Professional Documents

Culture Documents

30 ML Moulded Vial Filling OQ

30 ML Moulded Vial Filling OQ

Uploaded by

Subhash NaiduOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

30 ML Moulded Vial Filling OQ

30 ML Moulded Vial Filling OQ

Uploaded by

Subhash NaiduCopyright:

Available Formats

JODAS EXPOIM PVT. LTD.

OPERATIONAL QUALIFICATION

Equipment /System Name Powder Vial Filling & Bunging Machine

Protocol No. CE/PR/OQ/P-005 (S-03) Equipment /System No. CE/PR/VFM/005

Location Ceph. Block-Production Area Page No. 1 of 15

OPERATIONAL QUALIFICATION

OF

VIAL FILLING & BUNGING MACHINE (30 ML MOULDED VIALS)

EQUIPMENT No.: CE/PR/VFM/005

Format No. : QA009-F02-00

JODAS EXPOIM PVT. LTD.

OPERATIONAL QUALIFICATION

Equipment /System Name Powder Vial Filling & Bunging Machine

Protocol No. CE/PR/OQ/P-005 (S-03) Equipment /System No. CE/PR/VFM/005

Location Ceph. Block-Production Area Page No. 2 of 15

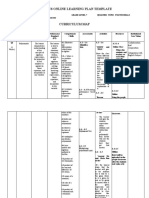

TABLE OF CONTENTS

1.0 OBJECTIVE: ................................................................................................................................ 3

2.0 REASON FOR QUALIFICATION: ............................................................................................... 4

3.0 PERSONNEL RESPONSIBILITIES:............................................................................................. 5

4.0 EXECUTION TEAM: ..................................................................................................................... 6

5.0 PRE REQUISITES: ....................................................................................................................... 6

6.0 EQUIPMENT /SYSTEM QUALIFICATION PROCEDURE: ........................................................... 7

7.0 DEVIATIONS/DISCREPANCIES RECORD: ............................................................................... 12

8.0 REFERENCE DOCUMENTS: ..................................................................................................... 13

9.0 ABBREVIATIONS: ..................................................................................................................... 13

10.0 ANNEXURES: ............................................................................................................................ 13

11.0 ATTACHMENTS ......................................................................................................................... 14

12.0 SUMMARY ................................................................................................................................. 15

Format No. : QA009-F02-00

JODAS EXPOIM PVT. LTD.

OPERATIONAL QUALIFICATION

Equipment /System Name Powder Vial Filling & Bunging Machine

Protocol No. CE/PR/OQ/P-005 (S-03) Equipment /System No. CE/PR/VFM/005

Location Ceph. Block-Production Area Page No. 3 of 15

1.0 OBJECTIVE:

The objective of this study is to demonstrate that the VIAL FILLING AND BUNGING MACHINE

located at Jodas Expoim Pvt. Ltd., plot No: 55, phase-3, Biotech Park, Karkapatla village is capable

of consistently and effectively filling and stopperring of 30 mL molded glass vials with 20mm rubber

stoppers.

Vial Size:

S.No Vial size & Type Neck size Stopper size

1 30 ml moulded vial 20 mm 20 mm plain rubber stoppers

Ref. CCF No.: CCPR/012-16.

Background: Initially The vial filling and bunging machine was qualified for 20 ml tubular vials and

20 ml moulded vials. ( Protocol No. CE/PR/OQ/P-005 & CE/PR/OQ/P-005(S-01) ). 30 ml moulded

change parts are added to the vial filling and bunging machine. Qualification of vial filling and

bunging machine for 30 ml moulded vials is doing with supplement protocol.

This Qualification includes:

Closure placement

Establishment of machine speeds & verification of Vial filling and bunging machine

Vial output verification

Format No. : QA009-F02-00

JODAS EXPOIM PVT. LTD.

OPERATIONAL QUALIFICATION

Equipment /System Name Powder Vial Filling & Bunging Machine

Protocol No. CE/PR/OQ/P-005 (S-03) Equipment /System No. CE/PR/VFM/005

Location Ceph. Block-Production Area Page No. 4 of 15

2.0 REASON FOR QUALIFICATION:

Please select the appropriate option by marking with “ " in the box given against each option:

New Installation (30 ml moulded change parts)

Change in location

Replacement of major component of the equipment with a new component.

