Vehicle Pre-Trip Inspection: Section

Vehicle Pre-Trip Inspection: Section

Uploaded by

Budi KurniawanCopyright:

Available Formats

Vehicle Pre-Trip Inspection: Section

Vehicle Pre-Trip Inspection: Section

Uploaded by

Budi KurniawanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Vehicle Pre-Trip Inspection: Section

Vehicle Pre-Trip Inspection: Section

Uploaded by

Budi KurniawanCopyright:

Available Formats

Section 5

Vehicle Pre-trip

Inspection

Professional Driver’s Manual • 107

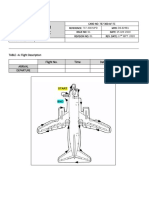

Pre-trip Circle Check Illustration

When preparing for the pre-trip circle check practical examination you must study the indepth information

in the following pages.

1 Approaching the vehicle 4 Driving compartment

4 f

a. Vehicle body for damage a. Seat and seat belts

b. Under vehicle for fluid leaks b. Mirrors

c. Wheels blocked c. Windshield wiper and washer

d. Horn

2 Parking brake set e. Lights

f. Steering wheel free play

3 Under the hood g. Gauges and warning lights

a. Fluid levels h. Accelerator pedal

Power steering fluid i. Heater and defroster 4

Oil j. Windshield and

windows

Coolant

b

Windshield washer fluid

b. Drive belts

c. Radiator

d. Hoses and components b

e. Frame rails and cross members

b

3 a, b, d 3 2

6 a,b

3 d

c, d, e, f, g h, i, j k,l,m c, d, f, g c, d, f, g

7

6 Walk-around c. Tires i. Safety inspection

sticker

a. Grill and front bumper, licence d. Rims, spacers and fasteners

plate e. Hub oil j. Fuel tanks, brackets,

b. Headlights (high and low steps and caps

f. Suspension

beam), k. Batteries

springs

clearance lights, l. Exhaust system

mounting hardware

identification lights, m.Cab securement

suspension components

taillights, n. Load securement

air suspension system

stop lights, (air leaks) o. Side of vehicle for damage

side marker lights, g. Frame rails and cross members p. Rear tailgate/doors

licence plate light, h. Doors, windows, grab handles q. Underride protection

reflectors, and mirrors r. Landing supports

hazard lights and turn signals s. Sliding bogie locking bars

108 • Professional Driver’s Manual

4 g 5 Emergency equipment 5 a-c

a. Flags, flares or reflectors

b. Fire extinguisher

c. First aid kit

b b

g, v

q

b n, 0

g, r c, d, e, f, g c, d, e, f, g

6 f 7 Trailer hitch 7 a 7 b

a. Fifth wheel

b. Plate and kingpin

Professional Driver’s Manual • 109

Checking a vehicle before starting out, as required

Vehicle Condition by law, will often prevent costly delays as well as

Every driver of a commercial motor vehicle and some reduce the chances of an accident resulting from a

private use vehicles must carry out and log an inspection mechanical failure.

as outlined in The Highway Traffic Act and its Regulations.

Carrying out an efficient pre-trip inspection in

A commercial motor vehicle is:

a minimum of time can be done by drivers who follows

a. a motor vehicle with a GVWR of 4,500 kg or a systematic inspection.

more that is a public service vehicle or

For information on commercial motor vehicle and trailer

commercial truck;

trip inspections contact Transportation Regulation.

b. a bus with a seating capacity of 11 or more,

including the driver, that is used for

transportation of persons or property on

Pre-Trip Circle Check

a highway for gain or compensation; or Examination

c. a school bus. For Class 1, 2, 3 including pick-up trucks with a trailer

over 4540 kg’s and Class 4 (buses) the applicant will

The inspection will take place before the vehicle’s first

be required to complete a pre-trip circle check on the

trip of the day, and if a trip lasts more than one day,

vehicle they supply as part of the road test. During the

before the trip begins on the first day, and no later

pre-trip, the applicant must be able to locate, identify

than the first rest stop on the second and every

and check the items or components as set out in

subsequent day.

this manual. Inadequately completing the pre-trip

Regardless of the maintenance policies of companies and/or air brake inspection will result in the

or vehicle owners, all drivers must be capable of discontinuance and failure of the road test.

determining if their vehicle is in safe operating

An applicant is expected to complete the pre-trip circle

condition as outlined in The Highway Traffic Act

check in a systematic manner to conserve time.

and its Regulations.

