N-0900-P-01-01 - Tailing Tower (C-0902)

N-0900-P-01-01 - Tailing Tower (C-0902)

Uploaded by

Darrel Espino AranasCopyright:

Available Formats

N-0900-P-01-01 - Tailing Tower (C-0902)

N-0900-P-01-01 - Tailing Tower (C-0902)

Uploaded by

Darrel Espino AranasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

N-0900-P-01-01 - Tailing Tower (C-0902)

N-0900-P-01-01 - Tailing Tower (C-0902)

Uploaded by

Darrel Espino AranasCopyright:

Available Formats

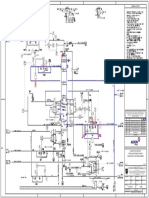

N-0900-P-01-01_Tailing Tower (C-0902)

N-0900-P-01-01_Tailing Tower (C-0902)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

D-0906 E-0906 E-0907 NOTES

TAILING TOWER REFLUX DRUM PGH TAILING TOWER CONDENSER PGH TAILING TOWER VENT CONDENSER

A 1. FOR LEGENDS, SYMBOLS, GENERAL NOTES AND ENGINEERING A

SIZE : 1,800mmID X 5,400mmT/T TYPE : H-AES TYPE : V-BEM DESIGN NOTES SEE DWG. A1-21140-0004A, 0004B AND 0004C.

TYPE : HORIZONTAL DUTY : 18.895 X 1.20 GJ/h DUTY : 0.3955 X 1.25 GJ/h 2. DELETED.

DESIGN PRESS. : 3.5 barg / F.V. SURFACE AREA : 760.3 m2 SURFACE AREA : 73.1 m2 3

DESIGN TEMP. : -29 / 105 °C DESIGN PRESS. (SHELL/TUBE) : (3.5/F.V.) / 10 barg DESIGN PRESS. (SHELL/TUBE) : 35 / (3.5/F.V.) barg

3. DELETED.

MATERIAL : CS DESIGN TEMP. (SHELL/TUBE) : 205 / 65 °C DESIGN TEMP. (SHELL/TUBE) : (-29/65) / 105 °C

TRIM : TR-09D06-A1D MATERIAL (SHELL/TUBE) : CS / CS MATERIAL (SHELL/TUBE) : CS / CS

FF 4. DELETED.

TRIM : TR-09E06-A1D TRIM : TR-09E07-B1D-C

TI

B 3"x4" 29062 5. PUSH BUTTON IN THE FIELD, CONTROL ROOM AND DCS ACTIVATES B

P-29002-30"-A1D-PP(50) L INTERLOCK WHICH CLOSES ISOLATION VALVE AND SHUTS DOWN

0915A SET @ PSV

OVERHEAD VAPOR CSO ALL ASSOCIATED PUMPS. VALVE LOCATED IN FIRE ZONE SHALL BE

FROM C-0902 3.5 barg 29135A WFL-29005-6"-A1K FIRE SAFE WITH FIRE SAFE ACTUATOR.

0915Q

6"x4" C1 3"x4" WET FLARE

WFL-29017-6"-A1K 6. LOCATE PUSH BUTTON 15 METERS FROM PUMP AT SAFE LOCATION.

8"x3" SET @

TW 3.5 barg 7. CHECK VALVES TO BE OF DISSIMILAR TYPE.

29031 C1 8. TWO PHASE FLOW. ANCHOR SECURELY.

CSO

C3 C1 PSV 1"x2"

CWR-29002-12"-H1A20 C1 29135B 6"x4" C1 PSV 9. DELETED.

0915M SET @ 3

CW RETURN 35.0 barg 29134A CFL-29003-2"-A21L 10. EXCHANGER, E-0906 TO BE ELEVATED ABOVE REFLUX DRUM, D-0906.

LO 1½" 8"x3" CSO C1 3

C 16"x12" WFL-29024-2"-A1K 3551 C

PP C2 CSO DRY FLARE 11. FV-29039 ELEVATION TO BE DETERMINED BY DEC TO PREVENT

1"x2" 1/400 FLASHING AT CONTROL VALVE INLET.

C1 1½"x1" SLOPE

CSC

SET @ CFL-29002-2"-A21L

E-0906 C1

2" 12. FOR SAMPLE CONNECTION DETAILS SEE DWG A1-JES1EP-0005A~D,F.

P-29041-8"-A1D

PSV 35.0 barg

NOTE 10 P-29042-8"-A1D 3

C1 29134B CSO

C1 13. THE LINE SHALL BE CONNECTED TO THE HIGHEST POINT OF

P-29096-2"-A1D A1D A1K

CSO

C2 C1 C1 DISCHARGE LINE BEFORE CHECK VALVE.

16"x12" 1½" RT-29003-1½"-B1D-C(25) 1½"x1" 3

C1 CFL-29004-1"-A21L 14. SAMPLING PROCESS DRAIN LINE TO BE CONNECTED TO PGD.

CWS-29002-12"-H1A20

0915M 3

CW SUPPLY CSC C1 3

C2 RT-29004-1½"-B1D-C(25)

P-29023-8"-A1D

FREE DRAINING

D C1 C(25) D

TG 3 RT-29005-1"-B1D-C(25)

A1D 29030 C1

C B1D

3/4" B1D B21L A21L

RT-29002-4"-B1D-C(40) RT-29002-4" -B1D-C(40)

TERTIARY REFRIGERANT 0607D

C2

HIGH LEVEL FY TO D-0615M

OVER RIDE 29039 FF

LG FF LC H

C FF FC

E-0907 29032 29032

L

FV

29039

29039

E E

N-0900-P-01-01_Tailing Tower (C-0902) RT-29001-3"-B1D-C(40) NOTE 11 RT-29001-2"-B1D-C(25)

0607F DETAIL "A"

NOTE 8 C1 3"x1" FC 2"x1" C1 TERTIARY REFRIGERANT

3/4"

P-29040-8"-A1D

C1 FROM D-0693 HS

C2 C1 29042D TO MCC FOR PUMP

1" 3 CLOSE START PERMISSIVE

PG C2 SLOPE P-29039-2"-A1D HB

1½"x1" 0915C 29042A

29038 VENT

VAC 1½" A1D OPEN

TO Z-0905 ULO ULC

B1D NOTE 6

FF 0915A HB IA 29042 29042

PV FROM PC-29030 29042B

F 3 ON C-0902 OVHD CLOSE F

29030 Z

C1 C3 N2-29006-2"-A1A R

N2-29006-2"-A1D 2937

H

20" D-0906 LG

FF LC NITROGEN

0915N Z

S

MH C1 2"x1½" FC 2"x1½" 2937 ATM.

