The Difference Between GL-4 and GL-5 Gear Oils by Richard Widman

The Difference Between GL-4 and GL-5 Gear Oils by Richard Widman

Uploaded by

Ameer Marco LawanCopyright:

Available Formats

The Difference Between GL-4 and GL-5 Gear Oils by Richard Widman

The Difference Between GL-4 and GL-5 Gear Oils by Richard Widman

Uploaded by

Ameer Marco LawanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

The Difference Between GL-4 and GL-5 Gear Oils by Richard Widman

The Difference Between GL-4 and GL-5 Gear Oils by Richard Widman

Uploaded by

Ameer Marco LawanCopyright:

Available Formats

The Difference between GL-4 and GL-5 Gear Oils

by Richard Widman

Revision 6-2020

The original target audience for this paper was my group of friends in the Corvair world, but it applies

to all cars, and is particularly important for all classic cars. I originally wrote this in 2013. This is the

fifth draft of this paper, updating several areas, especially the section on viscosities, based on emails I’ve

received.

There is a lot of confusion about gear oils and the API classifications. In this paper I will try to

differentiate the two oils and clear up the mysteries that are flying all over the internet. It is extremely

common, or normal, for all GL-5 oils to claim they cover the API GL-4 requirements for gear oils. This

is a true statement. Does that make them satisfactory for synchromesh or synchronized transmissions?

NO! They meet the GEAR OIL specifications, not transmission oil specifications. The API GL-4 and

GL-5 categories do not mention or have anything to do with transmission synchronizers.

History:

The gear oils of a few decades ago had lead additives that were effective at wear reduction, but not very

good for the environment. A long time ago they began to be replaced by gear oils with a phosphorous

additive (in itself a decent anti-wear additive) with active sulfur to grip hold of the gears and create a

very solid sacrificial layer of material that could be worn off, thereby protecting the gear surface.

Eventually it was discovered that the active sulfur was causing corrosion of brass and other soft metals

used in differentials and transmissions.

Somewhere around 30 years ago a deactivated or buffered sulfur was developed that would react with

the phosphorous to create the protective/sacrificial layer in the conditions created in the gear boxes

(temperature and pressure) without being corrosive to the brass, copper, etc. This additive system is

used in most gear oils today.

The problems arise when we try or need to use the same product in the transmission that we use in the

differential. Many people have called oil companies and been told by the “Techs” that answer their

questions that their oils have buffered sulfur and therefore are not corrosive to yellow metals, so their

GL-5 oils can be used with brass components. While that answer is totally correct, it does not address

the question asked: Can I use your GL-5 in my synchromesh transmission?

Let’s take a look at the API GL-5 rating. It is a rating for EP (Extreme Pressure) protection. The higher

the EP protection, the higher the GL category. In the mid 60's, Ford needed better protection in their

pickup trucks and GM developed the front wheel drive Oldsmobile Toronado that had a differential with

a very high angle of contact for power transmission to the wheels so a higher category was developed

(later to be called GL-6) to offer the protection needed. This level of protection can still be claimed, but

can no longer be tested since the Toronado rig used to test it is no longer available. (Note: The 1966 and

1967 Toronados had sun gears between the axle shafts instead of spyder gears and a very high offset,

while suffering from the high temperatures of the engine compartment and very high pressures.) This is

why you will frequently see GL-6 listed as “obsolete”. The test is obsolete, not the car or its needs. Many

other high performance cars continue to spec this level of EP performance.

In normal operation, the sulfur/phosphorous additive forms a black sacrificial coating on the gears and

anything it touches with a little pressure and temperature. As the gears turn, instead of wearing, the

sacrificial coating of additives is peeled off or worn off. This is normal and acceptable in all steel gears.

But when one or more of the surfaces is brass or another soft metal, the sacrificial coating is stronger

The Difference between GL-4 and GL-5 gear oils 1 of 13

than the base metal, and instead of just peeling off, it takes with it a few microns of brass that it is bound

to.

A traditional GL-4 gear oil of any given viscosity has about ½ of the level of sulfur/phosphorous additive

that would be in the GL-5 product, so the bond is not as strong, and therefore can be peeled off without

peeling a layer of brass (or less brass). This means that the GL-4 product provides a little less extreme

pressure protection, so in the differential of a high-powered car, it would not be the ideal product in the

differential. To understand this need we should be aware of the fact that the differential is where the final

torque is applied to the wheels (in most applications).

