Comparative Study On Partial Replacement of Rubber in Concrete

Comparative Study On Partial Replacement of Rubber in Concrete

Uploaded by

Prak BaCopyright:

Available Formats

Comparative Study On Partial Replacement of Rubber in Concrete

Comparative Study On Partial Replacement of Rubber in Concrete

Uploaded by

Prak BaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Comparative Study On Partial Replacement of Rubber in Concrete

Comparative Study On Partial Replacement of Rubber in Concrete

Uploaded by

Prak BaCopyright:

Available Formats

SSRG International Journal of Civil Engineering (SSRG-IJCE) – volume 4 Issue 3 – March 2017

Comparative study on Partial Replacement of

Rubber in concrete

Rohini.K#1, Anitha.N*2, Shanmuganathan.N#3, Dhavamani Doss.D4

B.E(Final Year students)1,2,Assistant Professor 3,4,

Department of Civil Engineering,S.K.P.Institute of Technology,Tiruvannamalai-606611,Tamilnadu.India

Abstract — This paper represent the study on strength, of landfills operations because of the bulkiness of the

properties and behavior of crumb rubber. The tires and their tendency to float to the surface with

concrete is one of the most widely used construction time. So many recycling methods for the rubber tire

material consists of cement, fine aggregate, coarse are carried according to the need from one of this

aggregate. Concrete is like a backbone of the process is making the tire rubber into crumb rubber .it

infrastructure to development of a nation. Generally is used in many work such as road construction mould

nowadays large quantity of rubber wastes are making etc... crumb rubber obtained by cryogenic

generated by the industries, vehicles etc...and they are process, milled tire rubbers treated with sodium

not properly disposed till now. These rubber wastes hydroxide solution to achieve a patter adhesion with

causes global warming. Hazardous waste materials the cement paste, scrap truck tire rubber ,tires tread

are being generated and accumulated in huge etc. The growth of rubber and plastic can be

quantities causing an increasing hazard to the considered non decaying materials that disturb the

environment. Hazardous materials can be considered surrounding environment. There is no doubt that the

non-decaying material accumulating with time. This increasing piles of tires create environmental concerns.

study deals with alternative solution for utilizing the The long term objective is to find a means to dispose

crumb rubber and its safe disposal by using it as of the crumb rubber in port land cement concrete and

partial replacement with fine aggregate for making still supply a final product with good engineering

concrete. properties. Therefore effectively reusing waste tires is

an urgent and important issue for saving energy and

Keywords— Crumb rubber, mechanical property, protecting the environment. The initial tire of crumb

durability, shredded tire, Ground rubber, slit tire, rubber was used as a asphalt. However the high

waste tire. viscosity and the higher temperature required in

I. INTRODUCTION production made in unpractical to be widely used.

The use of rubber product is increasing every year in From this study the effective utilization of rubber tire

worldwide. Almost 1000 million waste tires are waste as been developed and it made to used in the

generated in the world annually. By the year 2030 this concrete mixture as fine aggregate.

number of counting is expected to reach 1200million

At present the crumb rubber production in the

currently 75-80% of scrap tires are buried and landfills

south India is very less than north. So the material

only 25%or fewer are utilized as a fuel or as raw

availability was less because of less knowledge about

material for the manufacture of a number of

that. These can also include non-primary structural

miscellaneous rubber goods. It is not only wasteful but

applications of medium to low strength requirements

also costly. In 2014 approximately 22.4 million

benefiting from other features of this type of concrete

pounds of crumb rubber was used in synthetic turf

fields at California. Since 2008 20-25% crumb rubber 1.1Classification of tire: Tires are classified into

are produced in whole California. Tires are composed 4types they are slit tire, shredded tire or chipped tire,

of materials which do not decompose under ground rubber, and crumb rubber. Slit tires are

environmental conditions and cause serious produced in tire cutting machines. These machines can

contaminations. it is estimated that 285 million tires slit the tire into two halves or can separate the

are discarded annually in the United states and only sidewalls from the tread of the tires. Shredded tire or

30%(97million)are currently being used or recycled. chipped tires The old tires from cars, trucks, farm, off-

The remaining 66%(188 million)contribute to the road vehicles are used in this research. Shredded tires

already alarming environmental waste problem. are separated into two different category Pieces with

Disposal of whole tire has been banned in the majority dimensions not larger than 25mm.Pieces with

