New Testing Method For HV Circuit Breaker With Both Sides Grounded

New Testing Method For HV Circuit Breaker With Both Sides Grounded

Uploaded by

CARLOS LÓPEZCopyright:

Available Formats

New Testing Method For HV Circuit Breaker With Both Sides Grounded

New Testing Method For HV Circuit Breaker With Both Sides Grounded

Uploaded by

CARLOS LÓPEZOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

New Testing Method For HV Circuit Breaker With Both Sides Grounded

New Testing Method For HV Circuit Breaker With Both Sides Grounded

Uploaded by

CARLOS LÓPEZCopyright:

Available Formats

november 2 0 0 7

New testing method for HV Circuit

Breaker with both sides grounded

The background

The HV circuit breaker is the most important component of during the test, because, otherwise, the timing test cannot

an HV substation, as it has the task, sometimes the terrible be performed by the traditional test sets. This is the “de

task, to remove the fault, no matter what is the fault cur- facto” practice, even if laws and standards would not allow it.

rent. Even the nominal current could be difficult to be The point is that when the contact is closed there is no risk,

opened, as 2000 A on a 380 kV line mean something close but when, during the test, the contact is opened, the risk is

to half a GigaWatt per phase; yet, this is not the worst case, there: high voltage induction, no protection in case of fault.

when the current to be opened can be 20, 40 or even 80 As this is a risky practice, here comes the need for highly

times the nominal one. So, when the matter of what should skilled people.

be tested in a substation is being discussed, nobody argues

about the need of being pretty sure that the CB of the plant The ISA test solution

operate correctly.

ISA for almost 70 years it has been working side by side

with power utilities personnel helping them performing

On the other side, performing tests is an expensive task,

their work safely and efficiently.

demanding highly skilled engineers, strictly observed

ISA is making substation testing safer for the test engineers

procedures, programming and a relevant test execution

and at the same time helps make operation of utilities and

time. Laws and Standards dictate how the test should be

service companies more efficient.

performed in order to avoid any risk to people at work.

Our latest born equipments for testing Circuit Breakers, the

All this conflicts with the need of reducing time and the

CBA1000 and CBA2000, incorporate the main contact tim-

level of skill of people involved.

ing test and the contact resistance test, static or dynamic:

this means reducing the test time.

Circuit Breaker Testing

As all other test sets, time measurement cannot be

The most important tests performed on circuit breakers are: performed unless only one side is grounded. Now they

main contacts timing and contact resistance. These tests come along with the BSG option, that stands for Both Sides

required two instruments, that were connected in turn to Grounded, that allows to perform tests without removing

the circuit breaker main contact. the safety ground connections on both sides of the main

During these tests, the operator safety is ensured by contact. Working in this condition will bring all advantages

connecting to earth both sides of the test object. In the nor- described above, by removing the risk and the conse-

mal practice, the safety grounding is removed at one side quences of arc-flash and electrocution accidents.

The technology to measure the operating time of the circuit

breaker when it is grounded on both sides is based on

resistance measurement.

Circuit breakers are always placed in a very high position:

long connection cables must be used to ground them. The

resistance of these leads is usually in the range of 20 to 30

mΩ, whilst the contact resistance of the breaker is in the

range of 20 to 30 µΩ, and the resistance of the graphite

coating is in the range of 200 to 500 µΩ. Goal of the test

is a safe detection of the contact being: closed, graphite or

open, and not the measurement of the contact resistance;

so, as the grounding connection resistance is much bigger

than the graphite and contact resistance, its presence does

not affect the test.

CBA1000 connected to BSG-1000

november 2 0 0 7

And here comes our solution: connectors, for the connection of the BSG Main unit to

• A microOhm meter tester for each individual contact of CBA1000 or CBA2000.

the circuit breaker injects the test current and meters the Sequence of operation

contact resistance.

• The BSG measuring heads generate the current only

• The resistance value is measured and compared with two

when a test is to be performed.

thresholds, for instance 100 µΩ and 1 mOhm;

• The current generation is initiated by CBA1000 or

• R > 1000 µΩ: the contact is OPEN

CBA2000, by means of the Master output. The START

• R < 1000 µΩ and > 100 µΩ: GRAPHITE

signal goes to the BSG Main unit, that, in turn,

• R < 100 µΩ: the contact is CLOSED

commands the Measuring Heads.

The result is then converted into a voltage signal and

• When the current is OK the heads inform the CBA via the

provided to CBA1000 for two time measurements.

Main unit; at this moment, the CBA drives the CB coils,

and the time measurement starts.

