Module 4 - Engine

Uploaded by

William RuizModule 4 - Engine

Uploaded by

William RuizQSV 81/91 Series Gas Engines

Module 4 - Base Engine

Cummins Corporate Training

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01/ REV. 03.

QSV Gas Engines

Learning Objective

To identify key build changes between QSV Industrial Diesel

engines and QSV Industrial Gas engines. Participants will be able

to identify the base engine changes and additional components

associated with Cummins Gas engines.

Agenda

• Gas Engine Ratings.

• Gas Engine Layout.

• Diesel to Gas Component Changes.

• Gas Fuel System Components.

• Gas Ignition System Components.

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

2

QSV - Gas Engine Rating

POWER OUTPUT

• 89 Kw /Cylinder @1500, TA LUFT continuous, or

• 71 Kw /Cylinder @1200, TA LUFT continuous.

ENGINE SPEED

• 1500 rpm for Genset 50 Hz.

• 1200 rpm or 1500* rpm + G/Box for 60Hz Genset.

• 1500* rpm for gas compressor engine * Planned

COMPRESSION

• 12 : 1 = Fuel Methane Index ( MI ) > 70 (standard)

• 11.4 : 1 = Fuel Methane Index ( MI ) 60 - 70

• 10.5 : 1 = Fuel Methane Index ( MI ) 45 - 60

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

3

A-Bank View - V16

9

8

1

2

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

4

B-Bank View - V16

8

9

7 2

3

6

5

4

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

5

Flywheel-End View - V16

6

1

5

4

2

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

6

Free-End View - V16

9 2

8 4

5

6

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

7

Diesel Vs Gas Component Changes

180mm GAS COMPONENTS SHOWN

B A

Skirt Cooling Tapered Piston

Combustion Bowl Articulated design

Nozzle Cut-Out Pin

(x2)

Piston & Pin Design

• Diesel 170 mm bore - Composite Construction

• Gas 180 mm bore - Articulated, combustion bowl in piston crown.

• Diesel Pin - type ‘A’

• Gas Pin - type ‘B’ (Internal Taper - No load on skirt)

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

8

QSV 81/91 Piston Assembly

• Construction: Articulated Type.

• Aluminium skirt with steel crown,

bronze pin bores.

CTR

• Skirt lubrication via piston pin.

Skirt assembly either way - two nozzle

cut-outs.

• Combustion ‘Bowl’ set in piston

crown.

• Centre (CTR) position marked on

crown - assemble to Multi-duct.

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

9

Diesel Vs Gas Component Changes

• Multi- housing

Diesel - Pump element, pump

and valve roller tappets, push-

rod tube support, fuel supply

and return rails, oil supply

point to valve gear.

Gas - Valve roller tappets,

push-rod tube support, oil

supply point to valve gear only.

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

10

Diesel Vs Gas Component Changes

‘QSV’ Camshaft

shown

Camshaft

• Diesel - Pump and valve cam lobes.

• Gas - Valve cam lobes only (lobe profile change).

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

11

Diesel Vs Gas Component Changes

Valve Cover

• Diesel - Single point fixing with oil

seal

• Gas - Single point fixing with oil seal,

plug insulator and LT coil

(COP) connection, 300-350v dc.

NOTE: HT BELOW VALVE COVER

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

12

Diesel Vs Gas Component Changes

Insulator Assembly

Insulator

Locking tabs

Clamp

(locks sleeve &

seat assembly).

Sleeve

Plug Seat with

O-Ring

Cylinder Head

• Diesel - Centrally located injector (no water cooling MK1)

• Gas - Centrally located insulator assembly and spark plug with water cooled

plug seat. No cylinder access plug, remove spark plug. Knock sensor fitted to

front face.

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

13

Diesel Vs Gas Component Changes

• Liner

Diesel - 170mm bore.

Gas - 180mm bore.

• NOTE: The 180mm bore Gas Cylinder Liner outside diameter

and block bore are the same as the 170mm Diesel engine.