ISSN: 2348 – 8352 www.internationaljournalssrg.org Page 5

SSRG International Journal of Civil Engineering (SSRG-IJCE) – volume 4 Issue 3 – March 2017

dimensions not larger than 10mm.The shredded or content was investigated.Additionally, the effect of

chipped rubber are involved in two process. They are modifiers was evaluated. The mechanical property is

Primary and secondary shredding process. The size of vary from crumb rubber replacing fine aggregate to

replacing of mixture. Compared to the replacement of

the chips are vary from each process. The size of

mixture and replacing of crumb rubber the

primary shredding is can vary from large 300 to compressive strength value is vary from one to

460mm long by 100 to 230mm wide, to as small as another. Compressive strength for replacing of

100 to 150mm in length. And the secondary process mixture is higher than replacing of fine aggregate.

normal size 76mm to 13mm. Because replacement of mixture with Crumb rubber

reduced the mass of the cement.There are many

1.2 Types of Rubber: Ground rubber particles are reasons are available in lower strength of crumb

intermediate in size between tire chips and crumb rubber concrete. The first reason.The adhesion of

rubber. Ground rubber ranging in size vary from big rubber particles and cement paste is weaker than the

19mm as to small as 0.15mm.The is depends upon the mineral aggregate. Second reason the distribution of

size reduction equipment and intending application. rubber particles in the concrete mixture is non-

Ground rubber tire as asphalt binder, consuming on homogenous, why because compared to other

estimate 220million pounds, or approximately materials rubber have a lower specific gravity.Thirdly

12million tires.Crumb rubber is nothing but the fine the hydrophobic nature of rubber particles takes

granular or powdered particles is called crumb bubbles into the concrete mixture and increases the air

rubber.It is the processing of the tire into fine particles content. Due to the above reason mechanical strength

using cryogenic or mechanical process. This process is reduced when the crumb rubber is introduced into

is also used to remove the still and fabric component the concrete

of the tire crumb rubber ranging size vary from

4.75mm to less than 0.075mm. Generally 3 methods III. DURABILTIY AND APPLICATION OF CRUMB

are used to convert the waste tire into crumb rubber. RUBBER

Thus the methods are cracker mill process,granular Freezing-thawing resistance and sulfate resistance are

process, micro mill process.The cracker mill process is the important aspects of the durability of concrete. The

used to reduce the size of tire .the material are passing crumb rubber concrete had a good resistance against

between the rotating corrugated steel drums by this freezing-thawing compared to the normal

process used to an irregularly shaped torn particles concrete.There was more loss in compressive strength

having large surface. The size of these particles are for concrete less crumb rubber in sulfate

vary from 5mm to 0.5mm and are commonly known corrosion .Furthermore, the anti-corrosion coefficient

as ground crumb rubber. If the granular process shears gradually increased with the increase in percentage of

are using to rubber with revolving steel crumb rubber in concrete.The crumb rubber have

plates,producing the granulated rubber particle size more application.Some of the major application are

ranging vary from 9.5mm to 0.5mm used in Sport surface like Kindergarten playgrounds

and recreation areas,school sports areas,Tennis and

II. PROPERTIES OF CRUMB RUBBER Basketball courts, used in construction such as

Hanbing Liu et al(2016) says the Modifiers for the hospital, industrial and bathroom flooring,floor

pretreatment of crumb rubber ,including tire,foundation, waterproofing,dam,silo etc…,used in

emulsion,ethoxyline resin,synthetic resin,amino - Rubber and plastic products industries like pipe

acrylate(contact glue),chlorroprene adhesive and insulation and lining,garbagecans,shoe soles and

unsaturated resins(marble glue),they are commonly heels,wire cable insulation and in automotive industry

used in decoration and construction engineering.They Bumpers,splash guards and fenders,floor mats for cars

had satisfactory performance in improving adhesion and trucks,Floor liners for trucks and

and enhancing strength.Were directly introducing the vans.Comparison of Partial Replacement of various

crumb rubber in concrete. It will affect the mechanical rubber material by various research listed in table.1

properties and durability of concrete.But the variation

of properties in concrete with the changing of rubber

ISSN: 2348 – 8352 www.internationaljournalssrg.org Page 6

SSRG International Journal of Civil Engineering (SSRG-IJCE) – volume 4 Issue 3 – March 2017