29033 29033 L C1

ULCO UZCO USCO USO USC

2" C1 29042 29042 29042 29042 29042

≤ 80% 100%

C2

UC. 1½"

A1A

A1D

3 3 FF

C1 8"X6" 3 FV

6000 mm

29054

P-29033-1½"-A1D

FF C1

G C2 FC G

P-29024-6"-A1D

TI UV TSO

29039 2"x1½" FO 2"x1½" C1 29042

C1

C1 C1

D1D

A1D

1½"

P-29030-2"-D1D

UV

29042

RESET

PGD-29005-2"-A1D NOTE 5 Z

0915K FC

PGH DRAIN

TSO SEE

DETAIL 'A'

2930

3 FOR CONSTRUCTION

H H

FF FF FF R S

FF FC FC FC NEW DRAWING FOR NCP EXPANSION

29054 29038 FF

FV 29035 L FV

29035 29038

P-29031-3"-A1D C1 C1 C1 C3 C3 C1 ATM P-29028-4"-D1D

0915A 0915E

P-29024-6"-A1D

P-29036-1"-A1D

REFLUX C1 3"x1½"FO 3"x1½" 4"x2" FC 4"x2" C1 C6-180 CUT

21/12

TO C-0902 C1 FO FO NOTE 7 C1 TO E-0911 3 ISSUED FOR CONSTRUCTION YJL WJL HSO HHM SWL

P-29037-1"-A1D

P-29038-1"-A1D

1½" NOTE 12, 14 C1

/2018

29036 29037

P-29035-1"-A1D

NOTE 13

P-29033-1½"-A1D

17/08

P-29034-1½"-A1D

2 ISSUED FOR CONSTRUCTION YJL WJL HSO HHM SWL

I C1 TYPE 5C

S 2"

/2018 I

NOTE 13

15/06

29031 1 /2018 ISSUED FOR CONSTRUCTION YJL WJL HSO HHM SWL

27/04

0 /2018 ISSUED FOR DESIGN YJL WJL HSO HHM SWL

P-29028-4"-D1D

P-29032-3"-A1D ISSUE PROC

C1 P-29027-4"-A1D REV

DATE

DESCRIPTION CAD

ENG

LPE EM PM - - CLIENT

P-29025-6"-A1D

P-29029-4"-D1D

A1D

P-29031-3"-A1D

C1 C2 D1D "THIS DOCUMENT IS THE PROPERTY OF LUMMUS TECHNOLOGY INC. (LUMMUS). IT CONTAINS CONFIDENTIAL

P-29026-4"-A1D 6"X4" A1D C1 INFORMATION DESCRIBING TECHNOLOGY OWNED BY LUMMUS. IT IS TO BE USED ONLY IN CONNECTION WITH

C1 D1D A1D WORK PERFORMED BY LUMMUS. REPRODUCTION IN WHOLE OR IN PART FOR ANY PURPOSE OTHER THAN

C2 C1 C1 D1D WORK PERFORMED BY LUMMUS IS FORBIDDEN EXCEPT BY EXPRESS WRITTEN PERMISSION OF LUMMUS. IT IS

C2 C2 TO BE SAFEGUARDED AGAINST BOTH DELIBERATE AND INADVERTENT DISCLOSURE TO ANY THIRD PARTY."

PG PG A1D PG PG

J J

29034 A1D B1D C1 C1 29035 A1D B1D C1 STR C1 D1D 29036

NOTE 13 4"x2"

29037 JG SUMMIT OLEFINS CORPORATION

C1 C3 C3 B1D A1D 2904 NOTE 13 4"x2" C3 C3 C1

B1D A1D 2nd Stage Pygas Hydrogenation Unit

C:\Users\161600\Desktop\ 罹´\ 怠봬微퓬³_필리핀\Working\Latest\DPG-2\209371_A11X

3"x1½" 3"x1½" 6"x3" 6"x3"

1"

3

1" 1" 1" Batangas, The Philippines

STR STR

3 C1 D B1D 4"x2"

3 C1 D B1D 4"x2" 3/4" C1 3/4" C1

A1 BV A1 BV 2905 2906

PGD-29006-3/4"-A1D 3/4" STR 3/4" BVC1 3 RUN/STOP BVC1 PGD-29009-3/4"-D1D

3 C1 RUN/STOP

C1 XL 2903 XL XL XL

M M M M

G-0908A 29031A G-0908B 29031B 3 29032A

3

29032B

3

C2 E&C

RUN/STOP RUN/STOP C2

C2

K G-0908A/B C2 PGD-29007-3/4"-A1D C2 G-0909A C2 C2 G-0909B G-0909A/B K

PGH TAILING TOWER REFLUX PUMPS Z

2937

Z

2937

Z Z C2 PGH 2ND STAGE FEED PUMPS LUMMUS TECHNOLOGY

2932 2932

HS C1 HS 2934 C1 2934 C1

C1 2937 D1D 2937 D1D

TYPE : CENTRIFUGAL TYPE : CENTRIFUGAL

RATED CAPACITY : 22.1 m3/h

29031A

STOP

29031B

STOP A1D A1D

RATED CAPACITY : 40.9 m3/h

PIPING & INSTRUMENT DIAGRAM

OPERATING PRESS.(SUC/DISCH.): -0.46 / 2.49 barg HS PGD-29008-3/4"-A1D HS OPERATING PRESS.(SUC/DISCH.): -0.49 / 34.69 barg PYROLYSIS GASOLINE HYDROGENATION

29032A 29032B

MATERIAL (CASING/IMPELLER) : CS / CS 0915K 0915K STOP 0915K STOP 0915K MATERIAL (CASING/IMPELLER) : CS / CS TAILING TOWER REFLUX DRUM

MOTOR POWER : 5.5 KW MOTOR POWER : 90.0 KW

L TRIM : TR-09G08A/B-A1D TRIM : TR-09G09A/B-D1D L

SCALE: DWG. No: REV:

A1-JGS1EP-209370- 0915B 3

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

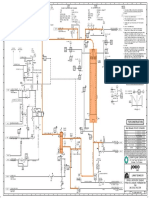

N-0900-P-01-02_Tailing Tower Bottom System

N-0900-P-01-02_Tailing Tower Bottom System

N-0900-P-01-03_Tailing Tower Overhead Reflux System

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

D-0906 E-0906 E-0907 NOTES

TAILING TOWER REFLUX DRUM PGH TAILING TOWER CONDENSER PGH TAILING TOWER VENT CONDENSER

A 1. FOR LEGENDS, SYMBOLS, GENERAL NOTES AND ENGINEERING A

SIZE : 1,800mmID X 5,400mmT/T TYPE : H-AES TYPE : V-BEM DESIGN NOTES SEE DWG. A1-21140-0004A, 0004B AND 0004C.

