please refer to 6.3.14 stocker motor : removal and installation)

VERSION (2) :

This function gives you the version of the EPROM, EEPROM1, EEPROM2.

SENSOR (4) :

· SENSOR1

“Front” and “Rear” are paper sensors located on the plotter bed, the indication is

OPEN or CLOSED. The “middle” sensor is for future use.

· SENSOR2

“Lever” sensor detects if pressure rollers are UP or DOWN.

“Cover” sensor detects if the safety cover is OPEN or CLOSED.

“Yorg” sensor is the sensor on the back of the penhead that detects Y origin

position and the position of the pressure rollers, the indication is OPEN or

CLOSED (when the penhead is in front of a pressure roller).

30 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

· SENSOR3

“Stocker” sensor detects if the stocker is IN or OUT of the machine.

“Pen” sensor detects if there is a pen loaded in the stocker, the indication is IN or

OUT.

“Pen Code” sensor detects the ID code of the Pen. (0 = Black, 1 = Silver)

31 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

5.2.2. Diagnostics 2 :

Panel test :

1) Display :

By pressing the (1) key, the whole LCD display will light up.

2) Led/Key :

By pressing the cursor keys, the different LED’s will be lit on the keypad. The

LCD will indicate the LED(‘s) that is (are) lit.

The LCD will also indicate any key that is pressed.

(Stop = EXIT)

3) Buzzer :

By pressing the (4) key, the buzzer will be heard.

32 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

5.2.3. Diagnostics 3 :

Penhead Diagnostics :

1) Torque (1), (3) test :

Tests the moving coil and drive circuit.

By pressing the keys (1) or (3) you can move the coil DOWN.

By pressing the keys (2) or (4) you can move the coil UP.

2) Encoder (2), (4) test :

Shows the readout of the pen head encoder.

(Move the head manually up/down).

Track is ± 11 mm.

XY-encoder test :

This test shows the readout of X/Y encoders when manually moving the head or grid rolls.

33 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

XY-polarity test :

Caution :

Before running this test, perform the XY encoder diagnostics test to check that the

polarity of the encoder is correct.

This test checks the drive circuit of the X and Y motors.

One current pulse is sent to the motors and the direction of the movement is checked by the encoders.

34 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

5.2.4. Diagnostics 4.

Paper :

Up/down :

Stocker :

There is only access to this menu if the stocker is loaded in the machine.

35 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

1) Initial (1) :

With this function you can initialise the stocker.

START (3) : starts the test

FINISH (4) : stops the test and you go back in the main stocker menu.

2) Penchange (3) :

This diagnostics allows you to check if the penchange is done correctly.

The counter counts the number of penchanges done.

3) Stepchange (4) :

This diagnostics allows you to check the penchange cycle step by step.

36 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

5.2.5. Diagnostics 5.

XY – Move :

1) Aging :

With this test you can make the plotter continual moving in the X- / Y- axis or both

axes together.

The duration of the operation is displayed (in hours, minutes, seconds).

2) Paper shift :

For this test, you must load a sheet of paper.

The test checks if the tracking of the media remains correct during the operation.

3) Quality :

For this test, you must load a sheet of paper and a pen.

This test is used to check the overall plot quality of the machine.

Before you press “start” (3), you have to position the head to the desired drawing

place on the paper by using the jog keys.

Press (1) to draw the ZIGZAG test.

Press (2) to draw the 45° test.

Press (3) to draw the DASH LINE test.

Press (4) to draw the CIRCLE test.

37 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

General (backup plots) :

1) Backup plot (3) :

Plots the USER parameters.

(Requires Min. A3 size paper and a pen)

2) Adjust plot (4) :

Plots the ADJUSTMENT values.

(Requires Min. A3 size paper and a pen)

38 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

5.2.6. Diagnostics 6.

No importance for maintenance and repair.

39 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

5.2.7. Adjust. 7.

Penchange rotation :

This function allows you to adjust the rotation angle.

For alignment procedure please refer to 6.3.14.1. Calibration pen change adjustment procedure.

40 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

Penchange Y :

This function allows you to adjust the Y-distance to take a tool out of the stocker.

For alignment procedure please refer to 6.3.14.1. Calibration pen change adjustment procedure.

41 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

Penchange Z :

This function allows you to set the correct Z value of the moving coil to take a tool out of the stocker.

For alignment procedure please refer to 6.3.14.1. Calibration pen change adjustment procedure.

42 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

5.2.8. Adjust. 8.

Caution :

The MUTOH MC-1300 Marathon cutting plotters are calibrated before shipping from the

factory. Do not perform this adjustment except when precision obviously worsens. An

accurate reference scale is required to perform this calibration.

An user adjustment can be done for special applications.

X-axis Length Adjustment :

The X-axis length calibration compensates tolerance on the grid roller diameters causing incorrect length of

the X-axis movement.