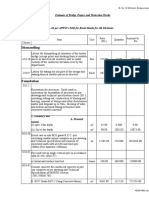

Table.1Comparison of Partial Replacement of various rubber material by various

research

S.No Author Title of the Journal Name Strength of Specimen

Name Paper Days Percentage Cube Cylinder Beam

(%) (N/mm2) (N/mm2) (N/mm2)

1 Er.Yongend An International Journal 0% 27.1 3.6 2.3

er Antil Experimental of Emerging 5% 25.3 2.8 2.1

Study on Technology and 7days 10% 19.5 1.5 2.0

Rubberized Advanced 15% 17.4 1.4 1.9

Concrete Engineering 20% 14.9 1.1 1.7

0% 36.2 4.6 3.4

5% 32.2 4.1 3.3

28days 10% 27.7 3.3 3.1

15% 24.8 2.8 2.9

20% 22.7 1.4 2.7

2 S.Selvakum Strength International Journal 0% 23.99 2.22 6.02

ar et Properties of of Innovative 5% 26.07 2.86 5.75

al.(2014) Concrete Using research in Science, 7days 10% 21.92 2.22 5.00

Crumb Rubber Engineering and 15% 18.65 2.01 4.96

with Partial Technology 20% 16.32 1.87 4.56

Replacement of

Fine Aggregate

0% 36.73 4.08 7.83

5% 38.66 3.50 7.01

28days 10% 33.47 2.96 5.83

15% 29.63 2.59 5.42

20% 22.17 2.17 5.00

3 A Mansoor Experimental International 0% 16.8 2.45 3.53

Ali Study on Conference on 5% 15.03 1.95 3.8

et.al.(2014) Concrete by Engineering Trends 7days 10% 14.10 1.76 4.64

Partial and Science 15% 12.74 1.48 3.6

Replacement &Humanities 20 10.22 1.24 3.12

Fine Aggregate

with crumb 0% 22 3.36 -

rubber 5% 20 2.76 -

14days 10% 18 2.38 -

15% 15 1.95 -

20% 13 1.41 -

0% 41.60 3.65 5.92

5% 36.14 2.94 6.53

28days 10% 35.11 2.47 6.73

15% 32.66 1.86 5

20% 29.33 1.43 4

4 Nithiya P Behavior of International Journal 0% 25.33 1.697 2.862

et.al.(2014) Partial of Structural and 5% 19.15 1.543 2.586

Replacement of Civil Engineering 7days 10% 13.44 1.432 1.577

Fine Aggregate Research 15% 9.88 1.216 0.875

with Crumb 20% 8.39 1.138 0.732

Rubber

ISSN: 2348 – 8352 www.internationaljournalssrg.org Page 7

SSRG International Journal of Civil Engineering (SSRG-IJCE) – volume 4 Issue 3 – March 2017