TYPE : HORIZONTAL DUTY : 18.895 X 1.20 GJ/h DUTY : 0.3955 X 1.25 GJ/h 2. DELETED.

DESIGN PRESS. : 3.5 barg / F.V. SURFACE AREA : 760.3 m2 SURFACE AREA : 73.1 m2 3

DESIGN TEMP. : -29 / 105 °C DESIGN PRESS. (SHELL/TUBE) : (3.5/F.V.) / 10 barg DESIGN PRESS. (SHELL/TUBE) : 35 / (3.5/F.V.) barg

3. DELETED.

MATERIAL : CS DESIGN TEMP. (SHELL/TUBE) : 205 / 65 °C DESIGN TEMP. (SHELL/TUBE) : (-29/65) / 105 °C

TRIM : TR-09D06-A1D MATERIAL (SHELL/TUBE) : CS / CS MATERIAL (SHELL/TUBE) : CS / CS

FF 4. DELETED.

TRIM : TR-09E06-A1D TRIM : TR-09E07-B1D-C

TI

B 3"x4" 29062 5. PUSH BUTTON IN THE FIELD, CONTROL ROOM AND DCS ACTIVATES B

P-29002-30"-A1D-PP(50) L INTERLOCK WHICH CLOSES ISOLATION VALVE AND SHUTS DOWN

0915A SET @ PSV

OVERHEAD VAPOR CSO ALL ASSOCIATED PUMPS. VALVE LOCATED IN FIRE ZONE SHALL BE

FROM C-0902 3.5 barg 29135A WFL-29005-6"-A1K FIRE SAFE WITH FIRE SAFE ACTUATOR.

0915Q

WET FLARE

N-0900-P-01-03_Tailing Tower Overhead Reflux System 8"x3"

6"x4" C1 3"x4"

SET @

WFL-29017-6"-A1K 6. LOCATE PUSH BUTTON 15 METERS FROM PUMP AT SAFE LOCATION.

TW 3.5 barg 7. CHECK VALVES TO BE OF DISSIMILAR TYPE.

29031 C1 8. TWO PHASE FLOW. ANCHOR SECURELY.

CSO

C3 C1 PSV 1"x2"

CWR-29002-12"-H1A20 C1 29135B 6"x4" C1 PSV 9. DELETED.

0915M SET @ 3

CW RETURN 35.0 barg 29134A CFL-29003-2"-A21L 10. EXCHANGER, E-0906 TO BE ELEVATED ABOVE REFLUX DRUM, D-0906.

LO 1½" 8"x3" CSO C1 3

C 16"x12" WFL-29024-2"-A1K 3551 C

PP C2 CSO DRY FLARE 11. FV-29039 ELEVATION TO BE DETERMINED BY DEC TO PREVENT

1"x2" 1/400 FLASHING AT CONTROL VALVE INLET.

C1 1½"x1" SLOPE

CSC

SET @ CFL-29002-2"-A21L

E-0906 C1

2" 12. FOR SAMPLE CONNECTION DETAILS SEE DWG A1-JES1EP-0005A~D,F.

P-29041-8"-A1D

PSV 35.0 barg

NOTE 10 P-29042-8"-A1D 3

C1 29134B CSO

C1 13. THE LINE SHALL BE CONNECTED TO THE HIGHEST POINT OF

P-29096-2"-A1D A1D A1K

CSO

C2 C1 C1 DISCHARGE LINE BEFORE CHECK VALVE.

16"x12" 1½" RT-29003-1½"-B1D-C(25) 1½"x1" 3

C1 CFL-29004-1"-A21L 14. SAMPLING PROCESS DRAIN LINE TO BE CONNECTED TO PGD.

CWS-29002-12"-H1A20

0915M 3

CW SUPPLY CSC C1 3

C2 RT-29004-1½"-B1D-C(25)

P-29023-8"-A1D

FREE DRAINING

D C1 C(25) D

TG 3 RT-29005-1"-B1D-C(25)

A1D 29030 C1

C B1D

3/4" B1D B21L A21L

RT-29002-4"-B1D-C(40) RT-29002-4" -B1D-C(40)

TERTIARY REFRIGERANT 0607D

C2

HIGH LEVEL FY TO D-0615M

OVER RIDE 29039 FF

LG FF LC H

C FF FC

E-0907 29032 29032

L

FV

29039

29039

E E

RT-29001-3"-B1D-C(40) NOTE 11 RT-29001-2"-B1D-C(25)

NOTE 8 C1 TERTIARY REFRIGERANT

0607F DETAIL "A"

3/4" C1 3"x1" FC 2"x1"

P-29040-8"-A1D

C1 FROM D-0693 HS

C2 C1 29042D TO MCC FOR PUMP

1" 3 CLOSE START PERMISSIVE

PG C2 SLOPE P-29039-2"-A1D HB

1½"x1" 0915C 29042A

29038 VENT

VAC 1½" A1D OPEN

TO Z-0905 ULO ULC

B1D NOTE 6

FF 0915A HB IA 29042 29042

PV FROM PC-29030 29042B

F 3 ON C-0902 OVHD CLOSE F

29030 Z

C1 C3 N2-29006-2"-A1A R

N2-29006-2"-A1D 2937

H

20" D-0906 LG

FF LC NITROGEN

0915N Z

S

MH C1 2"x1½" FC 2"x1½" 2937 ATM.

29033 29033 L C1

ULCO UZCO USCO USO USC

2" C1 29042 29042 29042 29042 29042

≤ 80% 100%

C2

UC. 1½"

A1A

A1D

3 3 FF

C1 8"X6" 3 FV

6000 mm

29054

P-29033-1½"-A1D

FF C1

G C2 FC G

P-29024-6"-A1D

TI UV TSO

29039 2"x1½" FO 2"x1½" C1 29042

C1

C1 C1

D1D

A1D

1½"

P-29030-2"-D1D

UV

29042

RESET

PGD-29005-2"-A1D NOTE 5 Z

0915K FC

PGH DRAIN

TSO SEE

DETAIL 'A'