Load an A1-size paper or larger and a pen.

43 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

Then select the test plot you want to draw :

· 500 mm (square of 500 mm)

· 20 inch (square of 20 inch)

· Robot 1 (accurate plot1) (Factory use only)

· Robot 2 (accurate plot2) (Factory use only)

Press (1) or (3) then the plotter will plot the selected drawing.

Remove the paper from the machine and measure the length of the X-axis lines as accurate as possible.

Press (2) or (4) “Input” to input the real (measured) values.

You can now decrease (1) or increase (2) the value of multi and also decease (3) or increase the value of

mm.

Press [ENTER] to confirm.

Press [EXIT].

Caution :

You cannot check if the calibration is correct by an internal test from the plotter. Check

the calibration by sending a file from the computer. If you would plot the 500 mm (20

inch) square again, it would be plotted without calibration.

44 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

Cutting mat height calibration (Roller) :

This test measures unevenness of the cutting mat +/- every 41 mm and stores this data in the EEPROM.

This data is used to compensate the pen height on these particular places.

Without paper loaded, put the Special Adjustment pen JD-41440 in the penholder.

Press (2) or (4) Roller.

Press (1) or (3) Measure.

Press [ENTER] to start the test.

The plotter starts to measure the cutting mat height every +/- 40 mm.

Press [ENTER] to save the correction data.

Caution :

It is recommended to perform the cutting mat height calibration after replacement of the

cutting mat.

45 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

5.2.9. Adjust. 9.

Rollup System :

1) Aging :

After inserting “How many times” the rollup system have to work and pressing enter, the rollup system will

repeat the rollup/off cycle for the inserted number of times. Check if the rollup system works well.

2) Motor :

By pressing (1),(2),(3) or (4) you can activate the motor on the rear or on the front of the rollup system. Note

that you have to select twice ON before the motor starts running. Check if the motor runs fine. It stops

automatically.

46 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

3) Settings :

The “Feed Length” is of no importance.

In the Setting “Rollup Time” is it possible to insert a time (in seconds). When the Rollup System is active and

after the inserted time it does not detect paper, the rollup system stops. (For example : when a sensor is

broken and the rollup system cannot detect anymore.)

47 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

Pen force calibration :

1) Adjustment :

· Adjustment pen used : JD-41440

· (2) toggles pen UP/DOWN

· Attach bar tension gauge of 50 g to pen and read the value when the pen lifts from the

paper.

48 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

· Enter the measured value.

· Attach a bar tension gauge of 500 g to pen and read the value when the pen tip lifts

from the paper.

· Enter the measured value.

49 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

2) Pen force verify :

This function checks the pen force calibration.

· Put adjustment pen JD-41440 in penhead.

· With (1) and (3) you can select a force between 10 g and 500 g. (10 g – 15 g – 20 g –

30 g – 40 g – 50 g – 100 g – 200 g – 300 g – 400 g –500 g)

· With (2) and (4) you can toggle UP or DOWN.

· Attach a bar tension gauge to the pen and verify the value.

50 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

Cutter :

This test makes the machine sheeting-off as many times as you have selected.

· Load a sheet of vinyl / paper.

· Load a knife (sheet – off) in position 8 of the stocker.

· Select the number of SHEET – OFF cycles.

· Select the length of the sheets.

51 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

5.2.10. Adjust. 10.

Not used for maintenance and repair.

52 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6. PARTS REPLACEMENT AND ADJUSTMENTS.

6.1. Maintenance access table for parts replacement.

Removal of following cover gives access to the following part or mechanical adjustment.

COVER Gives access to

Transparent cover Penhead

Pressure rollers

Cutting mat

Left cover X-motor assy

X-motor belt

X-motor belt tension adjustment

Y-motor assy

Y-motor belt

Y-motor belt tension adjustment

Right cover Keyboard assy

Stocker base assy

Y-axis return pulley assy = carriage drive belt tension adjustment

Pressure roller UP/DOWN sensor

Pressure roller UP/DOWN mechanism

Terminal board assy

Y-rail cover Pressure roller assy

Acrylic cover switch

Y-rail assy

Penhead flex cable assy

Pressure roller UP/DOWN assy

Pressure roller pressure adjustment

PCB box Main / driver board assy

EPROM set

EEPROM

Power supply board assy

Fan motor

Grid cover Grid rollers

Paper sensors

The following chapters are divided in three. The next chapter explains the maintenance of the mechanical

parts. The second chapter gives the explanation of the maintenance of the electronically parts. In the last

chapter you will find more details about maintenance of the rollfeed system.

53 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.2. Mechanical parts.

6.2.1. Cover left : removal and installation.

Step 1 : Remove the Acrylic Cover.

Step 2 : Tape down the Cover Sensor Switch.

Step 3 : Remove the Stocker and move by hand the Toolhead to the utmost right position into the stocker

compartment.