The technology used with the BSG to generate the test

• The head measures the contact resistance, compares it

current is similar to that used for the DRM of the CBA’s: a

to the threshold and communicates in real time the

large capacitor is charged and then discharged through an

result (CLOSED, GRAPHITE or OPEN) to the Main unit;

electronic circuit, that stabilizes the current to 20 A.

• The Main unit converts this information into a voltage

level that is sensed by CBA as CLOSED, RESISTANCE or

Description OPEN. These operations are performed at very high

Two types of BSG1000 are available: speed, so that the time measurement is not influenced;

- BSG1000-1, for testing one break per phase; • CBA measures the times, and displays the results as a

- BSG1000-2, for testing two breaks per phase (displayed thick – intermediate – thin line;

in the figure). • It is possible to change the resistance threshold

Each BSG1000 is made of the following elements: operating on the CBA screen.

• Three BSG Remote Heads, types 1 or 2. They are

connected close to the main breaker contacts, and

include the current generator and the two level

comparator, that communicates the result in digital form

to the Main unit. Each head has two type of cables, each

3 m long: one for the connection of the test current to

the CT under test, and the other one (shielded) for the

open / close detection of the CB contacts. One set of

cables for type 1; two sets for type 2.

• One BSG Main unit, that includes the microprocessor

supervising the heads, and the DAC’s for CBA inputs. It

is connected to the heads and to the CBA by a cable kit,

including:

- Three 8 m long cables, terminated with multi-pole

connectors, for the connection between remote heads

and the Main unit.

- One cable, 1 m long, terminated with multi-pole

APPLICATION NOTES OTTOBRE 2007 APPLICATION NOTES OTTOBRE 2007

november 2 0 0 7

Test set-up

Lift the Measuring head up Connect the Measuring Connect the Main unit Connect the Main unit

to the circuit breaker. Head control cable to the Master / Slave input to the output connector to the

Connect the Current BSG Main unit, in the CBA output CBA inputs, following the

terminals to the main CB Breaker Contact section. connector markings.

contacts.

Connect the voltage sensors

to the main CB contacts, so

that the current terminals

voltage drop does not

influence the resistance

measurement.

Siemens Graphite contacts

Besides, if the Circuit Breakers has a graphite nozzle,

CBA1000 displays the timing at which the graphite is

engaged, and when the main contact is reached, thus

allowing to check the deterioration of the graphite.

How does the BSG detects the graphite contacts?

The BSG has two voltage thresholds to detect which section

of the contact is engaged: graphite or metallic.

And the other Circuit Breakers ?

Siemens is very keen to use equipments which are able to

detect when the main contact is engaged by filtering out the

Graphite contact.

For other circuit breakers we have a similar picture: we can

measure the time when the main contact are engaged by

filtering out the Arcing contact.

In fact, the resistance profile is very similar to the Graphite

contact, and therefore the same Siemens method can be

applied to any sort of HV Circuit breaker making our

devices: CBA1000, CBA2000 and GSG the prefect tools for

a safe and more comprehensive circuit breaker testing.

BSG-1000 Remote Heads

ISA srl

Via Bergamo, 41

2 1 0 2 0 TA I N O ( Va ) I t a l y

Te l . + 3 9 0 3 3 1 9 5 6 . 0 8 1 We b s i t e : w w w. i s a t e s t . c o m

Fax + 39 0331 957.091 E-Mail: isa@isatest.com

You might also like

- Insulation Resistance (IR) Values - Electrical Notes & Articles100% (2)Insulation Resistance (IR) Values - Electrical Notes & Articles29 pages

- Eee ELECTRICAL MACHINES-I DC LAB MANUAL 10122019 PDFNo ratings yetEee ELECTRICAL MACHINES-I DC LAB MANUAL 10122019 PDF68 pages

- R.levi, V. Mrdic - Advanced Dynamic Testing of Substation Apparatus - TechCon 2016No ratings yetR.levi, V. Mrdic - Advanced Dynamic Testing of Substation Apparatus - TechCon 201615 pages

- Measurement of FLUKE Insulation Resistance MeggerNo ratings yetMeasurement of FLUKE Insulation Resistance Megger22 pages

- Insulation Resistance (IR) Values - Electrical Notes & ArticlesNo ratings yetInsulation Resistance (IR) Values - Electrical Notes & Articles31 pages

- TP ACTAS Effective Switchgear Testing ENGNo ratings yetTP ACTAS Effective Switchgear Testing ENG6 pages

- HIPOT Testing (Dielectric Strength Test)No ratings yetHIPOT Testing (Dielectric Strength Test)5 pages

- Wire Bond Electrical Structural Test MethodologiesNo ratings yetWire Bond Electrical Structural Test Methodologies11 pages

