Reinforced Concrete Wall Design Report: Material and Design Data

Reinforced Concrete Wall Design Report: Material and Design Data

Uploaded by

azwanCopyright:

Available Formats

Reinforced Concrete Wall Design Report: Material and Design Data

Reinforced Concrete Wall Design Report: Material and Design Data

Uploaded by

azwanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Reinforced Concrete Wall Design Report: Material and Design Data

Reinforced Concrete Wall Design Report: Material and Design Data

Uploaded by

azwanCopyright:

Available Formats

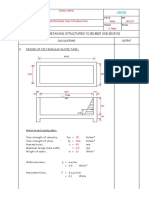

Reinforced Concrete Wall Design Report

MATERIAL AND DESIGN DATA

Load Allowance = 10 %

Code of Practice fcu (N/mm²) Ec, (N/mm²) fy (N/mm²) fyv (N/mm²) γc γs

BS8110 : 1997 30 24597 460 460 1.5 1.05

Cover (mm) Conc. Unit Weight (kN/m³) Steel Unit Weight (kg/m³)

25 24 7860

Design Calculation for RC Wall 1B (Core 1)

Wall Panel Thickness, t = 200 mm

Sub Panel 1 (Reg. 1)

Location in Panel: Wall Zone

Sub-Panel Length, b = 1850 mm | Gross Concrete Area, Ac = b × t = 370000 mm²

Design Status: Pass

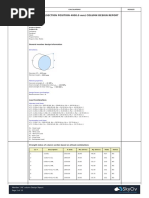

Reaction Table (3D) for RC Wall 1C/C-C1 Region 1

Reaction Edge Loading Source P Mx My Vx Vy X M

Dead Load 101.8 0.9 -1.6 -28.9 1.7 -753.2 -27.7

Top Edge

Live Load 26.1 0.4 -0.7 -16.0 0.8 -427.7 -15.6

Dead Load 135.6 0.5 3.9 -29.5 -2.4 1210.8 25.2

Bottom Edge

Live Load 20.1 0.0 1.7 -16.7 -0.7 1799.9 15.6

P - Axial Load (kN), Mx, My - Bending Moment About X-X / Y-Y Axis (kNm), Vx, Vy - Shear Force Along X-X / Y-Y Axis (kN)

X - Eccentricity of Axial Load from Left Reference of Section (mm), M - Moment by Eccentricity of Axial Load (kNm) where M = P × (Panel Length / 2 - X)

Sign of Top Edge Reactions have been reversed to be comparable to bottom edge

Loadings listed above does not consider load allowance of 10% specified by user

Sub-Frame 2D Analysis Result (Mx) for RC Wall 1C/C-C1Sub Panel 1 (Reg. 1)

Current Floor: 1B, Zone Length = 1850 mm

No. Floor Length Loc. D.L. L.L. Min. Max.

Top 0.27 0.11 0.55 0.69

1 1B 2050

Bot 0.76 0.21 1.40 1.40

Length - Distance of the first node to the last node of the 2D SubFrame Panel/Group Mesh (mm), Loc. - Location of Result (Top or Bottom of the Panel)

D.L., L.L. - Dead / Live Load Moment from Plan Sub-Frame Analysis (kNm)

Min., Max. - Minimum/Maximum Gravity Pattern Loading from Plan Sub-Frame Analysis (kNm)

Lower Floor: GB, Zone Length = 1850 mm

No. Floor Length Loc. D.L. L.L. Min. Max.

Top -0.07 -0.06 -0.20 -0.47

1 1B 2050

Bot -0.39 -0.34 -1.10 -1.72

Length - Distance of the first node to the last node of the 2D SubFrame Panel/Group Mesh (mm), Loc. - Location of Result (Top or Bottom of the Panel)

D.L., L.L. - Dead / Live Load Moment from Plan Sub-Frame Analysis (kNm)

Min., Max. - Minimum/Maximum Gravity Pattern Loading from Plan Sub-Frame Analysis (kNm)

Wall Panel 3D Analysis Result for Sub Panel 1 (Reg. 1)

Loading Reaction Load Mx

No P Mx My Vx Vy X M Process

Source Edge Comb. (Ecc)