Step 4 : Remove the Y-rail Cover.

Step 5 : Remove screws 2 and screw 3 (Please refer to the figure mentioned below).

Step 6 : Remove screw 4 (Please refer to picture mentioned below) and remove the cover.

Note :

To reinstall the cover left perform the above steps in reversed order.

54 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.2.2. Cover right : removal and installation.

Step 1 : Remove the Acrylic Cover.

Step 2 : Tape down the Cover Sensor Switch.

Step 3 : Remove the Stocker and move by hand the Toolhead to the utmost right position into the stocker

compartment.

Step 4 : Remove the Y-rail Cover.

Step 5 : Remove screws 2 and screw 3 (Please refer to the picture mentioned below).

Step 6 : Remove screw 4 (Please refer to the picture mentioned below) and remove the cover.

Step 7 : Be careful with the flat cable. If the cover need to be removed completely, pull the flat cable out

of the connector on the side of the keyboard PC board + remove the lever sensor cable.

Note :

To reinstall the right cover perform the above steps in reversed order.

55 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.2.3. Transparent cover assy : removal and installation.

Step 1 : Remove the transparent cover by unscrewing the two screws 7(2x) on the left side of the cover

(Please refer to the picture mentioned below) and slide in the shaft.

Note :

To reinstall the transparent cover perform the above steps in reversed order.

56 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.2.4. PCB box : open and close.

Step 1 : On the front side of the machine remove screws (please refer to the picture mentioned below)

while holding the PCB box.

Step 2 : Turn open the PCB box gently and be careful not to harm any cables or wires.

Note :

To close the PCB box, perform the above steps in reversed order.

57 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.2.5. Y-rail cover : removal and installation.

Step 1 : Remove the transparent cover (Please refer to 6.2.3. Transparent cover).

Step 2 : Tape down the cover switch.

Step 3 : Remove the Stocker and move by hand the Toolhead to the utmost right position into the stocker

compartment.

Step 4 : Remove the Y-rail cover.

Note :

To reinstall the Y-rail cover perform the above steps in reversed order.

58 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.2.6. Grid cover : removal and installation.

Step 1 : Remove the transparent cover (Please refer to 6.2.3. transparent cover).

Step 2 : Remove the Y-rail cover (Please refer to 6.2.5. Y-rail cover).

Step 3 : Remove the left and right cover (Please refer to 6.2.1. left cover and 6.2.2. right cover).

Step 4 : Open the PCB box (Please refer to 6.2.4. PCB box).

Step 5 : Remove the dummy plate (next to the PCB board) by unscrewing the different screws.

Step 6 : Unscrew the screws inside the box, to remove the front platen.

Step 7 : Remove the small hexagon screws that fix the grid cover.

Use an L-shaped hex-key of 1.27mm/ 1/20”.

Step 8 : Remove the front platen.

Caution :

If you want to remove the front platen, you have to rotate it, so that the attachment is opened.

(Please refer to the picture mentioned below)

Step 9 : Remove the grid cover.

Note :

To reinstall the grid cover perform the above steps in reversed order.

59 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.2.7. Cutting head : removal and installation.

Step 1 : Remove the transparent cover (Please refer to 6.2.3. Transparent cover).

Step 2 : Remove the Y-rail cover (Please refer to 6.2.5. Y-rail cover).

Step 3 : Remove the head cover by removing the screw in the middle of the cover and unscrew the

bottom screw a few turns.

The head cover can be removed by sliding it upwards.

Step 4 : Open the 2 white connectors by sliding them to the front and pull away the flex cables from the

connectors.

Remove the head PCB on top of the head by screws “C” (Please refer to the figure mentioned

below) and lay it somewhere on the Y-rail where the flex cable cannot be harmed.

Step 5 : Remove screw “A” that fixes the cutting head to the drive belt.

It is strongly recommended to use a magnetised (+) screwdriver in order not to drop the screws

inside the head.

Step 6 : Remove the “B” on the top of the head and slide away the leaf spring.

Step 7 : Turn over the top rollers to the front, lower the head a little and remove it in the front direction.

Note :

To reinstall the cutting head perform above steps in reversed order.

Caution :

After replacement of the cutting head the following electronically adjustments have to be

performed :

1) Cutting mat height measurement (Please refer to 5.2.4. Diagnostics 4).

2) Pen force calibration (Please refer to 5.2.9. Adjust 9).

3) Pen change alignment procedure (Please refer to 6.3.14.1. Calibration pen

change adjustment procedure.

60 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.2.8. Grid rollers : removal and installation.

Step 1 : Remove the grid cover (Please refer to 6.2.6. Grid Cover).

Step 2 : Unscrew the two screws from the X-motor a few turns and remove the X-drive belt.

Step 3 : Unscrew all the grid rollers (with 1.5mm hex key), and pull out gently the shaft out of the

machine. In this way every grid roller can be removed from the shaft.

