910 KW, Tier 3, Chilled Water, 15400 FT: Reference Design 9)

910 KW, Tier 3, Chilled Water, 15400 FT: Reference Design 9)

Uploaded by

dexiCopyright:

Available Formats

910 KW, Tier 3, Chilled Water, 15400 FT: Reference Design 9)

910 KW, Tier 3, Chilled Water, 15400 FT: Reference Design 9)

Uploaded by

dexiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

910 KW, Tier 3, Chilled Water, 15400 FT: Reference Design 9)

910 KW, Tier 3, Chilled Water, 15400 FT: Reference Design 9)

Uploaded by

dexiCopyright:

Available Formats

[Reference Design 9]

2

910 kW, Tier 3, Chilled Water, 15400 ft

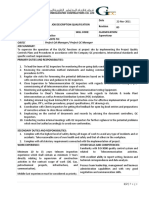

DESIGN OVERVIEW INTRODUCTION

The planning process of most projects can be iterative and thereby

Data Center IT Capacity

expensive. Data center projects are burdened with these challenges and can

910 kW

benefit greatly from simplification and time savings. Schneider Electric’s data

Adaptable from 200 kW to 2730 kW

center reference designs help customers optimize the planning process by

providing them with validated, proven, and documented data center physical

Target Availability

infrastructure designs. The use of these designs has a positive impact on not

Tier 3 just the project itself, but also on the performance, reliability, and efficiency of

the data center over its lifetime.

Annualized PUE at 100% Load

1.49 in Miami, FL USA

1.62 in Montreal, Canada Reference Design 9 includes design information for three spaces: IT space,

1.40 in St. Louis, MO USA facility power, and facility cooling. Combined together, they comprise the

integrated power, cooling and structural systems required to meet the

design’s specifications published in this overview document.

Total Racks and Average Density

140 racks at 6.5 kW/rack

IT & Facility Floor Space

2

15400 ft

Regional Voltage and Frequency

480V, 60Hz

ABOUT THIS DESIGN

Water-cooled chiller with cooling

tower architecture

Integrated row-based air

distribution

Energy savings through water-

side economizer during favorable

outdoor conditions

Highly redundant design for

increased availability and

concurrent maintenance

Highly scalable and adaptable

[Reference Design 9] 2

Facility Power

The facility power system supplies power to all of the critical and non-critical

components within the data center. The architecture used in this electrical

design is a dual path with 2N UPS and N+1 generators. Switching between

generator power and utility is achieved using a programmable logic controller

(PLC). A 3200 amp bus feeds PZ4 electrical and mechanical switchboards. In

the electrical room, UPSs are configured down-stream of the switchboards.

Two Symmetra MW units configured to 2N redundancy provide 1200 kW of

critical power to the IT room with 6 minutes of runtime. Valve regulated lead

acid (VRLA) batteries are housed in an isolated battery room. Two Galaxy 5000

UPS units configured to 2N redundancy provide 72 kW of power to the pumps in

DESIGN OPTIONS

the facility cooling system. Additional low-voltage transformers are included in

This reference design can be modified as

the design to support lighting and other building loads. The power distribution

follows without a significant effect on the architecture from the electrical room to the IT space utilizes a combination of LV

design’s performance attributes: panels and InfraStruxure power distribution units (PDUs). The facility power

system is designed to support additional peripheral devices like fire panels,

Add StruxureWare Power Monitoring access control systems, and environmental monitoring and control devices.

Expert Power meters in the electrical path monitor power quality and allow for

Provision for load bank predictive maintenance & diagnostics of the system. These meters also

Change UPS batteries integrate with StruxureWare Power Monitoring Expert.

Add/change standby generator options: Every component in this design is built and tested to the applicable ANSI,

Location NEMA, UL or IEEE standards.

Tank size Further design details and schematics are available in the engineering package.

Fuel type

FACILITY POWER BLOCK DIAGRAM

FACILITY POWER ATTRIBUTES

G G

Utility

3200A, 480V, 65kA

Name Value Unit

Utility

AC AC

Total amps (main bus) 3200 A

3200A, 480V, 65kA 3200A, 480V, 65kA

Input voltage (main bus) 480 V

2000A, 480V, 65kA 2000A, 480V, 65kA

Switchboard kAIC 65 kA

72 kW 1200kW

Symmetra SSW

72 kW 1200kW

Symmetra SSW

Power path Dual

Galaxy Galaxy

5000 MW 1200kW 5000 MW 1200kW

400A, LOAD 400A, LOAD Generator redundancy N+1

480V, BANK 480V, BANK

65kA 2000A, 480V, 65kA 65kA 2000A, 480V, 65kA

IT space UPS capacity 1200 kW

IT space UPS redundancy 2N

© 2013 Schneider Electric. All rights reserved.

