Construction Engineering of Phu My Cable-Stayed Bridge, Vietnam

Construction Engineering of Phu My Cable-Stayed Bridge, Vietnam

Uploaded by

Sravanthi MeharCopyright:

Available Formats

Construction Engineering of Phu My Cable-Stayed Bridge, Vietnam

Construction Engineering of Phu My Cable-Stayed Bridge, Vietnam

Uploaded by

Sravanthi MeharOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Construction Engineering of Phu My Cable-Stayed Bridge, Vietnam

Construction Engineering of Phu My Cable-Stayed Bridge, Vietnam

Uploaded by

Sravanthi MeharCopyright:

Available Formats

Construction Engineering of Phu My Cable-Stayed

Bridge, Vietnam

Summary

Abstract

The Phu My Bridge will span the Saigon River between Districts 7 and 2 in Ho Chi

Minh City. The bridge will form part of a new ring road currently under construction

around Ho Chi Minh City. The ring road will be an important transport link from the

southern Mekong delta region to the central and northern parts of Vietnam.

The Phu My Bridge contract includes the design and construction of a 705m long

cable stayed main bridge with a clear span of 380m, as well as the approach

structures on either side being approximately 758m on District 7 and 638m on District

2.

The main span deck will be 27m wide. Clearance to river traffic is provided with 45m

vertical clearance in a 250m wide zone. The pylons carrying the deck are designed

as an H frame and are approximately 140m high.

The main bridge deck is designed as an insitu reinforced and partly post tensioned

concrete slab supported on longitudinal and transverse beams and suspended from

the pylons by the stay cables.

The bridge is being constructed by BBBH Consortium, a joint venture between

Bilfinger Berger and Baulderstone Hornibrook. Phu My Bridge Corporation (PMC) as

the Client is a private consortium comprising Hanoi Construction Company, Investco,

Cienco 620, Thanh Danh Co, and CII. PMC has a thirty year BOT licence to operate

the bridge which will be part of a toll road.

This paper describes the bridge, the method used to construct and the construction

engineering used for the stage by stage analysis of the bridge and the on site role to

control the cable forces and bridge geometry during construction of the bridge.

Author Colin Edmonds, Principal, Cardno, MEng, CEng

Colin has over 15 years experience as an Engineer. He has worked in a variety of

countries including UK, Malaysia, Australia and Vietnam. He has particular

knowledge of bridge design. His experience covers construction technology as well

as design.

Co-Author George D. Moir, Design Manager, Bilfinger Berger, BEng (Hons)

CEng MICE

George has more than 16 years experience in design, construction and management

of multi-disciplinary infrastructure projects including mass transit, tunnelling, bridges

and elevated structure works. He has worked extensively within Europe and has over

10 years experience in the Asian region.

Construction Engineering Phu My Bridge - Edmonds

Co-Author Peter Walser, Project Manager, Leonhardt, Andrä und Partner,

Dipl.-Ing.

Peter has over 18 years experience in structural analysis and design of over 15 stay

cable bridges. From his stays in the USA, Korea, Hong Kong and Australia he gained

extensive knowledge on design and construction engineering.

Co-Author Martin Romberg, Structural Engineer, Leonhardt, Andrä und

Partner, Dipl.-Ing.

Martin has over 5 years experience in structural analysis and design of several stay

cable bridges in different countries. In the company he is responsible for the software

application for the bridge design.

Audiovisual Projector required for Powerpoint presentation

Telephone +612 9496 7700

Fax +612 9499 3902

E-mail colin.edmonds@cardno.com.au

Construction Engineering Phu My Bridge - Edmonds

Construction Engineering of Phu My Cable-Stayed

Bridge, Vietnam

Colin Edmonds, Principal, Cardno

George Moir, Design Manager, BBBH Consortium

Peter Walser, Project Manager, LAP

Peter Walser, Structural Engineer, LAP

Synopsis

The Phu My Bridge will span the Saigon River between Districts 7 and 2 in Ho Chi

Minh City. The bridge will form part of a new ring road currently under construction

around Ho Chi Minh City. The ring road will be an important transport link from the

southern Mekong delta region to the central and northern parts of Vietnam.

The Phu My Bridge contract includes the design and construction of a 705m long

cable stayed main bridge with a clear span of 380m, as well as the approach

structures on either side being approximately 758m on District 7 and 638m on District

2.

The main span deck will be 27m wide. Clearance to river traffic is provided with 45m

vertical clearance in a 250m wide zone. The pylons carrying the deck are designed

as an H frame and are approximately 140m high.

The bridge is being constructed by BBBH Consortium, a joint venture between

Bilfinger Berger and Baulderstone Hornibrook. This paper describes the construction

engineering used for the stage by stage analysis of the bridge and the on site role to

control the cable forces and bridge geometry during construction of the bridge.