Any major modification in existing equipment

Other (Please specify)

_______________________________________________________________________________

______________________________________________________________________________

Format No. : QA009-F02-00

JODAS EXPOIM PVT. LTD.

OPERATIONAL QUALIFICATION

Equipment /System Name Powder Vial Filling & Bunging Machine

Protocol No. CE/PR/OQ/P-005 (S-03) Equipment /System No. CE/PR/VFM/005

Location Ceph. Block-Production Area Page No. 5 of 15

3.0 PERSONNEL RESPONSIBILITIES:

Responsibilities of individual department / personnel while performing the Operational Qualification

of the Vial filling and bunging machine are as under :

Validation

Responsible for preparation and review of protocol.

Provision of training to all concerned persons on protocol prior to execution.

Assist in the investigation of OQ variances if any.

Execution, monitoring and review of the qualification activities.

Verifies that the test requirements described in protocol are meeting criteria for the

performed tests and properly documented.

Prepare the summary and conclusion of the qualification activity.

Production

Execution of the protocol.

Operate the equipment as per SOIs.

Investigation of OQ variances if any.

Head / Designee shall be responsible for review of the protocol, summary & conclusion and

approval of the completed Qualification protocol.

Engineering

Execution of the protocol in co-ordination with production (wherever applicable).

Assists investigation of OQ variances if any.

Head / Designee shall be responsible for review of the protocol, Summary & conclusion and

approval of the completed Qualification protocol.

Quality Assurance

Quality Assurance Head/ Designee shall be responsible for Approval of the protocol, review

of summary & conclusion and completed Qualification data and report.

Format No. : QA009-F02-00

JODAS EXPOIM PVT. LTD.

OPERATIONAL QUALIFICATION

Equipment /System Name Powder Vial Filling & Bunging Machine

Protocol No. CE/PR/OQ/P-005 (S-03) Equipment /System No. CE/PR/VFM/005

Location Ceph. Block-Production Area Page No. 6 of 15

4.0 EXECUTION TEAM:

4.1 Training to the Executors:

The executors shall be trained before the execution of protocol. Fill the details in training

Format as per the Training SOP No: QA006 and attach the training record.

4.2 List of Executors Involved in Qualification Study:

Record the details of the executors involved in the Qualification activity like name,

department, designation and training details with signature and date in the Annexure-1.

5.0 PRE REQUISITES:

Sr. Checked by Verified

Description Yes/No/NA

No. (PR) by (PR)

Installation of the Powder vial filling &

1. bunging machine is completed. (30 ml

moulded vial change parts).

2. All supporting utilities are connected.

Required power/electrical connections are

3.

given to control panel.

Training is imparted to personnel responsible

4.

to execute the study.

5. Others if any _____________.

Note: The above pre-requisites should be verified and if complete the Operational qualification shall

be carried out.

Comments:

Reviewed by (VA): Date:

Format No. : QA009-F02-00

JODAS EXPOIM PVT. LTD.

OPERATIONAL QUALIFICATION

Equipment /System Name Powder Vial Filling & Bunging Machine

Protocol No. CE/PR/OQ/P-005 (S-03) Equipment /System No. CE/PR/VFM/005

Location Ceph. Block-Production Area Page No. 7 of 15

6.0 EQUIPMENT /SYSTEM QUALIFICATION PROCEDURE:

The Operational qualification of the Vial filling and bunging machine (30ml moulded vials with 20mm

neck) shall be done by verifying / testing following parameters;

1. Closure placement

2. Establishment of machine speeds & verification of Vial filling and bunging machine performance

3. Vial output verification

4. The detailed procedure for execution of each test is provided in step 6.1 of this protocol.

The above-mentioned tests provide documented verification of the intended performance of the Vial

Filling and bunging machine throughout the representative / anticipated operating range.

The below mentioned change parts are made for 30 ml moulded vials.