1 G.L. B.E. LC1 244.3 -1.9 9.0 -74.8 -4.9 1296.2 66.2 2.4 Design

2 G.L. B.E. Min 149.2 -1.9 4.2 -32.5 -2.6 1210.8 27.7 1.5 Analysis

3 G.L. T.E. LC1 202.7 2.0 -3.7 -72.8 4.0 679.4 -70.1 2.0 Analysis

4 G.L. T.E. Min 112.0 1.0 -1.8 -31.8 1.9 753.2 -30.4 1.1 Analysis

Loading Source - G.L. for Gravity, W.L. for Wind Load, N.L. for Notional Load, S.L. for Seismic Load

Gravity Load Mx always uses greater of (3D, 2D Pattern Loading), Reaction Edge - Top Edge(T.E.) or Bottom Edge(B.E.)

Load Comb. - User Specified Load Combination in parameter, Min for minimum gravity load (1.0DL)

P - Axial Load (kN), Mx / My - Design Bending Moment About X-X / Y-Y Axis (kNm), Vx / Vy - Design Shear Force In X-X / Y-Y Axis (kN)

X - Eccentricity of Axial Load from Left Reference of Section (mm), M - Moment by Eccentricity of Axial Load (kNm) where M = P × (Panel Length / 2 - X)

Mx(Ecc) - Moment due to Minimum Eccentricity (emin) about wall minor axis (kNm)

Process - Process of Applied Loadings (Design/Analysis)

Load allowance of 10% has been added specified by user

Wall Zone Braced/Unbraced and Short/Slender Condition Table for RC Wall Sub Panel 1 (Reg. 1)

Wall Clear Height, lo = 3600 mm

Loading Braced/

No. P Vy ∆y Qy Short/ Slender

Source Unbraced

1 G.L. - - - - Braced Short

2 G.L.(Min) - - - - Braced Short

3 G.L. - - - - Braced Short

4 G.L.(Min) - - - - Braced Short

Loading Source - G.L. Gravity, W.L. for Wind Load, N.L. for Notional Load, S.L. for Seismic Load

P - Axial Force (kN), Vy - Shear Force in Wall Panel Local Y-Y Axis (kN)

∆y - RC. Wall Drift in Local Y-Y Axis (mm), Qy - RC. Wall Stability Index in Local Y-Y Axis (Q = P × ∆ / V × h)

Braced/Unbraced - RC. Wall Braced/Unbraced Condition in Local Y-Y Axis (mm), Limit Value = 0.05

Short/Slender - RC. Wall Short/Slender Condition in Local Y-Y Axis (mm)

All Gravity Load Cases Assigned as Braced regardless the Stability Index

Wall Zone Slenderness Limit Check

Wall Clear Height, lo = 3600 mm

Top Element Stiffness, KeTop = ∑KsTop + ∑KbTop + ∑KtwTop = 10659375.0 mm³

Bottom Element Stiffness, KeBot = ∑KsBot + ∑KbBot + ∑KtwBot = 7701358.7 mm³

Wall Stiffness, Kw = 4111111.1 mm³

Restraint Elements at the top part of wall zone

Elememt

No. Mark Width a, mm Depth b, mm Length L, mm Angle α, ° K

Type

1 Slab FS203:1 1025 150 1000 90.0 1729688

2 Slab FS257:1 1025 150 1000 90.0 1729688

3 Beam 1B39(230x600) - 1 230 600 6900 90.0 3600000

4 TWall C/1C-2A 200 3600 5000 90.0 933120000

5 TWall C1/1C-2A 200 3600 5000 90.0 933120000

K = 0 when the element is skipped from computation of restrain condition, please refer to the technical documentation

K = |Sin α| × [a × b³ / (12 × L)]

Restraint Elements at the bottom part of wall zone

Elememt

No. Mark Width a, mm Depth b, mm Length L, mm Angle α, ° K

Type

1 Slab FS191:1 2050 150 6900 90.0 501359

2 Beam GB33(230x600) - 1 230 600 6900 90.0 3600000

3 TWall C/1C-2A 200 4500 5000 90.0 1822500000

4 TWall C1/1C-2A 200 4500 5000 90.0 1822500000

K = 0 when the element is skipped from computation of restrain condition, please refer to the technical documentation

