Professional Documents

Culture Documents

Mpu 3 16

Mpu 3 16

Uploaded by

NopOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mpu 3 16

Mpu 3 16

Uploaded by

NopCopyright:

Available Formats

Magnetic Pickup (MPU)

Magnetic pickups convert mechanical motion into electrical Figure 2 shows output voltage as a function of surface speed.

energy without mechanical linkage or external power. These

transducers sense any ferromagnetic material having disconti- Note: The Altronic intrinsically-safe MPU has internal

nuities, such as gear teeth or slots, and generate an AC Voltage. voltage-limiting zener diodes. The output will never

The frequency of this voltage is equal to the number of discon-

exceed 18V (p-p) regardless of speed.

tinuities passing the pickup and is proportional to RPM when

the pickup is mounted in proximity to the teeth of a gear on a

rotating shaft. The AC output voltage is inversely proportional to the

clearance between the pole piece and the gear. In many

Figure 1 shows the typical construction of a MPU. The pole applications a 0.010 to 0.020 inch gap is adequate;

piece forms a magnetic path from the magnet , creating an ex-

however, if slow surface speed or maximum output is

ternal magnetic field in front of the sensor. When this magnetic

field is disrupted by a ferromagnetic material an AC voltage is

required, the gap should be as small as practical (0.005

induced in the coil. inches or less).

Figure 1

The amplitude of the output voltage depends on the sur-

face speed of the gear, the gap between the pole piece

and the gear, the gear tooth size and spacing, and the

load impedance. The pickup output voltage is directly

proportional to surface speed of the gear. Surface speed

is most often expressed in terms of inches per second. Figure 2

Surface Speed (IPS) = RPM x Gear dia. (inches) x 3.1416

60

Altronic, LLC – A Member of the

HOERBIGER Group

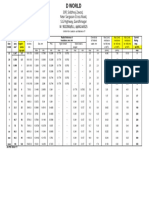

Figure 3 gives the optimum dimensions for a gear to DIMENSIONS

be used with a magnetic pickup. If maximum power is

required, the gear should be as close as possible to these

dimensions. In many applications small tooth gears are

adequate. At high speeds even a 90-pitch gear may be

satisfactory. Pitch is the number of teeth per inch diameter.

Pitch = Number of teeth +2

Diameter of gear (inches)

or

Dia. = Number of teeth + 2

Pitch

SPECIFICATIONS

Figure 3 Resistance........................................... 1200 OHMS MAX

Inductance................................................330 mH NOM.

A. Equal to or greater than D Output Voltage...................... 9V o-p MAX (18V p-p MAX.)

Temperature............................... Operating -65˚F to 225˚F

B. Equal to or greater than C

Ambient –100˚F to 225˚F

C. Equal to—or greater than—three times D

E. As close as possible; typically .005" or less TO ORDER

F. Equal to or greater than D

Thickness Length Altronic P/N

Note: Whenever possible a gear of 16 pitch or coarser

1.75" / 44.5mm 3.30" / 83.3mm 691118-1

should be used

2.5" / 63.5mm 4.05" / 102.8mm 691118-2

3.0" / 76.2mm 4.55" / 115.6mm 691118-3

4.5" / 114.3mm 6.05" / 153.7mm 691118-4

6.0" / 152.4mm 7.55" / 191.8mm 691118-6

712 Trumbull Avenue, Girard, Ohio 44420

(330) 545-9768 / Fax: (330) 545-3231

Email: sales.altronic.girard@hoerbiger.com

Form MPU 3-16 ©2016 Altronic, LLC

You might also like

- 1997-2003 TF R7 R9 Rodeo Workshop ManualDocument2 pages1997-2003 TF R7 R9 Rodeo Workshop ManualNop60% (5)

- Kobota z600Document4 pagesKobota z600Nop0% (1)

- Men in The Sun and Other Palestinian Stories - Ghassan KanafaniDocument118 pagesMen in The Sun and Other Palestinian Stories - Ghassan Kanafanianthroposophical80% (5)