The pre-trip inspection should take no more than

A person who carries out a vehicle pre-trip inspection

20 minutes to complete.

must make a trip inspection report in legible writing

that contains the following: Details of a pre-trip circle check will vary depending

on the vehicle being inspected, however, the principle

1. The licence plate number or unit number of

of making the pre-trip circle check should always

the vehicle and any trailer towed by it.

be followed.

2. The date of inspection.

If a vehicle is equipped with hydraulic brakes, an

3. A list of any safety defects. hydraulic brake system inspection as outlined in area H

at the end of this section, must be completed in

4. If no items are defective or required to be reported

conjunction with the pre-trip inspection.

on the vehicle or any trailer towed by it,

a statement to that effect. If a vehicle is equipped with air brakes, an air brake

inspection will be conducted in conjunction with the

5. The name and signature of the person who

pre-trip inspection. All applicants operating air brake

carried out the inspection.

equipped vehicles will be required to complete the air

If a driver believes or suspects that there is a safety defect brake system pre-trip inspection as outlined in the

they must report that belief or suspicion to the carrier. Air Brake Manual.

If the defect poses an unreasonable risk it must be

Note: When upgrading your driver’s licence from single

reported immediately. Any other case must be reported

to combination vehicles with air brakes, you will be

in a timely manner.

required to demonstrate the complete air brake steps for

Every commercial vehicle driver must have a current combination vehicles.

trip inspection report in their possession for the vehicle

Inadequately completing the pre-trip and/or air brake

and any trailer attached.

inspection will result in the discontinuance and failure

of the road test.

110 • Professional Driver’s Manual

All Vehicles Class 1, 2, 3, and Class 4 Buses

Inspect Inspection Method Report if

1. Approach vehicle and check:

1.1 Vehicle body for damage Visual Damaged.

1.2 Under vehicle for fluid leaks Visual Excessive fluid leaks.

2. Enter driving compartment and check:

2.1 Park brake is applied Visual Apply if not on.

3. Engine compartment, check:

3.1 Fluid levels to ensure adequate: Visual and Manual If levels are low fill adequately.

power steering fluid, oil, coolant

(do not remove radiator cap if hot),

transmission fluid, windshield washer fluid,

brake fluid if hydraulic brake system.

3.2 Drive belts for tension, cracking and wear. Visual and Manual Belt deteriorated or loose.

3.3 Radiator for leaks and security. Visual and Manual Leaks or loose.

3.4 Hoses and components for wear and leaks. Visual and Manual Leaks or deteriorated.

3.5 Frame rails and cross members for cracks Visual Insecure, cracked or broken.

and bending.

4. Driving compartment, check:

4.1 Seat and seat belt is adjusted and in Visually check that the seat Seat is damaged or distorted.

good shape. is anchored. Manually operate Seat fails to maintain selected

the seat and ensure adjustment adjustment. Any damage

is correct. Visually and that may reduce the

manually check seat belt effectiveness of the seat belt.

webbing and retractor

assembly.

Professional Driver’s Manual • 111

Inspect Inspection Method Report if

4.2 Turn key on: system check, start engine, Visual Warning lights or gauges

observe gauges and warning lights are not operating.

functioning properly.

4.3 Accelerator pedal for binding or sticking. Perform test with engine idling: Pedal binding; or engine will

depress accelerator pedal and not return to idle.

release.

4.4 Steering free play is not excessive. Visually and manually inspect Total movement greater than

with the engine running on shown in the following table.

vehicles equipped with power

Truck

steering. With the front wheels

in a straight ahead position, Steering wheel Steering lash

turn the steering wheel until Diameter power/manual

turning motion can be observed

Less than 50 mm/75 mm

at the front wheels, turn the

406 mm (16") (2.0")/(3.0")

steering wheel in the opposite

direction until motion can 406 mm to 75 mm/87 mm

be observed at the front wheels; 500 mm (3.0")/(3.5")

estimate the amount of steering (16")/(20")

lash. (Total movement observed

larger than 87 mm/100 mm

at steering wheel rim before

500 mm (20") (3.5")/(4.0")

movement at front wheel.)

Bus

less than 45 mm

300 mm

350 mm to 50 mm

400 mm

400 mm to 55 mm

450 mm

450 mm to 60 mm

500 mm

larger than 87 mm

500 mm

112 • Professional Driver’s Manual

Inspect Inspection Method Report if

4.5 Horn is working and audible. Activate system Horn fails to sound or is below

a reasonable audible level.

4.6 Windshield wipers and washer operation. Visual and Manual Windshield wipers fail to wipe

approximately 75% of the

windshield or contact the

windshield properly or return

to the “park” position.

Windshield washer fails to

apply solution to intended area

of the windshield.