2930

3 FOR CONSTRUCTION

H H

FF FF FF R S

FF FC FC FC NEW DRAWING FOR NCP EXPANSION

29054 29038 FF

FV 29035 L FV

29035 29038

P-29031-3"-A1D C1 C1 C1 C3 C3 C1 ATM P-29028-4"-D1D

0915A 0915E

P-29024-6"-A1D

P-29036-1"-A1D

REFLUX C1 3"x1½"FO 3"x1½" 4"x2" FC 4"x2" C1 C6-180 CUT

21/12

TO C-0902 C1 FO FO NOTE 7 C1 TO E-0911 3 ISSUED FOR CONSTRUCTION YJL WJL HSO HHM SWL

P-29037-1"-A1D

P-29038-1"-A1D

1½" NOTE 12, 14 C1

/2018

29036 29037

P-29035-1"-A1D

NOTE 13

P-29033-1½"-A1D

17/08

P-29034-1½"-A1D

2 ISSUED FOR CONSTRUCTION YJL WJL HSO HHM SWL

I C1 TYPE 5C

S 2"

/2018 I

NOTE 13

15/06

29031 1 /2018 ISSUED FOR CONSTRUCTION YJL WJL HSO HHM SWL

27/04

0 /2018 ISSUED FOR DESIGN YJL WJL HSO HHM SWL

P-29028-4"-D1D

P-29032-3"-A1D ISSUE PROC

C1 P-29027-4"-A1D REV

DATE

DESCRIPTION CAD

ENG

LPE EM PM - - CLIENT

P-29025-6"-A1D

P-29029-4"-D1D

A1D

P-29031-3"-A1D

C1 C2 D1D "THIS DOCUMENT IS THE PROPERTY OF LUMMUS TECHNOLOGY INC. (LUMMUS). IT CONTAINS CONFIDENTIAL

P-29026-4"-A1D 6"X4" A1D C1 INFORMATION DESCRIBING TECHNOLOGY OWNED BY LUMMUS. IT IS TO BE USED ONLY IN CONNECTION WITH

C1 D1D A1D WORK PERFORMED BY LUMMUS. REPRODUCTION IN WHOLE OR IN PART FOR ANY PURPOSE OTHER THAN

C2 C1 C1 D1D WORK PERFORMED BY LUMMUS IS FORBIDDEN EXCEPT BY EXPRESS WRITTEN PERMISSION OF LUMMUS. IT IS

C2 C2 TO BE SAFEGUARDED AGAINST BOTH DELIBERATE AND INADVERTENT DISCLOSURE TO ANY THIRD PARTY."

PG PG A1D PG PG

J J

29034 A1D B1D C1 C1 29035 A1D B1D C1 STR C1 D1D 29036

NOTE 13 4"x2"

29037 JG SUMMIT OLEFINS CORPORATION

C1 C3 C3 B1D A1D 2904 NOTE 13 4"x2" C3 C3 C1

B1D A1D 2nd Stage Pygas Hydrogenation Unit

C:\Users\161600\Desktop\ 罹´\ 怠봬微퓬³_필리핀\Working\Latest\DPG-2\209371_A11X

3"x1½" 3"x1½" 6"x3" 6"x3"

1"

3

1" 1" 1" Batangas, The Philippines

STR STR

3 C1 D B1D 4"x2"

3 C1 D B1D 4"x2" 3/4" C1 3/4" C1

A1 BV A1 BV 2905 2906

PGD-29006-3/4"-A1D 3/4" STR 3/4" BVC1 3 RUN/STOP BVC1 PGD-29009-3/4"-D1D

3 C1 RUN/STOP

C1 XL 2903 XL XL XL

M M M M

G-0908A 29031A G-0908B 29031B 3 29032A

3

29032B

3

C2 E&C

RUN/STOP RUN/STOP C2

C2

K G-0908A/B C2 PGD-29007-3/4"-A1D C2 G-0909A C2 C2 G-0909B G-0909A/B K

PGH TAILING TOWER REFLUX PUMPS Z

2937

Z

2937

Z Z C2 PGH 2ND STAGE FEED PUMPS LUMMUS TECHNOLOGY

2932 2932

HS C1 HS 2934 C1 2934 C1

C1 2937 D1D 2937 D1D

TYPE : CENTRIFUGAL TYPE : CENTRIFUGAL

RATED CAPACITY : 22.1 m3/h

29031A

STOP

29031B

STOP A1D A1D

RATED CAPACITY : 40.9 m3/h

PIPING & INSTRUMENT DIAGRAM

OPERATING PRESS.(SUC/DISCH.): -0.46 / 2.49 barg HS PGD-29008-3/4"-A1D HS OPERATING PRESS.(SUC/DISCH.): -0.49 / 34.69 barg PYROLYSIS GASOLINE HYDROGENATION

29032A 29032B

MATERIAL (CASING/IMPELLER) : CS / CS 0915K 0915K STOP 0915K STOP 0915K MATERIAL (CASING/IMPELLER) : CS / CS TAILING TOWER REFLUX DRUM

MOTOR POWER : 5.5 KW MOTOR POWER : 90.0 KW

L TRIM : TR-09G08A/B-A1D TRIM : TR-09G09A/B-D1D L

SCALE: DWG. No: REV:

A1-JGS1EP-209370- 0915B 3

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

N-0900-P-01-03_Tailing Tower Overhead Reflux System

N-0900-P-01-03_Tailing Tower Overhead Reflux System

N-0900-P-01-04_Tailing Tower Hot Well System

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

D-0910 NOTES:

PGH RECYCLE COMPRESSOR SUCTION DRUM 19. CHECK VALVES TO BE DISSIMILAR TYPE. 1. FOR LEGENDS, SYMBOLS, GENERAL NOTES AND ENGINEERING

A A

N-0900-P-01-04_Tailing Tower Hot Well System 20. SUPPLY BY K-0901 VENDOR. DESIGN NOTES SEE DWG. A1-21140-0004A, 0004B AND 0004C.

2. LOCATE SUCTION STRAINER AT MIMIMUM STRAIGHT RUN DISTANCE

SIZE : 1,000mmID X 3,000mmT/T

TYPE : VERTICAL TO COMPRESSOR SUCTION.

DESIGN PRESS. : 37 barg 3"x4" 3. COMPRESSOR IS PERMITTED TO START UP ONLY WHEN VALVE

DESIGN TEMP. : 150 °C IS 80% OPEN.

SET @

MATERIAL : CS 37.0 barg 4. COMPRESSOR SUCTION LINE TO BE PICKLED.

TRIM : TR-09D10-B1E PSV 5. LOCATE MOTOR OPERATED VALVE AS CLOSE TO K-0901 AS POSSIBLE.

4"x8" C1 WFL-29009-8"-A1K

29136A LOCATE ADJACENT DRAIN VALVES AND NITROGEN PURGE CONNECTION

B 0915Q AS CLOSE TO THE VALVE AS POSSIBLE. B

CSO 3"x4" WET FLARE

6"x3" SET @ 6. VALVE TO BE LOCATED AT HIGH POINT.

