Powerflex 525 Low Voltage Ac Variable Frequency Drive: Procurement Specification

Powerflex 525 Low Voltage Ac Variable Frequency Drive: Procurement Specification

Uploaded by

Jaime RamosCopyright:

Available Formats

Powerflex 525 Low Voltage Ac Variable Frequency Drive: Procurement Specification

Powerflex 525 Low Voltage Ac Variable Frequency Drive: Procurement Specification

Uploaded by

Jaime RamosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Powerflex 525 Low Voltage Ac Variable Frequency Drive: Procurement Specification

Powerflex 525 Low Voltage Ac Variable Frequency Drive: Procurement Specification

Uploaded by

Jaime RamosCopyright:

Available Formats

[PROJECT NUMBER] [PROJECT NAME]

[DATE] [PROJECT LOCATION]

ROCKWELL AUTOMATION PROCUREMENT SPECIFICATION

PROCUREMENT SPECIFICATION

PowerFlex 525

Low Voltage AC

Variable Frequency Drive

NOTICE: The specification guidelines in this document are intended to aid in the specification of

products. Specific installations have specific requirements, and Rockwell Automation does not

recommend or intend any specific application based solely upon the guidelines provided here.

Because of the variety of uses for this information, the user of, and those responsible for applying

this information, are responsible for ensuring the acceptability of each application and appropriate

use of the guidelines. In no event will Rockwell Automation be liable for misuse, misapplication or

reliance on these guidelines in connection with any specific application. Rockwell Automation also

disclaims indirect or consequential damages resulting from the use or application of this

information.

Note: To download or view a .doc file version of this procurement specification, please visit:

www.rockwellautomation.com/industries/procurement-specifications

PowerFlex 525 Low Voltage AC VFD Rockwell Automation

25B-SR001C-EN-E 1

[PROJECT NUMBER] [PROJECT NAME]

[DATE] [PROJECT LOCATION]

TABLE OF CONTENTS

PART 1 GENERAL........................................................................................................................... 3

1.01 SUMMARY......................................................................................................................... 3

1.02 RELATED SECTIONS........................................................................................................3

1.03 CERTIFICATIONS/REFERENCES....................................................................................3

1.04 SUBMITTALS..................................................................................................................... 4

1.05 CLOSEOUT SUBMITTALS (OPERATION AND MAINTENANCE MANUALS)...................4

1.06 QUALITY ASSURANCE.....................................................................................................5

1.07 DELIVERY, STORAGE AND HANDLING...........................................................................5

1.08 WARRANTY....................................................................................................................... 5

PART 2 PRODUCTS........................................................................................................................ 5

2.01 MANUFACTURERS........................................................................................................... 5

2.02 RATINGS........................................................................................................................... 5

2.03 CONSTRUCTION.............................................................................................................. 6

2.04 CONFIGURATION/PROGRAMMING.................................................................................8

2.05 COMMUNICATIONS..........................................................................................................8

2.06 CONTROL FEATURES......................................................................................................9

2.07 CONTROL I/O.................................................................................................................... 9

2.08 DIMENSIONS.................................................................................................................. 10

PART 3 EXECUTION..................................................................................................................... 10

3.01 EXAMINATION................................................................................................................. 10

3.02 INSTALLATION................................................................................................................ 10

3.03 START-UP SERVICE.......................................................................................................10

Rockwell Automation PowerFlex 525 Low Voltage AC VFD

2 25B-SR001C-EN-E

[PROJECT NUMBER] [PROJECT NAME]

[DATE] [PROJECT LOCATION]

SECTION XX XX XX

LOW VOLTAGE AC VARIABLE FREQUENCY DRIVE

PART 1 GENERAL

PART 2 SUMMARY

PART 3 The Variable Frequency Drive (VFD) system shall contain all components required to meet

the performance, protection, safety and certification criteria of this specification.

PART 4 RELATED SECTIONS

PART 5 Section 26 05 00 – Common Work Results for Electrical

PART 6 Section 26 00 00 – Electrical – General Provisions

PART 7 CERTIFICATIONS/REFERENCES

PART 8 Certifications and approvals shall include:

PART 9 c-UL-us – UL508C and CAN/CSA-C22.2 No. 14-05

PART 10 C-Tick – Radiocommunications Act: 1992; Std.: 2008; Labeling Notice: 2008

PART 11 CE –

PART 12 In conformity with EMC Directive (2004/108/EC) and Low Voltage Directive (2006/95/EC)