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

14

Diesel Vs Gas Specification Changes

Specification changes include:

• Large End & Mains Bearings - Not interchangeable!

QSV Diesel - Tri-metal, steel base with liner of either lead / bronze or

aluminium / tin, and overlay of Indium.

QSV Gas - Bi-metal, no Indium overlay, lower risk of corrosion (water plus

sulphur = acid) plus lower engine dynamic loads.

• Turbochargers and Boost Pressure

QSV Diesel - 4.5 Bar @ 1500, Holset - Model HX82

QSV Gas - 2.3 Bar @ 1500, Holset - Model HX82

• Timing

QSV Diesel - 4.0 mm pump cam lift @ 14º BTDC firing stroke (1500 rpm).

QSV Gas - 5.3 mm (+/- 0.08) exhaust cam lift @ 14º BBDC firing stroke

(all engines, valve timing only!).

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

15

Gas Supply Components

The natural gas supply system can be split into two parts;

components mounted external to the engine and those mounted on

the engine.

1) The components EXTERNAL to the engine:

• Main shut-off valve (manual).

• Gas filter.

• Flow meter (optional).

• Pressure reducer / regulator down to 150mBar.

• High pressure discharge valve.

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

16

Gas Supply Line

Gas Supply Line as shown Pressure High Pressure Discharge

normally 80mm diameter up Regulator with Valve 200mB.

to 3.0Bar inlet pressure, Safety Shut-off (Ball Valve, protects

50mm diameter over 3.0Bar. Valve system if Regulator fails)

Manual Shut-off Gas Flow Meter

Valve (Optional)

TO ENGINE

SSV - Safety Shut-off

MAINS

GAS Gas Filter Valve protects

SUPPLY diaphragm

(operates on dP

across Regulator)

Blow-off / Breather line

Manual reset!

Simplified gas supply system EXTERNAL to the engine - Supplied Loose

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

17

Hand Valve

• Concentric disc soft sealing butterfly valve.

• Install between flanges DIN/ISO 5211.

• Pressure rating up to dP 16Bar.

• Tight seal with flow in either direction.

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

18

Filter

• GF Type - general fine filter for all

gasses and air, 50 micron rating.

• Body cast - Aluminium & Silicon

(ALSi).

• Flanges to DIN 2533.

• Filter pad - removable polypropylene

fleece.

• Can be fitted in horizontal and

vertical indoor pipes.

• Max operating Temp + 80º C.

• Max pressure 2 or 4Bar.

Note: Direction of gas flow

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

19

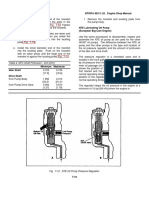

Pressure Regulator

• Gas pressure regulator with high Pressure

Control

level safety shut-off valve at adjustment

200mBar, manual reset only. Control

Actuator spring

• Pressure settings (3) inlet options; (diaphragm) Vent

1) 1.25 - 1.8 Bar / 150mBar

Actuator

2) 1.80 - 3.0 Bar / 150mBar

3) 3.00 - 4.0 Bar / 150mBar Tap

• Output & SSV pressure adjustable. connection

(sense)

Differential between set and

response pressure of the SSV SSV

Reset

should be not less than 20mBar. Tap con. shaft

SSV

Blow-off con.

• SSV and regulator range set by actuator spring

casing

colour-coded springs. SSV adjustment

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

20

Regulator Installation & Operation

Blow-off & Regulator breather

To ensure that the device lines (run separately)

will respond properly in the

event of rapid load changes,

the regulator breather line Pressure Typical Regulator

Regulator

should have the following Installation

dimensions: with SSV

Up to 3.0m long DN -15

TO ENGINE

Up to 5.0m long DN - 20

Tap Line

Over 5.0m long DN - 25

DN

MAINS GAS SUPPLY

Tap lines should be

connected to a length of outlet

pipe where turbulence is low, SSV Tap Line 5 x DN

i.e. at a minimum distance of 5

times the pipe diameter SSV - Safety

Shut-off Valve

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

21

SSV Reset Procedure.