Concrete 0% 32.43 2.630 4.400

5% 26.56 2.462 3.982

28days 10% 21.94 2.134 2.433

15% 9.69 1.855 1.890

20% 8.01 1.734 1.724

5 Ameer Effect of Crumb Anbar Journal for 0%(FC) 10.08 1.12 2.24

Abdulrahma Tires Rubber on Engineering sciences 7days 20%(FCR1) 7.75 0.89 1.80

n Hilal Some 30%(FCR2) 5.38 0.62 1.27

Properties of

Foamed

0%(FC) 15.56 1.38 3.21

Concrete

21days 20%(FCR1) 10.83 1.11 2.03

30%(FCR2 8.67 0.78 1.59

0%(FC) 17.21 1.55 3.42

28days 20%(FCR1) 13.62 1.21 2.23

30%(FCR2 10.71 0.83 1.78

6 Abhijitsinh Use of Crumb Afro - Asian 5% 14.58 - 3.5

Parmar Rubber as a International 10% 14.26 - 3.5

et.al.(2015) Partial Conference on 7days 15% 13.98 - 3.5

Replacement of Science, Engineering 20% 13.73 - 3.5

Coarse & Technology 25% 13.56 - 3.5

Aggregate in 30% 13.42 - 3.5

Conventional

Concrete

5% 20.04 - 3.42

10% 19.76 - 3.38

28days 15% 19.06 - 3.32

20% 18.56 - 3.28

25% 18.08 - 3.22

30% 17.77 - 3.18

5% 20.12 - -

10% 19.84 - -

56days 15% 19.11 - -

20% 18.59 - -

25% 18.23 - -

30% 17.97 - -

7 Sunil N. Effect of American Journal of 7days 0% - 2.11 4.00

Shah Chipped Engineering Research 3% - 1.47 3.00

et.al.(2014) Rubber (AJER) 6% - 1.42 2.55

Aggregates on 9% - 1.19 1.26

Performance of 12% - 1.14 1.00

Concrete 28days 0% - 2.39 4.88

3% - 2.31 4.55

6% - 2.19 4.25

9% - 1.83 3.10

12% - 1.67 2.50

8 Dr.J K Experimental Journal of Civil With FRP

Dattatreya investigation of Engineering and 0% - 2.23 -

et.al.(2015) crumb rubber Environmental 5% - 1.98 -

concrete Technology 10% - 1.81 -

confined 15% - 1.63 -

By FRP sheets

ISSN: 2348 – 8352 www.internationaljournalssrg.org Page 8

SSRG International Journal of Civil Engineering (SSRG-IJCE) – volume 4 Issue 3 – March 2017

Without FRP

0% - 3.11 -

5% - 2.94 -

10% - 2.69 -

15% - 2.26 -

This paper is the collection of various papers or results

IV. CONCLUSIONS

regarding to the strength and properties of crumb

This study deals with the comparative study among rubber. Hence by using this paper one can easily

the mechanical properties, durability and application compare the results who wished to undertake the

of crumb rubber and it is used to effective utilization investigation on crumb rubber utilization on in

of tire rubber wastes are replacement with various concrete.

material in the conventional concrete of various grades.

V.REFERENCES

[1] Er. Yogender Antil, “An Experimental Study on Rubberized [8] Dr. J. K.Datterya,Suresh,Raghu.N.E,”Experimental study of crumb rubber

Concrete,” International Journal of Emerging Technology and Confined by FRP Sheets,” Journal of Civil

Advanced Engineering (ISSN 2250-2459), Volume 4, page 309-316. EngineeringandEnvironmental Technology,ISSN :2349-

[2]S.Selvakumar,R.Venkatakrishnaiah “Strength Properties of 879X,Volume 2.No 9,page 63-67

Concrete Using Crumb Rubber with Partial Replacement of Fine [9] Khalid Battel Najim and Matthew Robert Hall, “Workability

Aggregate,”International Journal of Innovative Research in and Mechanical Properties of Crumb Rubber Concrete,”,Institution

Science,Engineering and Technology(ISSN 2347-6710),Volume of Civil Engineers, construction Materials Volume 166,pages 7-17.

4,page 1171-1175. [10] Jaylina Rana and Reshma Ryghooputh, “Partial Replacement

[3] A. Mansoor Ali, and A. Saravanan, “Experimental study on of Fine Aggregate by Rubber in Concrete,” Journal of Emerging

partial replacement of fine aggregate with crumb rubber,” Trends in Engineering and Applied Sciences,(ISSN:2141-

International conference on Engineering Trends and Science & 7016),page 312-317.

Humanities (ICETSH-2015). [11] Amjad A.Yasin, “Using Shredded Tires as an Aggregate in

[4] Nithiya.P,Portchejian.G“Behavior of Partial Replacement of Concrete”Contemporary Engineering Sciences,Vol.5,2012,no.10,

Fine Aggregate with Crumb Rubber Concrete,” International page 473-480.

Journal of Strucural and Civil Engineering Research(ISSN 2319- [12] Hanbing Liu, Xianqiang Wang, Yubo Jiao and Tao sha,

6009),Volume 3, page 63-72. “Experimental Investigation of the Mechanical and Durability

[5] Ameer abdul rahman Hilal “Effect of crumb tyre rubber on some Properties of Crumb Rubber Concrete,” Article of MDPI.

properties of foamed concrete,” Anbar Journal of engineering [13] Richard Twumasi-Boakye, “Ground Tire Rubber as a

sciences (AJES-2011), Vol.4,No.2. component material In Concrete Mixtures For Paving Concrete,”

[6] Abhijitsinh Parmar,Chahil Joshi, Aditi Parmar, Urvish Patel The Florida State University Famu-Fsu College Of Engineering.

andAvadh Vaghasiya (2015), “Use Crumb Rubber as a Partial [14] Louis Berger, “Recycling and Reuse of Crumb Rubber Infill

Replacement of Coarse Aggregate in Conventional Concrete,” Used in Synthetic Turf Athletic Fields,” Article.