PART 13 Standards EN 61800-3:2004 and EN 61800-5-1:2007

PART 14 TÜV –

PART 15 Standards EN ISO 13849-1:2008, EN ISO 13849-2:2008, EN 61800-5-2:2007, EN 61508

PARTS 1-7:2010, EN 62061:2005 and EN 60204-1:2009

PART 16 With embedded Safe-Torque-Off function, certified to ISO 13849-1 SIL2/PLd and meets

Functional Safety (FS)

PART 17 ATEX – Directive 94/9/EC

PART 18 KCC – Compliant with Article 58-2 of Radio Waves Act, Clause 3

PART 19 GOST-R – Certificate No. POCC US.ME92.H00040

PART 20 AC156

PART 21 EPRI – Semi F47, IEC 61000-4-34

PART 22 RINA – ELE283205CS marine certification

PART 23 Lloyd’s Register Type Approval Certificate 12/10068(E1)

PART 24 RoHS

PART 25 The VFD shall also meet the appropriate portions of the following specifications:

PART 26 NFPA 70 – US National Electrical Code

PART 27 NEMA ICS 3.1 – Safety Standards for Construction and Guide for Selection, Installation

and Operation of Adjustable Speed Drive Systems

PART 28 IEC 146 – International Electrical Code

PART 29 SUBMITTALS

PART 30 Submit under provisions of Section 01 30 00

PowerFlex 525 Low Voltage AC VFD Rockwell Automation

25B-SR001C-EN-E 3

[PROJECT NUMBER] [PROJECT NAME]

[DATE] [PROJECT LOCATION]

PART 31 Shop Drawings – Approval

PART 32 Elevation Drawings: Shall include dimensional information and conduit routing locations.

PART 33 Unit Descriptions: Shall include amperage ratings, enclosure ratings, fault ratings,

nameplate information, etc. as required for approval.

PART 34 Wiring Diagrams:

PART 35 Power Diagram: Shall include amperage ratings, circuit breaker frame sizes, circuit

breaker continuous amp ratings, etc. as required for approval.

PART 36 Control Diagram: Shall include disconnect devices, pilot devices, etc.

PART 37 Major components list.

PART 38 Product Data Sheets

PART 39 VFD publications.

PART 40 Data sheets and publications on all major components.

PART 41 Test procedures shall be per the manufacturer’s standards.

PART 42 CLOSEOUT SUBMITTALS (OPERATION AND MAINTENANCE MANUALS)

PART 43 Submit under provisions of Section 01 30 00

PART 44 Shop Drawings – Final as shipped

PART 45 Elevation Drawings: Shall include dimensional information and conduit routing locations.

PART 46 Unit Descriptions: Shall include amperage ratings, enclosure ratings, fault ratings,

nameplate information, etc. as required for approval.

PART 47 Wiring Diagrams:

PART 48 Power Diagram: Shall include amperage ratings, circuit breaker frame sizes, circuit

breaker continuous amp ratings, etc. as required for approval.

PART 49 Control Diagram: Shall include disconnect devices, pilot devices, etc.

PART 50 Major components list.

PART 51 Product Data Sheets

PART 52 VFD publications.

PART 53 Data sheets and publications on all major components.

PART 54 Test procedures shall be per the manufacturer’s standards.

PART 55 Operation and Maintenance Data

PART 56 Service and Contact information.

PART 57 VFD User Manual.

PART 58 Troubleshooting/Service Manual.

Rockwell Automation PowerFlex 525 Low Voltage AC VFD

4 25B-SR001C-EN-E

[PROJECT NUMBER] [PROJECT NAME]

[DATE] [PROJECT LOCATION]

PART 59 QUALITY ASSURANCE

PART 60 Qualifications:

PART 61 Manufacturers:

PART 62 The VFD and all associated optional equipment shall be UL listed or recognized.

PART 63 The VFD shall contain a UL label attached on the inside of the enclosure cabinet.

PART 64 Suppliers:

PART 65 All inspection and testing procedures shall be developed and controlled under the

guidelines of the supplier’s quality system and must be registered to ISO 9001 and regularly

reviewed and audited by a third party registrar.

PART 66 The VFD shall be factory pre-wired, assembled and tested as a complete package.

PART 67 DELIVERY, STORAGE AND HANDLING

PART 68 Supplier shall coordinate the shipping of equipment with the manufacturer.

PART 69 Supplier shall store the equipment in a clean and dry space at an ambient temperature

range of -40°C to 85°C (-40°F to 185°F).

PART 70 The supplier shall protect the units from dirt, water, construction debris and traffic.

PART 71 WARRANTY

PART 72 The manufacturer shall provide their standard parts warranty for eighteen (18) months

from the date of shipment or twelve (12) months from the date of being energized, whichever

occurs first.