- Safely Testing Circuit Breakers With The ct-7000 and ct-8000No ratings yetSafely Testing Circuit Breakers With The ct-7000 and ct-80006 pages

- Insulation Resistance (IR) Values - Electrical Notes & Articles100% (1)Insulation Resistance (IR) Values - Electrical Notes & Articles37 pages

- 12.testing of High Voltage Equipment and Insulation CoordinationNo ratings yet12.testing of High Voltage Equipment and Insulation Coordination53 pages

- An Overview of Dynamic Contact Resistance Measurement of HV Circuit Breakers100% (1)An Overview of Dynamic Contact Resistance Measurement of HV Circuit Breakers21 pages

- Insulation Resistance (IR) Values - Electrical Notes & ArticlesNo ratings yetInsulation Resistance (IR) Values - Electrical Notes & Articles29 pages

- Comment Insulation Resistance (IR) Values - Electrical Notes & ArticlesNo ratings yetComment Insulation Resistance (IR) Values - Electrical Notes & Articles41 pages

- Vacuum Bottle Breaker Application and Testing GuideNo ratings yetVacuum Bottle Breaker Application and Testing Guide6 pages

- EDOC - Why Earth Fault Loop Impedance Test Is Done100% (1)EDOC - Why Earth Fault Loop Impedance Test Is Done6 pages

- Continuity and Low Resistance Testing: StoryNo ratings yetContinuity and Low Resistance Testing: Story3 pages

- Insulation Resistance (IR) Values - Electrical Notes & ArticlesNo ratings yetInsulation Resistance (IR) Values - Electrical Notes & Articles28 pages

- HIPOT Testing - Electrical Notes & ArticlesNo ratings yetHIPOT Testing - Electrical Notes & Articles13 pages

- Continuity and Low Resistance Testing - Cover StoryNo ratings yetContinuity and Low Resistance Testing - Cover Story3 pages

- A-CBR108-201-EN Dynamic Contact Resistance Measurement (DRM)No ratings yetA-CBR108-201-EN Dynamic Contact Resistance Measurement (DRM)4 pages

- STEM: Science, Technology, Engineering and Maths Principles Teachers Pack V10From EverandSTEM: Science, Technology, Engineering and Maths Principles Teachers Pack V10No ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Use of T 3000 & T 2000 For Transformer Tests: ForewordNo ratings yetUse of T 3000 & T 2000 For Transformer Tests: Foreword3 pages

- Application Note: Universal Relay General Electric T60 Differential Relay 87 Module100% (1)Application Note: Universal Relay General Electric T60 Differential Relay 87 Module5 pages

- Temperature Monitoring & Protection: FeaturesNo ratings yetTemperature Monitoring & Protection: Features2 pages

- ELDS - Packing Guideline - 2629 - 19 - EN - AMC - NXNo ratings yetELDS - Packing Guideline - 2629 - 19 - EN - AMC - NX62 pages

- Vacuum Circuit-Breaker, Type VD4 X: Operation and MaintenanceNo ratings yetVacuum Circuit-Breaker, Type VD4 X: Operation and Maintenance2 pages

- Deh41472d - Manual de Instalacion G.E Akd-20 PDF100% (1)Deh41472d - Manual de Instalacion G.E Akd-20 PDF76 pages

- Schneider Electric - Acti-9-C120 - A9N18361No ratings yetSchneider Electric - Acti-9-C120 - A9N183614 pages

- Unit - Ii Single Phase and Three Phase Controlled Rectifiers100% (2)Unit - Ii Single Phase and Three Phase Controlled Rectifiers36 pages

- Prisma P Assembly Guide v2012 - DESW045ENNo ratings yetPrisma P Assembly Guide v2012 - DESW045EN33 pages

- KPR-06 - Distance Protection Relay TrainerNo ratings yetKPR-06 - Distance Protection Relay Trainer2 pages

- Questions & Answers On Basic Materials & Transformer ConstructionNo ratings yetQuestions & Answers On Basic Materials & Transformer Construction20 pages

- Transformer Technical Data Sheet For The 1LAP016371 - 2No ratings yetTransformer Technical Data Sheet For The 1LAP016371 - 21 page

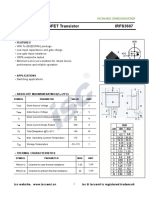

- Isc N-Channel MOSFET Transistor IRFS3607: FeaturesNo ratings yetIsc N-Channel MOSFET Transistor IRFS3607: Features2 pages

- Power Transformers - Design and Application - PEguruNo ratings yetPower Transformers - Design and Application - PEguru26 pages