4.7 Heater/defroster operation. Activate system Defroster motor fails to operate

in all selected positions.

Airflow over intended area

is not present.

4.8 Instrument lights are operational. Visual and Manual Not operating.

Turn signal indicators operational.

High beam indicator operational.

4.9 Condition and cleanliness of windows Visual Star or chip 12.7 mm (1/2") or

and windshield. greater in diameter; or any

intersecting cracks in glass

area, swept by windshield

wiper; or driver vision is

obscured or limited.

4.10 Adjustment and cleanliness of exterior Visual Insecure or obstructed or fails

and interior mirrors. to provide a clear view of

highway to the rear. Any mirror

that fails to maintain set

adjustment. Clouded as to

obscure vision.

5. Emergency equipment check:

5.1 Flags, flares or reflectors are present Visual Advanced warning device(s)

(if applicable). missing or broken.

5.2 Fire extinguisher is charged and stowed Visual Fire extinguisher missing

correctly (if applicable). or discharged (applicable

vehicles.)

5.3 First aid kit is present (if applicable). Visual First aid kit is missing or seal

broken (applicable vehicles.)

6. Outside checks:

6.1 Grill and front bumper are secure, Visual and Manual Loose or broken, plates

licence plate(s) valid and clean. not valid.

Professional Driver’s Manual • 113

Inspect Inspection Method Report if

6.2 Headlights (high and low beam), clearance Visually and manually inspect Any light is missing or

lights, identification lights, taillights, the operation of all the lights, broken or fails to illuminate

stop lights, side marker lights, licence plate except the hazard lights, with when its control device is

light, reflectors, reflective marking, hazard the vehicle engine running and actuated; or any lens or

lights and turn signals are operational the headlights, brake lights and reflector is broken,

and clean. all auxiliary lights illuminated; cracked or missing, reflective

inspect hazard lights with the markings missing.

ignition, headlights, brake lights

and auxiliary lights in the off

position, reflective marking

present on side and rear of

vehicle/trailer.

6.3 Front tires for cuts, bulges, air pressure, and Visual and Manual Any cords exposed due to

tread depth (not less than 3.2mm on front wear or damage; or evidence

steering tires). Rear tires for cuts, bulges, of tread separation or low air

air pressure, tread depth (not less than 1.6mm pressure. Insufficient tire

on rear tires), and no debris between dual tires. tread depth. Any abnormal

bump or bulge.

6.4 Mudflaps for security and condition. Visual Torn, insecurely mounted,

missing or not the full width

of the tire track. The lower end

of the mudflap is more than

than 350 mm (14") from the

ground.

6.5 Rims for cracks and slippage, spacers for Visual and Manual Rim bent, loose or cracked,

cracks or not seated properly, fasteners for or mounting holes elongated.

tightness, and hub oil level is adequate Spacers cracked or not seated

(if applicable). properly, fasteners loose,

missing, cross threaded or not

flush with the stud. Wheel or

lock rim assembly show signs

of cracking or severe damage.

Hub oil low.

6.6 Suspension for cracked or broken parts, Visually inspect for noticeable Broken springs or mounting

deflated or leaking airbags. sag or lean. hardware or deflated or

leaking airbag.

6.7 Frame rails and cross members for cracks Visual Insecure cracked or broken.

or bending.

6.8 Door(s), window(s), grab handles and mirror(s) Visual Insecure or obstructed; or fail

for security and provide a clear view. to provide a clear view.

6.9 Safety inspection decal is valid, clean and Visual No decal present or expired

visible (if applicable). decal.

114 • Professional Driver’s Manual

Inspect Inspection Method Report if

6.10 Fuel tank brackets or straps, steps and cap(s) Visual Cap missing, tank or lines

for security, and fuel lines for leaks. leaking or insecure.

6.11 Batteries for security and loose electrical Visual and Manual Loose.

connections.

6.12 Exhaust system and muffler for leaks Visually inspect with engine Any leaks.

and security. running.

6.13 Cab securement and suspension: Visually and manual inspect Cab not secure, air leak,

cab securely mounted, cab mounted (air pressure at normal air bag not inflated or bruised,

air bags and lines for leaks, shocks secure operating pressure). cab tilts to one side, shock

and not leaking. missing, broken leaking

or mounts loose.

6.14 Load securement, side and bottom doors, Visual and Manual Attachment points are cracked,

attachment points and securement elongated or broken.

equipment (chains, wire rope, webbing Securement equipment is

hooks, binders, etc.) stretched, cracked, broken or

inadequate strength or

insufficient tie-down

assemblies.