Caution :

Never replace only one grid roller but always the whole set.

Replacement of only one grid roller may result in noticeable deviation of media tracking.

Before unscrewing the grid rollers, mark the position of every roller on the shaft. This

will simplify the reinstallation.

NEVER unscrew or change the position off bearing blocks on the X-rail as this will result

in misalignment of the grid roller shaft.

Note :

To reinstall the grid rollers perform above steps in reversed order.

Caution :

After reinstallation of the grid rollers, the X-drive belt tension should be adjusted (Please

refer to 6.3.6.1.X-drive belt : tension adjustment).

61 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.2.9. Y-drive belt (long) : removal and installation.

6.2.9.1. Y-drive belt (long) : removal.

Step 1 : Remove the cutting head (Please refer to 6.2.7. cutting head).

Step 2 : Remove the covers left and right (Please refer to 6.2.1. cover left and 6.2.2.cover right).

Step 3 : On the right side of the machine, unscrew both screws 5, ± 5 turns in order to lower the tension of

the belt. (Please refer to the picture mentioned below.)

Step 4 : Remove two screws 4 and one plate 3 from the belt connection assy and pull out the belt

completely out of the Y-rail. (Please refer to the picture mentioned below.)

62 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.2.9.2. Y-drive belt (long) : installation and adjustment.

Step 1 : Hold the belt in the front of the machine and push one end through the slit of the right side plate.

Turn the belt around the pulley and push it in the second slit to enter at the back of the Y-rail.

Push it as far as possible and then use a flash light and look into the slit a the left side of the

machine.

With a pair of tweezers try to grab the belt and pull it through the slit.

Turn the belt around the return pulley and push it through the front slit to arrive at the starting

point of the belt again.

Step 2 : Close the belt with the connection plate assy and make sure that all the teeth of the connection

plate are used to hold the belt.

Step 3 : Turn the two screws on the return pulley (Please refer to 6.2.9.1. Y-drive belt (long) : removal) a

few turns in CW (clockwise) in order to get a little tension on the belt.

Step 4 : Install the cutting head (Please refer to 6.2.7. cutting head).

Step 5 : Move the head manually from the left to right and look for the tracking of the belt on the return

pulley.

If the belt moves upwards, turn the top screw CW or the bottom screw CCW (Counter clock

wise).

If the belt moves downwards, turn the top screw CCW or the bottom screw CW.

The aim is to make sure that the belt stays stable at the surface of the return pulley on he

complete range of the cutting head.

63 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

Step 6 : Similar to step 5 check the track of the belt on the drive pulley. (Right side of the machine).

If the belt moves upwards turn screw 8 (Please refer to the picture mentioned below) CW.

If the belt moves downwards turn screw 9 CCW.

Caution :

Pay attention to the tension on the belt during this alignment.

The tension should stay between acceptable values.

(Please refer to the next step.)

Step 7 : Move the head to the right end of the Y-rail and measure with a bar tension gauge (range 500 g,

MUTOH Part # JD-41446B) the tension of the belt in the middle of the Y-rail (Please refer to the

picture mentioned below).

Push the belt with the bar tension gauge (with steel belt tension attachment MUTOH Part # JD-

41565) to touch the rail and release gently the pressure on the gauge.

The moment that the belt starts to release from the rail is the moment of reading the value on the

bar tension gauge.

64 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

The values are different for each size of machine :

MC-1300

130 ± 5 g

The tension can be adjusted by turning the screws on the return pulley (Please refer to the

picture mentioned above) CW for more tension and CCW for less tension.

Caution :

While adjusting the tension, keep on checking the track of the belt on the return pulley

(Please refer to step 5).

65 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.2.10. Pressure roller pressure adjustment.

Step 1 : Switch off the machine and place the pressure rollers on the top of a grid roller.

Step 2 : Remove the transparent cover (Please refer to 6.2.3. transparent cover).

Step 3 : Remove the Y-rail cover (Please refer to 6.2.5. Y-rail cover).

Step 4 : Take a piece of polyester film of ± 300 cm long, 2.5 mm wide (12” x 1”) and put it between the

grid roller and pressure roller (Please refer to the picture mentioned below).

Attach the bar tension gauge (range : 5 kg, MUTOH Part # JD-41446C) to the pressure roller

shaft with a piece of rope or with the pressure measurement attachment JD-41563 and pull

simultaneously the film and the tension gauge under 90° angle.

The moment that the film is slipping between the rollers is the moment to read the value on the

tension gage.

The value should be 3.5 kg ± 0.1 kg for the MC-1300 Marathon Cutting Plotter.

To adjust the pressure, change the spring tension by turning the nuts A (Please refer to the

picture above) CW to increase or CCW to decrease the pressure on the rollers.

Important:

Very important is that all 3 pressure rollers are adjusted to the same pressure.