P-29044-10"-B1E 37.0 barg

NOTE 4 PSV 7. TWO OUT OF THREE HIGH HIGH LEVEL TRIP SIGNALS WILL CAUSE K-0901

C1 29136B WFL-29038-8"-A1K

SHUTDOWN AND ANY ONE WILL ALARM.

CSO

C1

4"x8" CSO 8. DELETED.

6"x3" C1 3

WFL-29026-2"-A1K 9. MOTOR OPERATED VALVES INCLUDE OPEN/CLOSE/STOP PUSH BUTTONS

A1K

CSC

C1

B1E

C1 INTEGRAL TO VALVE MOUNTED ACTUATOR. VALVES SHALL BE FIRE SAFE

P- 29048-6"-B1E WITH FIRE PROOF ACTUATOR. POWER AND CONTROL CABLES IN A FIRE ZONE

C C1 SHALL BE FIRE PROOFED. C

2" 10. DELETED.

C2 1½" P-29049-2"-B1E

3 11. DELETED.

PG 12. TWO OUT OF THREE HIGH HIGH TEMPERATURE TRIP SIGNAL WILL CAUSE

BV K-0901 SHUTDOWN AND ANY ONE WILL ALARM.

29042 D-0910 13. EACH TRANSMITTER TO HAVE SEPARATE IMPULSE LINE.

FC

29042 PLC 14. LEVEL GAUGE TO BE READABLE FROM GLOBE VALVE.

3 15. DELETED.

P-29062-10"-B1E 16. TWO OUT OF THREE LOW LOW FLOW TRIP SIGNAL WILL CAUSE K-0901

D 0915F SHUT DOWN AND ANY ONE WILL ALARM. D

HP OFFGAS 17. FOR SAMPLE CONNECTION DETAILS SEE DWG A1-JGS1EP-0005A~D,F.

FROM D-0909 3 Z

2932 2o.o.3 S R 3 18. FOR START UP & BACK UP.

NOTE 7 IA Z

C3 2934

FV

FF NOTE 14 29042 NOTE 6,20

LI H LG ATM

LT LZHH LAHH

29036 3 C2 P-29046-8"-B1E-PP(40) Z

29035 29035 29036 29036

P- 29047-6"-B1E

A,B,C 0915F 101

A,B,C SLOPE 8"x4" FO 8"x4" SLOPE LO MIN FLOW

E 18" TO E-0913 E

MH C1

FF HB K-0901 Z K-0901 HB Z

FALL 29045B TRIP 2932 29045A 102

FC FF TRIP

29042

29041 FV LI HH

29041

29036 XA XA

HG-29001-2"-B1E-DP(25) C1 C3 A,B,C

0605T 2" 2.o.o.3 NOTE 16 29041B 29041C

MAKE UP HYDROGEN 2"x1" FC 2"x1" C1 TL

MIN. FLOW

UC FI K-0901 K-0901

C1 FZLL Z

DP(25)

FROM D-0611A/B C2 NOTE 2 SHUTDOWN SHUTDOWN

2800 mm

PDG 29042 29042 2932 XA

1" STR LL

PGD- 29020-2"-B1E

29001 A,B,C 29041A K-0901

F C1 2909 TYPE 2 SHUTDOWN F

NOTE 17 SEE FF

SEE DETAIL "A" DETAIL "B" FF

UV HH TT AI SC FC FV

Z RESET

NOTE 13

H XA HB

29030 TI 29064 29030 29032 UV 29043 29043 2932

3 NOTE 12 29046 29046

29042 H2S 29031

M A,B,C C3 3 M "RESET ON"

P-29050-2"-B1E Z P-29045-8"-B1E-PP(40)

0905C 2932 0915E

TSO NOTE 9 RECYCLE GAS

300mm

HP OFFGAS TSO 8"x6" FO 8"x6"

NOTES 5,9 C2 TT MIN. L C2 C1 TO E-0911 XL

FROM D-0902 FT FI

NOTE 5

C1 29041 TZHH 29047

A1D

29042 29042

B1E

C2 C1 PI 29042 PLC

DIRT 3 SHUTDOWN SHUTDOWN

LEG PLC 29033 2oo3 BYPASS BYPASS

G PGD-29010-1½"-A1D PGD-29010-1½"-B1E L PT H 3 G

0915K C3 2" PT PI

PGH DRAIN C1 C1 C2 29033 29034 29034 XA Z HS

C2 C3 PG TAHH PLC 2932 29047

10"x6" 29047

LO 29059 29042 8"x6" P-29045-8"-B1E-PP(40)

NOTE 14 B1E C1 C1 TO ATM

P-29108-2"-B1E-PP(40)

C1 A1A AT SAFE LOCATION COMMON

C3 XA TROUBLE XA

DP(25) PP(40)

HG-29002-2"-B1E-DP(25) WFL-29041-1"-A1K 29034 ALARM 29034

G-111 V-111 0915Q

C1 C3 2"x1" WET FLARE

C3 SHUTDOWN TRIP AND

H AV-29001-1"-A1A ALARMS FOR K-0901 H

V-210

B1E-PP(40) C1 LO N2-29030-3/4"-A1A

3/4" AV-29002-1"-A1A

0915N

N2-29025-2"-A1A

A1A

C1

N-111 V-211 FOR CONSTRUCTION NEW DRAWING FOR NCP EXPANSION

1" AV-29003-6"-A1A

N-301 V-301

N2-29010-2"-A1A N2-29037-1"-A1A C1

0915N TW

NITROGEN

3 29048 21/12

3 /2018 ISSUED FOR CONSTRUCTION YJL WJL HSO HHM SWL

TW

WW-29005-1½"-A1A 29047 C1 CWR-29019-4"-H1A20 17/08

CW-202 0915M 2 /2018 ISSUED FOR CONSTRUCTION YJL WJL HSO HHM SWL

I 0915C I

4"x2" C2 LO 15/06

NOTE 19 Z M

K-0901 CW-102

1 /2018 ISSUED FOR CONSTRUCTION YJL WJL HSO HHM SWL

A1A 4"x2" LO 27/04

C2 0 /2018 ISSUED FOR DESIGN YJL WJL HSO HHM SWL

C3 B1E 101 3 C1

102 ISSUE PROC - - CLIENT

2932 CW-201 REV

DATE

DESCRIPTION CAD

ENG

LPE EM PM

C3 2934 4"x2" C1

C2 "THIS DOCUMENT IS THE PROPERTY OF LUMMUS TECHNOLOGY INC. (LUMMUS). IT CONTAINS CONFIDENTIAL

MIN. IA-301 IA-103 IA-101 IA-102 D-201 CWS-29021-4"-H1A20

BY VENDOR CW-101 0915M INFORMATION DESCRIBING TECHNOLOGY OWNED BY LUMMUS. IT IS TO BE USED ONLY IN CONNECTION WITH

PGD-29020-2"-B1E 4"x2" C1 WORK PERFORMED BY LUMMUS. REPRODUCTION IN WHOLE OR IN PART FOR ANY PURPOSE OTHER THAN

0405J C2

IA-29008-3/4"-H3A20 1/2"x3/4"

1/2"x3/4"

1½"x3/4"

1½"x3/4"

KNOCKOUT LIQUID NNF WORK PERFORMED BY LUMMUS IS FORBIDDEN EXCEPT BY EXPRESS WRITTEN PERMISSION OF LUMMUS. IT IS

TO BE SAFEGUARDED AGAINST BOTH DELIBERATE AND INADVERTENT DISCLOSURE TO ANY THIRD PARTY."