4x CHW Pumps

14x PDU Feeds

to IT Space

4x CHW Pumps 14x PDU Feeds

to IT Space

IT space UPS runtime @ rated load 6 minutes

1200A, 480V, 65kA 1200A, 480V, 65kA

IT space UPS output voltage 480 V

Facility cooling UPS capacity 72 kW

2x 4x Cond. Mech. Panel 2x 4x Cond. Mech. Panel

Cooling Chiller Water (CRAHs, Cooling Chiller Water (CRAHs, Facility cooling UPS redundancy 2N

Tower Pump AHUs) Tower Pump AHUs)

Facility cooling UPS runtime @ rated load 12 minutes

Schneider Electric www.schneider-electric.com

Document Number RD09DS Revision 1

[Reference Design 9] 3

Facility Cooling

The mechanical design utilizes chilled water as the primary medium for heat

dissipation. The architecture consists of dual chilled water loops. The cooling

system contains two 1196 kW water-cooled chillers in a 2N redundant

configuration. Water-side economization is achieved with a plate & frame heat

exchanger to save energy during favorable outdoor conditions.

In order to extend availability of chilled water during a power outage, redundant

7000 gallon water storage tanks provides 7 minutes of continuous cooling.

The piping architecture of the mechanical system feeds row-based InRow RC

CRAHs in the IT space. It also feeds room-based CRAHs in the electrical and

battery rooms. More information on the cooling configuration is provided in the

IT space section of this document.

DESIGN OPTIONS This design is instrumented to work with StruxureWare Cooling Monitoring

Expert.

This reference design can be modified as

Further design details such as dimensions, equipment placement, temperature

follows without a significant effect on the

set points, pipe sizing, flow rates, and pressure drops are available in the

design’s performance attributes:

engineering package.

Add StruxureWare Cooling

Monitoring Expert

FACILITY COOLING ATTRIBUTES

FACILITY COOLING BLOCK DIAGRAM

Piping detail inside IT space

Name Value Unit

Total cooling capacity 1196 kW

Input voltage 480 V

InRow InRow InRow

RC RC RC

… 76 units 300mm...

CW supply 300

mm

300

mm

300

mm Heat rejection medium Chilled water

CW return

Mechanical redundancy 2N

Water-cooled chiller

Outdoor heat exchange

with cooling tower

CW supply

Coolant supply temperature 46 F

CW return

InRow InRow InRow

RC

300

RC

300

RC

300

Coolant return temperature 56 F

mm mm mm

Storage tank size 7000 gallons

Ride-through time 7 minutes

Tower Tower

Secondary loop

pumps

Economizer type Water-side

VFD

Thermal Storage

CW supply

© 2013 Schneider Electric. All rights reserved.

Primary loop pumps VFD to IT space

VFD System

VFD Dirt/air

Strainers bypass

separator

Chiller

VFD

VFD

Heat

Exchanger

Expansion

Tower Tower

tank Secondary loop

City Water

pumps

VFD

Thermal Storage

CW supply

Primary loop pumps VFD to IT space

VFD System

VFD Dirt/air

Strainers bypass

separator

Chiller

VFD

VFD

Heat

Exchanger

Schneider Electric www.schneider-electric.com

Document Number RD09DS Revision 1

[Reference Design 9] 4

IT Space

The IT capacity of this design is 910 kW. The design is highly scalable and

adaptable; it can be configured to support IT loads within a range. Smaller

starting loads as low as 200 kW can be supported by making adjustments such

as reducing the number of IT pods or decreasing the quantity of UPS modules.

Likewise, this design can be used as a baseline for larger loads as high as 2730

kW by using a step and repeat approach to the design. This flexibility drives

efficiency and defers capital expenditure until needed.

The IT space design specifies all of the physical infrastructure systems, as well

as their physical arrangement/spacing, required to meet the overall design’s

performance attributes. This includes racks, PDUs, rack power distribution,

DESIGN OPTIONS cooling units, and airflow management systems.

This reference design can be modified as Each pair of rows (pod) within the IT space can be “stepped and repeated” in a

follows without a significant effect on the standardized and predictable manner. This enables right-sizing of power and

design’s performance attributes: cooling that scales with IT growth. Each pod supports an average power

density of 6.5 kW per rack. All the pods are outfitted with integrated power and

Add environmental and security cooling distribution.

management Each pod is powered by floor mount factory-configured power distribution units

Change rack options (tall, (PDUs). Every rack is configured with a metered rack-mount PDU to enable

wide, deep)

remote monitoring of the units for efficiency and capacity management.

Change power distribution options

Rack PDU type (basic, Each pod is cooled by N+1 redundant chilled water-based InRow RC CRAHs

switched) that control the supply of cool air by monitoring temperature variation at the rack

Add StruxureWare Data Center level.

Expert

The security of the room is maintained at multiple points. At the rack level,

access is controlled by a door lock and sensor. At the room level, security

cameras are utilized for monitoring.