- Compressor GE H-302 SpecDocument19 pagesCompressor GE H-302 SpecNop50% (2)

- Accident Prevention Training "STOP 6"Document26 pagesAccident Prevention Training "STOP 6"SANTOSH PRADHAN100% (2)

- 4110 Manual COMPLETO DENSOMETRO GURLEY PDFDocument21 pages4110 Manual COMPLETO DENSOMETRO GURLEY PDFZenón NoreñaNo ratings yet

- Thermo Fisher Scientific XL3 XL2 Hardware OverviewDocument37 pagesThermo Fisher Scientific XL3 XL2 Hardware OverviewMAmar100% (1)

- ICM Water & Particle Counter ManualDocument6 pagesICM Water & Particle Counter ManualHanna SofíaNo ratings yet

- TD107 Operation Manual PDFDocument42 pagesTD107 Operation Manual PDFshalabyahmedNo ratings yet

- Sn39mta 1Document3 pagesSn39mta 1pablogoncNo ratings yet

- Industrial Safety Supply, Inc.: Francisco A. LopezDocument29 pagesIndustrial Safety Supply, Inc.: Francisco A. Lopezart031125100% (1)

- Air Purifier CE Test ReportDocument36 pagesAir Purifier CE Test ReportMArcelaNo ratings yet

- Parker Valve Mobile Pulsar VPL-VP-VPO Model Code Book HY14-0108Document32 pagesParker Valve Mobile Pulsar VPL-VP-VPO Model Code Book HY14-0108NopNo ratings yet

- Volvo 940 Owners Manual 1991Document205 pagesVolvo 940 Owners Manual 1991NopNo ratings yet

- #ThrowbackThursday: H.E. Butt Piggly WigglyDocument1 page#ThrowbackThursday: H.E. Butt Piggly WigglycallertimesNo ratings yet

- Guia de Tadelakt Inglés PDFDocument31 pagesGuia de Tadelakt Inglés PDFEllaNo ratings yet

- PATHOPHYSIOLOGY UrtiDocument2 pagesPATHOPHYSIOLOGY UrtiCris Soland88% (8)

- Test Certificate: D & H Secheron Electrodes Pvt. LTDDocument1 pageTest Certificate: D & H Secheron Electrodes Pvt. LTDrahulkhokhar2023No ratings yet

- BioChem Pinch Valve User ManualDocument33 pagesBioChem Pinch Valve User ManualthynameisraymondNo ratings yet

- SYS600 - IEC 61107 Master ProtocolDocument32 pagesSYS600 - IEC 61107 Master ProtocolNguyen Duc100% (1)

- Test Certificate For Multi-Turn Actuators: Setting and Functional TestDocument1 pageTest Certificate For Multi-Turn Actuators: Setting and Functional TestSouvik DaluiNo ratings yet

- Accepptance Test Report of Acsr Rabbit ConductoorDocument1 pageAccepptance Test Report of Acsr Rabbit ConductoorFaizi MNo ratings yet

- .Technical Detail of UNINYVIN CABLEDocument1 page.Technical Detail of UNINYVIN CABLEJayNo ratings yet

- Calibration CertificateDocument2 pagesCalibration Certificatenate anantathatNo ratings yet

- Kit 138 New Bresle Salt PDFDocument2 pagesKit 138 New Bresle Salt PDFDian FaraNo ratings yet

- Vacuum Box Test Procedure: PurposeDocument4 pagesVacuum Box Test Procedure: Purposesaravan1891No ratings yet

- LP Gloster Pricelist Aug14 PDFDocument5 pagesLP Gloster Pricelist Aug14 PDFvjtheeeNo ratings yet

- Hamim Enterprise: A Life Safety CompanyDocument13 pagesHamim Enterprise: A Life Safety CompanyTaher AzadNo ratings yet

- Preventing and Identifying Potential Failures of Dead Break Elbows in Wind Farm Application - Brian - Peyres PDFDocument6 pagesPreventing and Identifying Potential Failures of Dead Break Elbows in Wind Farm Application - Brian - Peyres PDFSatadal DashNo ratings yet