TO C-0402M RUN/STOP/TRIP

J J

XL

29034

JG SUMMIT OLEFINS CORPORATION

C1 C1 C1 C1 DETAIL "A" DETAIL "B" 2nd Stage Pygas Hydrogenation Unit

IA-29009-3/4"-H3A20

C:\Users\161600\Desktop\ 罹´\ 怠봬微퓬³_필리핀\Working\Latest\DPG-2\209371_A11X

IA-29007-1"-H3A20

Z

Batangas, The Philippines

C2 2932 HB

ULCO 29031A CLOSE

HB JOG OPEN

29030 HB

29030A CLOSE

JOG OPEN 29031B

3 HB JOG CLOSE

3 NOTE 3 E&C

JOG CLOSE29030B

K IA-29003-1½"-H3A20 USCO UZCO Z K

0915N 29030 ≤80% 29030 2934

0915K

PGD-29011-1½"-A1D 3 LUMMUS TECHNOLOGY

PGH DRAIN C1 USC ULC

K-0901 ULO USO

29030

UV

29030

USC

29030

ULC ULO USO

29031

UV

29031 29031 29031

29030 29030 29031

PGH 2ND STAGE RECYCLE COMPRESSOR M M PIPING & INSTRUMENT DIAGRAM

TYPE : CENTRIFUGAL TSO TSO PYROLYSIS GASOLINE HYDROGENATION

RATED CAPACITY : 12,206 X 1.15 kg/h Z FL FL PGH 2ND STAGE RECYCLE

SUC. PRESS. : 25.08 barg 2932 COMPRESSOR

L DIS. PRESS. : 31.62 barg START PERMISSIVE COMPRESSOR AND SUCTION DRUM L

ABSORBED POWER (RATED) : 530.0 KW SCALE: DWG. No: REV:

14 A1-JGS1EP-209370- 0915D 3

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

You might also like

- Prof. Robin Dunbar Grooming, Gossip, and The Evolution of Language 0Document121 pagesProf. Robin Dunbar Grooming, Gossip, and The Evolution of Language 0Émulo de Tantos100% (4)

- Tendernotice 5 PDFDocument148 pagesTendernotice 5 PDFAbhijit BhandarkarNo ratings yet

- Vendor Document Historical ListDocument4 pagesVendor Document Historical ListmalleshNo ratings yet

- A4-Jgs1ep-Epc1-Qp-014 Rev. B (Welding Repair Procedure Ag&p)Document12 pagesA4-Jgs1ep-Epc1-Qp-014 Rev. B (Welding Repair Procedure Ag&p)Darrel Espino AranasNo ratings yet

- Sumitomo Chemical India LTD.: 6/2, Ruvapari Road, Bhavnagar. 364 005Document1 pageSumitomo Chemical India LTD.: 6/2, Ruvapari Road, Bhavnagar. 364 005Prathmesh GujaratiNo ratings yet

- Sumitomo Chemical India LTD.: 6/2, Ruvapari Road, Bhavnagar. 364 005Document1 pageSumitomo Chemical India LTD.: 6/2, Ruvapari Road, Bhavnagar. 364 005Prathmesh GujaratiNo ratings yet

- Iso-Propanol Production Report: Student Name: Course Name: Submission DateDocument18 pagesIso-Propanol Production Report: Student Name: Course Name: Submission DateAmir Javed official100% (1)

- P&ID May Nghien Malt 10t-hDocument1 pageP&ID May Nghien Malt 10t-halun nguyễn100% (1)

- Va1 Dec 00100 I M1D Pid 8301 PDFDocument1 pageVa1 Dec 00100 I M1D Pid 8301 PDFAnonymous JtYvKt5XENo ratings yet

- P&id 4D1JCR-MCC0101Document1 pageP&id 4D1JCR-MCC0101aaronNo ratings yet

- 20100PE-DW02-0013 Rev0 11-SD-2104Document1 page20100PE-DW02-0013 Rev0 11-SD-2104Jovit BeaNo ratings yet

- PFD Unit 2000 - ReferenceDocument2 pagesPFD Unit 2000 - ReferenceAgravante JakeNo ratings yet

- 2.63 Transmittal Log (PO-PGB-MBRD-0001) (VIT1)Document8 pages2.63 Transmittal Log (PO-PGB-MBRD-0001) (VIT1)zhangNo ratings yet

- Notes: Process Flow Diagram Melamine Off-Gas Condensation (Section 25)Document1 pageNotes: Process Flow Diagram Melamine Off-Gas Condensation (Section 25)rajindo1No ratings yet

- Greenlane Biogas Cover Page See Content On Following Page (S)Document3 pagesGreenlane Biogas Cover Page See Content On Following Page (S)Cibele AlvesNo ratings yet

- Painampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PDocument22 pagesPainampuram, Muthukurmandal, S.P.S.R. Nellore District, A.Pkkumar_717405No ratings yet

- R420-FR-2130 A/B: NotesDocument1 pageR420-FR-2130 A/B: NotesMubashir fareed100% (1)

- Consultant: Engineers India Limited Contractor: Onshore Construction FzeDocument6 pagesConsultant: Engineers India Limited Contractor: Onshore Construction Fzecrm 2No ratings yet

- Area 1 - PID - Startup Minimum RequirementsDocument20 pagesArea 1 - PID - Startup Minimum RequirementsCristian SoublettNo ratings yet

- Process Gas Compressors: Comprehensive Api 618 Compressor PortfolioDocument20 pagesProcess Gas Compressors: Comprehensive Api 618 Compressor PortfolioaliakbarNo ratings yet

- Indra: Detail Pre-Commissioning Procedure For Service Test of Cooling Water For Unit 040/041/042/043Document62 pagesIndra: Detail Pre-Commissioning Procedure For Service Test of Cooling Water For Unit 040/041/042/043AnhTuấnPhanNo ratings yet