But in the transmission, we should consider two factors:

• Due to the fact that the differential applies the final torque, normally we do not need the full EP

protection in the transmission where less torque (about 30%) is applied.

• We need to be able to break the EP protection to stop the spinning of the gears long enough to

mesh them or synchronize them.

When we use a GL-5 product in a transmission that requires GL-4, we normally find 2 to 4 times as much

copper in the used oil as we would with a GL-4 product (with used oil analysis). Eventually the

synchronizers wear to the point that they no longer make contact with the other half of the cone,

bottoming out before stopping the opposing gear. (Refer to the picture below.)

Some cars (including later Corvairs) came with military specs instead of API gear oil specs. So we should

consider that MIL-L-2105B is an equivalent to GL-4, and MIL-L-2105C, 2105D, and 2105E are GL-5

gear oil lubricants.

GL-3

It should be noted that while GL-3 is frequently considered obsolete since it has less protection than the

GL-4, some transmission manufacturers today specify GL-3 (Chrysler and Mitsubishi among them).

There are many formulations of GL-3 oils in the market, some with sulfur/phosphorous additive and

some with zinc/phosphorous. Almost any diesel motor oil classifies as a GL-3 or GL-4 in gear protection.

Synchromesh transmission oils

General Motors, Honda and others have developed oils that combine the best shift characteristics with

their transmission components for reduced wear. These products in general could classify as GL-4 oils if

they wanted to, but actually when we analyze their components they are very similar to 5W-30 diesel

motor oils, with a few friction modifiers added. The viscosity is closer to an ATF. They are way too thin

for a Corvair transmission or any other where a SAE 80W-90 or 75W-90 is recommended. I will explain

the viscosity differences below. I have added the viscosity curve and characteristics to the graphs. Note:

just about any diesel motor oil can pass the GL-4 gear oil ratings.

Modern transmission oils

I am getting questions about the application of traditional GL-4 or GL-5 oils in modern cars

or the use of modern transmission oils in classic cars, so let’s look into them.

A lot of study has gone into the development of oils that are more slippery, more protective, and more

efficient. The current emphasis on fuel economy has driven many new transmission designs and oils to

match them. The economy gains have come with gear and machining design (smaller synchronizers with

double sided contact surfaces fused onto the ring) in an assembly that not only permits, but requires,

thinner oils. They also cannot tolerate sulfur/phosphorous additives in the oil, depending on friction

modifiers and new compounds to achieve GL-4 or better performance. This can become confusing, as

The Difference between GL-4 and GL-5 gear oils 2 of 13

few lubricant manufacturers state their ingredients. All you see are claims for performance or

recommendations for their own brand. In most cases these new formulations are much better for the

transmission and its efficiency.

For the most part these are SAE 75W-80 and 75W-85 oils, although the 75W-85 fits well in cars where

SAE 80 were required. Too thin for most classic cars, but necessary for modern cars. The additive

package uses magnesium or calcium sulfonate compounds and often synthetic base oil, and will give you

better EP protection than a GL-4 sulfur/phosphorous oil. Many of these claim GL-4+ performance and

pass most of the old GL-5 and SAE J2360 extreme pressure tests, but additionally pass manufacturers

tests for synchronization. The problems of where to apply them lie with the auto manufacturers, where,

for example, Toyota specifies in their owner’s manual, their SAE 75W without defining the rest of it. Oil

sales people will sell you 75W-90, but what Toyota is really asking for is 75W-85 without

sulfur/phosphorous. From the comments I receive, a standard SAE 75W-90 GL-4 does cause hard

shifting and grinding in these Toyotas in 70ºF weather.

Nissan has the same problem with 75W-90 oil, but their manual clearly states 75W-80 for 6 speed

transmissions and 75W-85 for 5 speed transmissions. It does not specify "non sulfur/phosphorous" oil,

instead referring to "Genuine Nissan Oil" (which does not contain those additives).

VW calls for 75W oil that meets their spec. They are looking for a viscosity on the low end (or slightly

below) of a 75W-80 and no sulfur/phosphorous additives.