PART 73 This warranty applies to variable frequency drive systems.

PART 74 PRODUCTS

PART 75 MANUFACTURERS

PART 76 Allen-Bradley – PowerFlex 525 Low Voltage AC Variable Frequency Drive (No

substitutions)

PART 77 RATINGS

PART 78 The variable frequency drive (VFD) shall be designed to operate in one of the following

input voltage classes with -15%/+10% voltage tolerance:

PART 79 100 to 120 VAC, 1 phase.

PART 80 200 to 240 VAC, 1 phase.

PART 81 200 to 240 VAC, 3 phase.

PART 82 380 to 480 VAC, 3 phase.

PART 83 525 to 600 VAC, 3 phase.

PART 84 The VFD shall operate from an input frequency range of 47 to 63 Hz.

PowerFlex 525 Low Voltage AC VFD Rockwell Automation

25B-SR001C-EN-E 5

[PROJECT NUMBER] [PROJECT NAME]

[DATE] [PROJECT LOCATION]

PART 85 The VFD shall have a power rating of:

PART 86 100 to 120V: 0.4 to 1.1 kW / 0.5 to 1.5 HP.

PART 87 200 to 240V: 0.4 to 15 kW / 0.5 to 20 HP.

PART 88 380 to 480V: 0.4 to 22 kW / 0.5 to 30 HP.

PART 89 525 to 600V: 0.4 to 22 kW / 0.5 to 30 HP.

PART 90 The displacement power factor of the VFD shall be between 1.0 and 0.95, lagging, over

the entire speed range.

PART 91 The efficiency of the VFD shall be a minimum of 97% at full load and speed.

PART 92 The overload capability shall be:

PART 93 Normal Duty – 110% for up to 1 minute, 150% for up to 3 seconds.

PART 94 Heavy Duty – 150% for up to 1 minute, 180% for up to 3 seconds (200% programmable).

PART 95 The VFD shall have a maximum output frequency of 500 Hz.

PART 96 The VFD shall provide UL Listed Class 10 motor overload protection to comply with

N.E.C. Article 430.

PART 97 The VFD shall be designed to operate in the following environmental conditions:

PART 98 Ambient temperature range –

PART 99 -20°C to 50°C (-4°F to 122°F).

PART 100 -20°C to 60°C (-4°F to 140°F) with current derating.

PART 101 -20°C to 70°C (-4°F to 158°F) with current derating and control module fan kit (option).

PART 102 Relative humidity range – 0% to 95% non-condensing.

PART 103 Elevation –

PART 104 up to 1000 m (3280 ft.).

PART 105 up to 4000 m (13123 ft.) with current derating [2000 m (6561 ft.) for 525 to 600V drives].

PART 106 Shock and vibration –

PART 107 Shock: 15G peak for 11 ms duration (±1.0 ms).

PART 108 Vibration: 1G peak, 5 to 2000 Hz.

PART 109 CONSTRUCTION

A. The variable frequency drive (VFD) shall have a compact footprint and be of modular

design to provide for ease of installation and inventory reduction, consisting of:

1. A power module sized to meet the application.

2. A control module common to all VFD ratings.

3. The VFD shall be IP20/NEMA Open. Optional conduit box in IP21/IP30 NEMA Type

1 shall be available.

4. The VFD shall be able to be mounted in both vertical and horizontal orientation.

Frames A to C shall be able to be installed on a DIN rail. The VFD shall be capable

of side-by-side installation.

5. The VFD shall employ the following power components:

6. Diode or fully gated bridge on the input.

Rockwell Automation PowerFlex 525 Low Voltage AC VFD

6 25B-SR001C-EN-E

[PROJECT NUMBER] [PROJECT NAME]

[DATE] [PROJECT LOCATION]

7. Switching logic power supply operating from the DC bus.

8. MOV protection – phase to phase and phase to ground with jumpers to remove the

phase to ground unit when applicable.

9. Gold plated plug-in connections on printed circuit boards.

10. Microprocessor-based inverter logic isolated from power circuits.

11. Inverter section with no commutation capacitors.

12. The VFD shall have a standard built-in 7th IGBT for use as a dynamic braking

chopper. This IGBT shall be able to provide at least 100% braking torque on a

continuous basis with a properly sized externally-mounted brake resistor.

13. The VFD shall have two EMC options to comply to IEC 61800-3 specification, each

with an optional EMC earthling/grounding plate:

14. Embedded EMC filter – shall achieve 10 m for C2 and 20 m for C3.

15. External EMC filter – shall achieve 30 m for C1 and 100 m for C2 and C3.

16. The VFD shall have a standard USB port that connects to a PC for upgrading

firmware or uploading/downloading parameter configurations.