Row A Row B

P R C R C R R C R R C R R C R R C R R C R C R P

P/A-2/Z1 R/A-3/Z1 C/

A-4/

Z1

R/A-5/Z1 C/

A-6/

Z1

R/A-7/Z1 R/A-8/Z1 C/

A-9/

Z1

R/A-10/Z1 R/A-11/Z1 C/

A-

12/

Z1

R/A-13/Z1 R/B-1/Z2 C/

B-2/

Z2

R/B-3/Z2 R/B-4/Z2 C/

B-5/

Z2

R/B-6/Z2 R/B-7/Z2 C/

B-8/

Z2

R/B-9/Z2 C/

B-

10/

Z2

R/B-11/Z2 P/B-12/Z2

IT ROOM ATTRIBUTES

G

Gap

Row C Row D

R C R R C R R C R C R R C R C R R C R R C R

R/C-1/Z1 C/

C-2/

Z1

R/C-3/Z1 R/C-4/Z1 C/

C-5/

Z1

R/C-6/Z1 R/C-7/Z1 C/

C-8/

Z1

R/C-9/Z1 C/

C-

10/

Z1

R/C-11/Z1 P

P/C-12/Z1

P

P/D-1/Z2

R/D-2/Z2 C/

D-3/

Z2

R/D-4/Z2 C/

D-5/

Z2

R/D-6/Z2 R/D-7/Z2 C/

D-8/

Z2

R/D-9/Z2 R/D-10/Z2 C/

D-

11/

Z2

R/D-12/Z2

Name Value Unit

Row E

P R C R C R R C R R C R

Row F

R C R R C R R C R C R P

IT load 910 kW

P/E-2/Z4 R/E-3/Z4 C/ R/E-5/Z4 C/ R/E-7/Z4 R/E-8/Z4 C/ R/E-10/Z4 R/E-11/Z4 C/ R/E-13/Z4 R/F-1/Z3 C/F- R/F-3/Z3 R/F-4/Z3 C/F- R/F-6/Z3 R/F-7/Z3 C/F- R/F-9/Z3 C/F- R/F-11/Z3 P/F-12/Z3

E-4/ E-6/ E-9/ E- 2/ 5/ 8/ 10/

Z4 Z4 Z4 12/ Z3 Z3 Z3 Z3

Z4

Row G

G

Gap

Row H

Input voltage 480 V

R C R R C R R C R C R R C R C R R C R R C R

P P

Supply voltage to IT 120 / 208 V

R/G-1/Z4 C/ R/G-3/Z4 R/G-4/Z4 C/ R/G-6/Z4 R/G-7/Z4 C/ R/G-9/Z4 C/ R/G-11/Z4 R/H-2/Z3 C/ R/H-4/Z3 C/ R/H-6/Z3 R/H-7/Z3 C/ R/H-9/Z3 R/H-10/Z3 C/ R/H-12/Z3

G-2/ G-5/ G-8/ G- P/G-12/Z4 P/H-1/Z3 H-3/ H-5/ H-8/ H-

Z4 Z4 Z4 10/ Z3 Z3 Z3 11/

Z4 Z3

Row J

P

P/J-2/Z5

R

R/J-3/Z5

C

C/J-

R

R/J-5/Z5

C

C/J-

R

R/J-7/Z5

R

R/J-8/Z5

C

C/J-

R

R/J-10/Z5

R

R/J-11/Z5

C

C/J-

R

R/J-13/Z5

Row K

R

R/K-1/Z6

C

C/

R

R/K-3/Z6

R

R/K-4/Z6

C

C/

R

R/K-6/Z6

R

R/K-7/Z6

C

C/

R

R/K-9/Z6

C

C/

R

R/K-11/Z6

P

P/K-12/Z6

Average density 6.5 kW/rack

4/ 6/ 9/ 12/ K-2/ K-5/ K-8/ K-

Z5 Z5 Z5 Z5 Z6 Z6 Z6 10/

Z6

Row L

G

Gap

Row M

Number of racks 140 racks

R C R R C R R C R C R R C R C R R C R R C R

R/L-1/Z5 C/L- R/L-3/Z5 R/L-4/Z5 C/L- R/L-6/Z5 R/L-7/Z5 C/L- R/L-9/Z5 C/L- R/L-11/Z5 P P R/M-2/Z6 C/ R/M-4/Z6 C/ R/M-6/Z6 R/M-7/Z6 C/ R/M-9/Z6 R/M-10/Z6 C/ R/M-12/Z6

2

IT floor space 6700

2/ 5/ 8/ 10/ M- M- M- M-

P/L-12/Z5 P/M-1/Z6

© 2013 Schneider Electric. All rights reserved.

ft

Z5 Z5 Z5 Z5 3/ 5/ 8/ 11/

Z6 Z6 Z6 Z6

Row N Row P

P

P/N-2/Z9

R

R/N-3/Z9

C

C/

N-4/

R

R/N-5/Z9

C

C/

N-6/

R

R/N-7/Z9

R

R/N-8/Z9

C

C/

N-9/

R

R/N-10/Z9

R

R/N-11/Z9

C

C/

N-

R

R/N-13/Z9

R

R/P-1/Z10

C

C/

P-2/

R

R/P-3/Z10

R

R/P-4/Z10

C

C/

P-5/

R

R/P-6/Z10

R

R/P-7/Z10

C

C/

P-8/

R

R/P-9/Z10

C

C/

P-

R

R/P-11/

Z10

P

P/P-12/Z10

Single or dual cord Dual

Z9 Z9 Z9 12/ Z10 Z10 Z10 10/

Z9 Z10

Row Q

G

Gap

Row R Heat rejection medium Chilled water

R C R R C R R C R C R R C R C R R C R R C R

R/Q-1/Z9 C/ R/Q-3/Z9 R/Q-4/Z9 C/ R/Q-6/Z9 R/Q-7/Z9 C/ R/Q-9/Z9 C/ R/Q-11/Z9 P P R/R-2/Z10 C/ R/R-4/Z10 C/ R/R-6/Z10 R/R-7/Z10 C/ R/R-9/Z10 R/R-10/ C/ R/R-12/Z10