K = |Sin α| × [a × b³ / (12 × L)]

Effective Length Factor, β for Braced Condition

Relative Stiffness at Top of Element, αTop = 0.386

Relative Stiffness at Bottom of Element, αBot = 0.534

β1 = 0.7 + 0.05 × (αTop + αBot) = 0.75, β2 = 0.85 + 0.05 × Min (αTop, αBot) = 0.87

β = Min (β1, β2) = 0.75 < 1.0

Effective Length Factor, β for Unbraced Condition

Relative Stiffness at Top of Element, αTop = 0.386

Relative Stiffness at Bottom of Element, αBot = 0.534

β1 = 1.0 + 0.15 × (αTop + αBot) = 1.14, β2 = 2.0 + 0.3 × Min (αTop, αBot) = 2.12

β = Min (β1, β2) = 1.14

Wall Effective Height for Braced Condition, le = ßBraced × lo = 2700 mm

Wall Effective Height for Unbraced Condition, le = ßUnbraced × lo = 4104 mm

Clause 3.9.3.7.2 Limits of slenderness

Slenderness Ratio for braced condition le / h = 2700.0 / 200 = 13.5 ≤ 40 ← Checking for slenderness upper limit pass

Slenderness Result (Using Load Case Region 1 Load 1)

Lateral Force, V = 0, Use Stability Index Q = 0 for Gravity Load, The Element is Braced

Slenderness Ratio, sr = Leff / t = 2700.0 / 200 = 13.5 < 15 → The Wall is Short About X-X Axis

Design load selected is short (not slender), no slenderness iteration table and calculation will be shown

Loading Data

Design Loading Selected from Region 1 Load No. 1

Loading / Loadings from 3D Analysis Result

Loading Type Reaction Edge Load Comb. P Mx My Vx Vy X M

G.L. B.E. 1 244.3 -1.9 9.0 -74.8 -4.9 1296.2 66.2

Loading Type - Source of Loading (Gravity, Wind Load, Notional Load)

Reaction Edge - Top Edge(T.E.) or Bottom Edge(B.E.), Load Comb. - User Specified Load Combination

P - Axial Load (kN), Mx, My - Design Bending Moment About X-X / Y-Y Axis (kNm), Vx, Vy - Design Shear Force In X-X / Y-Y Axis (kN)

X - Eccentricity of Axial Load from Left Reference of Section (mm), M - Moment by Eccentricity of Axial Load (kNm) where M = P × (Panel Length / 2 - X)

Load allowance of 10% has been added specified by user

Sub-Panel Applied Axial Force, F = 244.3 kN

Sub-Panel Axial Force Capacity, FCap = 3615.2 kN

Sub-Panel Applied Moment About X-X Axis, Mx = 2.4 kNm

Sub-Panel Moment Capacity About X-X Axis, MxCap = 36.2 kNm

Sub-Panel Applied Moment About Y-Y Axis, My = 75.2 kNm

Sub-Panel Moment Capacity About Y-Y Axis, MyCap = 1113.6 kNm

Wall Sub-Panel Analysis/Design Passed

Vertical Reinforcement Provided: 14T12-300 (0.43%)

Shear Design and Checking Calculation

Basic Shear Design Data for Sub-Panel

H = 1850.0 mm, B = 200.0 mm, Concrete Cover, cov = 25 mm

Vertical Bar Diameter, ΦV = 12 mm, Horizontal Bar Diameter, ΦH = 10 mm

Effective Depth for Shear Design, d = H - cov - ΦH - ΦV / 2 = 1809.0 mm

Design Shear Force, V = 74.8 kN, Bending Moment, M = 2.0 kNm, Axial Force, N = 244.3 kN

Shear Stress, νss = V × 1000 / (b × d) = 74.8 × 1000 / (200.0 × 1809.0) = 0.21 N/mm²

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 74.8 × 1000 / (200.0 × 1809.0) = 0.21 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.15 % ≤ 3.0 %