17. With its RS-485 port, the VFD shall provide an interface for up to 2 independent

peripherals to be connected at one time at 19.2K Bps. Connection and identification

of peripheral interface DSI addresses shall require no user adjustments.

18. The VFD shall have an embedded EtherNet/IP port. A slot shall be available for dual

port EtherNet/IP, DeviceNet and PROFIBUS DP adapter cards.

19. A slot for an optional encoder card shall be available to perform simple positioning

control. Closed loop with encoder feedback shall be available to replace slip

compensation with trim for improved speed range and regulation.

20. The VFD shall have embedded control I/O.

21. The VFD shall have an embedded safe-torque off solution certified to SIL2 / PLd.

This requires the use of an external safety relay to meet ISO 13849-1. The safety

solution shall maximize safety, increase machine up-time and help protect personnel

and equipment. Communications shall be active throughout when safety is initiated.

22. The VFD’s printed circuit board shall be conformal coated, certified to IEC60721-3-2

with 3C2 (Chemical & Gases at the minimum).

23. The VFD’s control module shall have an integral Human Interface Module (HIM).

24. 5-digit LCD display with scrolling text, used to display drive operating conditions,

fault/alarm indications and programming information and capable of showing

multiple languages via selectable mode.

25. Status LED for drive condition.

26. Status LEDs for communications status, including embedded DSI status, adapter

health and communications network status.

27. Keys for navigation, start, stop and reverse.

28. Potentiometer used to control speed of the drive.

29. The VFD shall have an optional external Human Interface Module (HIM) available in

two package styles:

30. A backlit LCD display with graphics capability and rated for IP20/Type 1, used as a

handheld terminal by connecting via a separate cable or used in a bezel kit mounted

to a cabinet/panel. This package style is removable (slides out) without the use of a

tool.

PowerFlex 525 Low Voltage AC VFD Rockwell Automation

25B-SR001C-EN-E 7

[PROJECT NUMBER] [PROJECT NAME]

[DATE] [PROJECT LOCATION]

31. An IP66/UL Type 4X-12 remote-mounted version for cabinet/panel mounting that is

connected via cable.

32. The VFD’s control module shall have available a fan kit to accommodate horizontal

mounting and extreme ambient temperatures.

33. CONFIGURATION/PROGRAMMING

34. The variable frequency drive (VFD) shall be configurable using:

35. The HIM’s keypad and LCD display.

36. Connected Components Workbench™ – This software offers configuration and

programming.

37. Studio 5000™ Logix Designer – This software, a single development environment

for the entire control system, includes add-on profiles which minimize the need to

individually program the required parameters and tags. (Available to VFDs on

EtherNet/IP or ControlNet.)

38. Autogeneration of descriptive tag names and respective tag data types.

39. Wizards available to walk through configuration.

40. Copy and paste function to easily duplicate VFDs.

41. Single development environment – minimizes errors associated with multiple

software tools.

42. Configuring entire system from one environment – minimizes I/O mismatch errors.

43. Through the Studio 5000 Logix Designer, a Logix controller shall be able to use

Automatic Device Configuration (ADC) to detect a replaced VFD and download the

needed firmware and all configuration parameters. (Available to VFDs on

EtherNet/IP.)

44. With Studio 5000 software,

45. VFD configuration settings shall be stored in the project file and in the control

system’s PACs. This VFD I/O packet shall consist of:

46. VFD status and feedback, command and reference.

47. At least 8 data words of inputs and 8 data words of outputs that can be dynamically

configured to access any parameter.

48. VFDs shall be able to be flash-updated directly.

49. COMMUNICATIONS

50. The variable frequency drive (VFD) shall be capable of communications through

standard protocols, and EtherNet/IP and DeviceNet shall be the preferred networks.