With these new non-sulfur/phosphorous oils giving a minimum of GL-4 extreme pressure protection, I

believe manufacturers will stop specifying GL-3 when they revise their manuals. Recommendations are

also coming out from the additive makers to use these new formulations in place of the older

Synchromesh Fluids.

Transaxles

So, what do we put in transaxles where the transmission and differential are combined in one unit? This

is a good question, and the answer lies in the design and surface area of the gears. If the contact surfaces

of the gears are big enough to carry the weight and torque necessary, we depend less on the oil and its

additives. If the surface area is compact, we need to depend more on the additive's ability to handle the

boundary lubrication. When we have transaxles, we have to depend on the manufacturer to tell us what

product is correct.

When we have transaxles, we also need to be aware of whether the differential portion uses Limited Slip

“LSD” technology of some kind that limits the slipping of the wheels in mud and snow. This requires an

additive that lets a clutch bind the wheel movement together at a certain speed differential of the wheels.

This additive can be in any oil. Many GL-5 oils have a small amount. This is often enough for some

differentials as long as they were not rinsed out. Some systems need more additive than others. You can

usually tell if you need more additive by making a U-Turn. If the inner wheels click or try to lock up on

the turn, you need more additive. Often an oil that has a little of this additive will say it is satisfactory for

“service fill” or “top-off”.

How can you tell whether or not you have a limited slip differential? That is the easy part: Jack up both

driven wheels and spin one of them with your hand (transmission in neutral) if the other wheel spins the

same way, you have a limited slip differential. If it spins in the reverse direction, you do not. You can

also just jack up one wheel and try to spin it. If it refuses to turn, or turns with a lot of resistance, and the

car is in neutral, with no brake on, you have limited slip

The Difference between GL-4 and GL-5 gear oils 3 of 13

You will find numerous wrong comments on forums and other sites where users claim that GL-4

means LSD. That is totally false. A check of the API site could have set them straight.

Engine/Transaxle combinations

While not used in any Corvairs, there are cars where the same oil sump is used for lubrication of the

engine, transmission, and differential. With this design, the parts of the transmission and differential are

dimensioned for use of a GL-4 (or perhaps at one time even a GL-3). My 1975 Morris Mini is an example

of these cars. As far as I know, most have been fairly low HP engines, and where the higher HP (turbo

versions) were offered, synthetic oil was recommended. One caution that is not often mentioned in those

manuals: The multigrade oils used should be group II or stronger, or you should avoid extending the

interval beyond what is mentioned. The lesser quality multigrade oils tend to get their polymers ground

or sheered in the gears, just like some of the sludge prone OHV engines of today where gears are used

for synchronization of the cam and crank. Note: Corvair engines do not suffer from this sheer due to the

large diameter of the cam/crankshaft synchronization gears in the engine.

We can also note that the Chevrolet Luv pickups, as well as the Isuzu Rodeo and Trooper, many British

cars, and many others have recommended motor oil in the transmission for many years, even though they

have separate compartments. They only use gear oil in the differential, if it is separate.

The concept of using motor oil in these situations goes back to what I said towards the beginning. Most

motor oils can qualify for GL-4 (or at least GL-3) EP protection. As long as the torque on the gears in

low speed sliding action does not exceed what is covered by the GL-4, there is no benefit to

sulfur/phosphorous additives, but there is one for the synchronizers.

In the case of those single compartment motor/transaxle, there is an additional benefit of constantly

filtering the oil. The risk is that if you get gasoline in your oil you will thin out hydrodynamic film

protection in the gears. If you are running a mixture too rich, the additional soot (carbon particles) will

wear the gear surfaces as well as your camshaft. There is more information on these cars and oils in this

paper.

Viscosity:

First it should be noted that the SAE motor oil viscosity chart (J300) is different from the SAE gear oil

chart (J306). A SAE 40 motor oil has approximately the same viscosity as one of the thinner SAE 90 gear

oils, while the SAE 50 Motor oil is similar in viscosity to the thicker SAE 90 gear oils.

Viscosity has nothing to do with API Gear Oil classification (GL-4, GL-5, etc.). Some manual

transmissions specify an ATF (Automatic Transmission Fluid), others a SAE 75W-80 (almost the same

viscosity as the ATF), others a 75W-85, 75W-90 or 80W-90. Some specify a SAE 50 motor oil or SAE

50 CAT TO-4 transmission oil. The oil viscosity should be chosen according to the manufacturer's

recommendations for the temperatures where you will drive.