Q-2/ Q-5/ Q-8/ Q- P/Q-12/Z9 P/R-1/Z10 R-3/ R-5/ R-8/ Z10 R-

Z9 Z9 Z9 10/ Z10 Z10 Z10 11/

CRAC/CRAH type Row-based CRAH

Z9 Z10

Row S Row T

P

P/S-2/Z7

R

R/S-3/Z7

C

C/

S-4/

Z7

R

R/S-5/Z7

C

C/

S-6/

Z7

R

R/S-7/Z7

R

R/S-8/Z7

C

C/

S-9/

Z7

R

R/S-10/Z7

R

R/S-11/Z7

C

C/

S-

12/

Z7

R

R/S-13/Z7

R

R/T-1/Z8

R

R/T-2/Z8

C

C/T-

3/

Z8

R

R/T-4/Z8

R

R/T-5/Z8

R

R/T-6/Z8

R

R/T-7/Z8

C

C/T-

8/

Z8

R

R/T-9/Z8

P

P/T-10/Z8 CRAC/CRAH redundancy N+1

G

Gap

Row U

R

R/U-1/Z7

C

C/

R

R/U-3/Z7

R

R/U-4/Z7

C

C/

R

R/U-6/Z7

R

R/U-7/Z7

C

C/

R

R/U-9/Z7

C

C/

R

R/U-11/Z7 P

Row V

P

R

R/V-2/Z8

R

R/V-3/Z8

C

C/

R

R/V-5/Z8

R

R/V-6/Z8

R

R/V-7/Z8

C

C/

R

R/V-9/Z8

R

R/V-10/Z8

Containment type None

U-2/ U-5/ U-8/ U- P/U-12/Z7 P/V-1/Z8 V-4/ V-8/

Z7 Z7 Z7 10/ Z8 Z8

Z7

Schneider Electric www.schneider-electric.com

Document Number RD09DS Revision 1

[Reference Design 9] 5

Design Attributes

OVERVIEW Value Unit

Target availability Tier 3 Tier

Annualized PUE at 100% load 1.49 / 1.62 / 1.40

Data center IT capacity 910 kW

2

IT & facility floor space 15400 ft

Average density 6.5 kW/rack

FACILITY POWER Value Unit

Total amps (main bus) 3200 A

Input voltage (main bus) 480 V

Switchboard kAIC 65 kA

Power path Dual

Generator redundancy N+1

IT space UPS capacity 1200 kW

IT space UPS redundancy 2N

IT space UPS runtime @ rated load 6 minutes

IT space UPS output voltage 480 V

Facility cooling UPS capacity 72 kW

Facility cooling UPS redundancy 2N

Facility cooling UPS runtime @ rated load 12 minutes

FACILITY COOLING Value Unit

Total cooling capacity 1196 kW

Input voltage 480 V

Heat rejection medium Chilled water

Mechanical redundancy 2N

Outdoor heat exchange Water-cooled chiller with cooling tower

Coolant supply temperature 46 F

Coolant return temperature 56 F

Storage tank size 7000 gallons

Ride-through time 7 minutes

Economizer type Water-side

IT SPACE Value Unit

IT load 910 kW

Input voltage 480 V

Supply voltage to IT 120 / 208 V © 2013 Schneider Electric. All rights reserved.

Average density 6.5 kW/rack

Number of racks 140 Racks

2

IT floor space 6700 ft

Single or dual cord Dual

Heat rejection medium Chilled water

CRAC/CRAH type Row-based CRAH

CRAC/CRAH redundancy N+1

Containment type None

Schneider Electric www.schneider-electric.com

Document Number RD09DS Revision 1

[Reference Design 9] 6

Data center infrastructure management (DCIM)

Good design and quality construction alone do not ensure a highly available &

efficient data center. Data centers require on-going monitoring and management to

ensure the facility lives up to its design intent. StruxureWare for Data Centers is a

software management suite designed to collect and manage data about a data

center’s assets, resource use, and operational status throughout the life cycle of the

facility. This information is then distributed, integrated, and applied in ways that help

managers optimize the data center’s performance and meet IT, business, and

service-oriented goals. From IT assets to racks, rows, rooms and buildings,

StruxureWare for Data Centers delivers the right information to the right users at the

right time.

Control level: Experts, on site or remotely, can control process performance and

ensure business continuity in real time, while tracking energy consumption in a highly

critical and secure environment.

Operations level: Functional managers can optimize operations, energy, and assets

through smart analytical tools, often spanning multiple sites.

Enterprise level: C-level executives can drive their sustainability strategy efficiently,

choosing the best scenario that meets their business objective to conserve

enterprise-wide resources.