Construction Engineering Phu My Bridge - Edmonds Page 1 of 12

1. Introduction

The Phu My Bidge is a new cable stayed bridge currently under construction in Ho

Chi Minh City (HCMC), in Vietnam. The bridge will span the Saigon River between

Districts 7 and 2. The bridge will form part of a new ring road currently under

construction around Ho Chi Minh City. The ring road will be an important transport

link from the southern Mekong delta region to the central and northern parts of

Vietnam.

The main port, which is located slightly downstream (or south) of the centre of the

city and is forecast to be re-located further downstream within the next 10 years,

generates considerable heavy goods traffic. In addition a significant amount of

goods from manufacturing in the Mekong Delta also travels up though HCMC. Such

traffic currently crosses the Saigon River at the most southerly bridge, the Saigon

Bridge, located in the central district of HCMC. A reduction of the traffic congestion

in the centre of the city is necessary to insure efficient transportation conditions and

will be realized by the creation of an inner ring road, including the large Phu My

Bridge over the Saigon River linking the Southeast quadrant to the rest of the city.

The bridge is being constructed by the Bilfinger Berger Baulderstone Hornibrook

(BBBH) Consortium. A joint venture between two companies both within the Bilfinger

Berger group.

In October 2005 the client, Phu My Bridge Corporation (PMC) signed an agreement

with BBBH for the design and construction of the bridge. PMC as the Client is a

private consortium comprising Hanoi Construction Company, Investco, Cienco 620,

Thanh Danh Co, and CII. PMC has a 30 year BOT license to operate the bridge

which will be part of a toll road. The project cost is US$105 million.

Construction Engineering Phu My Bridge - Edmonds Page 2 of 12

2. Project Details

The project involved the design and construction of a 2101m long viaduct. The

viaducts consists of a 705m long cable stayed main bridge with a clear span of

380m, as well as the approach viaduct structures on either side of the river being

758m on District 7 and 638m on District 2.

3. Project Team

Construction of the bridge is being done by BBBH Consortium while the approach

viaducts have been subcontracted to Vietnamese contractor, Chau Thoi Concrete

Corporation 620 under close supervision of BBBH. Freyssinet have been engaged

as a specialist subcontractor for the installation of the cable stays, prestress, and

heavy lift.

Design of the main bridge and approach structures permanent works was split into

two packages. The main bridge design was produced in France by the consultant

Arcadis, whilst the approach structures were designed in Australia by Cardno.

A separate package was then created for the design of main bridge temporary work

and the construction engineering for the main bridge. This was a combined effort

between Cardno and Leonhardt, Andrä und Partner (LAP) from Germany. This

paper focuses on these aspects particularly the work carried out prior to construction

and the ongoing role during construction.

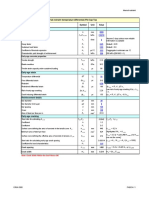

The chart below shows project organization for the Main Bridge

Phu My Bridge Corporation

Maunsell Vietnam

(The Employer’s

Representative)

BBBH Consortium

Specialist Arcadis Cardno / Golders Cardno / LAP

Subcontractors (Permanent Works – (Permanent Works – (Temporary Works –

Freyssinet Main Bridge) Approach Spans) Construction Engineering

Construction Engineering Phu My Bridge - Edmonds Page 3 of 12

4. Description of the Main Bridge

The main bridge is a three span cable stayed bridge. The spans are 380 m for central

span and 162.50 m for each back span. The total height of the pylons is 134.50 m

above top of pile caps levels and 93 m above deck level. Clearance to river traffic is

provided with a minimum 45m vertical clearance, at high tide, over a 250m wide zone

at the centre of the bridge.

4.1 Substructure

Each Main Bridge pylon is founded on 2

groups of 14 No. 2.05m diameter piles,

up to 80m depth, in addition the piles

have been base grouted in order to

ensure the base capacity of the

foundations. Each pylon pile cap is

composed of two sections of reinforced

mass concrete capping each group of

14 diameter 2.10 m piles. These are

locked together by means of a two cell

box girder.

The pilecap construction was carried on in many phases. As the pile cap does not lie

on the ground, a metallic frame was fixed at the top of the pile, supporting thin (20

cm) concrete slabs, on which a first pour (approximately 1.00 m) was carried out.

The rest of the pile cap is then poured when the first lift has reached sufficient

capacity to support the loads. The lateral formwork of the pile cap is made of precast

skirting panels, which extends below low water keeping the pilecap base above low

water level and ensuring a dry working area.