• If it is too thick (viscous) it will not displace fast enough from the synchronizers and will heat up

your transmission and cause hard shifts. It will also fail to flow properly in the needle bearings

or other tight spaces. It will also consume power and fuel.

• If it is too thin it will not provide the hydrodynamic lubrication that is required between gears

and in the bearings or bushings. It may also leak.

If we look at the service manual for the Corvair, the one I have from 1960 recommends SAE 80 Gear oil.

The Difference between GL-4 and GL-5 gear oils 4 of 13

While I do not have a SAE J306 viscosity chart earlier than the 1996 update, in the graph below we can

see those viscosity limits. What this means is that any given brand had to stay within that range for that

weight of oil.

You will note a huge range is possible between different brands within each range. The Red section on

the chart on the left the variation in viscosity for a SAE 90 gear oil, while the Blue portion shows the

variation allowable for a SAE 80 gear oil. On the right, we have the common viscosities. The 80W-90

that is shown is somewhat typical, running at the low end of the SAE 90 range. All are shown from

freezing to 60ºC.

SAE 80W-90 or 85W-90 oils are often referred to as multigrade oils. This is not true. They have no

polymers to modify their viscosity. They are simply SAE 90 oils with a normal (95 to 105) viscosity

index where the low temperature properties either meet the 80W or 85W specification. So, an 80W-90 is

at the low end of the SAE 90, while the 85W-90 is at the high end of the range for a SAE 90.

From personal experience and that of several friends who have tried them, I recommend staying away

from the 85W-90 in Corvairs and most other cars, since that puts it at the high end of the 90 scale. You

will notice a harder shift for the first few shifts of the day.

RED = SAE 90 BLUE = SAE 80

Remember, on the right, we are graphing an 80W-90 at the bottom of the range. In the following graph

we will compare them more closely, ignoring the top half of the SAE 90 range (85W-90), so this graph

is from the bottom of the red down. It still shows the same oils from 0ºC to 60ºC, but only from 2500

cSt down, eliminating all that white space in the previous graph.

In this graph we should be looking closely at the cold end of the lines (left), since that will show us how

The Difference between GL-4 and GL-5 gear oils 5 of 13

far we are from the recommended viscosity at operating temperature.

In the next graph we can see those same oils more closely once they have warmed up in the transmission.

Note the thick black dotted line that is the SAE 80, often recommended for classics of the 1950-1970

epoch, including the Corvair.

The Difference between GL-4 and GL-5 gear oils 6 of 13

Leaks

I often hear people say they need to increase the viscosity to compensate for leaks. While more viscosity

will reduce leaks, it also causes more wear of the main shaft and needle bearings, while making shifts

harder, as it is more difficult to displace from the synchronizers.

I also hear that synthetics will cause leaks. That is not a true statement on its own. Older oil formulations

often used oils that had more aromatics and molecules non-saturated molecules. These expanded the

seals, and to start out with, do a better job of sealing leaks. But then, in time, the seal wears, and dries.

The Difference between GL-4 and GL-5 gear oils 7 of 13

In other cases, the seals are just too old, or the oil hasn’t been changed enough to get fresh oil to the seal.

Synthetics, while containing some seal swell additives, may return those seals to their natural state,

shrinking them. There are two better solutions to leaks:

1. Replace the seals

2. Add a seal swell additive. These contain synthetic esters that will swell the seals back up. The

transmission I put in my Corvair was rebuilt back in the 60’s, and 40+ years later, I bought it and

put it in my car. It leaked from dried seals. I put 25 ml of a seal swell additive in it, and within 10

days or so, not a drop of oil came onto my garage floor.

Recommendations

In general, you should use your manual. Nobody knows the vehicle more than the people who put it

together. The exceptions are cars like the Corvair and other classics, where oils have changed

dramatically since the manuals were printed. There are other exceptions where those who write manuals

have no idea how a transmission works and are guided by wrong information from oil salespeople.

You need to realize that an oil with GL-4/GL-5 on the label is a GL-5. It is not appropriate for

synchronized transmissions.

