0 ratings0% found this document useful (0 votes)

148 viewsFabrication Shop Observations

Fabrication Shop Observations

Uploaded by

Perminder SinghThe document outlines various quality control and inspection issues observed at a fabrication shop. It notes problems such as improper matching of parts, variation in plate lengths and gaps, uneven welding quality, missing dimensions in drawings, and the need for standardized sizes and supplier certification. Improved inspection processes, documentation, and addressing dimensional inconsistencies are recommended.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Fabrication Shop Observations

Fabrication Shop Observations

Uploaded by

Perminder Singh0 ratings0% found this document useful (0 votes)

148 views1 pageThe document outlines various quality control and inspection issues observed at a fabrication shop. It notes problems such as improper matching of parts, variation in plate lengths and gaps, uneven welding quality, missing dimensions in drawings, and the need for standardized sizes and supplier certification. Improved inspection processes, documentation, and addressing dimensional inconsistencies are recommended.

Original Description:

observations

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

The document outlines various quality control and inspection issues observed at a fabrication shop. It notes problems such as improper matching of parts, variation in plate lengths and gaps, uneven welding quality, missing dimensions in drawings, and the need for standardized sizes and supplier certification. Improved inspection processes, documentation, and addressing dimensional inconsistencies are recommended.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

148 views1 pageFabrication Shop Observations

Fabrication Shop Observations

Uploaded by

Perminder SinghThe document outlines various quality control and inspection issues observed at a fabrication shop. It notes problems such as improper matching of parts, variation in plate lengths and gaps, uneven welding quality, missing dimensions in drawings, and the need for standardized sizes and supplier certification. Improved inspection processes, documentation, and addressing dimensional inconsistencies are recommended.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

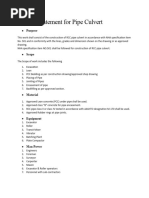

Fabrication shop Observations

1. Inward Inspection/Identification of MOC like flanges, reducer, pipe,

elbow, end Cap etc.

2. Inflation Record of Laser welded Plates.

3. Leak Test Record of Laser welded Plates.

4. Pickling Quality Check.

5. Assembly Leak Test Record.

6. Joint, Nipple, End Cap & Pipes matching not proper.

7. Reducer, End cap, Elbow, Flange Quality need to be improved.

8. Standardize Pipe, Elbow, Flange Sizes & take from Approved Supplier

with Test Certificate.

9. Door Fitting Not OK need to be make doors after completion of Housing.

10. Variation in Chiller plate Lengths.

11. Plate to plate distance not uniform.

12. Welding Quality need to be improved.

13. Variation in wall thickness of End cap, Elbow, Pipe.

14. Gap generates in Tank Outer after welding.

15. Welders sample to be made six monthly/yearly basis & Lab Test shall be

done.

16. Connection pipe shall be welded after putting tank/water channel on a

flat platform.

17. Diagonal Variation in water channel & Bank Assembly.

18. Record of welders shall be properly maintained for the fabricated

product.

19. In Drawing this should be given that how much pipe inserted in plate for

connection & also require welding bead need to be given. Some

dimensions were also missing in drawing that need to be given.

20. Gap in water channel Tank.

21. Gap between Housing & Comb.

22. Polishing shall be done stage wise as after assembly some areas remains

to polish as Polisher hand not reaches to location.

23. Stage wise Inspection of product like tank, housing, water channel etc.

24. Visual & Dimensional Report.

You might also like

- Storage Tank Inspection Check ListDocument2 pagesStorage Tank Inspection Check Listparthasarathy281275% (8)

- Method Statement For Chilled Water PipesDocument5 pagesMethod Statement For Chilled Water PipesImteyaz Ahmad50% (4)

- Job Procedure For Eriction of TankDocument13 pagesJob Procedure For Eriction of TankAnonymous i3lI9M100% (3)

- Method Statement For GI & PVC Conduit Installation Including AccessoriesDocument6 pagesMethod Statement For GI & PVC Conduit Installation Including AccessoriesDong Vanra100% (3)

- In-Service Storage Tank Inspection and Verification ChecklistDocument9 pagesIn-Service Storage Tank Inspection and Verification ChecklistAshif Khan100% (1)

- Method Statement For Installation, TESTING, COMISNNING of F.FDocument16 pagesMethod Statement For Installation, TESTING, COMISNNING of F.Fdemdiin100% (1)

- Vendor Drawing Review A Review of Valve DrawingsDocument3 pagesVendor Drawing Review A Review of Valve Drawingsthuyenquyen_vt100% (1)

- Specification Nov. 25, 2013Document4 pagesSpecification Nov. 25, 2013Mary Ann LictaoaNo ratings yet

- Boiler Survey & ConstDocument18 pagesBoiler Survey & ConstAmit ChouguleNo ratings yet

- 日报-2024年11月09日(英文)Document4 pages日报-2024年11月09日(英文)Habiba RachmayaniNo ratings yet