StruxureWare for Data Centers allows for flexibility when requirements and

implementation strategies change over time. StruxureWare software applications

and suites simplify integration time, improve reliability, enhance visibility to energy

information, and streamline operational efficiency.

>

© 2013 Schneider Electric. All rights reserved.

Demo:

Visit www.apc.com/software to learn more about StruxureWare for Data Centers!

Schneider Electric www.schneider-electric.com

Document Number RD09DS Revision 1

[Reference Design 9] 7

Get more information for this design:

Engineering Package

Every reference design is built with technical documentation

for engineers and project managers. This includes

engineering schematics (CAD, PDF), floor layouts,

equipment lists containing all the components used in the

design and 3D images showing real world illustrations of our

Floor layouts

reference designs.

3D spatial views

Documentation is available in multiple formats to suit the

needs of both engineers and managers working on data

center projects.

Bill of materials

One-line schematics

> Click here to register to receive the Engineering Package for this design, or email

ReferenceDesigns@Schneider-Electric.com.

Schneider Electric Life-Cycle Services

Team of over 7,000 trained specialists covering

every phase and system in the data center

© 2013 Schneider Electric. All rights reserved.

Standardized, documented, and validated

methodology leveraging automation tools and

repeatable processes developed over 45 years

Complete portfolio of services to solve your

technical or business challenge, simplify your

life, and reduce costs

Schneider Electric www.schneider-electric.com

Document Number RD09DS Revision 1

You might also like

- 深圳市海雷新能源产品目录 高清Document20 pages深圳市海雷新能源产品目录 高清iveslizhiranNo ratings yet

- PV Plant ControlDocument19 pagesPV Plant Controlhumberto ceballosNo ratings yet

- SUB CourseDocument2 pagesSUB Coursebrockwell496100% (1)

- OpenMiracle DbDesignDocument49 pagesOpenMiracle DbDesignssaurabh_ssNo ratings yet

- 200 KW, Tier 3, Chilled Water, 5250 FT: Reference Design 4)Document7 pages200 KW, Tier 3, Chilled Water, 5250 FT: Reference Design 4)dexiNo ratings yet

- 77 KW, Tier 2, Direct Expansion, 916 FT: Reference Design 41)Document7 pages77 KW, Tier 2, Direct Expansion, 916 FT: Reference Design 41)dexiNo ratings yet

- Semi-Prefabricated, 27762 FT: 1760 KW, Tier 3, Indirect Air EconomizerDocument7 pagesSemi-Prefabricated, 27762 FT: 1760 KW, Tier 3, Indirect Air EconomizerdexiNo ratings yet

- RD21DSR1 PDFDocument7 pagesRD21DSR1 PDFdexiNo ratings yet

- 3300 KW, Tier 3, Chilled Water, 70,000 FT: Reference Design 22)Document7 pages3300 KW, Tier 3, Chilled Water, 70,000 FT: Reference Design 22)dexiNo ratings yet

- 170 KW, Tier 1, Chilled Water, 2640 FT: Reference Design 69)Document7 pages170 KW, Tier 1, Chilled Water, 2640 FT: Reference Design 69)dexiNo ratings yet

- RD10DSR2Document7 pagesRD10DSR2MarlonNo ratings yet

- 90 KW, Tier II, Direct Expansion, 142.1 M, All-In-One Prefab Data Center Module - Busway or PDUDocument7 pages90 KW, Tier II, Direct Expansion, 142.1 M, All-In-One Prefab Data Center Module - Busway or PDUahmadgce04No ratings yet

- 790 KW, Tier 4, Chilled Water, 20000 FT: Reference Design 7)Document7 pages790 KW, Tier 4, Chilled Water, 20000 FT: Reference Design 7)dexiNo ratings yet

- 490 KW, Tier III, Chilled Water, Prefabricated, 697 M: Reference Design 86)Document7 pages490 KW, Tier III, Chilled Water, Prefabricated, 697 M: Reference Design 86)dexiNo ratings yet

- 780 KW, Pod-Based Build, Tier I, 1873 FT: Design OverviewDocument6 pages780 KW, Pod-Based Build, Tier I, 1873 FT: Design Overviewahmadgce04No ratings yet

- 900 KW, Tier 2, Chilled Water, 16100 FT: Reference Design 5)Document7 pages900 KW, Tier 2, Chilled Water, 16100 FT: Reference Design 5)dexiNo ratings yet

- 170 KW, Tier 2, Chilled Water, 2650 FT: Reference Design 70)Document7 pages170 KW, Tier 2, Chilled Water, 2650 FT: Reference Design 70)dexiNo ratings yet

- 1980 KW, Tier 2, Chilled Water, Prefabricated, 15125 FT: Reference Design 33)Document7 pages1980 KW, Tier 2, Chilled Water, Prefabricated, 15125 FT: Reference Design 33)dexiNo ratings yet

- 175 KW, Tier 2, Chilled Water, 4350 FT: Reference Design 2)Document7 pages175 KW, Tier 2, Chilled Water, 4350 FT: Reference Design 2)dexiNo ratings yet