For the Corvair and most other classics:

• Considering that most Corvairs have seen a lot of miles, there is probably some wear in the

transmission, so we could look at the higher viscosities within the recommendations unless it has

been rebuilt. Note in the graph that 75W-90 is more viscous than SAE 80 at operating

temperatures.

• This is a car that was produced long before any of the oils that are on the market today. My car

was a perfect example of what happens if you do not have any EP additives. The teeth on the

synchronizers were in excellent condition. But the rest of the transmission had severe signs of

wear. (See picture below)

The Difference between GL-4 and GL-5 gear oils 8 of 13

• Too much additive may reduce the wear on gears, needle bearings, and shafts in certain

conditions, but will wear out your synchronizers. You need to look for a GL-4 oil that does not

include GL-5 in its label, even though it looks good, even though it claims GL-4/GL-5 on the

label. The Corvair differential is well built with parts much bigger than those of many cars today.

Those gears can carry the power of the car. You can see in the following picture of a Toyota

synchronizer how the brass synchronizer has worn so much that the entire ring bottoms out and

no longer grabs.

• For many climates, the SAE 80W-90 is a good viscosity for the Corvair, but as you saw in the

viscosity graphs, it is much more viscous than the original recommendation of SAE 80. There

are products available that cover that full range with a SAE 75W-90 rating, or even a 75W-85.

This would be even better especially in cooler climates. The trick in the synthetic formulation of

75W-90 is a very high viscosity index in the synthetic base oil. You should note that these graphs

start out at zero Celsius (32ºF). You might need to shift below the -20ºC shown as a starting point

in these graphs. In this case, the synthetic oil is your best bet. Most manual automotive

transmissions will run between 30ºC and 50ºC in normal operation. I have been using 75W-90

GL-4 for several years and have much better shifts. Morning temperatures here are normally in

the 65ºF to 75ºF range.

• Corvairs with automatic transmissions: This is much simpler. Just use a good Dexron III (Dexron

VI is fine, but not required) in the transmission and a good GL-5 in the differential, adding the

LSD additive if the oil manufacturer does not include it and if you have “positraction”. They

may or may not include it. You have to read the label or spec sheet. As an example, I stock:

• 75W-80 GL-3 without LSD

• 75W-80 GL-4+ without LSD

• 75W-85 GL-4+ without LSD

• 75W-90 GL-4 with LSD and without

The Difference between GL-4 and GL-5 gear oils 9 of 13

• 75W-90 GL-5 with LSD and without

• 80W-90 GL-4 with LSD and without

• 80W-90 GL-5 with LSD and without

• 75W-140 GL-5 Synthetic with and without LSD

• 85W-140 with and without LSD

To confuse things a little more, we have to read the literature and sometimes consult with the

manufacturers. In looking for a few GL-4 products that would meet our needs, I identified Redline MT-

90 as a candidate, but then saw this on their website. I

questioned them and received this response.

“In your Corvair manual transaxle I would recommend the 75W90NS as a GL-5 type

gear oil was originally called for. A GL-4 gear oil is suitable for use in a zero or low

offset hypoid gear application, where extreme pressures of a high offset hypoid are

present a GL-5 gear oil is required. In your transaxle where high offset gears are not

present, a GL-4 gear oil could be used though we would recommend a GL-5 as called

for.”

While he confirms that the Corvair does not have high offset hypoid gears (“In your transaxle where

high offset gears are not present”), he says he recommends his GL-5 product because the Corvair

originally recommended GL-5 (“a GL-5 type gear oil was originally called for”). There is a problem

with that statement: The GL categories are based on the ASTM STP 512 standards which were originally

developed in 1972, three years after the end of the production of the Corvair.

We will also note here that, although not specified in the 1960 manual, later Corvair manuals specified

SAE 80 that meets the MIL-L-2105B spec. This is an equivalent to GL-4, while the later MIL-L-2105C,

2105D, and 2105E are GL-5 gear oil lubricants.

Here is a clarification from Lubrizol (one of the premier additive companies)

Summary

Just remember that GL-4 and GL-5 are gear oil ratings, not transmission oil ratings. Transmissions

have gears and synchronizers. These seemingly conflicting requirements must be met differently.