Construction Engineering Phu My Bridge - Edmonds Page 4 of 12

4.2 Towers

The pylons towers are H shaped. Each leg is a box section. The outer dimension

varies from 5.50 x 7.00 m to 3.00 x 5.00. The stay anchorages are located inside the

box. The legs are linked by 2 cross beams.

4.3 Tie Down Piers

The tie down piers are located at the end of each cable stay back span. The pie

down piers are twin rectangular columns with vertical prestress supported on large

diameter bored piles. The tie down pier is used to connect the last three stay cables

on the back span. The deck slab is solid concrete and is prestressed in both the

longitudinal and transverse directions.

Construction Engineering Phu My Bridge - Edmonds Page 5 of 12

4.4 Superstructure

The total width of the main span deck is 27m, this incorporates three lanes of traffic

in each direction, two car and truck lanes, a separated motorcycle lane and footways

for pedestrians.

The viaduct carriageway is composed of 2 x 3 lanes (including 2 x 1 lanes for

motorbikes and bicycles) edged by 2 x 1.50 m wide pavements.

There are two vertical planes of stay cables. The structure of the deck is composed

of two longitudinal concrete girders linked by transverse prestressed concrete cross

girders at 5m centres. The stay cables are connected to the longitudinal edge beams

by precast anchor pods located every 10m

Construction Engineering Phu My Bridge - Edmonds Page 6 of 12

5. Construction Method

6.1 Tower Construction

The towers were built using a jump form in 4m lifts. A

tower crane was located on the pilecap next to one leg

and a hoist was attached to the other. The towers were

constructed in the following sequence. The limiting

cases on the tower were caused by high wind events and

the forces created by the inclined tower legs.

• Construct 56m of tower leg and then install the

lower strut/lifting beam 48m above the pilecap.

The lower strut was used to control the forces and

deflections in the tower leg and also for lifting the

lower cross beam and piertable falsework.

• Construct the lower cross beam on the pilecap, attach the piertable falsework

and the precast anchor pods for the first segments.

• Use the lower strut to lift the lower cross beam and pier table falsework. This

heavy-lift was carried out by Freyssinet and involved lifting the 1200t assembly

30m into the air. Once the cross beam was in its correct position, stitch the

lower cross beam to the tower leg;

• Once the lower cross beam was connected and stitched the pier table could

be cast. This was done in three stages; first the central 10m was cast

followed by the 10m on the side span and then the 10m on the main span. It

was important that the deck construction could start as soon as possible and

not have to wait until the completion of the towers.

• Continue building the tower legs and install the intermediate strut 70m above

the pilecap. Remove lower strut. The intermediate strut is a needle beam

used to control the forces in the tower legs. It is also used to support a catch

platform for safety during the construction of the upper cross beam;

• Install upper strut. The upper strut acts as both a brace for the tower legs and

to support the formwork for the upper cross beam. Construct the upper cross

beam, remove the intermediate and upper strut and complete the tower legs

construction.

• Install and stress the first stays between the pier table and the tower. Release

and lower the pier table formwork and then lift the form travellers into position

ready to start deck construction. At this stage the geometry of the deck is

controlled by the length of the stays more than the force since the deck was

free to pivot on the bearing. The stays were installed in 25% increments up to

75% of their installation force. At this stage another survey was carried out

prior to making a final adjustment to the cable length.

Construction Engineering Phu My Bridge - Edmonds Page 7 of 12

6.2 Deck Construction

The following overall construction sequence was used for the main bridge.

a) - Build deck out from D7 Tower

The deck is constructed one segment at a time starting

on the river side. The sequence between the two sides

is partially offset to reduce the out of balance moments

and speed up the construction, i.e. the traveller on the

river side is launched to the next segment prior to

casting the land side.

b) - Install Buffeting Cable s

After 7 segments are cast on either side the buffeting

cables are installed. Only the land side is tensioned.

The river side is kept slack unless high winds occur

(greater than 20m/s gust at 10m elevation). This limits

the bending moments in the tower at deck level.

c) - Install Temporary Tie Down Cables

After 11 segments the temporary tie down cables are

installed on the land side. The land side buffeting

cables are released and the river side ones tensioned.

This then limits the bending moments in the whole

tower.

d) - D7 Sidespan Closure

After 15 segments are cast the 1.5m long side span

closure is cast. A survey is carried out prior to the

closure and the deck is position by releasing the

temporary tie down cable. The pour is carried out in the

evening to limit the temperature effects on the new

concrete.

e) - Move travellers and Repeat for D2 Deck

After the sidespan closure is complete the three

remaining river side segments are cast and the

travellers moved to the D2 side to repeat the process.

f) - Main Span closure

The 10m main span closure is cast using one of the

travellers. A full survey and adjustment of the stay

cables is carried out prior to casting. After casting the

SDL loads are placed and any further stay adjustments

are carried out if necessary.