6.15 Sides of vehicle for damage or load for shifting Visual Any exterior body panel that

(if applicable). is damaged or deteriorated so

that it constitutes a hazard.

Any compartment door that

is loose or has missing or

detached holding fixtures.

Load must be properly secured

before moving.

6.16 Rear tailgate/door(s) securely closed. Visual If cannot securely close.

6.17 Underride protection or rear bumper is secure Visual Insecure, broken or protruding

(if applicable). and is hazardous.

Footnote: For vehicles with hydraulic brakes see section H. Buses see section 8.

7. Additional checks for Combination Vehicle:

7.1 Fifth wheel: The trailer is sitting properly on Visual Cracked or insecurely

the fifth wheel, the locking handle is locked mounted; any weld that

and the fifth wheel jaws are locked around the is broken or latch lock that

kingpin of the trailer. Fifth wheel slide locks is inoperative, or eye or lunette

are fully locked and not damaged. Connections worn more than 9.5 mm (3/8").

other than fifth wheel: coupling devices are

locked and securely mounted, all safety chains

are attached securely.

7.2 Electrical cord is properly connected, Visual Insecure, broken or protruding

in good condition and stowed properly. and is hazardous.

7.3 Trailer safety inspection decal is valid, Visual No decal present or expired

clean and visible, (if applicable). decal.

Professional Driver’s Manual • 115

Inspect Inspection Method Report if

7.4 Landing supports are in the up position and Visual Place in the up position and

the crank handle is stowed properly. Check stow handle correctly. Any

for any damage to the loading supports damage.

and structure.

7.5 Sliding bogie locking bars or pins are secure Visual Locking bars or pins are

and not damaged. not secure or damaged.

7.6 Spare tire for security and condition Visual Not secure or condition (see 6.3).

(if applicable).

7.7 Trailer licence plate for validity. Visual Licence not valid.

8. Additional checks for Buses:

8.1 All interior lights are operational. Visual Not working.

8.2 Aisle and stairwell lights are operational. Visual Not working.

8.3 Passenger seats and handrails for security. Walk the full length of the Any seat or attaching fixture

interior of the bus, observe seat that has a defect that may

assemblies and attaching fixtures constitute a hazard to any

as well as stanchion bars. person. Any stanchion bar

that is not attached in its

intended receptacle and

presents a hazard to any person.

8.4 Emergency exits and warning buzzer are Visual and Manual Visibly damaged or not

operational from inside and outside working.

(if applicable).

8.5 Service door control is functional. Activate entrance and exit door Any door that fails to function

control mechanism. as intended. Brake or

brake/accelerator interlock

system fails to function as

intended. Interlock system fails

to release when doors are

closed and locked.

8.6 Additional auxiliary heaters or Manual Does not blow air in desired

air conditioners are operational. location.

116 • Professional Driver’s Manual

Inspect Inspection Method Report if

8.7 Interior condition of bus, floor, dash, steps, Visual Interior body panels are

windows and operator’s compartment. damaged and present a hazard

to any person. Floor is damaged

or worn and presents a hazard

to any person. Dash area has

defects that present a hazard to

any person. Steps are not clean

and in good condition to

prevent tripping or slipping.

Windows are not free from

cracks or damage that may

present a hazard to any person.

Window latches and emergency

release hardware are not

present or in good condition.

Operator’s compartment has

defects that may cause a hazard

to the operator.

8.8 Wheelchair lift and kneeling feature or wheel With engine running, cycle Audible alarm fails to function.

chair ramp are operational, (if applicable). wheelchair lift, lower and raise Lift safety devices fail to

kneeling bus or deploy ramp. function as intended. Lift

does not complete cycle.

Interlock system fails to

activate and release as

intended. Bus does not return

to level position after kneeling.

8.9 Wheelchair restraints are operational and Visual and Manual Restraint missing or

secure, (if applicable). inoperative.

Hydraulic brake system inspection

Complete the brake check for vehicles with hydraulic brake system, as follows:

H.1 Electric motor (brake assist) With the vehicle engine stopped, Electric motor fails to operate.

(if applicable) apply moderate pressure to the

service brake pedal, electric motor

operating should be audible.

H.2 Vacuum boost operation (if applicable) With the engine stopped, depress Brake pedal fails to move.

the service brake pedal several

times to eliminate vacuum, then

with light foot pressure on the

pedal (12 kg or 25 lbs) start the

engine.

Professional Driver’s Manual • 117

Inspect Inspection Method Report if

H.3 Brake warning indicator Visually inspect and apply service Brake warning indicator lamp

(with parking brake released) brake pedal. operates continuously or when

brake is applied.