- Convey Weigh "Belt Pro" Conveyor Belt Scales: High PerformanceDocument4 pagesConvey Weigh "Belt Pro" Conveyor Belt Scales: High PerformanceDAVID ALBERTO MORA CARDENASNo ratings yet

- SRI SensorDocument7 pagesSRI SensorArun GuptaNo ratings yet

- Hvws System For 10 Mva TransformerDocument26 pagesHvws System For 10 Mva Transformershashi ranjanNo ratings yet

- DPT Format.Document1 pageDPT Format.selvakumarNo ratings yet

- Op - Artes 400 Ii - EngDocument19 pagesOp - Artes 400 Ii - EngLuis Aguero CantilloNo ratings yet

- Belt Drive AllignmentDocument3 pagesBelt Drive AllignmentMichaelNo ratings yet

- 802P Universal Indicator Manual 350Document15 pages802P Universal Indicator Manual 350Davesh JadonNo ratings yet

- Actuator Data SheetsDocument4 pagesActuator Data SheetsCibi SubramaniamNo ratings yet

- Crompton - Qap-Rev-0Document6 pagesCrompton - Qap-Rev-0gulatimanish1985No ratings yet

- Tests According To IEC-En Standards (WAGO)Document11 pagesTests According To IEC-En Standards (WAGO)va3ttnNo ratings yet

- Pic152a ViDocument2 pagesPic152a Viiyappan5016100% (1)

- StandardsDocument30 pagesStandardsYuan GaoNo ratings yet

- Advantage & Disadv of Bellow & Slip JointDocument2 pagesAdvantage & Disadv of Bellow & Slip JointSharun Suresh0% (1)

- DCS Interview QuestionDocument8 pagesDCS Interview QuestionZulhelmiNo ratings yet

- RDSO PE SPEC AC 0138-2009 Rev 2 or LatestDocument23 pagesRDSO PE SPEC AC 0138-2009 Rev 2 or LatestRajnish KumarNo ratings yet

- SensorDocument11 pagesSensorharshitNo ratings yet

- Eddy Probe SystemsDocument44 pagesEddy Probe Systemsravide76No ratings yet

- 60.30-069 - 1994specification For Differential PressureDocument5 pages60.30-069 - 1994specification For Differential PressurepradeepNo ratings yet

- ProductCatalog PYROMATIONDocument212 pagesProductCatalog PYROMATIONDiego John Gavilanes UvidiaNo ratings yet

- Honeywell Genetron AZ20, R410A Specs PDFDocument18 pagesHoneywell Genetron AZ20, R410A Specs PDFFRALEJONo ratings yet

- Saudi Aramco Test Report: MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 ElectDocument5 pagesSaudi Aramco Test Report: MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 Electkarthi51289No ratings yet

- CableFixing PDFDocument6 pagesCableFixing PDFhumshkhNo ratings yet

- 744 and 745 Load Cells - 2586Document1 page744 and 745 Load Cells - 2586Luis IglesiasNo ratings yet

- MiCOM P12x PDFDocument8 pagesMiCOM P12x PDFsyamsudin4077100% (1)

- Stripper InfoDocument30 pagesStripper Infonedian_2006No ratings yet

- PM 10Document76 pagesPM 10Luis ManzoNo ratings yet

- 11kw 220v 1450rpm Afs225x Datasheet Jop DCDocument6 pages11kw 220v 1450rpm Afs225x Datasheet Jop DCcherif yahyaouiNo ratings yet

- FL4000H Multi-Spectrum Infrared Flame DetectorDocument2 pagesFL4000H Multi-Spectrum Infrared Flame DetectorRomdhoni Widyo BaskoroNo ratings yet

- Certificatewelding Machine CertificatesDocument1 pageCertificatewelding Machine Certificatestariq_hussain_20No ratings yet

- K19500 Operation ManualDocument14 pagesK19500 Operation Manualmoh_ichwanuddinNo ratings yet

- B24 Power Meter RegistersDocument27 pagesB24 Power Meter RegistersRoy ChaiNo ratings yet