0.15% of steel is used for calculation of compressive member

Effective Depth Ratio, edr = 400 / d = 400 / 1809.0 = 0.221

(400 / d)^ ¼ = 0.686 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.15}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.36 N/mm²

Clause 3.4.5.12: eqn. 6a

VhM Ratio = V × h / M = 74809 × 1850.0 / 2043431 = 67.73 > 1.00, VhM Ratio taken as 1.00

Design Shear Capacity, νc1' = νc + 0.60 × (N / Ac) × VhM = 0.357 + 0.60 × (244253.2 / 370000.0) × 1.00 = 0.753 N/mm²

Clause 3.4.5.12: eqn. 6b

Design Shear Capacity, νc2' = νc × SQRT[(1 + N / (Ac × νc)] = 0.357 × SQRT[(1 + 244253.2 / (370000.0) × 0.36] = 0.602 N/mm²

Select νc2' as νc' for design

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.207 < νc' + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 200) / (0.95 × 460) = 0.183 mm²/mm

Using link diameter ΦH = 10 mm (SAsv = 157.1 mm²) and spacing, Sv = 300 mm

SAsv_SvProv = SAsvProv / Sv = 157.1 / 300 = 0.524 mm²/mm ≥ SAsv_Sv (0.183 mm²/mm)

Provided 2 X 12T10-300, Shear Checking / Design Passed

Total horizontal steel area provided, AsProv(H) = 24 × 78.5 = 1885 mm²

Minimum steel percentage required, AsMin = 0.01 × 0.25 × (3600 × 200) = 1800 mm² <= 1885, OK

Checking for horizontal steel percentage passed

You might also like

- Water Retaining Structures To Bs 8007 and Bs 8110: Calculations OutputDocument93 pagesWater Retaining Structures To Bs 8007 and Bs 8110: Calculations Outputazwan100% (4)

- Sedimentation Tank DesignDocument6 pagesSedimentation Tank DesignManish KumarNo ratings yet

- Simple Beam ExampleDocument13 pagesSimple Beam ExampleJMATALLANAARENASNo ratings yet

- ChannelDocument2 pagesChannelyasirjurabaNo ratings yet

- Annexure V Canopy DesignDocument6 pagesAnnexure V Canopy Designkrishna100% (1)

- Trimdek DesignDocument10 pagesTrimdek Designakgupta733779No ratings yet

- Analysis: Tedds Calculation Version 1.0.23Document10 pagesAnalysis: Tedds Calculation Version 1.0.23Sachin AgarwalNo ratings yet

- RC Beam Analysis and Design (ACI318)Document12 pagesRC Beam Analysis and Design (ACI318)JMATALLANAARENASNo ratings yet

- ANALYSIS AND DESIGN OF BEAMDocument16 pagesANALYSIS AND DESIGN OF BEAMMbabazi RodneyNo ratings yet

- WL-2 1kpaDocument3 pagesWL-2 1kpamuralidharan10901No ratings yet

- RCC31R Rigorous One-Way SlabsDocument148 pagesRCC31R Rigorous One-Way SlabsMohammad Twaha JaumbocusNo ratings yet

- Column DesignDocument2 pagesColumn Designjohnstruct archNo ratings yet

- RCC31R Rigorous One-Way SlabsDocument389 pagesRCC31R Rigorous One-Way SlabsCioabla BogdanNo ratings yet

- 15m Brick Wall Frame 2021-08-21Document21 pages15m Brick Wall Frame 2021-08-21Jack WenNo ratings yet

- ETABS Concrete Frame DesignDocument2 pagesETABS Concrete Frame DesignRabi DhakalNo ratings yet

- First Floor RC Slab Design (EN1992)Document5 pagesFirst Floor RC Slab Design (EN1992)Shingirai JoeNo ratings yet

- WL-3 6kpaDocument3 pagesWL-3 6kpamuralidharan10901No ratings yet

- BeamDocument10 pagesBeamdoggNo ratings yet

- Bearing Design Design NoteDocument4 pagesBearing Design Design Notearepelli madhuNo ratings yet