H.4 Brake pedal reserve Test with the engine running if Pedal moves towards the floor

the vehicle is equipped with more than 65%.

power brakes; apply and maintain

a moderate foot force to the service

brake pedal for one minute.

H.5 Park brake Apply parking brake and, with Park brake fails to hold vehicle.

engine running at an idle and

the transmission engaged,

attempt to move the vehicle.

H.6 Brake performance Move the vehicle forward and Brake pull exists or brake

apply the service brakes. Also performance appears to be

move vehicle ahead and less than adequate.

apply electric trailer brakes

(if applicable).

118 • Professional Driver’s Manual

NOTES:

Pre-trip Circle Check

• If a vehicle is equipped with air brakes,

Tear Out Sheet an air brake inspection will be conducted in

You may use this checklist for your test. Do not add to, conjunction with the pre-trip inspection. All

or write on this form. If altered it cannot be used on applicants operating air brake equipped

the test. The Professional Driver’s Manual has specific vehicles will be required to complete the air

inspection information that must be studied prior to brake system pre-trip inspection as outlined

the test. in the Air Brake Manual.

• When upgrading your driver’s licence

Key points:

from single to combination vehicles with

• You need to locate the items to be checked and air brakes, you will be required to

tell the examiner how and what you check on demonstrate the complete air brake steps

that part. Never assume the examiner has enough for combination vehicles.

information and delete items. When the examiner

Inadequately completing the pre-trip and/or

is satisfied in your knowledge of the area you may

air brake inspection will result in the

be asked to move along.

discontinuance and failure of the road test.

• The pre-trip inspection should be done in

a systematic manner to conserve time. This

pre-trip should take no more than 20 minutes

to complete.

• If using a trailer with electric brakes, the system

must be inspected to ensure it is operating properly.

✄

Professional Driver’s Manual • 119

All Vehicles Additional Checks for

• Approach vehicle Combination Vehicles

• Vehicle secure • Fifth wheel/coupling device

ENGINE COMPARTMENT • Air lines, glad hands and electrical cord

• Fluids • Landing supports and crank handle

• Drive belts, hoses • Sliding bogie locking bars/pin (if applicable)

• Batteries

• Frame rails and cross members

Additional Checks for Buses

• Interior lights

DRIVING COMPARTMENT (IN-CAB)

• Seats and handrails, wheel chair restraints

• Controls

(if applicable)

EMERGENCY EQUIPMENT (if applicable) • Emergency exits (if applicable)

OUTSIDE CHECKS • Service door(s)

• Bumpers • Auxiliary heaters (if applicable)

• Lighting equipment • Wheelchair lift or kneeling feature (if applicable)

• Tailgate, doors, mirrors, load

• Safety sticker

• Licence plates

• Fuel tank

• Exhaust system

• Tires

• Rims

• Suspension

• Splash guards

• Hub oil (if applicable)

HYDRAULIC BRAKE INSPECTION

(non air brake vehicles only at this point)

120 • Professional Driver’s Manual

In-Service Inspections Pre-Hill Inspection

In addition to the pre-trip inspection, trucks and trailers Anytime a sign is posted that requires truck drivers to

should be inspected at regular intervals throughout the stop in the pull-out area and inspect their brakes

trip. The driver should stop the vehicle clear of the before proceeding down the steep hill ahead, drivers

travelled portion of the highway and check: must comply.

• wheel lugs and nuts; Before proceeding down the grade, truck drivers

equipped with air operated braking systems must check:

• tires for condition, pressure and overheating;

• compressor is maintaining full reservoir pressure;

• hubs and drums for heat;

• slack adjusters for push rod travel and take up

• brakes for operation (See Air Brake Manual);

slack if required, and you are authorized in

• coupling devices; slack adjustment;

• load security; • check for air leaks;

• drive lines and oil leaks; • security of glad hands and lines;

• lights and windshield visibility; • drums for overheating;

• record an in-service inspection in the log book. • emergency valve operation.

Truck drivers equipped with hydraulic brake systems

Post-Trip Inspection will check:

At the end of the final trip of the day you must conduct • pedal reserve;

a post-trip inspection on your vehicle. This inspection is

• vacuum booster operating;

similar to a pre-trip inspection. During this inspection

you must check for any damage or defects that may have • drums for over-heating;

developed on your vehicle during the trip. You must also

• visual inspection for hydraulic fluid leaks.

complete a post-trip inspection report. This report must

note any defects found during the post-trip inspection. You must stop and check your brakes when this sign

The post-trip inspection can be added to the report you is posted.

completed during the pre-trip inspection at the start

of that day.