- Tank Field Inspection and Test ProcedureDocument29 pagesTank Field Inspection and Test ProcedureFadlul Akbar Herfianto100% (2)

- Tank Field Inspection and Test ProcedureDocument29 pagesTank Field Inspection and Test Proceduresbmmla91% (22)

- Water Meter SpecificationDocument10 pagesWater Meter SpecificationJignesh ThakkarNo ratings yet

- Checklist For InspectionDocument12 pagesChecklist For InspectionAnoopNo ratings yet

- M002-Job Procedure Ag PipingDocument8 pagesM002-Job Procedure Ag PipingVijayaraman Rajendran100% (1)

- Check Lists PreparationDocument6 pagesCheck Lists PreparationMedhaNo ratings yet

- Tank ProcedureDocument5 pagesTank ProcedurejacquesmayolNo ratings yet

- Inspection TankDocument22 pagesInspection Tanksbmmla100% (2)

- Procedure For Rain Water Drainage Pipe InstallationDocument1 pageProcedure For Rain Water Drainage Pipe InstallationWilliam SpencerNo ratings yet

- Method Statement On Ductile PipeDocument7 pagesMethod Statement On Ductile PipeHayle Dela CruzNo ratings yet

- Tank SpecificationDocument6 pagesTank SpecificationEng. Abobakr Alsufyani Sr.Mechnical engineer-No ratings yet

- Wellbore Schematics: - Potential - ProblemsDocument22 pagesWellbore Schematics: - Potential - ProblemsNorBertoChavezNo ratings yet

- Method statement for Reinforcement work Re (1)Document4 pagesMethod statement for Reinforcement work Re (1)krcqualityNo ratings yet

- 日报-2024年11月04日(英文)Document3 pages日报-2024年11月04日(英文)Habiba RachmayaniNo ratings yet

- Method Statement: ApprovalDocument21 pagesMethod Statement: ApprovalzhanghuiNo ratings yet

- Method Statement PlumbingDocument8 pagesMethod Statement Plumbinggvs raoNo ratings yet

- Shell Plate Dimension CheckDocument7 pagesShell Plate Dimension Checksetak50% (2)

- Tank Erection ProcedureDocument15 pagesTank Erection Procedurejohney294% (16)

- TUV India HEAT EXCHANGER InspectionDocument43 pagesTUV India HEAT EXCHANGER InspectionParthiban NCNo ratings yet

- 3 Upvc Method of Statement ABOVE GRD UPVCDocument4 pages3 Upvc Method of Statement ABOVE GRD UPVCMark SimNo ratings yet

- DefinitionsDocument7 pagesDefinitionsqwertykey3991No ratings yet

- Reconditioning of ValvesDocument6 pagesReconditioning of ValvesPaul PhiliphsNo ratings yet

- Plumbing MethodologyDocument8 pagesPlumbing MethodologyAjay MedikondaNo ratings yet

- Typ. Construction MethodologyDocument29 pagesTyp. Construction MethodologyvijayshelkeNo ratings yet

- 1 - MS-PVC Conduitingaccessories Installation WorksDocument6 pages1 - MS-PVC Conduitingaccessories Installation WorksAraf KalamNo ratings yet

- Method Statement For Chilled Water PipesDocument5 pagesMethod Statement For Chilled Water PipesYoYoRamez100% (1)

- Phe TS19 10 23Document17 pagesPhe TS19 10 23K. CHANDRASEKHARNo ratings yet

- Section 449 Precast Concrete Drainage Products 449-1 DescriptionDocument5 pagesSection 449 Precast Concrete Drainage Products 449-1 Descriptionbem.05swNo ratings yet

- Material Specification in TenderDocument3 pagesMaterial Specification in TenderenggmohanNo ratings yet

- Method StatementDocument10 pagesMethod StatementEmmanuel kusimoNo ratings yet

- M - E T - C PICO Hose Reel Piping - AcessDocument3 pagesM - E T - C PICO Hose Reel Piping - AcesskassthureiNo ratings yet

- DCS-026 DTD 08.08.10 Method Statement For Water Tank Walls Casting With BlockoutsDocument12 pagesDCS-026 DTD 08.08.10 Method Statement For Water Tank Walls Casting With Blockoutsmirza057No ratings yet

- Method of Statement PlumbingDocument13 pagesMethod of Statement PlumbingJesin Abdul Jaleel A100% (1)

- Uls Storage TankDocument19 pagesUls Storage Tankmrsafavi7No ratings yet

- Fixtures & FittingsDocument3 pagesFixtures & FittingsCindy AmyzaNo ratings yet

- Cone Roof Tank Erection ProcedureDocument8 pagesCone Roof Tank Erection ProcedureBoby Thomas100% (1)

- C12A and Code Case.Document28 pagesC12A and Code Case.inorwoodNo ratings yet

- Introduction To Piping FabricationDocument5 pagesIntroduction To Piping FabricationSyed IbrahimNo ratings yet

- Heat Exchanger Inspection PDFDocument8 pagesHeat Exchanger Inspection PDFreezmanNo ratings yet