- 345 KW, Tier 2, Chilled Water, 3960 FT: Reference Design 72)Document7 pages345 KW, Tier 2, Chilled Water, 3960 FT: Reference Design 72)dexiNo ratings yet

- 48 KW, Pod-Based Build, Tier I, 646 FT: Design OverviewDocument6 pages48 KW, Pod-Based Build, Tier I, 646 FT: Design Overviewahmadgce04No ratings yet

- 1008 KW, Tier 3, Chilled Water, 15310 FT: Reference Design 82)Document7 pages1008 KW, Tier 3, Chilled Water, 15310 FT: Reference Design 82)dexiNo ratings yet

- UPS & Battery Room CoolingDocument12 pagesUPS & Battery Room CoolingRamNo ratings yet

- 5.2 MW, Pod-Based Build, Chilled Water, 85000 FT: Reference Design 65)Document7 pages5.2 MW, Pod-Based Build, Chilled Water, 85000 FT: Reference Design 65)dexiNo ratings yet

- Role of Isolation Transformers in Data Center UPS System 1703176926Document26 pagesRole of Isolation Transformers in Data Center UPS System 1703176926u17068607No ratings yet

- Schneider Nrjed111045en (Print)Document2 pagesSchneider Nrjed111045en (Print)cysautsNo ratings yet

- Cable Etap 01 18 2IN1 PDFDocument77 pagesCable Etap 01 18 2IN1 PDFMichael BesaNo ratings yet

- Introduction To NuScale DesignDocument26 pagesIntroduction To NuScale DesignLazarescu ElenaNo ratings yet

- ETAP - System Studies & Relay Coordination - FullDocument49 pagesETAP - System Studies & Relay Coordination - Fullelectrical_1012000No ratings yet

- White Paper 75 Comparing UPS System DesignDocument27 pagesWhite Paper 75 Comparing UPS System DesignRiad RiadNo ratings yet

- Data Center TechnologyDocument38 pagesData Center TechnologyBagus Aj100% (2)

- Apc Application Note #126: Selection Procedure For Inrow Chilled Water ProductsDocument9 pagesApc Application Note #126: Selection Procedure For Inrow Chilled Water ProductsdexiNo ratings yet

- UPS Technologies & IP Bus UPS-System: Presented by Julian GobeyDocument49 pagesUPS Technologies & IP Bus UPS-System: Presented by Julian Gobeyibc cbsNo ratings yet

- CIM Iterface Specification V1.0Document26 pagesCIM Iterface Specification V1.0tepen387139No ratings yet

- Eaton Metal Enclosed Switchgear Mvs 38kv Design Guide Dg022013enDocument18 pagesEaton Metal Enclosed Switchgear Mvs 38kv Design Guide Dg022013enericka catapangNo ratings yet

- Data Center ReportDocument66 pagesData Center Reportp100% (1)

- As 62271 100 2008 High Voltage Switchgear and Controlgear High Voltage Alternating Current Circuit BreakersDocument10 pagesAs 62271 100 2008 High Voltage Switchgear and Controlgear High Voltage Alternating Current Circuit Breakersmr3478No ratings yet

- Technical Comparison of On-Line vs. Line-Interactive UPS DesignsDocument14 pagesTechnical Comparison of On-Line vs. Line-Interactive UPS Designsdrpiratheepan4274No ratings yet

- Power Supply Systems Series 900: Control and Signalling Unit SPSC2000-A 90Document28 pagesPower Supply Systems Series 900: Control and Signalling Unit SPSC2000-A 90Oleg Kuryan50% (2)

- Fault Tolerant Power Compliance Specification - v2Document3 pagesFault Tolerant Power Compliance Specification - v2Doruk BakırNo ratings yet

- STULZ CyberAir3 Brochure 1214 enDocument36 pagesSTULZ CyberAir3 Brochure 1214 enkambiadoNo ratings yet

- Distribution Management System (DMS) : SpecificationsDocument30 pagesDistribution Management System (DMS) : Specificationsanbkhn90100% (1)

- Installation of I-LINE II-EngDocument27 pagesInstallation of I-LINE II-EngThức VõNo ratings yet

- SD Series - SurgeProtection Devices PDFDocument8 pagesSD Series - SurgeProtection Devices PDFSym ShaNo ratings yet

- Distribution Systems, Substations, and Integration of Distributed GenerationDocument63 pagesDistribution Systems, Substations, and Integration of Distributed GenerationandhrimnirNo ratings yet

- ITU RecommendationsDocument25 pagesITU Recommendationscoolbuddy_2k4No ratings yet

- Intellisolar SCADA - Smart Solar Monitoring SolutionDocument5 pagesIntellisolar SCADA - Smart Solar Monitoring SolutionKeshav SoniNo ratings yet

- SMR NuScale Power PDFDocument25 pagesSMR NuScale Power PDFDan PascaruNo ratings yet

- International Telecommunication Union: RecommendationDocument25 pagesInternational Telecommunication Union: Recommendationghosh_souvikNo ratings yet

- Introduction of RTDSDocument11 pagesIntroduction of RTDSSUJIT KUMAR MONDALNo ratings yet