- KlopDocument388 pagesKlopRakeshNo ratings yet

- 01 102 PP10GA 006 Layout1Document1 page01 102 PP10GA 006 Layout1Sachin ShindeNo ratings yet

- S-03710 P42118-Rev. 3-P18-Steam DrumDocument1 pageS-03710 P42118-Rev. 3-P18-Steam Drumwylie01No ratings yet

- IPS MBD21907 in 522 Datasheet of Emergency Relief Valve ADocument3 pagesIPS MBD21907 in 522 Datasheet of Emergency Relief Valve ANikhil KarkeraNo ratings yet

- Pid Area 284Document10 pagesPid Area 284ATALAYNo ratings yet

- A10 A Pid Va 718605 201Document1 pageA10 A Pid Va 718605 201zhangNo ratings yet

- MVR P&ID OF WASTE WATER CONCENTRATOR .VSDDocument1 pageMVR P&ID OF WASTE WATER CONCENTRATOR .VSDHardikNo ratings yet

- Add Item N N°Document268 pagesAdd Item N N°Bilel MahjoubNo ratings yet

- P&ID - 22343 Scrubber de Aminas.Document1 pageP&ID - 22343 Scrubber de Aminas.Hernán GarcíaNo ratings yet

- P&ID Referencia Planta de CalDocument3 pagesP&ID Referencia Planta de CalLeonel Alejandro100% (1)

- SET P&ID - Filter Cellar - Tibasosa PDFDocument9 pagesSET P&ID - Filter Cellar - Tibasosa PDFJairo Hernando Rojas PulidoNo ratings yet

- Mds HPH 1 - Skoda PowerDocument3 pagesMds HPH 1 - Skoda PoweridilfitriNo ratings yet

- Column & HE Sizing - PresentationDocument76 pagesColumn & HE Sizing - PresentationRaihan FuadNo ratings yet

- 01 P&ID Nitrogen System - Building 2,3,5Document1 page01 P&ID Nitrogen System - Building 2,3,5MTT VIETPRONo ratings yet

- 08572-Trht-Ms-Ppfm003-A06-003 - e General Arrangement Drawing Filtered Raw Water Storage TankDocument3 pages08572-Trht-Ms-Ppfm003-A06-003 - e General Arrangement Drawing Filtered Raw Water Storage TankSamer ArousNo ratings yet

- 3rd Storey Plumbing Layout Plan Rev 0 (Color, Revit)Document1 page3rd Storey Plumbing Layout Plan Rev 0 (Color, Revit)ZenChanNo ratings yet

- NSRPDocument19 pagesNSRPPhương PhạmNo ratings yet

- DBB (DN50 CL600)Document1 pageDBB (DN50 CL600)hameed100% (1)

- A10 A Pid Va 718589 203Document1 pageA10 A Pid Va 718589 203zhangNo ratings yet

- 20100PE-DW02-0005 Rev0 11-SD-2121-4Document1 page20100PE-DW02-0005 Rev0 11-SD-2121-4Jovit BeaNo ratings yet

- Single PumpDocument1 pageSingle PumpbmanojkumarNo ratings yet

- Customer: Ge Packaged Power PROJECT PO: 411513279 PROJECT NO.: 1370344 Project Name: Termoyopal Project Location: Yopal, ColombiaDocument2 pagesCustomer: Ge Packaged Power PROJECT PO: 411513279 PROJECT NO.: 1370344 Project Name: Termoyopal Project Location: Yopal, ColombiaomarNo ratings yet

- A037 Ds 01 Water MonitorDocument1 pageA037 Ds 01 Water MonitorshabahatNo ratings yet

- Piping Class - AR75Document2 pagesPiping Class - AR75Дмитрий РыбаковNo ratings yet

- Surge Vessel Testing: (Update As of 30th April 2015)Document2 pagesSurge Vessel Testing: (Update As of 30th April 2015)Syed AliNo ratings yet

- AS 3601 Modular Mounting Systems Letter ENDocument20 pagesAS 3601 Modular Mounting Systems Letter ENcenter steel110100% (1)

- DWGDocument1 pageDWGsuhailfarhaanNo ratings yet

- Lo21-21-P-Pi-21 - Rev.pDocument2 pagesLo21-21-P-Pi-21 - Rev.psvnaik14100% (1)

- 510 C 013 (Absorber II)Document2 pages510 C 013 (Absorber II)idilfitriNo ratings yet

- PB02-STG-001 Steam Turbine System (A10-P-2001)Document1 pagePB02-STG-001 Steam Turbine System (A10-P-2001)zhangNo ratings yet

- Pts 0800 - A (Process Description)Document6 pagesPts 0800 - A (Process Description)ingegnere1234100% (1)

- PDS For Prewash Flash Column - R0Document8 pagesPDS For Prewash Flash Column - R0idilfitriNo ratings yet

- Rev 1 CCR P&id CommentsDocument2 pagesRev 1 CCR P&id Commentsxentrer100% (1)

- Oleum - A Department of Instrumentation & Control Technology (Dict) Engineering VentureDocument5 pagesOleum - A Department of Instrumentation & Control Technology (Dict) Engineering VentureArnel MorenoNo ratings yet

- Data Sheet Ko Drum 43-401Document14 pagesData Sheet Ko Drum 43-401sokrat sebtiNo ratings yet

- A307 3314 1243 Enq Rev0 PDFDocument196 pagesA307 3314 1243 Enq Rev0 PDFChintan HingooNo ratings yet

- VMS PDFDocument1 pageVMS PDFritoh8657No ratings yet

- Industrial Shed Column Reinforcement Details-ModelDocument1 pageIndustrial Shed Column Reinforcement Details-Modelayadi_archiNo ratings yet

- N-0900-P-02-01 - PGH 2nd Stage Reactor (R-0902)Document11 pagesN-0900-P-02-01 - PGH 2nd Stage Reactor (R-0902)Darrel Espino AranasNo ratings yet

- N-0900-P-03-01 - H2S Stripper (C-0903) : Z-0901 D-0915X E-0913 D-0909Document9 pagesN-0900-P-03-01 - H2S Stripper (C-0903) : Z-0901 D-0915X E-0913 D-0909Darrel Espino AranasNo ratings yet

- Schematic, Amplifier Channel, Ex 4000-B Schematic, Amplifier Channel, Ex 4000-BDocument6 pagesSchematic, Amplifier Channel, Ex 4000-B Schematic, Amplifier Channel, Ex 4000-BsolidmfXD1995No ratings yet