Asian International Conference on Science, Engineering & [15] Salman zafar, Production and Applications of Crumb

Technology (AAICSET-2015) ISBN: 9-780993-909238. Rubber,”Indusrtrial Waste Management,Recycling,Artical.

[7] Sunil. N. Shah,Pradip. D. Jadhao, S.M. Dumne, “Effect of

chipped rubber aggregates on performance of concrete” American

Journal of Engineering Reasearch , Vol-3,pg(93-101

ISSN: 2348 – 8352 www.internationaljournalssrg.org Page 9

You might also like

- How to Build a Global Model Earthship Operation I: Tire WorkFrom EverandHow to Build a Global Model Earthship Operation I: Tire WorkNo ratings yet

- Uses of Crumb Rubber and Natural Rubber BitumenDocument20 pagesUses of Crumb Rubber and Natural Rubber Bitumennishankgopishetty67% (3)

- Safety LeadershipDocument38 pagesSafety LeadershipPrak Ba100% (2)

- K K Chitkara - Construction Project ManagementDocument290 pagesK K Chitkara - Construction Project ManagementPrak Ba76% (21)

- Capstone ProjectDocument34 pagesCapstone ProjectKristle R Bacolod100% (2)

- Jaswanth Document OrgDocument54 pagesJaswanth Document OrgNaga KiranNo ratings yet

- RubcreteDocument20 pagesRubcretemanjima anil100% (1)

- Jsjsjs PDFDocument17 pagesJsjsjs PDFKlisman A. Flores DurandNo ratings yet

- 2023 V14i260Document11 pages2023 V14i260D. AnweshNo ratings yet

- Use of Waste Rubber Tyres in Construction of Bituminous Road - An OverviewDocument3 pagesUse of Waste Rubber Tyres in Construction of Bituminous Road - An OverviewInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- J Conbuildmat 2017 02 107Document7 pagesJ Conbuildmat 2017 02 107Jerson SotoNo ratings yet

- Partial Replacement of Discarded Rubber Tyres With Coarse AggregateDocument18 pagesPartial Replacement of Discarded Rubber Tyres With Coarse AggregatePrasanna Gayathri VinnakotaNo ratings yet

- Rubcrete, Use of Rubber in ConcreteDocument6 pagesRubcrete, Use of Rubber in Concreterahuldasbi100% (1)

- Use of Waste Tyre Rubber in A Partial Replacement of Aggregate in ConcreteDocument54 pagesUse of Waste Tyre Rubber in A Partial Replacement of Aggregate in ConcreteDurgesh PardeshiNo ratings yet

- Ijciet 09 07 094Document10 pagesIjciet 09 07 094DINESH KUMARNo ratings yet

- Concrete Aggregates From Discarded Tyre RubberDocument6 pagesConcrete Aggregates From Discarded Tyre RubberRussell JosephNo ratings yet

- .Experimental Study On Use of Waste Rubber Tyres in Road PavementDocument2 pages.Experimental Study On Use of Waste Rubber Tyres in Road PavementZeyad Tareq Al SaroriNo ratings yet

- A Study On Crumb Rubber: Opportunities For Development of Sustainable Concrete in The New MillenniumDocument2 pagesA Study On Crumb Rubber: Opportunities For Development of Sustainable Concrete in The New MillenniummurkyNo ratings yet

- Rubber 7Document13 pagesRubber 7بسام دبورNo ratings yet

- A Study On Crumb Rubber: Opportunities For Development of Sustainable Concrete in The New MillenniumDocument2 pagesA Study On Crumb Rubber: Opportunities For Development of Sustainable Concrete in The New MillenniumNipuna WanninayakeNo ratings yet

- Effect of Using Ground Waste Tire Rubber As Fine Aggregate On The Behaviour of Concrete MixesDocument9 pagesEffect of Using Ground Waste Tire Rubber As Fine Aggregate On The Behaviour of Concrete MixesMaridil IsidroNo ratings yet

- Crumb Rubber Modified Bitumen and Quarry Dust in Flexible PavementsDocument7 pagesCrumb Rubber Modified Bitumen and Quarry Dust in Flexible PavementsaiplNo ratings yet