- Principles of MV SWG Testing 02: Functional TestsDocument6 pagesPrinciples of MV SWG Testing 02: Functional TestsAhmed Mohsen HandoussaNo ratings yet

- Liebert ITA 5kVA Brochure 091022Document2 pagesLiebert ITA 5kVA Brochure 091022destroflameNo ratings yet

- EMSP009 06 G Eterracontrol Cfereader Alstom 2011.03.07Document28 pagesEMSP009 06 G Eterracontrol Cfereader Alstom 2011.03.07Aldi ErzanuariNo ratings yet

- Microscada For Substation Automation: Intelligent Investment Offer From Abb Flexible SolutionDocument2 pagesMicroscada For Substation Automation: Intelligent Investment Offer From Abb Flexible SolutionrhomadonaNo ratings yet

- Modbus Card - Data SheetDocument3 pagesModbus Card - Data SheetDishant SharmaNo ratings yet

- 520 KW, Tier 2, Chilled Water, 4823 FT: Reference Design 73)Document7 pages520 KW, Tier 2, Chilled Water, 4823 FT: Reference Design 73)dexiNo ratings yet

- RD11 5.1 Management Use Case en R0Document25 pagesRD11 5.1 Management Use Case en R0АндрейТрубниковNo ratings yet

- RD11 2.1 Facility Power Overview EN R0Document1 pageRD11 2.1 Facility Power Overview EN R0АндрейТрубниковNo ratings yet

- RD99DSR5Document11 pagesRD99DSR5akspervaizNo ratings yet

- 643O41 Time Server Netsilon PDFDocument4 pages643O41 Time Server Netsilon PDFdexiNo ratings yet

- User Manual Netsilon PDFDocument74 pagesUser Manual Netsilon PDFdexiNo ratings yet

- 653B21 Time Server Netsilon PDFDocument4 pages653B21 Time Server Netsilon PDFdexiNo ratings yet

- 643J31 Time Server SecureSyncDocument4 pages643J31 Time Server SecureSyncdexiNo ratings yet

- Ksih-6y6tlv R0 en 2 PDFDocument9 pagesKsih-6y6tlv R0 en 2 PDFdexiNo ratings yet

- Airflow Uniformity Through Perforated Tiles in A Raised-Floor Data CenterDocument11 pagesAirflow Uniformity Through Perforated Tiles in A Raised-Floor Data CenterdexiNo ratings yet

- Sigma C Master Clock Instructions PDFDocument46 pagesSigma C Master Clock Instructions PDFdexiNo ratings yet

- Jnin-6n7srz R0 en PDFDocument12 pagesJnin-6n7srz R0 en PDFdexiNo ratings yet

- Knuerr CoolFlex PDFDocument6 pagesKnuerr CoolFlex PDFdexiNo ratings yet

- Apc Application Note #126: Selection Procedure For Inrow Chilled Water ProductsDocument9 pagesApc Application Note #126: Selection Procedure For Inrow Chilled Water ProductsdexiNo ratings yet

- APC Application Note #69: Air Distribution Unit ApplicationDocument4 pagesAPC Application Note #69: Air Distribution Unit ApplicationdexiNo ratings yet

- Interpack2003-35282: Techniques For Controlling Airflow Distribution in Raised-Floor Data CentersDocument8 pagesInterpack2003-35282: Techniques For Controlling Airflow Distribution in Raised-Floor Data CentersdexiNo ratings yet

- Energy Efficient Electric Motor Selection PDFDocument66 pagesEnergy Efficient Electric Motor Selection PDFdexiNo ratings yet

- APC Application Note #69: Air Distribution Unit ApplicationDocument4 pagesAPC Application Note #69: Air Distribution Unit ApplicationdexiNo ratings yet

- Iso 22301 Business Continuity Management PDFDocument13 pagesIso 22301 Business Continuity Management PDFdexi100% (3)

- Fulltext01 PDFDocument64 pagesFulltext01 PDFdexiNo ratings yet

- h14515 VNX Family Ds PDFDocument6 pagesh14515 VNX Family Ds PDFdexiNo ratings yet

- Intel-Air-Cooled Data Centers PDFDocument20 pagesIntel-Air-Cooled Data Centers PDFdexiNo ratings yet

- IPack2005 73273 PDFDocument8 pagesIPack2005 73273 PDFdexiNo ratings yet

- Impact of Hot and Cold Aisle Containment On Data Center Temperature and Efficiency PDFDocument14 pagesImpact of Hot and Cold Aisle Containment On Data Center Temperature and Efficiency PDFdexiNo ratings yet

- In-Building Telecommunication Network: Specification Manual Guidelines For FTTX in New BuildingsDocument63 pagesIn-Building Telecommunication Network: Specification Manual Guidelines For FTTX in New BuildingsdexiNo ratings yet

- Enclosure Heat Load PDFDocument55 pagesEnclosure Heat Load PDFdexiNo ratings yet

- Guide To BCM Third Edition ProtivitiDocument66 pagesGuide To BCM Third Edition ProtivitiaalfonsopNo ratings yet

- Effects of Doors On Airflow and Cooling WP PDFDocument10 pagesEffects of Doors On Airflow and Cooling WP PDFdexiNo ratings yet