Sr. No. Details of Change parts Quantity (No.s) Material

1 Turret (PCD 121) 5 Delrin

2 Turret (PCD 181.5) 5 Delrin

3 Turret (PCD 211.75) 2 Delrin

4 Turret (PCD 302.5) 1 Delrin

5 Turret (Servo) 2 Delrin

6 Turret (Rejection) 1 Delrin

7 Vial guide – I(Conveyor) 1 Delrin

8 Vial guide – II(Conveyor) 1 Delrin

9 Vial guide – III(Conveyor) 1 Delrin

10 Vial guide – IV(Conveyor) 1 Delrin

11 Vial guide – V(Conveyor) 1 Delrin

12 Vial guide – VI(Conveyor) 1 Delrin

13 Vial guide – VII(Conveyor) 1 Delrin

14 Vial guide – VIII(Conveyor) 1 Delrin

15 Vial guide – IX(Conveyor) 1 Delrin

Format No. : QA009-F02-00

JODAS EXPOIM PVT. LTD.

OPERATIONAL QUALIFICATION

Equipment /System Name Powder Vial Filling & Bunging Machine

Protocol No. CE/PR/OQ/P-005 (S-03) Equipment /System No. CE/PR/VFM/005

Location Ceph. Block-Production Area Page No. 8 of 15

Sr. No. Details of Change parts Quantity (No.s) Material

16 Vial guide – (Track changer - 1 Delrin

small)

17 Vial guide – (Track changer - 1 Delrin

Bigl)

18 Vial guide – X(Outfeed Front) 1 Delrin

19 Vial guide – XI(Outfeed back) 1 Delrin

20 Vial guide – XII(Rejection tray) 1 Delrin

21 Suction pin 12 SS304

22 Int. Guide – I (Front) 1 Delrin

23 Int. Guide – II (Back) 1 Delrin

24 Un scrambler Guide – I 1 Delrin

25 Un scrambler Guide – II 1 Delrin

26 Un scrambler Guide – III 1 Delrin

27 Un scrambler Guide – IV 1 Delrin

28 Bellows 12 Delrin

29 Bracket For Un scrambler Guide 1 Delrin

6.1 Test Data:

The detailed procedure for execution of each test described above is given in the following pages.

Switch on the main power of Vial filling and bunging machine and enter in the "SCADA / HMI" by

following the SOI.

Format No. : QA009-F02-00

JODAS EXPOIM PVT. LTD.

OPERATIONAL QUALIFICATION

Equipment /System Name Powder Vial Filling & Bunging Machine

Protocol No. CE/PR/OQ/P-005 (S-03) Equipment /System No. CE/PR/VFM/005

Location Ceph. Block-Production Area Page No. 9 of 15

6.1.1 Closure placement

Objective : The objective of the Height establishment for stopper pressing unit is to

establish the minimum and maximum height for stoppering of 30 ml

moulded vials with 20 mm rubber stoppers

Tools required : 30 mL moulded glass vials & 20 mm Rubber stopper.

Test procedure : Set the machine at established minimum machine speed for 30 ml

vials.

Set the Stopper pressing unit to the maximum height in accordance

with the vial size and record the height of pressing unit.

Run the Vial filling and Stoppering Machine as per SOI and collect

minimum of 1000 no’s.

Inspect the 500 nos. of vials for proper stoppering at maximum

stoppering height for placing the stopper uniformly & axially without

any gap.

Carry out the stoppering by decreasing the stopper pressing unit

height at minimum machine speed for applicable vial size & rubber

stopper.

Inspect the vials 500 no’s of for proper stoppering at minimum

stoppering height for placing the stopper uniformly & axially without

any gap.

Note: Ensure that the visual defects inspection activity shall be

carried out by visual inspector.

Repeat the above procedure at established maximum speed

Record the observations in Annexure-2.

Acceptance criteria : The minimum & maximum stoppering height should produce acceptable

product such that

- The rubber stoppers shall be placed on vials uniformly without any

gap.

- No popping out of rubber stopper shall be observed.