- 003 TEKO B3 C 050 DFE 02 10.1 YA Staticki Proracun 6 EnglishDocument43 pages003 TEKO B3 C 050 DFE 02 10.1 YA Staticki Proracun 6 EnglishVasilijeNo ratings yet

- Project Job No.: U U Ua CR 4 U NDocument1 pageProject Job No.: U U Ua CR 4 U NAnonymous 0x2pwMCWgjNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 18EMACAKL7JTANKDocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 18EMACAKL7JTANKSanjeev SanjeevNo ratings yet

- LL1-0 89kNDocument6 pagesLL1-0 89kNmuralidharan10901No ratings yet

- PS4dDocument7 pagesPS4dgeethkumaraNo ratings yet

- LL2-0 73kNperMDocument3 pagesLL2-0 73kNperMmuralidharan10901No ratings yet

- Research Paper Study On Comparative Analysis of The TDocument14 pagesResearch Paper Study On Comparative Analysis of The Tlilharerakesh12No ratings yet

- ETABS 2016 Concrete Frame Design: IS 456:2000 Column Section DesignDocument2 pagesETABS 2016 Concrete Frame Design: IS 456:2000 Column Section DesignSamikshya ShahNo ratings yet

- Member Reinforced Concrete Column Design Report (AS-3600) PDFDocument13 pagesMember Reinforced Concrete Column Design Report (AS-3600) PDFdongshengNo ratings yet

- Design of Structural MemberDocument50 pagesDesign of Structural Memberfrancis sebastian lagamayoNo ratings yet

- Villa Assaf ReportDocument37 pagesVilla Assaf ReportReda AtianNo ratings yet

- Structural Calculation of Embed Balustrade-R2Document46 pagesStructural Calculation of Embed Balustrade-R2vengadNo ratings yet

- Aci 95Document14 pagesAci 95Joseph AsfourNo ratings yet

- Tapered High Mast VerficationDocument11 pagesTapered High Mast VerficationBN KWNo ratings yet

- Etabs Column Design MT CalculationDocument2 pagesEtabs Column Design MT CalculationAung SoneNo ratings yet

- LL1-0 89kpaDocument3 pagesLL1-0 89kpamuralidharan10901No ratings yet

- Midasit: 1. General InformationDocument2 pagesMidasit: 1. General InformationEng Phearum100% (1)

- Steel column and base plate design (EN1993)Document8 pagesSteel column and base plate design (EN1993)Sulakx KuruNo ratings yet

- Sheet Pile Design: Fspiii S275 Hot RolledDocument1 pageSheet Pile Design: Fspiii S275 Hot Rolledhessian123No ratings yet

- Chapter 5 B&WDocument12 pagesChapter 5 B&WPoshan DhunganaNo ratings yet

- Calculation PDFDocument126 pagesCalculation PDFmohammed almahrooqiNo ratings yet

- ETABS 2015 15.1.0-Design DetailsDocument2 pagesETABS 2015 15.1.0-Design DetailsdenyfateNo ratings yet

- WL-1 75kpaDocument6 pagesWL-1 75kpamuralidharan10901No ratings yet

- 150x100x10UA STANDARD LINTEL 3.6mDocument9 pages150x100x10UA STANDARD LINTEL 3.6mTerry CheukNo ratings yet

- Ang Residence (Flatdeck 1.0mm X 100mm THK Slab)Document6 pagesAng Residence (Flatdeck 1.0mm X 100mm THK Slab)Pandaman227No ratings yet

- Fer Pot S-SolDocument3 pagesFer Pot S-SolhadjmiloudbhmNo ratings yet

- ETABS Concrete Frame Design: ETABS 19.0.0 License # 1AVSJX3S5D5WKQEDocument2 pagesETABS Concrete Frame Design: ETABS 19.0.0 License # 1AVSJX3S5D5WKQEAastha AdhiakariNo ratings yet

- Aashto LRFD Railway FlyoverDocument54 pagesAashto LRFD Railway FlyoverShaileshRastogiNo ratings yet

- WL 2.1kpa (10 8)Document6 pagesWL 2.1kpa (10 8)muralidharan10901No ratings yet

- ETABS 2015 15.1.0-Design DetailsDocument2 pagesETABS 2015 15.1.0-Design DetailsdenyfateNo ratings yet