- AXIS P3375-LVE Network Camera: Classic, Outdoor-Ready HDTV 1080p Fixed Dome For Any Light ConditionsDocument3 pagesAXIS P3375-LVE Network Camera: Classic, Outdoor-Ready HDTV 1080p Fixed Dome For Any Light ConditionsdexiNo ratings yet

- Group Business Continuity Plan Summary 2018 PDFDocument4 pagesGroup Business Continuity Plan Summary 2018 PDFdexiNo ratings yet

- APC (EMEA) Sizing Guide For Cisco Switches and Routers With Multiple Power SuppliesDocument2 pagesAPC (EMEA) Sizing Guide For Cisco Switches and Routers With Multiple Power SuppliesdexiNo ratings yet

- Rethinking The Wild PDFDocument4 pagesRethinking The Wild PDFdavid.jungNo ratings yet

- Research About PyrophobiaDocument8 pagesResearch About PyrophobiaShravan KumarNo ratings yet

- 1.definisi Kurikulum Dan PengajaranDocument34 pages1.definisi Kurikulum Dan PengajaranZahayu Resources100% (2)

- EurasianStudies 0110 EPA01521Document186 pagesEurasianStudies 0110 EPA01521Iulia CindreaNo ratings yet

- Cloud Storage ServicesDocument49 pagesCloud Storage ServicesMaha OmarNo ratings yet

- Coaching Session For MTs SummitDocument43 pagesCoaching Session For MTs SummitAda RicanaNo ratings yet

- Continuous Thermal Processing of Foods Pasteurization and UHT SterilizationDocument481 pagesContinuous Thermal Processing of Foods Pasteurization and UHT SterilizationHieu Dang Duy100% (2)

- Information For Exchange Students - WS21-22Document48 pagesInformation For Exchange Students - WS21-22anisNo ratings yet

- Self ReflectionDocument2 pagesSelf Reflectionapi-575341265No ratings yet

- Measures of VariabilityDocument20 pagesMeasures of VariabilityMaja Mae FloresNo ratings yet

- SOP MCP-Pertamina BabelanDocument7 pagesSOP MCP-Pertamina BabelanMuhammad Fajar ArmanNo ratings yet

- QC Supervisor Telecommunication PDFDocument2 pagesQC Supervisor Telecommunication PDFafareenkhanNo ratings yet

- Fourpillars of Reasonable ArgumentDocument35 pagesFourpillars of Reasonable ArgumentGuillermo AlvarezNo ratings yet

- Format. Hum - A Study On Work Life Balance With Special ReferenceDocument8 pagesFormat. Hum - A Study On Work Life Balance With Special ReferenceImpact JournalsNo ratings yet

- Chinas Three Warfares Amp The South China Sea PDFDocument559 pagesChinas Three Warfares Amp The South China Sea PDFRsandee70100% (1)

- MTech Thesis Format M.D.UDocument11 pagesMTech Thesis Format M.D.Usubrampati33% (3)

- Activities Guide and Evaluation Rubric - Unit 2 - Task 4 - Speaking Task Forum and Practice Session.Document11 pagesActivities Guide and Evaluation Rubric - Unit 2 - Task 4 - Speaking Task Forum and Practice Session.Edgar RamirezNo ratings yet

- Sander 1972Document9 pagesSander 1972bibek1306No ratings yet

- Fraclac For ImagejDocument38 pagesFraclac For ImagejJod JDNo ratings yet

- Qualification Specification - Level 6 NVQ Certificate in BSLDocument40 pagesQualification Specification - Level 6 NVQ Certificate in BSLBSLcourses.co.ukNo ratings yet

- Cities For A Small Planet (Architecture Urbanism Art) PDFDocument95 pagesCities For A Small Planet (Architecture Urbanism Art) PDFFelipe100% (1)

- MATLAB Workshop 1 - Numbers and Arithmetic: Change Display Format, Quit MATLABDocument7 pagesMATLAB Workshop 1 - Numbers and Arithmetic: Change Display Format, Quit MATLABSelene SombraNo ratings yet

- Gumbel and Log Pearson-IIIDocument8 pagesGumbel and Log Pearson-IIIShahid khanNo ratings yet

- Sampling Methods: Prof. Dr. Kirti MahajanDocument51 pagesSampling Methods: Prof. Dr. Kirti Mahajandipanshu100% (1)

- Krebs, Harry D - The Religious Thought of Nishitani Keiji - Thesis PDFDocument166 pagesKrebs, Harry D - The Religious Thought of Nishitani Keiji - Thesis PDFCarlos BarbosaNo ratings yet

- Indopol H 300Document1 pageIndopol H 300CarlosNo ratings yet

- TSNC Nano SC RevDocument12 pagesTSNC Nano SC RevtalatzahoorNo ratings yet

- MNGT3108 - M6-Total Quality ManagementDocument7 pagesMNGT3108 - M6-Total Quality ManagementMa. Angela RosauroNo ratings yet

- LP1 Sikolohiyang PilipinoDocument23 pagesLP1 Sikolohiyang PilipinoAbegailNo ratings yet