- Stoppering must be performed correctly, completely and axially to the

vial body and the stopper must not have any scratches, cracks.

Format No. : QA009-F02-00

JODAS EXPOIM PVT. LTD.

OPERATIONAL QUALIFICATION

Equipment /System Name Powder Vial Filling & Bunging Machine

Protocol No. CE/PR/OQ/P-005 (S-03) Equipment /System No. CE/PR/VFM/005

Location Ceph. Block-Production Area Page No. 10 of 15

6.1.2 Establishment of machine speeds & verification of Vial filling and bunging machine

performance

Objective : The objective is to establish the minimum and maximum machine

speeds for 30 ml moulded vial and to ensure the correct applications like

vial feeding, powder feeding, powder dosing, stopper feeding,

stoppering of vials and vial out feed.

Tools required : 30 mL moulded vials & 20 mm Rubber stopper.

Test procedure : Set the machine at minimum possible speed and run the machine as

per SOI to verify smooth functioning of machine and establish the

minimum speed for single, double , triple and four doses and record

the observations in Annexure No – 3

Run the Vial filling and bunging machine for 5 minutes

Repeat the above step at maximum possible speed and record the

observations in Annexure No – 3

Set the machine at established minimum speed and target fill weight

as 250 mg for 30ml vials and operate the vial filling and stoppering

machine as per SOI.

Inspect the vial feeding performance from infeed conveyor to powder

dosing machine.

Check the vial transport to the track-1 and track-2.

Observe the operation of gas pre purging station.

Check the powder dosing from dosing station into vials.

Observe the operation of gas post purging station.

Inspect the proper vial traveling from dosing station to stoppering

station.

Check the stopper feeding to stoppering station and placing of

stoppers from stoppering station onto the vials.

Check the vial transport on out feed conveyor.

Check for any unusual observations if any throughout the activity

and record.

Format No. : QA009-F02-00

JODAS EXPOIM PVT. LTD.

OPERATIONAL QUALIFICATION

Equipment /System Name Powder Vial Filling & Bunging Machine

Protocol No. CE/PR/OQ/P-005 (S-03) Equipment /System No. CE/PR/VFM/005

Location Ceph. Block-Production Area Page No. 11 of 15

Record all the observations in the Annexure No – 4

Acceptance criteria : Established machine speeds are for reference purpose only.

The vial feeding, transport to the track-1 and track-2, powder

dosing, gas purging, stoppering and vial exit from out feed conveyor

should be correctly performed. Machine shall be free from any

unusual observations.

6.1.3 Production Capacities at Minimum and Maximum Set Speed

Objective : The objective of production capacities at minimum and maximum

established speeds is to check and ensure the output characteristics of

the machine w.r.t to minimum and maximum dosing for 30ml Vials.

Tools required : 30 mL moulded glass vials & 20 mm Rubber stopper.

Test procedure : Set the machine at established minimum speed (with single, double ,

triple and four doses)

Start filling of test batch using gamma sterilized lactose and stop the

machine after 3 minutes of elapsing time.

Record the number of units produced as per machine encoder in

HMI and compare with expected output and record the observations

in Annexure No – 5

Repeat the above procedure at established maximum speed.

Repeat the procedure for two more times.

Acceptance criteria : The actual output shall meet ± 4% to the set speed without any

unusual observations.

Format No. : QA009-F02-00

JODAS EXPOIM PVT. LTD.

OPERATIONAL QUALIFICATION

Equipment /System Name Powder Vial Filling & Bunging Machine

Protocol No. CE/PR/OQ/P-005 (S-03) Equipment /System No. CE/PR/VFM/005

Location Ceph. Block-Production Area Page No. 12 of 15

7.0 DEVIATIONS/DISCREPANCIES RECORD:

List the deviations/discrepancies observed if any during the Operational qualification of the Vial

Filling and bunging machine and evaluate the deviations/discrepancy as per the SOP No.: QA009

and implement the corrective actions for the same and attach the deviations/discrepancy record.

If deviations/discrepancies are resolved satisfactorily the Vial Filling and bunging machine can be

released for performance qualification up on approval of report.