Uneven pressure will result in bad media tracking.

66 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.3. Electrical parts.

6.3.1. Main PC board : removal and installation.

Step 1 : Open the PCB box (Please refer to 6.2.4. PCB box).

Step 2 : Unplug all the connectors, remove all screws from the board and remove the board. Do not

forget to remove the screws from the parallel and serial communication connector.

Note :

Pay attention to the position of all connectors and the proper place of all the

cables.

This will simplify the installation.

To reinstall the Main PC board perform the above steps in reversed order.

Warning :

Check the DIP switch settings on the board.

The position of the DIP switches determines the size of machine where the

board will be used.

67 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

DIP switch settings on Main PC board :

8 7 6 5 4 3 2 1

MC 1300 Marathon Type Off On Off Off Off Off Off Off

Diagnostics Off Off Off Off Off Off Off On

No checking of pinch roller position Off Off Off Off Off On Off Off

Warning :

After Main PC board replacement put EEROM from initial board in the new

one (Please refer to 6.3.2. EEPROM initialisation and replacement).

This way no other adjustments or user parameters have to be reinstalled.

If for some reason the EEPROM must be replaced, the following data must

be checked and if necessary readjusted. (please refer to the next page)

68 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.3.2. EEPROM initialisation and replacement.

For EEPROM initialisation see “Diagnostics 1”, Memory, EEPROM (Please refer to 5.2.1. Diagnostics 1).

After initialisation or replacement of the EEPROM the following data may be changed and need to be

reinstalled :

q INIT1 = settings in normal operation mode = USER parameters such as :

· Origin

· Speed

· Acceleration

· Force

· Offset

· Shuffle length

· Tool selection

· Page mode

· Replot factor

· Smoothing

· Communication parameters

· Command set (language)

q INIT2 = Adjustments in Diagnostics mode :

· X axis length adjustment

· Cutting mat height measurement

· Knife force calibration

· Toolholder height adjustment (penchgZ)

· Stocker origin adjustment (penchgRot)

· Toolhead to stocker alignment (penchgY)

69 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.3.3. Power supply board : removal and installation.

Step 1 : Open the PCB box (Please refer to 6.2.4. PCB box).

Step 2 : Remove the connectors and the screw from the grounding wire and remove the board.

Note :

To reinstall the board perform the above steps in reversed order.

Power supply output connections :

PIN SIGNAL COLOUR PIN SIGNAL COLOUR

1 + 5V Red 7 FG Green

2 - 5V Red 8 - 12V Blue

3 SG Black 9 AG Black

4 SG Black 10 + 12Vb Orange

5 + 12Va Orange 11 PG Black

6 + 40V Yellow 12 PG2 Black

70 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.3.4. Terminal board : removal and installation.

Step 1 : Remove the right cover (Please refer to 6.2.2. right cover).

Step 2 : Unplug all the connectors, remove all screws (4x) from the board and remove the board.

Note :

Pay attention to the position of all connectors and the proper place of all the cables.

This will simplify the installation.

Note :

To reinstall the board perform the above steps in reversed order.

71 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.3.5. Keyboard : removal and installation.

Step 1 : Remove the right cover (Please refer to 6.2.2. right cover).

Step 2 : Remove the flat cable from the keyboard PC board.

Step 3 : Remove screws (4x) from the right cover (inside right cover) and remove the keyboard.

Note :

To reinstall the keyboard perform the above steps in reversed order.

72 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.3.6. X-motor and drive belt : removal and installation.

Step 1 : Remove the left cover (Please refer to 6.2.1. left cover).

Step 2 : Open the PCB box (Please refer to 6.2.4. PCB box).

Step 3 : Remove the X-motor connector and the X-encoder connector from the main PCB.

Step 4 : Remove the screws from the X-motor and remove the belt and the motor.

Note :

To reinstall the X-motor perform the above steps in reversed order.

6.3.6.1. X-drive belt : tension adjustment.

Step 1 : From the side of the X-motor, attach a piece of rope (or the pressure measurement attachment

JD-41563) around the motor body as possible to the side plate.

Step 2 : Be sure that the motor screws are not fixed and pull the bar tension gauge (Range : 5 kg,

MUTOH Part # JD-41446C) for 3.75 kg ± 0.05 kg.

Turn manually the grid shaft a few turns and fix the motor screws.

73 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.3.7. Y–motor and drive belt : removal and installation.

Step 1 : Remove left cover and PCB box (Please refer to 6.2.1. left cover and to 6.2.4. PCB box).

If the drive belt must be removed, remove the right cover to (Please refer to 6.2.2. right cover).

Step 2 : Remove the Y-motor connector and the Y-encoder connector from the mainboard and pull the

cables out of the PCB box.

Step 3 : Remove the 2 screws from the Y-motor and remove the motor.