Construction Engineering Phu My Bridge - Edmonds Page 8 of 12

6.3 Deck Erection Cycle

The deck is constructed in balanced cantilever starting from each tower. 10m long

segments are cast using a form traveller. The typical erection sequence is as follows

• Cast new Segment, on the morning

after casting carry out as built survey;

• Move rolling beam and stress front

cross girder. Required concrete

strength 30MPa;

• Destress and remove stressbars at

anchor pods and restress stay cable.

Required concrete strength 30MPa.

• Remove longitudinal strut. Lower

Traveller and stress rear cross

girder. Required concrete strength

35MPa;

• Launch Traveller halfway towards

new position;

• Install precast anchor pods during the launch;

• Complete launch and raise traveller. Survey position of traveller and make

adjustment to alignment if required;

• Place precast cross girders and edge beam reinforcement cages. Required

concrete strength 40MPa;

• Start fixing deck reinforcement. Up to 25t of rebar could be placed before stay

installation;

• Install longitudinal strut between anchor pods to the previous segment;

• Install and stress stay cable. The stay cable is attached to the anchor pod

which is stressed to the traveller. The horizontal component of the load is

transferred to the previous segment via the longitudinal strut. The vertical load

component of this first stay force is kept constant at about 100t for each stay,

which helped support the traveller during casting of the concrete. Required

concrete strength 45MPa;

• Complete deck reinforcement and carry out prepour survey and cast new

Segment.

After the initial learning phase this cycle was regularly achieved in 5 days with the

sidespan cycle lagging 2 days behind the main span cycle.

Construction Engineering Phu My Bridge - Edmonds Page 9 of 12

6. Construction Engineer Role – Design Phase

BBBH engaged Cardno and LAP to carry out the construction engineering and the

design of some of the major temporary works. Prior to construction commencing on

site the Construction Engineer agrees with the contractor the following:

• Weights and requirements for major temporary works items;

• The best estimate of the time required for construction, as it was important to

accurately determine the time dependant effects;

• When to install the stay cable;

• When to install the temporary tie-down cables and when and how often to

restress;

• When to dismantle the forms and supports at the pier tables for both the tower

and the hold down pier;

• Exact local sequences, for typical segment construction as well as for side

span and main span closure procedures.

Once this is done the Construction Engineer models the sequence including

consideration of the time dependant effects. To do this a sophisticated stage by

stage analysis of the bridge was carried out.

It software program also possesses a powerful solver which can determine the forces

to be applied to each stay at installation such that the forces at the end of

construction are the same as those calculated by the permanent works designer.

This is done by the program which solves a set of simultaneous equations with the

constraints being the final stay forces, tower forces, etc. The input variables are the

stay stressing forces and other adjustments such as jacking prior to the closure

pours.

Once the stay forces are calculated the camber curves and support reactions will be

calculated. The purpose of the analysis was to achieve a clear understanding of the

following;

• Exact forces and deflections of all parts during all erection stages;

• Forces in the buffeting cables and temporary tie down cables;

• Forces in the temporary falsework at the hold down pier

The analysis also calculates Adjustment values to account for variations in

• Temperature conditions;

• Variation in construction live loads.

The erection analysis was based on the results of the permanent works design and

took into account the most accurate actual parameters, dimensions and weights. In

doing this special care was taken to address

• Dead weight, actual concrete density and reinforcement content;

• Section properties;

• P/T forces;

• Shrinkage and creep values

Construction Engineering Phu My Bridge - Edmonds Page 10 of 12

The object of the analysis is to meet the reality as close as possible, both in the

position of the bridge and in the built in forces provided by the permanent works

design, which must be achieved to be consistent with the final design assumptions.

In addition an erection stress analysis was carried out to ensure that the structural

capacity of all the bridge elements will not be exceeded at any of the individual

erection stages

Based on their previous experience of cable stay bridges and working in Vietnam

BBBH had a clear view of how they wished to construct the bridge such that it would

be quick and economical to build.

7. Construction Engineer Role – Construction Phase

During the construction the role of the construction engineer included the following:

• Monitor the survey results

• Adjust traveller shim values to create the correct precamber

• Adjust restress force to account for deck loading, temperature, stay force,

survey results.

• Advise contractor on possible changes to construction sequence

• Review temporary works designs

In the morning following the casting of a deck segment the following information is

obtained:

• A survey is carried out of the last four segments on the leading edge plus the

tower.

• In addition a load map is taken of the major loading on the deck such as

reinforcement stock, strand, mobile crane

• A lift off test is done on the cable on the new segment to determine the stay

force.