1 3

If excessive pressure differential occurs

between the set pressure of the regulator and

the response pressure of the SSV, then the SSV

will trip. Follow the procedure below to reset:

1. Equalise pressure across valve by depressing

plunger using special tool provided.

2. Unscrew dust cover from SSV reset

mechanism.

3. Inspect mechanism, slot on shaft should be

Horizontal. If slot is Vertical, the SSV has

tripped. To reset, fit supplied box spanner and

rotate mechanism anti-clockwise.

2 4. Refit SSV reset mechanism dust cover.

NOTE: It is not necessary to isolate the gas

supply in order to perform the above procedure.

However, if you do, open the isolation valve

slowly in order to avoid re-tripping the SSV. SSV Special Tools

Slot in mechanism should be HORIZONTAL

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

22

Typical Installation

Pressure

Regulator

Breather

Line

Regulator

& SSV

Tap Lines

High

Pressure

Discharge

Valve

Blow-off

Safety

Shut-off

Valve

Breather

Line

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

23

Gas Supply Components

2) The supply components mounted ON the engine:

• Gas Control Valve - Solenoid operated twin shut-off valves (for

isolation & safety, includes adjustable high and low pressure

safety switches).

** ‘V’ Engines

• Gas Flow Control Assembly (FloTech)** fitted with

• Gas /Air Mixer** multiple units

• Turbocharger (Holset HX82 series on ‘V’)**

• Charge Air / Gas Cooler

• Actuator / Driver (throttle)**

• SSM 558 Module (Sub Systems Module) Fuel & Ign. control**

• MCM700 (Master Control Module) Throttle control / speed

MCM700 / SSM 558 module functions will be covered in the Control Module

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

24

‘V’ Engine Gas Circuit Schematic

To - Turbochargers - Charge Air / Fuel Cooler - Throttle Actuators - cylinders

4 x Mixers

Gas control assy. Gas control assy.

(FloTech No.1) (FloTech No.2)

Twin Solenoid Valve GMF Sensor.

(may be mounted Flow Calculation

externally). via SSM 558

HP Safety Valve

Duty Cycle (200mBar)

Valve

Regulator

Filter

Components Mounted Externally Mounted

on the Engine Components

Isolation Valve

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

25

Gas Supply System

The Natural Gas supply system ON the engine:

• Gas Control Valve - 24v dc solenoid

operated twin shut-off valves with vent.

(for isolation & safety).

• Normal shutdown shuts off supply via this

valve.

• LP protection set at 80mBar (adjustable).

• HP protection set at 180mBar (adjustable).

• Valve operation can be checked by listening

to the sound of the valve operating when

switching the valve isolating switch on the

OEM panel.

THE CONTROL VALVE THEN SUPPLIES TWO SEPARATE GAS FLOW ASSEMBLIES ON

THE ENGINE, ONE AT THE FREE-END & ONE AT THE FLYWHEEL-END.

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

26

Gas Control Valve

Features PRESSURE

SENSOR AS

• Twin Solenoid (24v dc) FITTED TO

CONTROL

• High / Low pressure settings VALVE

180mBar / 80mBar.

Operational Checks

SINGLE SOL

• Check manual power switch is CONTROL

VALVE

operational prior to engine start. SHOWN

• Verify proper solenoid & vent

operation prior to engine start.

• Verify that pressure safeties are

operational.

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

27

Gas Control Assembly (Duty Cycle)

ONE OF TWO IDENTICAL UNITS

Typical Value; AIR GAS MIXER

FITTED TO ‘V’ ENGINES

P1 = 1.15Bar abs. INTAKE

P2 = 0.9Bar abs.