- WELL - ENV2018 N WorkshopDocument5 pagesWELL - ENV2018 N WorkshopDarrel Espino AranasNo ratings yet

- WELL - ENV2009 W Fire STNDocument5 pagesWELL - ENV2009 W Fire STNDarrel Espino AranasNo ratings yet

- DEP 31.38.01.11-Gen. (Piping General Requirements) - InformativeDocument24 pagesDEP 31.38.01.11-Gen. (Piping General Requirements) - InformativeDarrel Espino AranasNo ratings yet

- A4-Jgs1ep-Epc1-Qp-016 Rev. B (Flange Management Procedure)Document20 pagesA4-Jgs1ep-Epc1-Qp-016 Rev. B (Flange Management Procedure)Darrel Espino Aranas100% (1)

- A4-Jgs1ep-Epc1-Qp-016 Rev. A (Flange Management Procedure)Document21 pagesA4-Jgs1ep-Epc1-Qp-016 Rev. A (Flange Management Procedure)Darrel Espino AranasNo ratings yet

- A4-Jgs1ep-Epc1-Qp-016 Rev. A (Flange Management Procedure)Document21 pagesA4-Jgs1ep-Epc1-Qp-016 Rev. A (Flange Management Procedure)Darrel Espino Aranas100% (1)

- A4-Jgs1ep-Epc1-Qp-016 Rev. B (Flange Management Procedure)Document22 pagesA4-Jgs1ep-Epc1-Qp-016 Rev. B (Flange Management Procedure)Darrel Espino AranasNo ratings yet

- A4-JGS1EP-EPC1-MS-55-009 Method Statement For Refractory Installation - RA PDFDocument15 pagesA4-JGS1EP-EPC1-MS-55-009 Method Statement For Refractory Installation - RA PDFDarrel Espino AranasNo ratings yet

- N-0900-P-03-01 - H2S Stripper (C-0903) : Z-0901 D-0915X E-0913 D-0909Document9 pagesN-0900-P-03-01 - H2S Stripper (C-0903) : Z-0901 D-0915X E-0913 D-0909Darrel Espino AranasNo ratings yet

- Vpci PMC NCR 0026 PDFDocument51 pagesVpci PMC NCR 0026 PDFDarrel Espino AranasNo ratings yet

- Fu150sc SMDocument102 pagesFu150sc SMDarrel Espino AranasNo ratings yet

- N-0900-P-02-01 - PGH 2nd Stage Reactor (R-0902)Document11 pagesN-0900-P-02-01 - PGH 2nd Stage Reactor (R-0902)Darrel Espino AranasNo ratings yet

- SNSD - Run Devil RunDocument16 pagesSNSD - Run Devil RunAisy SarahNo ratings yet

- Samhitokta Conceptual Review of Marma and PranayatanaDocument4 pagesSamhitokta Conceptual Review of Marma and PranayatanaAnonymous sAVN1eN5NuNo ratings yet

- INTRODUCTIONDocument8 pagesINTRODUCTIONmalindaNo ratings yet

- The Teaching of Spherical Breathing: Using 18 BreathsDocument6 pagesThe Teaching of Spherical Breathing: Using 18 BreathsBBNo ratings yet

- KrushKrokMnemonics 1 1Document23 pagesKrushKrokMnemonics 1 1Fianyo DavidNo ratings yet

- Research Report - Zero Budget Natural Farming (Draft)Document43 pagesResearch Report - Zero Budget Natural Farming (Draft)Thashkent PaikadaNo ratings yet

- Lab Report No. 2Document5 pagesLab Report No. 2Kouji MaedaNo ratings yet

- Muscle System Lab ReportDocument7 pagesMuscle System Lab Reportapi-269985211100% (2)

- Family Planning 1-3Document41 pagesFamily Planning 1-3Atoba AbiodunNo ratings yet

- Introduction To PeriodonticsDocument28 pagesIntroduction To PeriodonticsHeba S Radaideh100% (3)

- Paper - 8A: Parasitology and Public Health: ZoologyDocument31 pagesPaper - 8A: Parasitology and Public Health: ZoologylaaltooNo ratings yet

- Salinity Tolerance in Chrysanthemum MorifoliumDocument7 pagesSalinity Tolerance in Chrysanthemum MorifoliumShailendra RajanNo ratings yet

- Fizik Worksheet Atomic Structure Separate With AnswersDocument69 pagesFizik Worksheet Atomic Structure Separate With AnswersqausarinarisaNo ratings yet

- Traditional Approach To Capital StructureDocument3 pagesTraditional Approach To Capital StructureShariful HoqueNo ratings yet

- Culinary History of Monosodium GlutamateDocument7 pagesCulinary History of Monosodium GlutamateSarthak NayakNo ratings yet

- Car - 66 - Log - Book Ame IndiaDocument13 pagesCar - 66 - Log - Book Ame IndiaKitKat ShArryNo ratings yet

- Tax Invoice: SHANKAR GAS SERVICE (0000142921)Document2 pagesTax Invoice: SHANKAR GAS SERVICE (0000142921)Ayush KumarNo ratings yet

- DH 0923Document12 pagesDH 0923The Delphos HeraldNo ratings yet

- Bio-Feedback: Hardik P Parab Moderator: Preetha R JohnDocument63 pagesBio-Feedback: Hardik P Parab Moderator: Preetha R JohnHimani Dalmia100% (1)

- PWR 301a Mod 1Document3 pagesPWR 301a Mod 1angerico rafilNo ratings yet

- Confirmation - Check-InDocument2 pagesConfirmation - Check-InTaqien AbscNo ratings yet

- 4.06 Yellow Fever (Transcript) - Super-WikiDocument30 pages4.06 Yellow Fever (Transcript) - Super-WikiimbuziliroNo ratings yet

- Position PaperDocument3 pagesPosition Paperapi-303097719No ratings yet

- Body of Knowledge: Certified Welding Inspector (CWI) Certified Welding Educator (CWE) Welding Inspector Endorsement (SIE)Document1 pageBody of Knowledge: Certified Welding Inspector (CWI) Certified Welding Educator (CWE) Welding Inspector Endorsement (SIE)Ján KožičkaNo ratings yet

- PlasteredDocument10 pagesPlasteredjkyraimundoNo ratings yet

- RMCDocument40 pagesRMCFiroj AlamNo ratings yet

- Milling Plant PerformanceDocument10 pagesMilling Plant PerformanceMuralidhar chowdaryNo ratings yet

- Healthcare Waste ManagementDocument39 pagesHealthcare Waste ManagementNamoAmitofou100% (1)

- 1g 1g 1g. 1u 1u 1u GDocument2 pages1g 1g 1g. 1u 1u 1u GAfrah MNo ratings yet