Construction Engineering Phu My Bridge - Edmonds Page 11 of 12

The survey is compared to the predicted position of the deck and tower for that

stage. An adjustment is made for the actual loads on the deck, cable stay force and

temperature. From this analysis the Construction Engineer determines the restress

length of the stay cable and the appropriate shim values for the next traveller

position. This information was required by site within a few hours so as not to delay

the construction cycle.

Adjustments to the traveller shims affect the local curvature while changes to the stay

force have a greater effect on the overall geometry of the bridge. During construction

the results from the survey were studied to check the accuracy of the analysis, some

of the variables for which sensitivity analysis was carried out included:

• Variation in traveller weight. The design had assumed a traveller weight of

210t. When this was lifted to the deck the weight of the traveller was

calculated to be 235t. An update of the analysis was therefore carried out to

calculate revised precambers and stay forces;

• Deck stiffness. The deflections of the deck depend on the modulus of

elasticity of the concrete used and also the effective width of the deck section.

• Stay stiffness. The strand used is provided with test certificates giving the

area and modulus of the strand;

• Deck weight. The deck weight included in the design allowed for the

reinforcement used. A comparison was carried out with the density of actual

concrete used and the original assumption;

• Traveller stiffness. The traveller was modeled separately using a 3-D package

with all the members to calculate its stiffness. The stiffness of the traveller

was compared to the results found on site when loads were applied to the

traveller.

During the construction of the bridge deck it was noted that the deflections of the

bridge were greater than that predicted by the model. As noted there are several

possible reasons for this occurring, however, one of the more likely seemed to be an

increase in the traveller weight and deck weight. During the erection of the bridge

the stay forces were increased by 1.5% above their design values to balance these

deflections.

Construction Engineering Phu My Bridge - Edmonds Page 12 of 12

8. Conclusion

In summary this paper highlights some of the features used for the speedy

construction of a cable stay bridge.

The project required significant planning and design to agree and optimize the

construction methods. This involved a lot of collaboration between the contractor

and construction engineer and has resulted in relatively few issues occurring during

the construction process and a rapid achievement of the 5 day construction cycle

with a short ‘learning process’. The role of the construction engineer both in the

preconstruction and construction phase forms an important part of this team.

A contract duration of 34 months was originally anticipated with the project scheduled

to be open to traffic by the end of 2009. At the time of writing it is planned to

complete the bridge in 32 months. This will allow the bridge to be opened for traffic

in October 2009.

The main span closure is due to

take place in June 2009

Construction Engineering Phu My Bridge - Edmonds Page 13 of 12

You might also like

- S58 - Stay Cable Replacement of The Luling Bridge - LTC2013Document47 pagesS58 - Stay Cable Replacement of The Luling Bridge - LTC2013walaywanNo ratings yet

- Boyne BridgeDocument43 pagesBoyne Bridgeianfld100% (1)

- Saxton MillauDocument10 pagesSaxton MillauBilalABasheerNo ratings yet

- Early Thermal CrackingDocument5 pagesEarly Thermal CrackingSravanthi Mehar100% (1)

- Phu My BridgeDocument7 pagesPhu My BridgetecanasioNo ratings yet

- Structural Analysis of The Sutong BridgeDocument8 pagesStructural Analysis of The Sutong BridgeMahmood MuftiNo ratings yet

- Bang Na ExpresswayDocument13 pagesBang Na ExpresswayRavi GuptaNo ratings yet

- A Critical Analysis of The Donghai Bridge, ShanghaiDocument10 pagesA Critical Analysis of The Donghai Bridge, ShanghaiPunithan PunithanNo ratings yet

- Scope of Morth ProjectsDocument26 pagesScope of Morth ProjectsRahul ChauhanNo ratings yet

- DSI-Multistrand Stay Cable Systems en 01Document24 pagesDSI-Multistrand Stay Cable Systems en 01sertackcdgNo ratings yet

- Second Vivekananda BridgeDocument2 pagesSecond Vivekananda BridgedarmumbaiNo ratings yet

- Multi Strand Stay Cable Systems Revised 20220530 TM DIGITALDocument52 pagesMulti Strand Stay Cable Systems Revised 20220530 TM DIGITALliumr645No ratings yet

- Nit WBHDCLDocument194 pagesNit WBHDCLManish Choudhary100% (1)

- Seminar Document - EIT - IRR Cable-Stayed Bridge - 13 October 2007Document35 pagesSeminar Document - EIT - IRR Cable-Stayed Bridge - 13 October 2007DrPadipat ChaemmangkangNo ratings yet

- DESIGN ISSUES For Railway Bridges On High Speed & A Case Study: Cable Stayed BridgeDocument34 pagesDESIGN ISSUES For Railway Bridges On High Speed & A Case Study: Cable Stayed BridgeJogesh S SondhiNo ratings yet