PRESSURE SENSORS 1 & 2

dP

P1 GAS mass FLOW DUTY CYCLE VALVE

P2

SENSOR (FloTech)

GAS TO

IN TURBO’S

VENTURI

5v

By-pass line

G.M.F

reduces 0v

turbulence and SENSOR

(Hot Wire) Mark Space Ratio

increases

measurement GAS MIXER

resolution

All control signals to and from SM558

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

28

Gas Control Assembly

Gas Mass Flow Sensor

• Low maintenance. P1

• Requires calibration on replacement.

Duty Cycle Valve (FloTech)

• Low maintenance. GMF

• No calibration required on Duty

replacement. Cycle

Valve

Pressure Sensors

• P1 & P2 Fuel pressure in and out Component position and location

of gas control assembly shown, two units on ‘V’ engines.

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

29

Gas Control Assembly

Pressure

Gas Mass Flow Sensor Sensor ( P2)

(GMF)

Control ‘Butterfly’

Pressure

Duty Cycle Valve

Sensor ( P1)

(FloTech)

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

30

Gas Mixer

T A

U

R I

P2 B

O R

GAS IN - 0.9Bar abs.

PROFILE OPERATING PRINCIPLE

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

31

Throttle Actuators

• From each of the Gas mixers the fuel passes

to two Holset Turbochargers. Gas / Air Flow

• Fuel flows through Charge Air Cooler.

• Fuel supplied to Intake plenum via two*

throttle actuators.

2 x Throttle Actuators

• At “normal” conditions (temp/amb) engine ( Woodward Proact)

runs on one actuator, second (B - bank)

remains at min. position (8 - 10% feedback on

Calterm).

• With increased temp/pressure and 65-70 %

duty cycle B-bank actuator will begin to open.

2 x Heater Elements

NOTE: Throttle actuators rotate in the same

direction but are handed for access to the coupling

grub screw, therefore the part numbers are different.

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

32

Ignition Components

The following components are provided on each engine:

• Spark plug - one per cylinder

• COP (Coil on Plug)

• CCD/PDM (Capacitor Discharge/Prognostic Diagnostic Module)

• SSM 558 (Sub Systems Module)

NOTE: Additional engine monitoring is provided by the CENSE

module, this module does not perform any of the control functions.

THE ABOVE MODULES ARE SUPPLIED WITH INFORMATION BY A

NUMBER OF SENSORS / SENDERS MOUNTED ON THE ENGINE. THE

SENSORS AND MODULE FUNCTIONS WILL BE COVERED IN THE

CONTROL MODULE.

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

33

Cummins QSV Gas Ignition System

• Fully Electronic Design to ensure precise timing and

spark control.

• Closed-Loop Control - multi-strike capability based

on breakdown voltage of COP previous cycle, 6 max.

• Variable Energy System.

• Monitors In-Cylinder Pressure (by spark resistance).

• Varies Spark Energy based on In-Cylinder Pressure.

- At Low loads, Cylinder boost pressure lower,LESS spark energy required -

12/18KV to start fuel burn.

- At High loads, Cylinder boost pressure higher, MORE spark energy required

- 26KV to start fuel burn.

Traditional Ignition Systems must address high load environment. Therefore

always fire the plug at max energy levels.

Result: 2 X + Spark Plug Life

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

34

Control & Ignition Modules

• CCD - one per bank, Bank ID Modules located in “Hot Box”

ignition control, 9 cyl connector

max. Output 300 - 350v

• SSM 558 - one per bank,

ignition & throttle control

SSM 558

CCD / PDM

View on Face of SSM 558 Module

Module

SM558 CCD

SSM558

1

A 10 1

B 10 10

B 1 10

A 1

41 50 41 50 50 41 50 41

Front View - Male Connectors Face View of Connectors (When Removed) - Female

Male Pin Connectors Pin Connectors

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

35

Coil-On-Plug

• One COP per cylinder.

• Eliminates high-tension leads.

• Output range 12,000 to 36,000 v.