Sr. No. Description of the Deviation/Discrepancy

Format No. : QA009-F02-00

JODAS EXPOIM PVT. LTD.

OPERATIONAL QUALIFICATION

Equipment /System Name Powder Vial Filling & Bunging Machine

Protocol No. CE/PR/OQ/P-005 (S-03) Equipment /System No. CE/PR/VFM/005

Location Ceph. Block-Production Area Page No. 13 of 15

8.0 REFERENCE DOCUMENTS:

Nil

9.0 ABBREVIATIONS:

Sr. No Abbreviations Description

1. SOI Standard Operating Instruction

2. OQ Operational Qualification

3. VA Validation

4. EN Engineering

5. PR Production

10.0 ANNEXURES:

Annexure-1 : List of executors

Annexure-2 : Closure placement

Annexure-3 : Establishment of maximum and minimum machine speeds

Annexure-4 : Verification of machine performance

Annexure-5 : Production capacity at Maximum and minimum speeds

Format No. : QA009-F02-00

JODAS EXPOIM PVT. LTD.

OPERATIONAL QUALIFICATION

Equipment /System Name Powder Vial Filling & Bunging Machine

Protocol No. CE/PR/OQ/P-005 (S-03) Equipment /System No. CE/PR/VFM/005

Location Ceph. Block-Production Area Page No. 14 of 15

11.0 ATTACHMENTS

Sr.

Title

No.

Format No. : QA009-F02-00

JODAS EXPOIM PVT. LTD.

OPERATIONAL QUALIFICATION

Equipment /System Name Powder Vial Filling & Bunging Machine

Protocol No. CE/PR/OQ/P-005 (S-03) Equipment /System No. CE/PR/VFM/005

Location Ceph. Block-Production Area Page No. 15 of 15

12.0 SUMMARY

Checked Verified

Description Yes/No/NA

by (PR) by(PR)

All acceptance criteria set forth in the Operational

qualification were met

All applicable data sheets were signed as checked and

verified.

Deviations if any

Whether acceptable

If not acceptable, action taken

END OF THE DOCUMENT

Format No. : QA009-F02-00

You might also like

- Oos SopDocument10 pagesOos SopSolomonNo ratings yet

- Autoclave Validation Comparison of Different GuidelineDocument10 pagesAutoclave Validation Comparison of Different Guidelineabdelhakim ougaidaNo ratings yet

- Friability Tester IQ ProtocolDocument25 pagesFriability Tester IQ ProtocolJames Huang75% (4)

- User Requirement Specification For Moisture Analyser: Company NameDocument6 pagesUser Requirement Specification For Moisture Analyser: Company Namevamshi krishnaNo ratings yet

- 21 CFR Part 11 Vs EU Annex 11 - Computer System ValidationDocument16 pages21 CFR Part 11 Vs EU Annex 11 - Computer System ValidationAnkit VaidyaNo ratings yet

- Cleaning Validation Guidelines - A Complete ListDocument11 pagesCleaning Validation Guidelines - A Complete ListSanjay SharmaNo ratings yet

- Root Cause Identification For NVPC ExcursionDocument23 pagesRoot Cause Identification For NVPC ExcursionpalashcdaasNo ratings yet

- FA142C Program ManualDocument24 pagesFA142C Program ManualnohalmoNo ratings yet

- Pre - Assessment (4th Quarter)Document2 pagesPre - Assessment (4th Quarter)Joycel Comia0% (1)

- 9 C Validation Protocol TABLETDocument20 pages9 C Validation Protocol TABLETMohammed ZubairNo ratings yet

- Laf PQDocument19 pagesLaf PQzoher.validationNo ratings yet

- Validation VialWasher OQ NIHDocument30 pagesValidation VialWasher OQ NIHcongacon3aNo ratings yet

- Qualification Procedure For Vial Washing Machine - Pharmaceutical GuidelinesDocument1 pageQualification Procedure For Vial Washing Machine - Pharmaceutical GuidelinesAli Goutas50% (2)