51. Through its USB port, the VFD shall be capable of direct connection to a PC.

52. Through its integral RS-485 port, the VFD shall be able to use Modbus RTU:

53. For programming from a PC.

54. In a multi-drop network configuration.

55. Through its integral Ethernet port, the EtherNet/IP network is supported.

56. The VFD shall be able to communicate with at least 2 networks at the same time.

Rockwell Automation PowerFlex 525 Low Voltage AC VFD

8 25B-SR001C-EN-E

[PROJECT NUMBER] [PROJECT NAME]

[DATE] [PROJECT LOCATION]

57. The VFD shall have available adapter cards, including:

58. Dual port EtherNet/IP – to support Device Level Ring topology.

59. DeviceNet.

60. PROFIBUS DP.

61. VFD communications adapters shall have individually selectable fault actions in the

case of a communications loss or if the controller is idle (in program mode or

faulted):

62. Faulting the VFD.

63. Stopping the VFD.

64. Zeroing data written to the VFD.

65. Holding the VFD in its last state.

66. Using a user-selectable fault configuration.

67. CONTROL FEATURES

68. The variable frequency drive (VFD) shall be programmable for the following motor

control modes:

69. Volts per Hertz.

70. Sensorless vector control.

71. Closed loop velocity vector control.

72. Sensorless vector control with Economizer.

73. Permanent magnet motor control (scheduled for a future firmware release).

74. The VFD shall be capable of open loop and closed loop speed regulation

applications.

75. Programmable features shall include:

76. Flying start

77. V/F ratio

78. Bus regulator

79. Process PID

80. Fiber-application-specific features

81. Common DC bus

82. 1/2 DC bus operation

83. Regulation with encoder feedback or analog input

84. Multi-drive connectivity (with communication option card)

85. StepLogic Function (relay and timers)

86. 16 preset speeds

87. The VFD shall include energy cost reduction potential through energy monitoring

features and Economizer and permanent magnet motor control modes.

88. CONTROL I/O

89. The variable frequency drive (VFD) shall have 2 analog inputs (1 unipolar and 1

bipolar), independently isolated from the rest of the drive I/O.

90. The VFD shall have 7 digital inputs (24 VDC, 6 programmable) to provide

application versatility.

PowerFlex 525 Low Voltage AC VFD Rockwell Automation

25B-SR001C-EN-E 9

[PROJECT NUMBER] [PROJECT NAME]

[DATE] [PROJECT LOCATION]

91. The VFD shall have 1 analog output that is scalable, 10-bit, suitable for metering or

as a speed reference for another drive.

92. The VFD shall have 2 digital outputs and 2 relay outputs (1 form A and 1 form B) to

be used to indicate various drive, motor or logic conditions.

93. DIMENSIONS

94. Frame A: 152 mm (5.98 in.) H x 72 mm (2.83 in.) W x 172 mm (6.77 in.) D

95. Frame B: 180 mm (7.08 in.) H x 87 mm (3.42 in.) W x 172 mm (6.77 in.) D

96. Frame C: 220 mm (8.66 in.) H x 109 mm (4.29 in.) W x 184 mm (7.24 in.) D

97. Frame D: 260 mm (10.23 in.) H x 130 mm (5.11 in.) W x 212 mm (8.34 in.) D

98. Frame E: 300 mm (11.81 in.) H x 185 mm (7.28 in.) W x 279 mm (10.98 in.) D

PART 110 EXECUTION

PART 111 EXAMINATION

PART 112 Verify that location is ready to receive equipment.

PART 113 Verify that the building environment can be maintained within the service conditions

required by the manufacturer of the VFD.

PART 114 INSTALLATION

PART 115 Installation shall be in compliance with all manufacturer requirements, instructions and

drawings.

PART 116 START-UP SERVICE

PART 117 At a minimum, the start-up service shall include:

PART 118 Perform pre-power check

PART 119 Megger motor resistances: phase-to-phase and phase-to-ground

PART 120 Verify system grounding per manufacturer’s specifications

PART 121 Verify power and signal grounds

PART 122 Check connections

PART 123 Check environment

PART 124 Drive power-up and commissioning:

PART 125 Measure incoming power phase-to-phase and phase-to-ground

PART 126 Measure DC bus voltage

PART 127 Measure AC current unloaded and loaded

PART 128 Measure output voltage phase-to-phase and phase-to-ground

PART 129 Verify input reference signal

PART 130 All measurements shall be recorded.

PART 131 Drive shall be tuned for system operation.

PART 132 Drive parameter listing shall be provided.