If the vehicle is equipped with air brakes, see the

Air Brake Manual for additional items to be inspected

during the post-trip inspection.

Professional Driver’s Manual • 121

Notes

122 • Professional Driver’s Manual

You might also like

- CMRT Practice QuestionsDocument2 pagesCMRT Practice Questionslinbaba123100% (2)

- Boeing 737-300 Transit CheckDocument6 pagesBoeing 737-300 Transit CheckUmer JavedNo ratings yet

- 2015 02 Fall Protection Test and Answer KeyDocument2 pages2015 02 Fall Protection Test and Answer KeyR.Ranjan PradhanNo ratings yet

- Sample Maintenance Sheet: TrailerDocument2 pagesSample Maintenance Sheet: TrailerTris50% (2)

- Crawler Crane Inspection ReportDocument9 pagesCrawler Crane Inspection ReportAdvent ManurungNo ratings yet

- BMTDSL Submarine Concept Design DatasheetDocument2 pagesBMTDSL Submarine Concept Design DatasheetTheyaga GanesanNo ratings yet

- ME134-Internal Combustion Engine (Syllabus-Same Grade With Class Record)Document4 pagesME134-Internal Combustion Engine (Syllabus-Same Grade With Class Record)Yohan ManaligodNo ratings yet

- Form Checklist Inspeksi Hoist CraneDocument1 pageForm Checklist Inspeksi Hoist CraneM AzharNo ratings yet

- ENR - FM.HSE.16 Hoise CraneDocument1 pageENR - FM.HSE.16 Hoise CraneEKO PRIBADINo ratings yet

- Annual Vehicle Inspection Report TemplateDocument1 pageAnnual Vehicle Inspection Report TemplateAdolphe HotereshiNo ratings yet

- Inspection ChecklistDocument2 pagesInspection ChecklistBerp OnrubiaNo ratings yet

- Annual Vehicle Inspection ReportDocument1 pageAnnual Vehicle Inspection ReportjakonazerNo ratings yet

- 2020-Mip-Inspection-Electronic-Form 2 PDFDocument2 pages2020-Mip-Inspection-Electronic-Form 2 PDFtoddNo ratings yet

- E-Test: ST ND RD THDocument2 pagesE-Test: ST ND RD THneneng hernawatiNo ratings yet

- Student Skill Promotion Test: Automotive MechanicDocument12 pagesStudent Skill Promotion Test: Automotive MechanicCinta Tak BertuanNo ratings yet

- Vehicle Inspection Form 01Document1 pageVehicle Inspection Form 01GuruNo ratings yet

- Medicine EmpireDocument4 pagesMedicine EmpirenyahegomohammedNo ratings yet

- Ceph+SB+7 25 12 RedDocument1 pageCeph+SB+7 25 12 RedOliver MladenovskiNo ratings yet

- Removal and InstallationDocument10 pagesRemoval and InstallationPetr LisoňNo ratings yet

- Instruction Manual: For Alt-Azimuth MountDocument16 pagesInstruction Manual: For Alt-Azimuth MountJimy Unfried-SilgadoNo ratings yet

- APS-Form Cutting Torch & Welding Equipment Inspection - RevisedDocument2 pagesAPS-Form Cutting Torch & Welding Equipment Inspection - ReviseddvggfdhdbdfvbNo ratings yet

- Level I Questions Visual and Optical Testing MethodDocument30 pagesLevel I Questions Visual and Optical Testing MethodAndres TorresNo ratings yet

- PRO - ECO1 - S8-G1 - 14-18 JuinDocument349 pagesPRO - ECO1 - S8-G1 - 14-18 JuinCHALABI FARES100% (1)

- National Certificate in Automotive MachanicsDocument63 pagesNational Certificate in Automotive MachanicsMuwonge StephanoNo ratings yet

- API 510 Api 510 - Closed - CLOSED-6 6Document4 pagesAPI 510 Api 510 - Closed - CLOSED-6 6jhover graosNo ratings yet

- Sample Questions: Answer Key: 1-C, 2-B, 3-C, 4-B, 5-A, 6-BDocument2 pagesSample Questions: Answer Key: 1-C, 2-B, 3-C, 4-B, 5-A, 6-BAbdo JondiNo ratings yet

- Q3 Compiled ElementsDocument5 pagesQ3 Compiled Elementschuapril681No ratings yet

- KOn. Keahlian XI TKRODocument2 pagesKOn. Keahlian XI TKROJuli Hardo Purba TanjungNo ratings yet

- Mooney M20R - ChecklistDocument14 pagesMooney M20R - ChecklistJoão SantosNo ratings yet