- 8.3 Operation Qualification Protocol For Dispensing BoothDocument4 pages8.3 Operation Qualification Protocol For Dispensing BoothTanveer Ahmed Quadri100% (1)

- Checklist of Validation of Dy Heat SterilizerDocument8 pagesChecklist of Validation of Dy Heat Sterilizersami2210No ratings yet

- Validation of Sterilization of AutoclavesDocument15 pagesValidation of Sterilization of AutoclavesErich Hermann Günther Molina100% (3)

- Validation of Sterilization: GMP and Qa Class: BDocument50 pagesValidation of Sterilization: GMP and Qa Class: BHikmah Purnama AzaniNo ratings yet

- Cleaning Validation (CV) Procedure and Protocol - Guideline SOPsDocument30 pagesCleaning Validation (CV) Procedure and Protocol - Guideline SOPsDeepakNo ratings yet

- URS-Glass WasherDocument19 pagesURS-Glass Washerssureshkar7699100% (2)

- Installation Qualification Protocol For Walk - in Incubator System Name: Walk - in Incubator Document No.: NECPL/IQ/11220I/1 Page No.: 1 of 25Document25 pagesInstallation Qualification Protocol For Walk - in Incubator System Name: Walk - in Incubator Document No.: NECPL/IQ/11220I/1 Page No.: 1 of 25vipin100% (1)

- Iq of LyophilizerDocument36 pagesIq of Lyophilizermkm969No ratings yet

- Autoclave Validation: Presented by Paul Yeatman Bsc. MicrobiologistDocument17 pagesAutoclave Validation: Presented by Paul Yeatman Bsc. Microbiologistzfo302No ratings yet

- Performance Qualification Protocol Vial Washing MachineDocument17 pagesPerformance Qualification Protocol Vial Washing MachineBirol ErgenNo ratings yet

- IVT - Validation Final ReportDocument5 pagesIVT - Validation Final ReportDoan Chi ThienNo ratings yet

- Hold Time Stability Studies in Pharmaceutical Industry Review 2167 7689.1000104Document8 pagesHold Time Stability Studies in Pharmaceutical Industry Review 2167 7689.1000104Quang Hiếu NgôNo ratings yet

- Xoxiban 20mg Tab VPDocument13 pagesXoxiban 20mg Tab VPziauddin bukhariNo ratings yet

- Site Validation Master PlanDocument20 pagesSite Validation Master Planaborder-06-sonnetNo ratings yet

- Hold Time Study For Cleaned FBD BagsDocument6 pagesHold Time Study For Cleaned FBD BagsDevendra Dwivedi100% (1)

- Risk Assessment For Purified WaterDocument53 pagesRisk Assessment For Purified Waterparuchurietindra100% (1)

- Hold Time Study SOP Indian Pharma 1Document3 pagesHold Time Study SOP Indian Pharma 1ziadddNo ratings yet

- SMF Update SOLITAIRE PDFDocument35 pagesSMF Update SOLITAIRE PDFmaheshNo ratings yet

- Validation Protocall For AutoclaveDocument7 pagesValidation Protocall For AutoclaveBalakrishnan S NadarNo ratings yet

- DQ Report For BrineDocument12 pagesDQ Report For BrineNishit SuvaNo ratings yet

- Process Validation - Moist Heat Sterilization For PharmaceuticalsDocument15 pagesProcess Validation - Moist Heat Sterilization For PharmaceuticalsPalash DasNo ratings yet

- URS Lab Scale Counter Pressure Autoclave (Rev 1b)Document12 pagesURS Lab Scale Counter Pressure Autoclave (Rev 1b)puneetogupta100% (2)

- Form URS FPP Vial Washing Machine 050307.odtDocument10 pagesForm URS FPP Vial Washing Machine 050307.odtNur ChamidahNo ratings yet

- Standard Operating Procedure Somatec: Title: Sop For Pao TestDocument3 pagesStandard Operating Procedure Somatec: Title: Sop For Pao TestMajed HossainNo ratings yet

- Tablet Machine Qualification ProtocolDocument22 pagesTablet Machine Qualification ProtocolScribdTranslationsNo ratings yet