END OF SECTION

Rockwell Automation PowerFlex 525 Low Voltage AC VFD

10 25B-SR001C-EN-E

You might also like

- NEXTracker NX Horizon 2.4 Installation Manual Rev - CDocument56 pagesNEXTracker NX Horizon 2.4 Installation Manual Rev - Cclaudia herreraNo ratings yet

- Obo - CodeDocument548 pagesObo - CodeMuhammad UsmanNo ratings yet

- NEC Requirements For Limited Energy & ComunicationsDocument196 pagesNEC Requirements For Limited Energy & ComunicationsSalvador RamirezNo ratings yet

- Preliminary Acceptance Test: PAT For 7250 iXR Nokia Mobily ITN ProjectDocument26 pagesPreliminary Acceptance Test: PAT For 7250 iXR Nokia Mobily ITN Projectarbaz khan0% (1)

- Low Voltage NEMA Motor Control Centers: Procurement SpecificationDocument32 pagesLow Voltage NEMA Motor Control Centers: Procurement SpecificationJorge Campano RojasNo ratings yet

- Programmable Logic Controllers Micro820: Procurement SpecificationDocument9 pagesProgrammable Logic Controllers Micro820: Procurement SpecificationrajavinugmailcomNo ratings yet

- SECTION 26 29 23 Variable-Frequency Motor Controller: (Project Number) (Project Name) (DATE) (Project Location)Document16 pagesSECTION 26 29 23 Variable-Frequency Motor Controller: (Project Number) (Project Name) (DATE) (Project Location)gkNo ratings yet

- Specification of 24V DC MotorsDocument9 pagesSpecification of 24V DC Motorswaleed.liaquat.kkNo ratings yet

- LC 90le760xDocument77 pagesLC 90le760xبوند بوندNo ratings yet

- 32 D 44 eDocument142 pages32 D 44 eValerică HizanuNo ratings yet

- Installation and Use Instructions: PatentedDocument32 pagesInstallation and Use Instructions: PatentedvizanteaNo ratings yet

- 7SR242 Duobias Complete Technical ManualDocument384 pages7SR242 Duobias Complete Technical ManualAnonymous wl7fgzivP100% (1)

- PanelboardsDocument15 pagesPanelboardsMohamed FaragNo ratings yet

- Method Statement-Main-28139Document10 pagesMethod Statement-Main-28139rajaram shettyNo ratings yet

- Wavetek Portable RF Power Meter Model 1034A (1499-14166) Operating and Maintenance Manual, 1966.Document64 pagesWavetek Portable RF Power Meter Model 1034A (1499-14166) Operating and Maintenance Manual, 1966.Bob Laughlin, KWØRLNo ratings yet

- WGR7640 IC: Device Revision GuideDocument11 pagesWGR7640 IC: Device Revision Guidejjfb16No ratings yet

- 7sr242 DuobiasDocument382 pages7sr242 DuobiasSagun KatuwalNo ratings yet

- January 25 2012 RDGD 352 Design Testing and Performance of Exposure Devices eDocument16 pagesJanuary 25 2012 RDGD 352 Design Testing and Performance of Exposure Devices eMuhammad Raza MalikNo ratings yet

- Functional Specification For Deck CraneDocument31 pagesFunctional Specification For Deck Craneaiyubi20% (1)

- 4.1.7 Contr A35 - MetalClad Switchgear, Protection & Control PanelssDocument49 pages4.1.7 Contr A35 - MetalClad Switchgear, Protection & Control PanelssxNo ratings yet

- Koc Standard For Low Voltage Switchgear DOC. NO. KOC-E-009: Standards PublicationDocument45 pagesKoc Standard For Low Voltage Switchgear DOC. NO. KOC-E-009: Standards Publicationinb100% (1)

- Eaton Guidespec Mts Molded Case All Frames 26 36 13 01Document7 pagesEaton Guidespec Mts Molded Case All Frames 26 36 13 01tmatma074No ratings yet

- UntitledDocument202 pagesUntitledOngwae Mathew TeyaNo ratings yet

- PVI-6000-OUTD-US Manual PDFDocument94 pagesPVI-6000-OUTD-US Manual PDFIoan NovacNo ratings yet

- AQ V211 Manual 1.05ENDocument241 pagesAQ V211 Manual 1.05ENLuís Pinto PereiraNo ratings yet

- 8 Ae 617Document56 pages8 Ae 617padaguiNo ratings yet

- Automation Engineering Practice For Pressure Definitions: AEP-32e 13 January 2010Document25 pagesAutomation Engineering Practice For Pressure Definitions: AEP-32e 13 January 2010arraziy fauzanNo ratings yet

- MS For Hydro Test ModDocument7 pagesMS For Hydro Test ModIbrahim KhanNo ratings yet

- Ag 0104 6047902 en 2122 DeskDocument32 pagesAg 0104 6047902 en 2122 Deskolivier.bigouretNo ratings yet

- 5Document65 pages5indrajeetNo ratings yet

- SEG MRR1 RotorRelayDocument24 pagesSEG MRR1 RotorRelayKamil Gökberk ErginNo ratings yet

- 5786 - GTR 12 RevDocument77 pages5786 - GTR 12 RevAbhishek TomarNo ratings yet

- S Gen Lightning 00Document15 pagesS Gen Lightning 00raviaggrawalla8727No ratings yet