- Checklist Alat BeratDocument1 pageChecklist Alat Beratarin ALPNo ratings yet

- 300 Verado Fourstroke Verado Closed Compartment Technology (CCT) Installation and Owners Manual SupplementDocument13 pages300 Verado Fourstroke Verado Closed Compartment Technology (CCT) Installation and Owners Manual SupplementNoman RasheedNo ratings yet

- NECO Auto Mechanical Work Past Question Paper and Answer PDF DownloadDocument10 pagesNECO Auto Mechanical Work Past Question Paper and Answer PDF DownloadCharles Obaleagbon50% (2)

- Up 3Document5 pagesUp 3tufailNo ratings yet

- Visual Nivel 1 2 y 3pdf PDF Free (1) (14 33)Document20 pagesVisual Nivel 1 2 y 3pdf PDF Free (1) (14 33)moussaguisse21No ratings yet

- BicycleDocument36 pagesBicycle9j97ctrw5gNo ratings yet

- EXAMEN DE SUBSANACIÓN - PDF Dic 22 NewDocument4 pagesEXAMEN DE SUBSANACIÓN - PDF Dic 22 NewBrayan ChiquezNo ratings yet

- Akes and Clutches T13Document6 pagesAkes and Clutches T13devera reynaldNo ratings yet

- 2015 02 Fall Protection Test and Answer KeyDocument4 pages2015 02 Fall Protection Test and Answer Keysayedattafsiddique7No ratings yet

- EHA CHECK LIST - Machine Fitness: Job Data Site Data Machine DataDocument3 pagesEHA CHECK LIST - Machine Fitness: Job Data Site Data Machine DataHari Hara SuthanNo ratings yet

- Sample: Excavator Safety TrainingDocument61 pagesSample: Excavator Safety Trainingvega f anka100% (1)

- Mtbalt 1Document38 pagesMtbalt 1Nelson VillateNo ratings yet

- English 3: Unit 5: Buying A Car Online Session 1Document13 pagesEnglish 3: Unit 5: Buying A Car Online Session 1Bryan Nick Espinal LadosNo ratings yet

- Preventive Maintenance ChecklistDocument3 pagesPreventive Maintenance ChecklistDominador J. Santos Jr.No ratings yet

- Car-Pre Delivery Inspection v2 - 3Document4 pagesCar-Pre Delivery Inspection v2 - 3manav SinglaNo ratings yet

- Chapter 04 Preventive Maintenance ProgramDocument6 pagesChapter 04 Preventive Maintenance ProgramRajvir GrewalNo ratings yet

- Model DE Electronically Controlled Diesel Fuel Injection Pump Operation and Instruction ManualDocument60 pagesModel DE Electronically Controlled Diesel Fuel Injection Pump Operation and Instruction ManualjiovanniNo ratings yet

- Booms Pre-Delivery ChecklistDocument1 pageBooms Pre-Delivery ChecklistOzlem MepNo ratings yet

- Luxfer SOPMPV Manual Rev 3bDocument16 pagesLuxfer SOPMPV Manual Rev 3bandreicarbuneanuNo ratings yet

- Check List Inspeccion Frame - 798 AcDocument2 pagesCheck List Inspeccion Frame - 798 AcPaola Uriol CerquinNo ratings yet

- 1/10 4Wd Nitro Monster TruckDocument12 pages1/10 4Wd Nitro Monster Truckjaredesilva92No ratings yet

- 25 - VT Q&a 1-3Document38 pages25 - VT Q&a 1-3Ameem TariqNo ratings yet

- CP690 Cotton Picker Maintenance and Cleaning GuideDocument20 pagesCP690 Cotton Picker Maintenance and Cleaning GuideFélix lucio ChozempaNo ratings yet

- Hur Co DrawingsDocument22 pagesHur Co DrawingsdullecncNo ratings yet

- Ryobi 40 Volt Hedge Trimmer ManualDocument34 pagesRyobi 40 Volt Hedge Trimmer ManualqfmdvqbsyzNo ratings yet

- Jomar Product TroubleshootingDocument2 pagesJomar Product TroubleshootingWasim AbbasNo ratings yet

- Brakes and Clutches T13Document6 pagesBrakes and Clutches T13SkylarNo ratings yet

- Inspection Checklist-Over Head CraneDocument2 pagesInspection Checklist-Over Head CraneWalid DarwishNo ratings yet

- Removal & Assembly: 1. Paper Feed Tray UnitDocument9 pagesRemoval & Assembly: 1. Paper Feed Tray UnitRheana DomingoNo ratings yet