When someone tells you that their GL-5 covers GL-4, remember they are correct as far as EP protection,

but that is only half the answer. When they say their Sulfur/Phosphorous additive will not corrode the

yellow metals, they are also correct, but if there are enough to meet GL-5 protection, they will slowly

peel away your brass synchronizers.

The Difference between GL-4 and GL-5 gear oils 10 of 13

What should you do if you cannot find a GL-4 that does

not include GL-5 on its label? My next choice, and one

I almost did even though I have plenty of GL-4 80W-90,

would be a SAE 50 oil that meets CAT TO-4

specifications. My third choice would be a SAE 50 diesel

motor oil of the highest API classification I could find,

preferably group II. As you will see on this graph, the

temperature curve for a SAE 50 motor oil (or CAT

transmission oil) and a SAE 80W-90 are very similar.

But we should not get carried away thinking we cannot

find a GL-4 oil. There is plenty available in 75W-90. I

get emails from all over the world, and we almost always

come up with an answer.

What should you do if you've put a bigger engine in the

Corvair or dramatically increased the HP? I would use a

synthetic GL-4 oil. If I felt it was not enough (gut

feeling, stubbornness, etc.), I would send it away for

analysis, then use a GL-5 for the same period of time and

analyze it. If the GL-4 is not sufficient protection, it will

show up in iron particles in the sample. The GL-5 might reduce the iron wear, but you can see for yourself

how much copper increases. The only problem with this is the sample base is not statistically valid. But

it will give you more than a guess unless you have magnetic plugs or magnets on your filter.

I have received comments from people who have used VW transaxles with 150 to 200 hp engines in

racing situations, where they say the synchronizers are expendable, but the gears are expensive and hard

to come by, so GL-5 is better. It will make for harder shifts, but if you are going to quadruple the torque,

you may be better off that way. It is a personal decision.

Here is a simple explanation of the problem from Nissan:

It is interesting to note in this explanation by Lubrizol how the new SAE J2360 (replaces the GL-5 rating)

is explained:

“SAE J2360 is a global quality standard specified by many North American OEMs and

by growing numbers elsewhere in the world. The rigorous approval requirements,

including controlled field testing and independent committee review, ensure that products

approved under the SAE J2360 Standard meet the very highest demands of axles and

non-synchronized manual transmissions.” (emphasis added).

The Difference between GL-4 and GL-5 gear oils 11 of 13

The important part of that statement for us is the last part: “and non-synchronized transmissions”,

since our transaxles are synchronized.

Here is a synchronizer that has been worn

by GL-5 oil. You will note that there are no

longer any teeth on the brass, completely

worn or “peeled” away

Product possibilities

I hate to call these recommendations, but will list what I can of products that I know of and that are

available in the US. As always, this is as of this writing, and all information is gathered from the

Internet. Local availability will vary.

First let’s remember that the details are in the spec sheets. Some brands make it hard to find the

information.

I can applaud Mystic Oil's clarification when they start their spec sheet this way (although later in the

sheet they only mention the various GL classifications. Note how they say “and non-synchronized

manual transmissions.”

Texaco, on the other hand, does not mention this

limitation, although it is the same. They just don't

mention transmissions at all in their 80W-90 gear

oil. They leave it up to the consumer to realize that

transmissions don't use normal gear oils (as such).

The list:

My list is a short one. If you want me to add something I can look at it if you send me a link. I've been

looking and don't see much. These are listed in alphabetical order.

• Amsoil Synthetic manual Transmission and Transaxle Gear Lube 75W-90 GL-4

• Mannol Basic Plus GL-4+, 75W-90. Although I had never heard of it, it appears to be widely

available.

• Liqui-Moly High Performance Gear Oil (GL4+) SAE 75W-90

• BMW MTF L-4 is a 75W-90 with the new formulation. I don’t see any GL claims by BMW.

• Citgo Citgear Standard XD 75W-90 GL-4

• Pennzoil Gearplus 80W-90 GL-4

• Pennzoil Synthetic 75W-90 GL-4 (from the spec sheet, the best overall viscosity curve)

The Difference between GL-4 and GL-5 gear oils 12 of 13

• Quaker State Multi-purpose Gear Lubricant 80W-90 GL-4

• Redline MT90 is a good possibility, although their

web page has this disclaimer. Note my

observations on page 10.