- Meghna River Bridge Feasibility StudyDocument4 pagesMeghna River Bridge Feasibility Studydr.afroza1875No ratings yet

- Akashi Kaikyo Bridge: The Longest Suspension Bridge With Its Greatest Engineering FeatDocument33 pagesAkashi Kaikyo Bridge: The Longest Suspension Bridge With Its Greatest Engineering FeatAllyne CristinaNo ratings yet

- RDT05004 PDFDocument271 pagesRDT05004 PDFsgdrgsfNo ratings yet

- Lecture 1Document36 pagesLecture 1Anubhav Chaudhary100% (1)

- Bath Buxton Smith Royal Albert BridgeDocument10 pagesBath Buxton Smith Royal Albert BridgeChen Wai PengNo ratings yet

- $the Formwork To The Millau ViaductDocument104 pages$the Formwork To The Millau ViaductPopa AndreiNo ratings yet

- 21 M.V. Jatkar and G.P. Joshi (May 2005)Document4 pages21 M.V. Jatkar and G.P. Joshi (May 2005)Mayank SinghNo ratings yet

- Pushover Analyses of TwoDocument6 pagesPushover Analyses of TwogazmirNo ratings yet

- Extradosed Bridges in Poland-Design and Constructi PDFDocument10 pagesExtradosed Bridges in Poland-Design and Constructi PDFFitsum AbebeNo ratings yet

- Diaphragm DetailsDocument54 pagesDiaphragm DetailswalidNo ratings yet

- Minimizing Construction Problems in Segmentally Precast Box Girder Bridges PDFDocument285 pagesMinimizing Construction Problems in Segmentally Precast Box Girder Bridges PDFAditya PratamaNo ratings yet

- VSL China PRC Ching Chau Min Jian BridgeDocument2 pagesVSL China PRC Ching Chau Min Jian BridgeblaqhaqarNo ratings yet

- Twenty Third Report: Standing Committee On Railways (2018-2019)Document41 pagesTwenty Third Report: Standing Committee On Railways (2018-2019)Virendra Kumar PareekNo ratings yet

- Akashi Kaikyo BridgeDocument110 pagesAkashi Kaikyo Bridgekhawaja AliNo ratings yet

- Bridge TechnologyDocument67 pagesBridge Technologythanzawtun1981No ratings yet

- Countermeasures To Protect Bridge Abutments From ScourDocument21 pagesCountermeasures To Protect Bridge Abutments From ScourfarhanNo ratings yet

- Harpreet Singh New Presentation Yamuna Bridge EPE Package V - Presentation-2Document31 pagesHarpreet Singh New Presentation Yamuna Bridge EPE Package V - Presentation-2Varun VermaNo ratings yet

- MK4 DMK Stay Cable System Brochure PDFDocument24 pagesMK4 DMK Stay Cable System Brochure PDFIndra MishraNo ratings yet

- Concrete Highway Arch Bridges in BangladeshDocument10 pagesConcrete Highway Arch Bridges in BangladeshBridge WingNo ratings yet

- Third Bosphorus Bridge Greisch Jy Del FornoDocument92 pagesThird Bosphorus Bridge Greisch Jy Del FornoMuhammad Umar Riaz100% (1)

- MAin BRG Drawing Index1Document11 pagesMAin BRG Drawing Index1venkatd123603No ratings yet

- 4.3 - K F Tam, Gammon - PDFDocument11 pages4.3 - K F Tam, Gammon - PDFsouthchayNo ratings yet

- Construction Control of The Yamen Cable-Stayed Bridge: Han Dajian Su ChengDocument6 pagesConstruction Control of The Yamen Cable-Stayed Bridge: Han Dajian Su Chengarindam1508No ratings yet

- Lecture 01 - Construction EngineeringDocument18 pagesLecture 01 - Construction EngineeringKw TseNo ratings yet

- Akashi Kaiko BridgeDocument13 pagesAkashi Kaiko BridgeArthur RebouçasNo ratings yet

- Hendon Park Footbridge and The Waterview Shared Path Bridges Connecting CommunitiesDocument10 pagesHendon Park Footbridge and The Waterview Shared Path Bridges Connecting CommunitieskingdbmNo ratings yet

- Design of A High Speed Rail Arch Bridge Over The Alcántara Reservoir (Spain)Document8 pagesDesign of A High Speed Rail Arch Bridge Over The Alcántara Reservoir (Spain)cocodrilopopNo ratings yet

- Hodariyat Bridge: Abu Dhabi, UaeDocument1 pageHodariyat Bridge: Abu Dhabi, UaeIndra MishraNo ratings yet