- Case Studies in Construction Materials: Najib N. Gerges, Camille A. Issa, Samer A. FawazDocument16 pagesCase Studies in Construction Materials: Najib N. Gerges, Camille A. Issa, Samer A. FawazAkshaykumar IngleNo ratings yet

- A Study On Crumb Rubber: Opportunities For Development of Sustainable Concrete in The New MillenniumDocument3 pagesA Study On Crumb Rubber: Opportunities For Development of Sustainable Concrete in The New MillenniumSaadiya Saeed AnsariNo ratings yet

- Experimental Study On Comparison of Conventional Concrete With Waste Rubber Tyre ConcreteDocument17 pagesExperimental Study On Comparison of Conventional Concrete With Waste Rubber Tyre ConcreteMr KalyanNo ratings yet

- Akshay Final 2Document43 pagesAkshay Final 2Durgesh PardeshiNo ratings yet

- Project Proposal: Study On Waste Tyre Rubber As Concrete AggregatesDocument7 pagesProject Proposal: Study On Waste Tyre Rubber As Concrete AggregatesshuhaibNo ratings yet

- Study On Crumb Rubber Concrete Using Ggbs & Nano-Tio: Shreyas L. BedagkarDocument7 pagesStudy On Crumb Rubber Concrete Using Ggbs & Nano-Tio: Shreyas L. BedagkarAniruddha DalviNo ratings yet

- Utilization of Rubber Waste in Construction of Flexible PavementDocument8 pagesUtilization of Rubber Waste in Construction of Flexible Pavementathirah mfNo ratings yet

- TSP JRM 22846Document32 pagesTSP JRM 22846karima GadriNo ratings yet

- Waste Management: Arin Yilmaz, Nurhayat DegirmenciDocument6 pagesWaste Management: Arin Yilmaz, Nurhayat DegirmenciYeluri Sesha ChoudaryNo ratings yet

- IJTE - Volume 6 - Issue 2 - Pages 99-110Document12 pagesIJTE - Volume 6 - Issue 2 - Pages 99-110Jelian GraceNo ratings yet

- Use of Recycled Rubber-2669Document38 pagesUse of Recycled Rubber-2669Aravind kumarNo ratings yet

- Partial Replacement of Coarse AggregateDocument8 pagesPartial Replacement of Coarse AggregateNgala KennethNo ratings yet

- 1 s2.0 S2090447917301132 MainDocument10 pages1 s2.0 S2090447917301132 MainAravind kumarNo ratings yet

- Template GJRADocument3 pagesTemplate GJRATahseenNo ratings yet

- Template IJSRDocument3 pagesTemplate IJSRDanielNo ratings yet

- To Modify The Properties of Concrete by Using Rubber Crumb & Ceramic Waste, Prof. Manish Sudhakarrao DeshmukhDocument11 pagesTo Modify The Properties of Concrete by Using Rubber Crumb & Ceramic Waste, Prof. Manish Sudhakarrao Deshmukhmukesh poundekarNo ratings yet

- Used of Recycled Tyre/Rubber As Course Aggregate and Stone Dust As Fine Aggregate in Cement Concrete WorksDocument7 pagesUsed of Recycled Tyre/Rubber As Course Aggregate and Stone Dust As Fine Aggregate in Cement Concrete WorksIOSRjournalNo ratings yet

- IJCRT2204686Document7 pagesIJCRT2204686DINESH KUMARNo ratings yet

- Design and Fabrication of Rubber TIre Recycling MachineDocument31 pagesDesign and Fabrication of Rubber TIre Recycling Machinerynsasa191No ratings yet

- PROJECTDocument24 pagesPROJECTMr Kalyan100% (1)

- Saurabh Project File (Waste Tyre Road)Document27 pagesSaurabh Project File (Waste Tyre Road)ÃjâY Sîñgh ÇhãûhâñNo ratings yet

- 7 Recycling of Waste Tire Rubber in Asphalt and Portland Cement Concrete An OverviewDocument8 pages7 Recycling of Waste Tire Rubber in Asphalt and Portland Cement Concrete An OverviewkusmiraNo ratings yet

- An Overview of Crumb Rubber Modified Asphalt: International Journal of Physical Sciences September 2011Document6 pagesAn Overview of Crumb Rubber Modified Asphalt: International Journal of Physical Sciences September 2011zamani1No ratings yet