To install the Y-motor perform above steps in reversed order and perform the belt tension

adjustment (Please refer to 6.3.7.1. Y-motor and drive belt : installation and adjustment).

Step 4 : Release the tension on the Y-drive belt (long) (Please refer to 6.2.9. Y-drive belt (long)).

Remove the screw on top of the pulley shaft and remove the pulley assy from the bracket.

If this is not possible, the Y-drive belt (long) must be more released from tension by turning the

screws of the return pulley CCW.

Now the Y-belt (short) can be removed.

6.3.7.1. Y-motor and drive belt : installation and adjustment.

Step 1 : Install the Y-drive belt (short) by performing the above steps in reverse order.

Step 2 : Tighten the screws from the Y-motor a few turns, but do not fix them.

Step 3 : Attach the bar tension gauge (range : 5 kg, MUTOH Part # JD-41446C) to the motor shaft (Use a

piece of rope or pressure measurement attachment JD-41563) and pull for 3.5 kg ± 0.05 kg.

While pulling the gauge, move the cutting head manually left and right a few turns before fixing

the motor screws.

74 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.3.8. Head flex cable : removal and installation.

Step 1 : Remove the transparent cover (Please refer to 6.2.3. Transparent cover).

Step 2 : Remove the Y-rail cover (Please refer to 6.2.5. Y-rail cover).

Step 3 : Remove the right cover (Please refer to 6.2.2. Right Cover)

Step 4 : Remove the head cover by removing the screw in the middle of the cover and unscrew the

bottom screw a few turns.

The head cover can then be removed by sliding it upwards.

Step 5 : Open the two white connectors by sliding them to the front and pull away the two flex cables from

the connectors.

Remove the head PCB on top of the head by two screws and lay it somewhere on the Y-rail

where the flex cable cannot be harmed.

Step 6 : Remove the flex cables from the terminal boards (® under right cover).

Step 7 : Remove the cable guides that are holding the flex cable.

Step 8 : Remove the flex cable.

Note :

Pay attention to the position of the cable in the way that it is guided all

through the machine.

This will simplify the installation.

Note :

To reinstall the head flex cable perform the above steps in reversed order.

75 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.3.9. Paper sensors : removal and installation.

Step 1 : Remove the grid cover (Please refer to 6.2.6. grid cover).

Step 2 : Remove the cables from the sensors and remove the sensors.

Note :

To reinstall the paper sensors perform the above steps in reversed order.

76 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.3.10. Transparent cover sensor : removal and installation.

Step 1 : Remove the transparent cover (Please refer to 6.2.3. transparent cover).

Step 2 : Remove the Y-rail cover (Please refer to 6.2.5. Y-rail cover).

Step 3 : Remove the right cover (Please refer to 6.2.2. Right Cover).

Step 4 : Remove the connector from the terminal board (White cable). Remove the two screws and

remove the switch.

Note :

Pay attention to the position of the cable in the way that it guided all through

the cover.

This will simplify the installation.

Note :

To reinstall the transparent cover sensor perform the above steps in reversed order.

77 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.3.11. Pressure roller UP/DOWN sensor : removal and installation.

Step 1 : Remove the right cover (Please refer to 6.2.2. right cover).

Step 2 : Remove the sensor.

Note :

To reinstall the sensors perform the above steps in reversed order.

78 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.3.12. Fan motors : removal and installation.

Step 1 : Open the PCB box (Please refer to 6.2.4. PCB box).

Step 2 : Remove the dummy plate (next to the PCB board) by unscrewing the different screws.

Step 3 : Remove the fan motor cable(s) (red, black, brown) from the main PCB board.

Step 4 : Remove the fan motors.

Note :

To reinstall the fan motors perform the above steps in reversed order.

79 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.3.13. Stocker home position sensor : removal and installation.

Step 1 : Remove the right cover (Please refer to 6.2.2. right cover).

Step 2 : Remove the sensor connector from the terminal board.

Step 3 : Remove the sensor by pushing the hook and rotating the sensor (Please refer to the picture

mentioned below).

Note :

To reinstall the stocker home position sensor perform the above steps in reversed order.

80 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.3.14. Stocker motor : removal and installation.

Step 1 : Remove the right cover (Please refer to 6.2.2. right cover).

Step 2 : Remove the transparent cover (Please refer to 6.2.3. transparent cover).

Step 3 : Remove the Y-rail cover (Please refer to Y-rail cover).

Step 4 : Remove the screws that hold the stocker motor.

Step 5 : Turn the setscrew a few turns and remove the stocker foot.

Step 6 : Remove the stocker motor cables and remove the stocker motor.

Note :

To reinstall the stocker motor perform the above steps in reversed order.

6.3.14.1. Calibration pen change adjustment procedure.

Þ Power on the unit in diagnostic mode (Please refer to 5.2. diagnostic mode).