- QPS-C5 Industrial & Costal Painting Procedure-OP - PP - WI - 006 - C5 PDFDocument4 pagesQPS-C5 Industrial & Costal Painting Procedure-OP - PP - WI - 006 - C5 PDFDeepak UpadhyayNo ratings yet

- Flash RT - The Inspector Model 200Document12 pagesFlash RT - The Inspector Model 200MohdHuzairiRusliNo ratings yet

- AUMA Katalog Techn Unterlagen Getriebe enDocument248 pagesAUMA Katalog Techn Unterlagen Getriebe enleocastarlenasNo ratings yet

- XXG-Ceramic Tube Directional: Max. Penetrate A3 Steel (MM)Document2 pagesXXG-Ceramic Tube Directional: Max. Penetrate A3 Steel (MM)SerkanNo ratings yet

- Shakun Polymers Limited: Spl-Afosr High Performance PVC CompoundDocument2 pagesShakun Polymers Limited: Spl-Afosr High Performance PVC CompoundquycoctuNo ratings yet

- Stator RTD Sensor 300Document4 pagesStator RTD Sensor 300Cristian GarcíaNo ratings yet

- Magnetic Pick Ups BrochureDocument2 pagesMagnetic Pick Ups Brochureadswa2000100% (1)

- Sensors SpeedhallDocument2 pagesSensors SpeedhallahmadshikemohmadNo ratings yet

- Photo Detectors ManualDocument14 pagesPhoto Detectors ManualJosé PiracésNo ratings yet

- Truing Commutators and Slip-RingsDocument4 pagesTruing Commutators and Slip-RingsTariq AhmedNo ratings yet

- Rod End: A Product DescriptionsDocument18 pagesRod End: A Product DescriptionsNopNo ratings yet

- Rod End SeriesDocument14 pagesRod End SeriesNopNo ratings yet

- Rod Ends PHS PHSB POS POSB PHSA PBDocument8 pagesRod Ends PHS PHSB POS POSB PHSA PBNopNo ratings yet

- Charging System: Battery Load (A)Document15 pagesCharging System: Battery Load (A)NopNo ratings yet

- Specific Safety RulesDocument7 pagesSpecific Safety RulesNopNo ratings yet

- Technical Data: PBS Push ButtonsDocument2 pagesTechnical Data: PBS Push ButtonsNopNo ratings yet

- 1996 Ford Ranger 1996 Ford RangerDocument2 pages1996 Ford Ranger 1996 Ford RangerNopNo ratings yet

- PBL3 Combination Push Buttons and Pilot LightsDocument2 pagesPBL3 Combination Push Buttons and Pilot LightsNopNo ratings yet

- G310 Product Manual - (Compatible With Crimson 2) (For Reference Only - See G310C2G310R2G310S2 For New Designs) PDFDocument8 pagesG310 Product Manual - (Compatible With Crimson 2) (For Reference Only - See G310C2G310R2G310S2 For New Designs) PDFNopNo ratings yet

- CVV CableDocument7 pagesCVV CableNopNo ratings yet

- Hyundai: No Engine Car Name/Year/Model Full Set Head Set Cylinder HeadDocument8 pagesHyundai: No Engine Car Name/Year/Model Full Set Head Set Cylinder HeadNopNo ratings yet

- DJM Monitor Boxes For Temperature ControllersDocument3 pagesDJM Monitor Boxes For Temperature ControllersNopNo ratings yet

- 1224 Ridgid PDFDocument7 pages1224 Ridgid PDFNopNo ratings yet

- LIT-C Stainless Steel Valves-USA LoResDocument20 pagesLIT-C Stainless Steel Valves-USA LoResNopNo ratings yet

- Fisher ET Control Valve PDFDocument48 pagesFisher ET Control Valve PDFNopNo ratings yet

- Users Manual: 99 Washington Street Melrose, MA 02176 Phone 781-665-1400 Toll Free 1-800-517-8431Document51 pagesUsers Manual: 99 Washington Street Melrose, MA 02176 Phone 781-665-1400 Toll Free 1-800-517-8431NopNo ratings yet