- FCJJ-31 User ManualDocument8 pagesFCJJ-31 User ManualArun KumarNo ratings yet

- EXAMEN DE RECUPERACIÓN TRACTOR ORUG AaaDocument2 pagesEXAMEN DE RECUPERACIÓN TRACTOR ORUG AaaFresciaColquehuancaGonzalesNo ratings yet

- GM5 (B) Pacino Intel Discrete & UMA Block DiagramDocument62 pagesGM5 (B) Pacino Intel Discrete & UMA Block DiagramCarlos Costa100% (1)

- 5992-2013EN Nemo Outdoor TEDocument31 pages5992-2013EN Nemo Outdoor TEHrvoje ErorNo ratings yet

- Title: Smart Health Care Problem StatementDocument3 pagesTitle: Smart Health Care Problem StatementVishwanath DesaigoudarNo ratings yet

- Quick Manual For Pro100Document21 pagesQuick Manual For Pro100Daniel StamenkoskiNo ratings yet

- MN006055A01-AA Enus MOTOTRBO Customer ProgrammingDocument651 pagesMN006055A01-AA Enus MOTOTRBO Customer ProgrammingOscar EscobarNo ratings yet

- DBMS Unit-1 PPT 1.2 (Advantages & Disadvantages of DBMS, Components, Overall System Tructure)Document5 pagesDBMS Unit-1 PPT 1.2 (Advantages & Disadvantages of DBMS, Components, Overall System Tructure)lightNo ratings yet

- Congestion Recognition in Mobile Networks: Rami AlisawiDocument62 pagesCongestion Recognition in Mobile Networks: Rami AlisawitadeleNo ratings yet

- Realization of Control System Concepts Using Matlab and SimulinkDocument4 pagesRealization of Control System Concepts Using Matlab and Simulinkvijay81541No ratings yet

- ION-CEDI-BR Ion PureDocument8 pagesION-CEDI-BR Ion PureAndri YantoNo ratings yet

- DC - Experiment - No. 4Document9 pagesDC - Experiment - No. 4amol maliNo ratings yet

- Laptop Buying Guide PDFDocument5 pagesLaptop Buying Guide PDFJohn CenaNo ratings yet

- Catatan Tugasan Harian Ft19 Fa29 2017Document1 pageCatatan Tugasan Harian Ft19 Fa29 2017Nurul Nadia KamarudinNo ratings yet

- Emb Lab Manual FinalDocument142 pagesEmb Lab Manual FinalSatheesh Kumar100% (1)

- Lab - 01 DFA SimulationDocument4 pagesLab - 01 DFA SimulationSR ReliabilityNo ratings yet

- ICT Lecture 17Document16 pagesICT Lecture 17Muhammad UmarNo ratings yet

- Multi-Carrier HSDPA (RAN17.1 02)Document247 pagesMulti-Carrier HSDPA (RAN17.1 02)riamaNo ratings yet

- Establishment User ManualDocument29 pagesEstablishment User ManualAzharNo ratings yet

- Unit Iii Statistical Process Control and Process CapabilityDocument26 pagesUnit Iii Statistical Process Control and Process CapabilityDurai Raj KumarNo ratings yet

- Inteligent Field InstrumentsDocument4 pagesInteligent Field InstrumentsmarcalpiNo ratings yet

- Markview Scanning and Oracle PayablesDocument6 pagesMarkview Scanning and Oracle Payablesprabhakar_reddy_1No ratings yet

- Chapter 6: InternetDocument3 pagesChapter 6: InternetMustafa RadaidehNo ratings yet

- Software License Terms For Microsoft Report BuilderDocument2 pagesSoftware License Terms For Microsoft Report Builderlojio9627No ratings yet

- Control Systems Training - Session 01: Introduction To Industrial AutomationDocument31 pagesControl Systems Training - Session 01: Introduction To Industrial AutomationUmaNo ratings yet

- Difference Between Dry Type Transformers VsDocument4 pagesDifference Between Dry Type Transformers Vsmilad rouhiniaNo ratings yet

- Comment - Mouda - R0 - VFD Data SheetDocument34 pagesComment - Mouda - R0 - VFD Data SheetAshok reddyNo ratings yet

- What Is Technical WritingDocument7 pagesWhat Is Technical WritingEmyNo ratings yet

- Understanding and Using Web ADI in Oracle HRMS (ID 360105.1)Document17 pagesUnderstanding and Using Web ADI in Oracle HRMS (ID 360105.1)Saquib Mahmood0% (1)

- System 300 Modular Plants: Terex Minerals Processing Systems System 300Document2 pagesSystem 300 Modular Plants: Terex Minerals Processing Systems System 300gambit galihNo ratings yet