- Comparative Cost Analysis For Viaduct 1 and Viaduct 2Document82 pagesComparative Cost Analysis For Viaduct 1 and Viaduct 2Saahil BaderNo ratings yet

- Strukturas MSS PresentationDocument52 pagesStrukturas MSS PresentationumutakinNo ratings yet

- Bridge DesignDocument68 pagesBridge DesignHASSAN SK MDNo ratings yet

- 13 Phu My Cable Stayed BridgeDocument18 pages13 Phu My Cable Stayed BridgeLengendary PhubrNo ratings yet

- The Third Narmada Extrados Bridge in India: Bridge Designer™: Case Study #3Document12 pagesThe Third Narmada Extrados Bridge in India: Bridge Designer™: Case Study #3ShaileshRastogi100% (1)

- A Cable-Stayed Bridge With Main Span of 1088 MetersDocument9 pagesA Cable-Stayed Bridge With Main Span of 1088 Metersmdkml2No ratings yet

- High Speed Rail in IndiaDocument36 pagesHigh Speed Rail in IndiaNamesh Killemsetty100% (1)

- Bach Dang - Option1 - 20160201Document20 pagesBach Dang - Option1 - 20160201Nguyen Ngoc DiemNo ratings yet

- Can Tho Bridge VietnamDocument2 pagesCan Tho Bridge VietnamIndra Nath MishraNo ratings yet

- E Ting Kau BridgeDocument1 pageE Ting Kau Bridgekenyu89No ratings yet

- (MIDAS Expert Webinar Series) Case Study of Integral Bridge StructureDocument70 pages(MIDAS Expert Webinar Series) Case Study of Integral Bridge StructureAnkit GuptaNo ratings yet

- Design and Construction of Concrete Filled Steel Tubular Arch Bridge PDFDocument7 pagesDesign and Construction of Concrete Filled Steel Tubular Arch Bridge PDFnishantsky1990No ratings yet

- L&T-built Iconic Durgam Cheruvu Cable Stay Bridge Dedicated To The People of HyderbadDocument2 pagesL&T-built Iconic Durgam Cheruvu Cable Stay Bridge Dedicated To The People of HyderbadIndra MishraNo ratings yet

- New Saraighat Bridge-A Vital Link To Gat PDFDocument17 pagesNew Saraighat Bridge-A Vital Link To Gat PDFGEETHU K SNo ratings yet

- Phu My Bridge Project Info SheetDocument2 pagesPhu My Bridge Project Info SheetIndra Nath MishraNo ratings yet

- Sutong BridgeDocument8 pagesSutong BridgeDhindeM100% (1)

- Suspension Bridge in Hong KongDocument14 pagesSuspension Bridge in Hong KongNisay ArchineerNo ratings yet

- Enginuity Tutorial: Making Project Manager DecisionsDocument14 pagesEnginuity Tutorial: Making Project Manager DecisionsSravanthi MeharNo ratings yet

- Design Report - RS36ADocument18 pagesDesign Report - RS36ASravanthi MeharNo ratings yet

- BGA Foundation ExampleDocument1 pageBGA Foundation ExampleSravanthi MeharNo ratings yet

- Design of Friction Slab On Cut Rock Wall - Rs 39A: Width of Foundation Width of Toe 0.00 MDocument7 pagesDesign of Friction Slab On Cut Rock Wall - Rs 39A: Width of Foundation Width of Toe 0.00 MSravanthi MeharNo ratings yet

- Shear - ULS-70m - LF 1.1Document6 pagesShear - ULS-70m - LF 1.1Sravanthi MeharNo ratings yet

- Rail Structure Interaction-Hewson - PresentationDocument29 pagesRail Structure Interaction-Hewson - PresentationSravanthi MeharNo ratings yet

- Daily Desk Stretches: Shoulder & Side Neck Neck Hand, Wrist & FingersDocument3 pagesDaily Desk Stretches: Shoulder & Side Neck Neck Hand, Wrist & FingersSravanthi MeharNo ratings yet

- End Block Design AidDocument6 pagesEnd Block Design AidAhsan KhanNo ratings yet

- Static Analysis-Laterally Loaded Pile DesignDocument55 pagesStatic Analysis-Laterally Loaded Pile DesignSravanthi MeharNo ratings yet

- Study On Effect of Skew Angle in Skew Bridges: Ansuman Kar, Vikash Khatri, P. R. Maiti, P. K. SinghDocument6 pagesStudy On Effect of Skew Angle in Skew Bridges: Ansuman Kar, Vikash Khatri, P. R. Maiti, P. K. SinghIJERDNo ratings yet

- Analysis of Box Girder Bridges Inc Effects of DistortionDocument14 pagesAnalysis of Box Girder Bridges Inc Effects of DistortionSravanthi Mehar100% (1)