- The Survey On: Data Mining Data Warehousing & OLAPDocument5 pagesThe Survey On: Data Mining Data Warehousing & OLAPEditor IJRITCCNo ratings yet

- Use of Waste Tyre in Road ConstructionDocument19 pagesUse of Waste Tyre in Road ConstructiondhanrajramotraNo ratings yet

- Literature Review On Concrete Containing Crumb Rubber - Bharuch2k15c0107 - (Pg. 22-24)Document3 pagesLiterature Review On Concrete Containing Crumb Rubber - Bharuch2k15c0107 - (Pg. 22-24)Er Devraj Khandelwal67% (3)

- Improving Properties of Granular Soil Using Waste MaterialsDocument67 pagesImproving Properties of Granular Soil Using Waste MaterialsArmaan GuptaNo ratings yet

- An Experimental Investigation On PartialDocument5 pagesAn Experimental Investigation On PartialAzhar MohamedNo ratings yet

- Using Recycled Waste Tyre in Concrete Paving BlocksDocument14 pagesUsing Recycled Waste Tyre in Concrete Paving BlocksTung-Chai LingNo ratings yet

- Rubberized ConcreteDocument8 pagesRubberized ConcreteAman VermaNo ratings yet

- Use of Reclaimed Rubber Cell in Highway Pavement: An Experimental ResearchDocument6 pagesUse of Reclaimed Rubber Cell in Highway Pavement: An Experimental ResearchHazbullah ShajiNo ratings yet

- 2012 An Overview of Crumb Rubber Modified AsphaltDocument6 pages2012 An Overview of Crumb Rubber Modified Asphaltramudu oneNo ratings yet

- Checked ICRT2017 17IT070157 Final Version FernanDocument15 pagesChecked ICRT2017 17IT070157 Final Version FernanMD. NASIF HOSSAIN IMONNo ratings yet

- Use of Waste Tyres in Road ConstructionDocument11 pagesUse of Waste Tyres in Road Constructionvotetorecieve 1100% (1)

- Experimental Investigation On Partial Replacement of Aggregates in Concrete Using Ceramic and Tyre WastesDocument5 pagesExperimental Investigation On Partial Replacement of Aggregates in Concrete Using Ceramic and Tyre WastesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 3.3 Use of Waste Tyres For Road ConstructionDocument26 pages3.3 Use of Waste Tyres For Road Constructionvrrrru100% (2)

- Applied Sciences: Ffect of Addition of AntioxidantDocument23 pagesApplied Sciences: Ffect of Addition of AntioxidantUlikersSportNo ratings yet

- Pub2 Bekhiti Trouzine 2014Document5 pagesPub2 Bekhiti Trouzine 2014ajiNo ratings yet

- How To Sand Your Own Timber Floor: The Ultimate DIY Guide With PicturesFrom EverandHow To Sand Your Own Timber Floor: The Ultimate DIY Guide With PicturesNo ratings yet

- Ap Building Penalization SchemeDocument27 pagesAp Building Penalization SchemePrak BaNo ratings yet

- Ap BPS Power Point PresentationDocument1 pageAp BPS Power Point PresentationPrak BaNo ratings yet

- Cata Exhaust FansDocument40 pagesCata Exhaust FansPrak BaNo ratings yet

- Flight Ticket - Vijayawada To Bangalore: Fare Rules & BaggageDocument2 pagesFlight Ticket - Vijayawada To Bangalore: Fare Rules & BaggagePrak BaNo ratings yet

- Contaminant Transport Through Landfill LinersDocument7 pagesContaminant Transport Through Landfill LinersPrak BaNo ratings yet

- Is 4997-1968Document22 pagesIs 4997-1968Prak BaNo ratings yet

- Geotechnical Reuse of Waste MaterialnewDocument42 pagesGeotechnical Reuse of Waste MaterialnewPrak BaNo ratings yet

- Leachate Collection System Design Unit - 2Document21 pagesLeachate Collection System Design Unit - 2Prak BaNo ratings yet

- Industrial Waste CharecteristicsDocument10 pagesIndustrial Waste CharecteristicsPrak BaNo ratings yet

- June 2016 Review Annexure - DDocument5 pagesJune 2016 Review Annexure - DPrak BaNo ratings yet

- NCR - Embankment and Base Course Prices - PHILCON PRICESDocument5 pagesNCR - Embankment and Base Course Prices - PHILCON PRICESGueanne ConsolacionNo ratings yet