Þ Select ‘DIAGNOSTIC 7’ with menu UP/DOWN keys.

Three adjustments should be performed and in the following order.

1) Toolholder height adjustment (penchgZ).

q Press the [OFFSET] key to select PchgZ.

q Close the cover and press the [ENTER] key (no tool in the stocker or in the toolholder).

q Move the head manually in the stocker for ± 1 cm.

q Manually turn the stocker clockwise (CW) and check if the biggest finger from the stocker

can move in the groove of the toolholder.

q If the finger touches the upper part of the toolholder : Press ‘arrow up’ (+Z) to make the

position of the toolholder higher and the finger can move into the groove.

q If the finger can move into the groove but the play between the upper part of the finger and

the groove is more than 0.2 mm, press ‘arrow down’ (-Z) to make the position of the

toolholder lower until the play is 0.1 mm (- 0, + 0.1).

Caution :

Do not make the position of the toolholder higher than the above

specifications.

Press the [ENTER] key and press the [ENTER] key again to confirm the value and store into the

EEPROM.

81 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

2) Stocker origin adjustment (penchgROT).

q Press the [FORCE] key and then the [ENTER] key.

q Open the acrylic cover.

q Put a tool in position 1 of the stocker.

q Move the head manually in and out the stocker

a) If the head grabs the tool but the stocker moves one step counter clockwise (CCW),

press ‘arrow up’ (CCW) ones. The stocker will rotate twice.

Move the head in/out the stocker a few times.

Repeat pressing ‘arrow up’ (CCW) until the stocker stays in the correct position while

moving the head in and out the stocker.

While moving he head in and out the stocker the tool should move from the stocker to the

toolhead and vice versa. If this is the case the alignment is OK.

b) If the head does not grab the tool or the tool cannot put back in the stocker, press

‘arrow down’ (CW) ones. The stocker will rotate twice.

Repeat pressing ‘arrow down’ (CW) until the tool can be taken from the stocker and put

back into the stocker while moving the head manually in/out the stocker.

If this is the case the alignment is OK.

Close the cover and press the [ENTER] key and the [ENTER] key again to confirm the value

and store into the EEPROM.

3) Toolhead to stocker alignment (penchgY).

q When in diagnostic 7 menu press the [TEST] key (penchgY).

q Put a tool in position 1 of the stocker.

q Press and hold the ‘arrow up’ key. The toolholder will move into the stocker very slowly.

Hold the key until the toolholder has fully entered the stocker and you can see the stocker

is pushed to the right by the toolholder.

q Press the ‘arrow down’ key. The stocker moves back and the moment the stocker does

not move anymore, press another 2 times the ‘arrow down’ key.

q Press the [ENTER] key and the [ENTER] key again to confirm the value and store in the

EEPROM.

q Switch off the machine

4) Stocker test.

q Switch on in diagnostic mode.

q Select ‘DIAGNOSTIC 4’ with the arrow keys.

q Put one or more tools in the stocker.

q Press the [OFFSET] key (stocker).

q Pres the [TEST] key (penchange) and then the [TEST] key (start). The machine will start

continuously changing the tools.

q If changing is OK press the [OFFSET] key (finish) and power off the machine.

82 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.4. Rollfeed Parts.

6.4.1. Remarks.

Important :

Before any service operation is performed :

· Remove all conveyor rolls.

· Shut down the MC-1300 Marathon Cutting Plotter and disconnect the power cord.

Caution :

Some operations require the plotter body to be taken of the rollfeed. This has to be

done with the assistance of a second person.

83 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.4.2. Removing the Gear Cover.

(The same procedure applies for both the front and the rear gear cover assembly.)

Step 1 : Unscrew the 6 screws M4x6 holding the gear cover.

Step 2 : Disconnect the cable from the photo sensor.

Step 3 : The gear cover can now be removed.

84 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.4.3. Removing the PCB cover.

Step 1 : Disconnect the ribbon cable from the connector.

Step 2 : Unscrew the two screwlocks on the DB-37 connector.

Step 3 : Unscrew the 4 cap screws M4x6 holding the PCB cover.

Step 4 : Remove the PCB cover by gently moving it forward over the connector.

85 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.4.4. Replacing the gear motor assembly.

Caution :

The MC-1300 Marathon body should be taken of the leg to perform this operation.

The same procedure applies for both the front and the rear gear motor assembly.

Step 1 : Remove the PCB cover.

Step 2 : Disconnect the motor connector (Front : J15 / Rear : J14).

Step 3 : Remove the gear cover.

Step 4 : Remove the cable guide bracket (8 screws M4x6).

Step 5 : Unscrew the 5 screws holding the gear motor assembly.

86 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

Step 6 : The gear motor assembly can now be taken out of the endplate assembly.

Step 7 : Place the replacement gear motor assembly in the endplate.

Step 8 : Use the two holes diameter 4 to position the motor assembly.