- Xoxiban 10mg Tab VPDocument13 pagesXoxiban 10mg Tab VPziauddin bukhariNo ratings yet

- Inprocess Testing Capsule 1Document4 pagesInprocess Testing Capsule 1AKKAD PHARMANo ratings yet

- QBD Application in Pharm Industry PDFDocument83 pagesQBD Application in Pharm Industry PDFSetyo Budiarto100% (1)

- Protocol PQ1Document28 pagesProtocol PQ1Tuan NguyenNo ratings yet

- 9.1 Design Qualification Protocol For Dynamic Pass BoxDocument10 pages9.1 Design Qualification Protocol For Dynamic Pass BoxKeval Patel100% (1)

- Process Validation Protocol of Desvel 50Mg Tablet: Medisure Laboratories Pakistan (PVT.) LTDDocument16 pagesProcess Validation Protocol of Desvel 50Mg Tablet: Medisure Laboratories Pakistan (PVT.) LTDsamia khanNo ratings yet

- PQ Autoclave HPHV Steam SterilizerDocument26 pagesPQ Autoclave HPHV Steam SterilizerVitalis Mbuya100% (1)

- VMPDocument15 pagesVMPshah241No ratings yet

- PQ WfiDocument9 pagesPQ Wfisami2210No ratings yet

- Change Control Matrix For Facility ChangeDocument2 pagesChange Control Matrix For Facility ChangePrem Goel100% (1)

- Validation and Facility Design PDFDocument16 pagesValidation and Facility Design PDFjpabloqfNo ratings yet

- Prot OQ HVACDocument12 pagesProt OQ HVACamrinNo ratings yet

- 2.Pv Semisolid FDADocument37 pages2.Pv Semisolid FDARahayu Maulida RNo ratings yet

- Alarm Verification Protocol FOR Incubators (Microbiology, Q-Block)Document10 pagesAlarm Verification Protocol FOR Incubators (Microbiology, Q-Block)cpkakope100% (1)

- Capsule FillingDocument23 pagesCapsule FillingErum ManzoorNo ratings yet

- Aseptic Process Validation (By Media Fill Trial)Document19 pagesAseptic Process Validation (By Media Fill Trial)ziaddd100% (2)

- Cleaning Validation ProtocolDocument3 pagesCleaning Validation Protocolpuneetogupta100% (1)

- JETT AutoclaveURSDocument29 pagesJETT AutoclaveURSBadar RizwanNo ratings yet

- D.Y.Patil. College of Pharmacy, Pune: Instrument DetailsDocument3 pagesD.Y.Patil. College of Pharmacy, Pune: Instrument DetailsNavdeep ChaudharyNo ratings yet

- The Media Fill Approach An UpdateDocument3 pagesThe Media Fill Approach An UpdateajmalnasirNo ratings yet

- Oos GuidanceDocument48 pagesOos GuidanceAnjamSoodNo ratings yet

- Data Integrity and Compliance: A Primer for Medical Product ManufacturersFrom EverandData Integrity and Compliance: A Primer for Medical Product ManufacturersNo ratings yet

- Vignan'S University Vadlamudi: A Project Report OnDocument75 pagesVignan'S University Vadlamudi: A Project Report OnSubhash NaiduNo ratings yet

- Effect of Lateral Torsional Buckling On Web Tapered I-Beams: CR CR CR DDocument10 pagesEffect of Lateral Torsional Buckling On Web Tapered I-Beams: CR CR CR DSubhash NaiduNo ratings yet

- Som Book 2019 - Final BookDocument70 pagesSom Book 2019 - Final BookSubhash NaiduNo ratings yet

- Methodology Taper DesignDocument14 pagesMethodology Taper DesignSubhash NaiduNo ratings yet

- All Shure Mics Data SheetsDocument12 pagesAll Shure Mics Data SheetsRosana Mabel VillaNo ratings yet

- Journal of Electroanalytical Chemistry: Tim Tichter, Dirk Andrae, Christina RothDocument11 pagesJournal of Electroanalytical Chemistry: Tim Tichter, Dirk Andrae, Christina RothALEJANDRA FONTALVO STUDENTNo ratings yet