- Draft Report PDFDocument10 pagesDraft Report PDFSupun Aravinda JayawardhaneNo ratings yet

- Final Twoway SlabDocument20 pagesFinal Twoway Slabvishnumani3011No ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1UARYUV5QA3ALLSDocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1UARYUV5QA3ALLSRakesh ShresthaNo ratings yet

- LL-0 73knpermDocument7 pagesLL-0 73knpermmuralidharan10901No ratings yet

- Report 30 TonDocument10 pagesReport 30 TonMARYANo ratings yet

- Report 30 TonDocument10 pagesReport 30 TonMARYANo ratings yet

- Design Calculation For 9 MM Fibrous Plaster CeilingDocument13 pagesDesign Calculation For 9 MM Fibrous Plaster CeilingNur Fadzlini RamliNo ratings yet

- WL-1 2kpaDocument6 pagesWL-1 2kpamuralidharan10901No ratings yet

- 7tc1 Top FixedDocument2 pages7tc1 Top FixedEmily ShumNo ratings yet

- WL-2 1kpaDocument6 pagesWL-2 1kpamuralidharan10901No ratings yet

- WIND02 v2-21: Detailed Wind Load Analysis Per ASCE 7-16Document4 pagesWIND02 v2-21: Detailed Wind Load Analysis Per ASCE 7-16Neil Checalla ApazaNo ratings yet

- 17.52mm Glass - Elligton-1.6kpaDocument3 pages17.52mm Glass - Elligton-1.6kpamuralidharan10901No ratings yet

- Application For Top-Up Switching Valuation Oct2021Document6 pagesApplication For Top-Up Switching Valuation Oct2021azwanNo ratings yet

- Gee - SW Pe Calculation (Old)Document16 pagesGee - SW Pe Calculation (Old)azwan100% (1)

- Gee - SW PeDocument7 pagesGee - SW PeazwanNo ratings yet

- Slab Design - OkDocument35 pagesSlab Design - OkazwanNo ratings yet

- GEE - SW PE Calculation (Rev01)Document7 pagesGEE - SW PE Calculation (Rev01)azwanNo ratings yet

- GEE - SW Hyraulic CalculationDocument2 pagesGEE - SW Hyraulic CalculationazwanNo ratings yet

- Pilecap Design by Bending Theory To B.S 8110 & B.S 8004Document59 pagesPilecap Design by Bending Theory To B.S 8110 & B.S 8004azwanNo ratings yet

- Slab Summary Report - RFDocument11 pagesSlab Summary Report - RFazwanNo ratings yet

- Beam Key Plan Report - 2BDocument17 pagesBeam Key Plan Report - 2BazwanNo ratings yet

- Beam Design Detail Report: Material and Design DataDocument33 pagesBeam Design Detail Report: Material and Design DataazwanNo ratings yet

- Beam Design Detail Report: Material and Design DataDocument20 pagesBeam Design Detail Report: Material and Design DataazwanNo ratings yet

- Beam Design Detail Report: Material and Design DataDocument10 pagesBeam Design Detail Report: Material and Design DataazwanNo ratings yet

- Beam Design Detail Report: Material and Design DataDocument32 pagesBeam Design Detail Report: Material and Design DataazwanNo ratings yet

- Chee ReportDocument6 pagesChee ReportkagoNo ratings yet

- Sourcebook of Alternative Technologies For Freshwater Augumentation in Some Countries in AsiaDocument5 pagesSourcebook of Alternative Technologies For Freshwater Augumentation in Some Countries in AsiaNambi HarishNo ratings yet

- External Prestressing Concrete Columns With Fibrous Composite BeltsDocument16 pagesExternal Prestressing Concrete Columns With Fibrous Composite BeltsmagdyamdbNo ratings yet

- Rule VII Guidelines-1-1Document10 pagesRule VII Guidelines-1-1CEDEÑO, Jhon Mark T.No ratings yet