- Application For IRD Sponsored Projects - ConsultanciesDocument2 pagesApplication For IRD Sponsored Projects - ConsultanciesSravanthi MeharNo ratings yet

- Damping RatioDocument2 pagesDamping RatioSravanthi MeharNo ratings yet

- Losses in Prestress-Friction, Anchorage SlipDocument16 pagesLosses in Prestress-Friction, Anchorage SlipSravanthi MeharNo ratings yet

- Design Principles Ar. Laurie BakerDocument17 pagesDesign Principles Ar. Laurie BakerPooja vijayNo ratings yet

- Pin-Fuse Joint FinalDocument10 pagesPin-Fuse Joint FinalShubham BeraNo ratings yet

- The Reference For More Than .: Quality 50 YearsDocument6 pagesThe Reference For More Than .: Quality 50 Yearsumuhuza salomonNo ratings yet

- BGS-AU-057 Rev B1Document21 pagesBGS-AU-057 Rev B1Allwyn AbrahamNo ratings yet

- Portal MethodDocument10 pagesPortal MethodDoer_91No ratings yet

- Design, Construction, and Field-Testing of An RC Box Culvert Bridge Reinforced With GFRP BarsDocument11 pagesDesign, Construction, and Field-Testing of An RC Box Culvert Bridge Reinforced With GFRP BarsHamza AldaeefNo ratings yet

- Types and Sizes of RebarsDocument17 pagesTypes and Sizes of RebarsWyncie CariñoNo ratings yet

- GFRC Cladding PanelsDocument6 pagesGFRC Cladding PanelsAtul DabasNo ratings yet

- Products Inc.: A Subsidiary of FC Industries, IncDocument2 pagesProducts Inc.: A Subsidiary of FC Industries, IncEdy AcuñaNo ratings yet

- RDC 2 - 24: P1 Section 15x30: A-A B-BDocument3 pagesRDC 2 - 24: P1 Section 15x30: A-A B-BDrancyNo ratings yet

- Design of Plate Girders As Per IS 800 2007-LSM - Unsupported - LatestDocument30 pagesDesign of Plate Girders As Per IS 800 2007-LSM - Unsupported - Latestmehdihasan80% (5)

- ENG 2020-1168-01 Calcs - Seren ParkDocument27 pagesENG 2020-1168-01 Calcs - Seren ParkMona GamalNo ratings yet

- VERNACULAR TERMS in Philippine Construction Flashcards - QuizletDocument6 pagesVERNACULAR TERMS in Philippine Construction Flashcards - Quizletmerla graceNo ratings yet

- sAMPLING eSTIMATEDocument16 pagessAMPLING eSTIMATEYsabelle TagarumaNo ratings yet

- Silo WallDocument5 pagesSilo WallMunish GaurNo ratings yet

- Rcc95 Continuous Beams (Tables)Document8 pagesRcc95 Continuous Beams (Tables)Steve JsobNo ratings yet

- Dispenser Island Civil BoqDocument3 pagesDispenser Island Civil Boqjay_p_shahNo ratings yet

- Selangor UBBL 1986Document175 pagesSelangor UBBL 1986Frankie Chan0% (1)

- Tensile Strength Behavior of Uhpc and Uhpfrc: SciencedirectDocument6 pagesTensile Strength Behavior of Uhpc and Uhpfrc: SciencedirectAkashNo ratings yet

- Metal Fatigue OverviewDocument59 pagesMetal Fatigue OverviewMahesh RajaNo ratings yet

- 1 Foundation Plan: Footing Schedule Reinf. Conc. ColumnDocument1 page1 Foundation Plan: Footing Schedule Reinf. Conc. ColumnJaymark SorianoNo ratings yet

- SteelDocument24 pagesSteelsaranya rNo ratings yet

- Group 2 Folded PlateDocument3 pagesGroup 2 Folded PlatePriya ChauhanNo ratings yet

- Small Moment Base Plate ExampleDocument5 pagesSmall Moment Base Plate ExampleHAFIZNo ratings yet

- RAB Serang Sumbersih KosonganDocument5 pagesRAB Serang Sumbersih KosonganMahdi M AliNo ratings yet

- Marriage Hall - DesignDocument85 pagesMarriage Hall - DesignMuhammad Shahid Hussain89% (9)

- ER288-Wp Concrete TestDocument1 pageER288-Wp Concrete TestalfieNo ratings yet

- Timber Engineering Step 2Document399 pagesTimber Engineering Step 2Colin Booth100% (2)

- ETABSDocument1 pageETABSJasser BerriosNo ratings yet

- DCC 3113 Nota Bab 10Document6 pagesDCC 3113 Nota Bab 10Alif KarimiNo ratings yet