- Inf DesktopDocument82 pagesInf DesktopAnderssen ViannaNo ratings yet

- InteractionDocument3 pagesInteractionMaria Katrinka Sophia MartiresNo ratings yet

- Grade 8 Integrated Science Week 2 Lesson 1 Worksheet 2 and Answer SheetDocument4 pagesGrade 8 Integrated Science Week 2 Lesson 1 Worksheet 2 and Answer SheetBalram HaroldNo ratings yet

- Steam Jet EjectorDocument6 pagesSteam Jet Ejectorjayanta_198967% (3)

- Edexcel Science Unit P1 Universal Physics Test 13 - 14 Double ScienceDocument19 pagesEdexcel Science Unit P1 Universal Physics Test 13 - 14 Double SciencePaul BurgessNo ratings yet

- WELDING ConsumableDocument12 pagesWELDING ConsumableMuhammad Fitransyah Syamsuar Putra100% (2)

- Web Dynpro Questions and AnswersDocument22 pagesWeb Dynpro Questions and AnswersRommel SorengNo ratings yet

- Tad550Ge: 4.76 Liter, In-Line 4 CylinderDocument2 pagesTad550Ge: 4.76 Liter, In-Line 4 CylinderAzilan AriaNo ratings yet

- Piper Turbo Arrow IV Presentaciòn 16-11Document43 pagesPiper Turbo Arrow IV Presentaciòn 16-11EdwinAlonsoPinzónNo ratings yet

- Consumer Self Confidence (CSC)Document4 pagesConsumer Self Confidence (CSC)Kashvi RajeshNo ratings yet

- Permutation and Combination DPP (1-10) 12thDocument27 pagesPermutation and Combination DPP (1-10) 12thRahul Jain75% (16)

- B.C. Punmia - SOM PDFDocument584 pagesB.C. Punmia - SOM PDFravi verma75% (4)

- Panel Data Econometrics KenyaDocument114 pagesPanel Data Econometrics KenyadessietarkoNo ratings yet

- 2023 Evaluación de La Viavilidad de Buses Eléctricos e HidrogenoDocument14 pages2023 Evaluación de La Viavilidad de Buses Eléctricos e HidrogenoVictor Angel Andres Gallegos MedinaNo ratings yet

- Documentation - For Snake - Game - ProjectDocument6 pagesDocumentation - For Snake - Game - ProjectShubham ShirkeNo ratings yet

- EE2001 - Digital Systems Lab: Vinita VasudevanDocument8 pagesEE2001 - Digital Systems Lab: Vinita VasudevanJatinKumarNo ratings yet

- Jetson Xavier Accelerated GStreamer User GuideDocument46 pagesJetson Xavier Accelerated GStreamer User GuidecsgaddisNo ratings yet

- N Convert Recurring Decimals To Fractions PDFDocument3 pagesN Convert Recurring Decimals To Fractions PDFMusaib BhatNo ratings yet

- 2 Klon SPM Quad Eqn 2003 - 2014 - EdDocument32 pages2 Klon SPM Quad Eqn 2003 - 2014 - EdAnonymous 0fagPbbloNo ratings yet

- L-132XYD (Ver 17B)Document5 pagesL-132XYD (Ver 17B)yafix34669No ratings yet

- Advanced Pneumatic Technology For Semi-Automated Kurdai ProductionDocument8 pagesAdvanced Pneumatic Technology For Semi-Automated Kurdai ProductionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Grade 7Document3 pagesGrade 7Christian James NepomucenoNo ratings yet

- Dac 2Document8 pagesDac 2Rishab jainNo ratings yet

- CSCI5273 PS4 Solutions-2Document11 pagesCSCI5273 PS4 Solutions-2Sales TeamNo ratings yet

- St-200 CC Abg BrochureDocument2 pagesSt-200 CC Abg BrochureSmart BiomedicalNo ratings yet

- Max.e - Mini Technical Description ENGDocument5 pagesMax.e - Mini Technical Description ENGJohn BarrowNo ratings yet