- Versa SolenoidValves CatDocument28 pagesVersa SolenoidValves CatNopNo ratings yet

- Chem 373 - Dry Lab II: Practice For The Quantum Mechanical PostulatesDocument2 pagesChem 373 - Dry Lab II: Practice For The Quantum Mechanical PostulatesNuansak3100% (1)

- Environmental Biodegradation of Synthetic Polymers II. Biodegradation of Different Polymer GroupsDocument17 pagesEnvironmental Biodegradation of Synthetic Polymers II. Biodegradation of Different Polymer GroupssonchemenNo ratings yet

- University of Cordilleras College of Nursing NCP: Mycobacterium TuberculosisDocument3 pagesUniversity of Cordilleras College of Nursing NCP: Mycobacterium TuberculosisLyn MhoreNo ratings yet

- Hosea 4:6: Israelite Ignorance: Cross ReferencesDocument4 pagesHosea 4:6: Israelite Ignorance: Cross ReferencesEYE EYENo ratings yet

- 6.1. Past Tense and Present Perfect: During Your Holiday? When You Were Younger? Last Year?Document10 pages6.1. Past Tense and Present Perfect: During Your Holiday? When You Were Younger? Last Year?GabrielaLeNo ratings yet

- SIPOC - PUVANA Water 2022Document22 pagesSIPOC - PUVANA Water 2022Ahmed HussienNo ratings yet

- Incentive Scheme 2008 As Amended Upto 31.12Document35 pagesIncentive Scheme 2008 As Amended Upto 31.12apu_biswasNo ratings yet

- 2.04 BrucknerDocument17 pages2.04 BrucknerSon NguyenNo ratings yet

- First Quarter Summative TestDocument12 pagesFirst Quarter Summative TestFlorence Lizardo Liwanag100% (1)

- Module 5 TeamsportsDocument18 pagesModule 5 Teamsportszedy gullesNo ratings yet

- 3.7 Running Well Completion PDFDocument19 pages3.7 Running Well Completion PDFJohn CooperNo ratings yet

- Economic Growth of Information Technology (It) Industry On The Indian EconomyDocument4 pagesEconomic Growth of Information Technology (It) Industry On The Indian EconomyijcnesNo ratings yet

- Application Forms PDFDocument2 pagesApplication Forms PDFsnhd_swprNo ratings yet

- FM ModulationDocument6 pagesFM ModulationVishwanath Petli100% (2)

- 2nd Bhaskar Steel Bss Power Quotation - (New)Document4 pages2nd Bhaskar Steel Bss Power Quotation - (New)Vijay TarakNo ratings yet

- Bioqt 01Document84 pagesBioqt 01Osama AlrawabNo ratings yet

- Hsmarine Tugs and WorkboatsDocument3 pagesHsmarine Tugs and WorkboatsBoruida MachineryNo ratings yet

- Panda KasaharaDocument3 pagesPanda Kasaharaapi-204191877No ratings yet

- Esp 1904 A - 70 TPH o & M ManualDocument50 pagesEsp 1904 A - 70 TPH o & M Manualpulakjaiswal85No ratings yet

- Witch Hunters Errata PDFDocument6 pagesWitch Hunters Errata PDFLorenzo SaldenNo ratings yet

- Unit V-Life Assisting and Therapeutic Devices Cardiac PacemakerDocument17 pagesUnit V-Life Assisting and Therapeutic Devices Cardiac PacemakernsrimadhavarajaNo ratings yet

- Lessosn 1: Aquatic Activities: at The End of This Chapter, The Student Will Be Able ToDocument14 pagesLessosn 1: Aquatic Activities: at The End of This Chapter, The Student Will Be Able ToJames Vidad100% (1)

- PT OrthoDocument129 pagesPT OrthoHarish Kumar NNo ratings yet

- Ekoheat Brochure EngelsDocument4 pagesEkoheat Brochure EngelsNoviantoNo ratings yet

- Describing Types of Technical ProblemsDocument2 pagesDescribing Types of Technical ProblemsDonny PranataNo ratings yet