- Commissioning Systems, Protective RelayDocument48 pagesCommissioning Systems, Protective RelayNissi Jimmy100% (3)

- "Circulation Pump": Testing & Commissioning Method StatementDocument14 pages"Circulation Pump": Testing & Commissioning Method Statementselcuk pekenNo ratings yet

- 32 PDFDocument49 pages32 PDFharmlesdragonNo ratings yet

- SECTION 23 05 14 Variable Frequency Drives: Based On DFD Master Electrical Spec Dated 10/2/2017Document7 pagesSECTION 23 05 14 Variable Frequency Drives: Based On DFD Master Electrical Spec Dated 10/2/2017htanhNo ratings yet

- Specification For Electrical Installations: Rev. Date Description/issued For Prepared Authorised Client: Project: TitleDocument55 pagesSpecification For Electrical Installations: Rev. Date Description/issued For Prepared Authorised Client: Project: TitleNael SwedanNo ratings yet

- 363252728i2 - AFC QCU20 Single Party Service Quad Channel Unit (RDT)Document24 pages363252728i2 - AFC QCU20 Single Party Service Quad Channel Unit (RDT)John WNo ratings yet

- CD1000A - User Manual V1.0Document88 pagesCD1000A - User Manual V1.0Engr ShoaibNo ratings yet

- 02-Technical Specification - GENERAL TECHNICAL REQUIREMENTS (Rev 12) PDFDocument77 pages02-Technical Specification - GENERAL TECHNICAL REQUIREMENTS (Rev 12) PDFSanjay RoutNo ratings yet

- Sample SAT Procedure (Only For Reference)Document3 pagesSample SAT Procedure (Only For Reference)Mohammed SinanNo ratings yet

- PowerFlex 520 User ManualDocument244 pagesPowerFlex 520 User ManualValdirei Silva100% (1)

- 400 Series Installation and Configuration Manual 2 3 3Document92 pages400 Series Installation and Configuration Manual 2 3 3IZODETE SACRAMENTONo ratings yet

- 2023 02 17 ST Racord PV La Reteau LG Procurare TRAFO - EN Rev 02Document30 pages2023 02 17 ST Racord PV La Reteau LG Procurare TRAFO - EN Rev 02Daniel PopaNo ratings yet

- Powerflex 755 Ac Drives: Hardware Service ManualDocument472 pagesPowerflex 755 Ac Drives: Hardware Service ManualJefferson NickNo ratings yet

- 248083310-1 R3 (OpMan Remote 2 PN Series) LetterDocument58 pages248083310-1 R3 (OpMan Remote 2 PN Series) LetterManish PatelNo ratings yet

- 132 KV Surge Arrester - Technical SpecificationDocument11 pages132 KV Surge Arrester - Technical SpecificationvikasmikkuNo ratings yet

- Rexroth-RD 500 RD52 Drive Control Device Field-Oriented Vector Control Application ManualDocument270 pagesRexroth-RD 500 RD52 Drive Control Device Field-Oriented Vector Control Application ManualNuma Key LumaNo ratings yet

- Part Technical Specification Front Impact Absorption SystemDocument37 pagesPart Technical Specification Front Impact Absorption SystempremanandNo ratings yet

- Hitachi P50H401 Service Manual PDFDocument123 pagesHitachi P50H401 Service Manual PDFCharles Albert67% (3)

- Manual Studio 5000 SafetyDocument540 pagesManual Studio 5000 SafetyAdson BrunoNo ratings yet

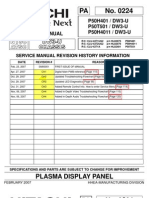

- PA No. 0224: Plasma Display PanelDocument123 pagesPA No. 0224: Plasma Display PanelJoe NovogradacNo ratings yet

- Allengers 325 RF - Installation and Service Manual PDF Relay Series and Parallel CircuitsDocument1 pageAllengers 325 RF - Installation and Service Manual PDF Relay Series and Parallel CircuitsAung Kyaw LinnNo ratings yet

- Generator Protection REG650 ANSI: Type Test CertificateDocument64 pagesGenerator Protection REG650 ANSI: Type Test CertificateILBERIPUCINo ratings yet

- Guidelines For Specification of Generating EquipmentDocument81 pagesGuidelines For Specification of Generating Equipmentcrowjik5672100% (2)

- Handbook of Microwave Component Measurements: with Advanced VNA TechniquesFrom EverandHandbook of Microwave Component Measurements: with Advanced VNA TechniquesRating: 4 out of 5 stars4/5 (1)