Step 9 : Mount the gear motor assembly using the 5 screws M4x8.

Step 10 : Lead the cable through the cableclip and through the rectangular hole in the cable guide.

Step 11 : Connect the cable to the appropriate connector on he PCB board.

Step 12 : Reassemble the cable guide bracket.

Step 13 : Reconnect the cover sensor cable.

Step 14 : Reassemble the gear cover.

87 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.4.5. Replacing the rollfeed PCB.

Step 1 : Remove the PCB cover.

Step 2 : Disconnect all connectors

Step 3 : Unscrew the screws holding the PCB-assembly.

Step 4 : Remove the PCB.

Step 5 : Fix the new PCB using the 4 screws.

Step 6 : Reconnect all connectors.

Step 7 : Reassemble the PCB-cover using the 4 screws M4x6. Do not tighten these screws before the 2

screwlocks on the DB-37 connector are fixed.

88 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.4.6. Replacing a photo sensor at the front- or rear guidebar.

Step 1 : Remove the Guidebar Cover (unscrew the 10 screws M3x6).

Step 2 : Disconnect the cable from the malfunctioning Photo Sensor.

Step 3 : Unscrew the screw holding the Photo Sensor. The Photo Sensor can now be removed.

Step 4 : Mount the replacement Photo Sensor, using the positioning dimple on the sensor and the self-

tapping screw.

Step 5 : Reconnect the cable.

Step 6 : Reassemble the Guidebar Cover.

89 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

6.4.7. Replacing a photo sensor in the front- or rear gear cover.

Step 1 : Remove the Gear Cover.

Step 2 : Disconnect the cable to the Photo Sensor connector.

Step 3 : Remove the malfunctioning Photo Sensor by unscrewing the two screws M3x12.

Step 4 : Mount the new Photo Sensor.

Note :

Mount the Photo Sensor with the “eye” looking through the hole and the connector

away from the media roll opening in the cover. (The picture shows the front cover

situation.)

Step 5 : Reconnect the cable to the Photo Sensor connector.

Step 6 : Reassemble the Gear Cover.

90 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

7. JIG TOOL LIST.

7.1. Jig tool list.

PART NAME PART Number

Adjustment pen 10 g JD-41440

Bar tension gauge 50 g JD-41446A

Bar tension gauge 500 g JD-41446B

Bar tension gauge 5 kg JD-41446C

Pressure measurement attachment JD-41563

Steel belt tension attachment JD-41565

L shaped Allen key 1.27 mm (1/20”)

+ Screw driver (Philips) # 1

+ Screw driver (Philips) # 2

- Screw driver

Open wrench 13 mm

Box wrench 13 mm

7.2. Special glue.

External screw locking glue : LOCTITE 7400 (VERNISTOP)

Screw thread locking glue : LOCTITE 243

Glue for fixing Y-motor pulley : LOCTITE 406

91 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

92 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

8. PLOTTERBODY AND ROLLFEED.

93 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

1. Flanges : Support/carry the roll media.

2. Tension Roller : Support roll media and rollfeed system.

3. Media Shaft : Support/carry the roll media.

4. Carousel/Stocker : This carousel can hold up to 8 different tools, allowing

flexible switching from one application to another. It can

be easily removed to install and/or take out tools.

5. Control Panel : Panel with LCD display, indicator LEDs and control keys.

6. Power Switch : Turns the plotter ON or OFF.

7. Blue & Black Buttons : Release media on the rollfeed system.

8. Carriage Cover : For safety reasons, the cutter will not work while the cover

is open. The cover will also prevent objects from falling

into the cutting zone.

9. Cutting Mat : Provides a reliable cutting surface and prevents damage

to the knife tip.

10. Platen & Grid Cover : Supports the media and guides the movement of the

media along the X-axis.

11. Serial Interface Connector : (At the left side of the PCB box.) RS-232 serial interface

connector to connect the cutter to the host computer.

12. Parallel Interface Connector : (At the left side of the PCB box.) Centronics parallel

connector to connect the cutter to the host computer’s

printer port for fast data transfer.

13. Power Connector : Connector for the power cord, which plugs into the main

power supply of the cutter.

14. Caster Wheels : The cutting plotter’s legs are equipped with 4 pre-installed

caster wheels, two of which have a lock switch.

94 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

9. PARTS LIST PLOTTERBODY

9.1. Platen and alignment (MY-23342).

Ref. Description Partnumber Qty

1 Platen ME-23913 2

2 Grid cover ME-23304 1

95 AP-74040, Rev 1.0, 25/01/02

Maintenance Manual – MC-1300 Marathon Cutting Plotter

9.2. Right cover and keyboard assy (MY-23539).

Ref. Description Partnumber Qty

1 Cover right DE-10539 1

2 Cover sensor bracket ME-23021 1

3 Switch assy DE-46871 1