• Improves ignition system reliability and

output.

• Liquid crystal polymer injection

moulding with paper wound coil

construction.

Coils designed for 40,000 h + life

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

36

COP Assembly

COP PIN LAYOUT

E

D A

C B

A = + V dc.

B = - V dc.

C = H V sensor -Ve.

D = HV sensor +Ve.

E = Not Used.

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01 / REV. 03.

37

Module 4 - Base Engine

End

Cummins Corporate Training

QSV Gas CUMMINS CORPORATION

CUMMINS CORPORATE TRAINING

G / Base Engine / BMG / 01 - 01/ REV. 03.

You might also like

- QSKV 45/60: Heads: CYLINDER HEAD - Familiarization Scene AudioNo ratings yetQSKV 45/60: Heads: CYLINDER HEAD - Familiarization Scene Audio3 pages

- Service Manual: Chassis, Mast & Options P17500 P20000No ratings yetService Manual: Chassis, Mast & Options P17500 P200007 pages

- SPB 75 Oil Selection and Maintenance - Rev06No ratings yetSPB 75 Oil Selection and Maintenance - Rev067 pages

- Application Note Cummins PT Fuel SystemsNo ratings yetApplication Note Cummins PT Fuel Systems10 pages

- Every Drill: Diesel Engines For Compressor Applications100% (1)Every Drill: Diesel Engines For Compressor Applications6 pages

- CENSE™ CM530 Obsoleted and Replaced by Next Generation CENSE™ CM2330No ratings yetCENSE™ CM530 Obsoleted and Replaced by Next Generation CENSE™ CM23309 pages

- Pages From Cummins NTA855 Operation and Maintenance Manual-2No ratings yetPages From Cummins NTA855 Operation and Maintenance Manual-22 pages

- Diesel Powered Generating Sets 250 KW - 340 KW 50 HZ NT855 Series Engines100% (1)Diesel Powered Generating Sets 250 KW - 340 KW 50 HZ NT855 Series Engines4 pages

- Copia de QSK19 Engine Fuel System Familiarization (Sólo Lectura)No ratings yetCopia de QSK19 Engine Fuel System Familiarization (Sólo Lectura)73 pages

- According To "Webster": A Feedback Device Providing Control of A Machine. Controlling Fuel To Engine. Engine Driven Generator SetNo ratings yetAccording To "Webster": A Feedback Device Providing Control of A Machine. Controlling Fuel To Engine. Engine Driven Generator Set41 pages

- Vibration Excessive: This Troubleshooting Procedure Should Be Followed For The Following Symptoms100% (2)Vibration Excessive: This Troubleshooting Procedure Should Be Followed For The Following Symptoms23 pages

- Influence of Ambient Temperature ConditionsNo ratings yetInfluence of Ambient Temperature Conditions20 pages

- Series 4000 Diesel Engines: For Stationary Power GenerationNo ratings yetSeries 4000 Diesel Engines: For Stationary Power Generation6 pages

- MTU Serie 4000 Gas (Rango 772 - 1948 KW)No ratings yetMTU Serie 4000 Gas (Rango 772 - 1948 KW)2 pages

- A Comparison of Thermodynamic Loss Models Suitable For Gas Turbine Propulsion: Theory and TaxonomyNo ratings yetA Comparison of Thermodynamic Loss Models Suitable For Gas Turbine Propulsion: Theory and Taxonomy9 pages

- Procedures For The Search of The Optimal Configuration of District Heating NetworksNo ratings yetProcedures For The Search of The Optimal Configuration of District Heating Networks11 pages

- dC16 084a. 405 KW (550 HP) : Us Tier 4F, Eu Stage IvNo ratings yetdC16 084a. 405 KW (550 HP) : Us Tier 4F, Eu Stage Iv4 pages

- Wuxi Otto Auto Parts Co.,Ltd: Your Trusted Common Rail Parts Supplier!100% (1)Wuxi Otto Auto Parts Co.,Ltd: Your Trusted Common Rail Parts Supplier!3 pages