- 364 419 PDFDocument56 pages364 419 PDFDonNo ratings yet

- Bending Fatigue of Stainless Steel Shear Pins BelongingDocument15 pagesBending Fatigue of Stainless Steel Shear Pins BelongingAldi YansahNo ratings yet

- Alappuzha Panchakarma EstimateDocument12 pagesAlappuzha Panchakarma Estimateanwarkdr@gmail.comNo ratings yet

- SL No. Description UOM Qty Rate AmountDocument6 pagesSL No. Description UOM Qty Rate AmountSreekanth SattirajuNo ratings yet

- XXX X XXXX XXXX X XX XX 00 20xx Ieee DesDocument4 pagesXXX X XXXX XXXX X XX XX 00 20xx Ieee DesDan OdunlamiNo ratings yet

- Topic 2 - Designing The HighwayDocument10 pagesTopic 2 - Designing The Highwaygreg100% (2)

- Bricks: LT Col G M Faruque Ce Dept, MistDocument32 pagesBricks: LT Col G M Faruque Ce Dept, MistRj 30No ratings yet

- Fosroc Structuro W415: Constructive SolutionsDocument2 pagesFosroc Structuro W415: Constructive SolutionsVincent JavateNo ratings yet

- Staad. Pro. A Tool For Civil Engineer'S: Presented By:-Rohit Rai, (Assistant Professor Muit, LucknowDocument12 pagesStaad. Pro. A Tool For Civil Engineer'S: Presented By:-Rohit Rai, (Assistant Professor Muit, LucknowRohit RaiNo ratings yet

- False Ceiling: MMBC 7Th SemDocument54 pagesFalse Ceiling: MMBC 7Th SemBmssa 2017BNo ratings yet

- Truss 01: Mr. & Mrs. Sire Henrik Andersson A Proposed Penthouse ExtensionDocument1 pageTruss 01: Mr. & Mrs. Sire Henrik Andersson A Proposed Penthouse ExtensionChrysler DuasoNo ratings yet

- A Comparative Study On Three Different Types of Shear Walls in Different Location in Buildings Subjected To Seismic Loading by Linear Static AnalysisDocument10 pagesA Comparative Study On Three Different Types of Shear Walls in Different Location in Buildings Subjected To Seismic Loading by Linear Static AnalysisIftesham BasharNo ratings yet

- Bearing CapacityDocument53 pagesBearing Capacitylike a roseNo ratings yet

- Performance of High-Strength Concrete Corbels: Aci Structural Journal Technical PaperDocument9 pagesPerformance of High-Strength Concrete Corbels: Aci Structural Journal Technical PaperpicottNo ratings yet

- Catalogue - en - Arcoplus Reversò 6166 626Document4 pagesCatalogue - en - Arcoplus Reversò 6166 626Niraj BorikarNo ratings yet

- Rigid PCADocument36 pagesRigid PCAEmad Elhussieny100% (2)

- Saep 306Document13 pagesSaep 306Narvis RinconNo ratings yet

- viewNitPdf 3197038 PDFDocument12 pagesviewNitPdf 3197038 PDFabNo ratings yet

- International Council For Research and Innovation in Building and Construction Working Commission W18 - Timber StructuresDocument444 pagesInternational Council For Research and Innovation in Building and Construction Working Commission W18 - Timber Structuresaerodanger100% (1)

- Hydraulic Performance Coarse Rockfill Deposits HansenDocument13 pagesHydraulic Performance Coarse Rockfill Deposits HansenjcasafrancaNo ratings yet

- Proposed Roofing ShedDocument7 pagesProposed Roofing ShedBekaar AadameeNo ratings yet

- Joint Design Module 5Document77 pagesJoint Design Module 521f1006013No ratings yet

- 2022 Buildcrete Product Installation ManualDocument13 pages2022 Buildcrete Product Installation ManualIan Patrick WijayaNo ratings yet

- A) Rock Wall Contact, and B) Wall Contact Before 10 CM ShearDocument1 pageA) Rock Wall Contact, and B) Wall Contact Before 10 CM ShearJio MarnnNo ratings yet

- Bridge Condition Survey ManualDocument25 pagesBridge Condition Survey ManualkmabdNo ratings yet