- 1 s2.0 S095965261830742X MainDocument20 pages1 s2.0 S095965261830742X MainHassan juttNo ratings yet

- Astm d3515-01 Standart Specif HmaDocument18 pagesAstm d3515-01 Standart Specif HmagamaNo ratings yet

- ASTM C1634-15 Concrete Facing BrickDocument3 pagesASTM C1634-15 Concrete Facing BrickPatrick DimaculanganNo ratings yet

- Precast Concrete CurbsDocument3 pagesPrecast Concrete Curbsgskodikara2000No ratings yet

- Irc 063-1976Document9 pagesIrc 063-1976kruttika_apNo ratings yet

- Dismantling: Estimate of Bridge Proper and Protection WorksDocument11 pagesDismantling: Estimate of Bridge Proper and Protection WorksHoque joynulNo ratings yet

- SEMINARDocument18 pagesSEMINARFathima AfeefaNo ratings yet

- Reckli en Concrete-Surface-RetarderDocument21 pagesReckli en Concrete-Surface-RetarderssekbanNo ratings yet

- Farm To Market Road Terms DefinitionsDocument17 pagesFarm To Market Road Terms Definitionscara vistaNo ratings yet

- C1492Document7 pagesC1492jaysonpaulb.bulosanNo ratings yet

- 3 ConcreteWorksDocument19 pages3 ConcreteWorksMuhammad AgungNo ratings yet

- Understanding Nominal and Design Mixes of ConcreteDocument3 pagesUnderstanding Nominal and Design Mixes of ConcreteTwinkleNo ratings yet

- BS PD 6682-1-2003 PDFDocument22 pagesBS PD 6682-1-2003 PDFyahNo ratings yet

- Materials Engineer Accreditation Examination March 11, 2006: Not Exceeding 45 MinutesDocument3 pagesMaterials Engineer Accreditation Examination March 11, 2006: Not Exceeding 45 MinutesHenry SyNo ratings yet

- MASOP307 Opening Fixation AID in PRDocument56 pagesMASOP307 Opening Fixation AID in PRKENNY -IgishinwaNo ratings yet

- NIT Schedule For Balance Work For Construction of New High School Building at Hardi (Bolck Nawagarh) I/c Water Supply & Sanitary PAC Rs.-38.89 LakhsDocument12 pagesNIT Schedule For Balance Work For Construction of New High School Building at Hardi (Bolck Nawagarh) I/c Water Supply & Sanitary PAC Rs.-38.89 LakhsAri RangelNo ratings yet

- FS Ss-S-200eDocument23 pagesFS Ss-S-200eGiorgos LympertasNo ratings yet

- IGL - C&D Waste Management-Mr Aditya Gurudanti12Document3 pagesIGL - C&D Waste Management-Mr Aditya Gurudanti12nilueNo ratings yet

- Rocas y Minerales Industriales - Es.enDocument34 pagesRocas y Minerales Industriales - Es.enYeber Magno MoralesNo ratings yet

- User's Surface: Guide: Double Bituminous TreatmentDocument26 pagesUser's Surface: Guide: Double Bituminous TreatmentShoyeeb AhmedNo ratings yet

- Module 1 Conmatls Chapter 4Document10 pagesModule 1 Conmatls Chapter 4Kriselle DulayNo ratings yet

- Combined NBCDocument622 pagesCombined NBCDinesh GuptaNo ratings yet

- AA Bridge 91500Document16 pagesAA Bridge 91500kplhooda24No ratings yet

- Minimum Material Testing RequirementsDocument34 pagesMinimum Material Testing RequirementsMark James MateoNo ratings yet

- Civil Engg Materials Lab ManualDocument34 pagesCivil Engg Materials Lab ManualAli RazaNo ratings yet

- Code Description Unit Quantity Rate Amount: Sub Head: 16-Road WorkDocument2 pagesCode Description Unit Quantity Rate Amount: Sub Head: 16-Road WorkSanjan Sameer100% (1)

- Sustainable Shotcrete UsingDocument6 pagesSustainable Shotcrete UsingFabiano MoraisNo ratings yet

- Block 74-A Champawat-A - SoR - MORTHDocument71 pagesBlock 74-A Champawat-A - SoR - MORTHBHAWAN BISHTNo ratings yet