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- The SQUID Handbook: Fundamentals and Technology of SQUIDs and SQUID SystemsFrom EverandThe SQUID Handbook: Fundamentals and Technology of SQUIDs and SQUID SystemsNo ratings yet

- Industrial Automation and Robotics: A Comprehensive Guide to Automated Systems and RoboticsFrom EverandIndustrial Automation and Robotics: A Comprehensive Guide to Automated Systems and RoboticsNo ratings yet

- Materials System Specification: Saudi Aramco Desktop StandardsDocument13 pagesMaterials System Specification: Saudi Aramco Desktop StandardsEagle Spirit100% (1)

- M-Series™ Quantum User ManualDocument48 pagesM-Series™ Quantum User ManualMartha CajasNo ratings yet

- FireplaceDocument14 pagesFireplacejddoey23No ratings yet

- GH Cp343-1ex30 76Document67 pagesGH Cp343-1ex30 76KoertBNo ratings yet

- tx-ds575x Manual e PDFDocument44 pagestx-ds575x Manual e PDFMike G0% (1)

- Nfpa 423 2004Document26 pagesNfpa 423 2004kordamirimohammad4No ratings yet

- Motor: Permanent Magnet DC 2-Wire Reversible Connection Diagram 07410101Document2 pagesMotor: Permanent Magnet DC 2-Wire Reversible Connection Diagram 07410101NavneetGargNo ratings yet

- Aries Netlink™ Configuration Tool (ACT8000) : User's GuideDocument178 pagesAries Netlink™ Configuration Tool (ACT8000) : User's GuideGilberto GuerreroNo ratings yet

- Catalog 2018 LowresDocument140 pagesCatalog 2018 LowresSAMNo ratings yet

- Opw 2000 Series Installation ManualDocument16 pagesOpw 2000 Series Installation ManualrubenNo ratings yet

- Pares 80.01Document40 pagesPares 80.01Yogesh MittalNo ratings yet

- LG Goldstar Manual 38616Document109 pagesLG Goldstar Manual 38616Joel García100% (1)

- Schneider Electric UL489 Vs UL1077 - GuidelineDocument2 pagesSchneider Electric UL489 Vs UL1077 - GuidelinerubenNo ratings yet

- IEEE STD C57.12.01-2020Document49 pagesIEEE STD C57.12.01-2020danfengye123No ratings yet

- SECTION 11130 Audio-Visual Equipment Rev 0Document14 pagesSECTION 11130 Audio-Visual Equipment Rev 0Munir RasheedNo ratings yet

- 0970 - MAN - LCWM - 61070041 - y - EN - InstallationServiceManualDocument46 pages0970 - MAN - LCWM - 61070041 - y - EN - InstallationServiceManualBrian EliúNo ratings yet

- Pioneer DVD-V7400Document88 pagesPioneer DVD-V7400David F. DealNo ratings yet

- s.aMHI: Cmaa Is An Affiliate of MhiDocument87 pagess.aMHI: Cmaa Is An Affiliate of MhiConstruction Engineering Infra100% (1)

- TCL L32D3260-MT10B-LA 1service Manual PDFDocument62 pagesTCL L32D3260-MT10B-LA 1service Manual PDFKornaek Saelim100% (1)

- 750 - 751 - 754 - 774 - 794-Operators-Manual TaylorDocument57 pages750 - 751 - 754 - 774 - 794-Operators-Manual TaylorMiguel DexsNo ratings yet

- Bonded Moca Network Adapter: Coaxial-To-Ethernet Conversion KitDocument16 pagesBonded Moca Network Adapter: Coaxial-To-Ethernet Conversion KitRobertNo ratings yet

- Atkinson Dynamics Intercoms Models AD-26, AD-27, AD-56, and AD-57Document28 pagesAtkinson Dynamics Intercoms Models AD-26, AD-27, AD-56, and AD-57JOSE92190No ratings yet

- Danfossirv 302Document46 pagesDanfossirv 302FabricioPexNo ratings yet

- Seriesc - Catalog Cube GreenheckDocument56 pagesSeriesc - Catalog Cube GreenheckSergio Cataño GaleanoNo ratings yet

- Cable ColorDocument4 pagesCable ColorNghia Huynh Ngoc0% (1)

- Example Short Circuit Current Faults - Scenario 9Document7 pagesExample Short Circuit Current Faults - Scenario 9PGNo ratings yet

- 2739 Cable TrayDocument64 pages2739 Cable Trayอะไรๆก็เรา ทั้งเพNo ratings yet