- How - To Calculate Dike Containment VolumeDocument3 pagesHow - To Calculate Dike Containment VolumeAimsKapoorNo ratings yet

- Requirement Budget Proposal - 2023.03.26Document10 pagesRequirement Budget Proposal - 2023.03.26vijaysubbiah87No ratings yet

- Method Statement For Pipe Culvert by Anil KumarDocument2 pagesMethod Statement For Pipe Culvert by Anil KumarAsad Ashfaq0% (1)

- Fabrication and Erection ProcedureDocument13 pagesFabrication and Erection ProcedureshivanshsovNo ratings yet

- Awwa d103 PotableDocument9 pagesAwwa d103 PotableAnonymous UArnIExNo ratings yet

- Awwa d103 PotableDocument9 pagesAwwa d103 PotableAnonymous UArnIExNo ratings yet

- Section 15420 Water Storage Tanks and Accessories Part 1 - General 1.01 Work IncludedDocument8 pagesSection 15420 Water Storage Tanks and Accessories Part 1 - General 1.01 Work IncludedFadi FarseNo ratings yet

- Machines, Tools and Methods of Automobile ManufactureFrom EverandMachines, Tools and Methods of Automobile ManufactureRating: 4 out of 5 stars4/5 (1)

- Handbook of PVC Pipe Design and Construction, 6th EditionFrom EverandHandbook of PVC Pipe Design and Construction, 6th EditionNo ratings yet

- Laboratory W Nawm: Servicts 'Document3 pagesLaboratory W Nawm: Servicts 'Perminder SinghNo ratings yet

- Sciessent PIB - LJPowder Rev 0 PDFDocument2 pagesSciessent PIB - LJPowder Rev 0 PDFPerminder SinghNo ratings yet

- Inspection Report: IR NO.: AAP/B18010 & B18012/1 Page 1 of 1 Date: 04.09.2018Document1 pageInspection Report: IR NO.: AAP/B18010 & B18012/1 Page 1 of 1 Date: 04.09.2018Perminder SinghNo ratings yet

- MTC - 4 MMDocument1 pageMTC - 4 MMPerminder SinghNo ratings yet

- Ff"Olv: - 0'"N-OprDocument1 pageFf"Olv: - 0'"N-OprPerminder SinghNo ratings yet

- M/C-OM-10: Sr. No. Date Customer Capacity Qty RemarksDocument15 pagesM/C-OM-10: Sr. No. Date Customer Capacity Qty RemarksPerminder SinghNo ratings yet

- 1/1 MM 1.2/1.2 MM 1.5/1.5 MM 2mm 2mm 2mm 4.5mm 5mm 5.5mm: Double EmbossDocument1 page1/1 MM 1.2/1.2 MM 1.5/1.5 MM 2mm 2mm 2mm 4.5mm 5mm 5.5mm: Double EmbossPerminder SinghNo ratings yet

- Welder Continuation Log: Welder Name: Welder ID: Date of Initial QualificationDocument1 pageWelder Continuation Log: Welder Name: Welder ID: Date of Initial QualificationPerminder Singh100% (1)

- Date Shift Insp Customer Dimensions DWG No. Plate No. Heat No T-Thk. Length WidthDocument24 pagesDate Shift Insp Customer Dimensions DWG No. Plate No. Heat No T-Thk. Length WidthPerminder SinghNo ratings yet

- Welding Procedure Datasheet: ScopeDocument5 pagesWelding Procedure Datasheet: ScopePerminder SinghNo ratings yet

- Batch No. Heat No: Material Customer NameDocument1 pageBatch No. Heat No: Material Customer NamePerminder SinghNo ratings yet

- Batch No. Heat No: Material Customer NameDocument1 pageBatch No. Heat No: Material Customer NamePerminder SinghNo ratings yet

- Factors Affecting Weld QualityDocument1 pageFactors Affecting Weld QualityPerminder SinghNo ratings yet

- Analysis Report (Spot) : Pure AR Ar+HeDocument2 pagesAnalysis Report (Spot) : Pure AR Ar+HePerminder SinghNo ratings yet

- Laser Welding-OM07 Analysis 9:00 AM To 4:02 PMDocument4 pagesLaser Welding-OM07 Analysis 9:00 AM To 4:02 PMPerminder SinghNo ratings yet

- Gases For Laser Welding - Linde Gas RussiaDocument1 pageGases For Laser Welding - Linde Gas RussiaPerminder SinghNo ratings yet

- Sr. No Details of Rework Machine Customer Thickness Top Bottom ThicknessDocument2 pagesSr. No Details of Rework Machine Customer Thickness Top Bottom ThicknessPerminder SinghNo ratings yet

- MHI 202 3 400/1.4301/EPDM: Phone Fax Customer Customer No. Contact Project Project No. Position No. LocationDocument1 pageMHI 202 3 400/1.4301/EPDM: Phone Fax Customer Customer No. Contact Project Project No. Position No. LocationPerminder SinghNo ratings yet