- Manual Principio de Operacion Hitachi ZW310 (Ingles)No ratings yetManual Principio de Operacion Hitachi ZW310 (Ingles)492 pages

- Athers340 150814131829 Lva1 App6892 PDFNo ratings yetAthers340 150814131829 Lva1 App6892 PDF15 pages

- Periodical Service Scania P380: Maintenance SheetNo ratings yetPeriodical Service Scania P380: Maintenance Sheet2 pages

- Nissan Navara Rear Axle Removing InstructionNo ratings yetNissan Navara Rear Axle Removing Instruction20 pages

- Overview 2019: The Customization Programme For Ferrari F12No ratings yetOverview 2019: The Customization Programme For Ferrari F1210 pages

- Cadillac 1GYFK66887R215663 2023-10-19031837PM 032534No ratings yetCadillac 1GYFK66887R215663 2023-10-19031837PM 0325343 pages

- QSKV 45/60: Heads: CYLINDER HEAD - Familiarization Scene AudioQSKV 45/60: Heads: CYLINDER HEAD - Familiarization Scene Audio

- Service Manual: Chassis, Mast & Options P17500 P20000Service Manual: Chassis, Mast & Options P17500 P20000

- Every Drill: Diesel Engines For Compressor ApplicationsEvery Drill: Diesel Engines For Compressor Applications

- CENSE™ CM530 Obsoleted and Replaced by Next Generation CENSE™ CM2330CENSE™ CM530 Obsoleted and Replaced by Next Generation CENSE™ CM2330

- Pages From Cummins NTA855 Operation and Maintenance Manual-2Pages From Cummins NTA855 Operation and Maintenance Manual-2

- Diesel Powered Generating Sets 250 KW - 340 KW 50 HZ NT855 Series EnginesDiesel Powered Generating Sets 250 KW - 340 KW 50 HZ NT855 Series Engines

- Copia de QSK19 Engine Fuel System Familiarization (Sólo Lectura)Copia de QSK19 Engine Fuel System Familiarization (Sólo Lectura)

- According To "Webster": A Feedback Device Providing Control of A Machine. Controlling Fuel To Engine. Engine Driven Generator SetAccording To "Webster": A Feedback Device Providing Control of A Machine. Controlling Fuel To Engine. Engine Driven Generator Set

- Vibration Excessive: This Troubleshooting Procedure Should Be Followed For The Following SymptomsVibration Excessive: This Troubleshooting Procedure Should Be Followed For The Following Symptoms

- Series 4000 Diesel Engines: For Stationary Power GenerationSeries 4000 Diesel Engines: For Stationary Power Generation

- A Comparison of Thermodynamic Loss Models Suitable For Gas Turbine Propulsion: Theory and TaxonomyA Comparison of Thermodynamic Loss Models Suitable For Gas Turbine Propulsion: Theory and Taxonomy

- Procedures For The Search of The Optimal Configuration of District Heating NetworksProcedures For The Search of The Optimal Configuration of District Heating Networks

- dC16 084a. 405 KW (550 HP) : Us Tier 4F, Eu Stage IvdC16 084a. 405 KW (550 HP) : Us Tier 4F, Eu Stage Iv

- Wuxi Otto Auto Parts Co.,Ltd: Your Trusted Common Rail Parts Supplier!Wuxi Otto Auto Parts Co.,Ltd: Your Trusted Common Rail Parts Supplier!

- Manual Principio de Operacion Hitachi ZW310 (Ingles)Manual Principio de Operacion Hitachi ZW310 (Ingles)

- Overview 2019: The Customization Programme For Ferrari F12Overview 2019: The Customization Programme For Ferrari F12

- Cadillac 1GYFK66887R215663 2023-10-19031837PM 032534Cadillac 1GYFK66887R215663 2023-10-19031837PM 032534