• Shell Spirax G SAE 90 GL-4 (I do not recommend this due to its extremely high low

temperature viscosity.)

• Shell Spirax S3 G 80W-90 GL-4 (A little thicker than most 80W-90)

• Chevron had a product called Chevron Manual Transaxle oil that was excellent, but I cannot

find it except in clearance sites. I don't know if it has been replaced.

Considering all the requests I get for other classics, which often use different viscosities, but need the

same protection, I’m adding a list of products that I see now (June, 2020) that have the new technology

additives, meeting GL-4+ without the Sulfur/Phosphorous additives. I am going by their spec sheets.

• Penrite Trans Gear: 75W-80 (Their 75W-90 is old technology sulfur/phos)

• Penrite Pro Gear GL-4:75W-85 & 75W-90 (GL-4+) Be careful with labels, they are confusing.

In general, I recommend 75W-90 in a Corvair transmission especially if it is synthetic, there are some

very good GL-4 Synthetic 75W-90 oils in the market for Mercedes, Volvo and Mack truck and bus

transmissions that would be excellent, especially in colder climates. Really cold climates would be

better served with the new generation of Synthetic 75W-85 GL-4+.

I hope this clears up some of the confusion and avoids transmission damage. If you have additional

questions, feel free to send them to me at oil@asboman.com

If you have not read the report on motor oils, you can find it here:

Selection of the right motor oil for flat tappet engines.

The Difference between GL-4 and GL-5 gear oils 13 of 13

You might also like

- Emails Re Miami-Dade Surplus Parcel in Palmetto BayDocument23 pagesEmails Re Miami-Dade Surplus Parcel in Palmetto BayPolitical CortaditoNo ratings yet

- BMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesFrom EverandBMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesNo ratings yet

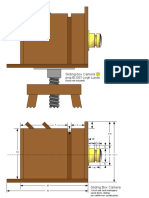

- Box Sliding Camera PlansDocument5 pagesBox Sliding Camera PlansAmeer Marco Lawan100% (1)

- Repair RF Basic PDFDocument7 pagesRepair RF Basic PDFAmeer Marco LawanNo ratings yet

- Transaxle OilDocument11 pagesTransaxle OilSunilkumar ReddyNo ratings yet

- GL4 GL5 OilsDocument10 pagesGL4 GL5 Oilsanndrew0No ratings yet

- Diferenca Entre GL4 e GL5 - Transaxle - OilDocument14 pagesDiferenca Entre GL4 e GL5 - Transaxle - OilClaudio U. S.No ratings yet

- Transaxle OilDocument10 pagesTransaxle Oilkontejner93No ratings yet

- Diferenca Entre Gl4 e Gl5Document7 pagesDiferenca Entre Gl4 e Gl5Claudio U. S.No ratings yet

- Gear Oil ClassificationDocument27 pagesGear Oil ClassificationSiva ReddyNo ratings yet

- A Study of Automotive Gear LubesDocument28 pagesA Study of Automotive Gear LubesgerardoctavaraNo ratings yet

- Annex Fleet 14 - Engine Oil GuideDocument9 pagesAnnex Fleet 14 - Engine Oil GuideewalasameagatheNo ratings yet

- Compared Recognized by Manufacturers and Associations For Best Type of Engine OilDocument60 pagesCompared Recognized by Manufacturers and Associations For Best Type of Engine OilEngine Tuning UpNo ratings yet

- Study of Automotive Gear Oils FromDocument28 pagesStudy of Automotive Gear Oils FromBruce Wappman100% (8)

- RotellaDocument17 pagesRotellalowtech41No ratings yet

- Lubricants CATEGORIESDocument6 pagesLubricants CATEGORIEShassantaufik.iqiNo ratings yet

- More Than You Ever Wanted To Know About Motor Oil: Date: Fri, 9 Jul 99 21:22:04 - 0700 From: Ed HackettDocument7 pagesMore Than You Ever Wanted To Know About Motor Oil: Date: Fri, 9 Jul 99 21:22:04 - 0700 From: Ed HackettGirinathNo ratings yet

- Engine OilDocument14 pagesEngine OildonlynNo ratings yet

- Api Engine Oil ClassificationsDocument3 pagesApi Engine Oil ClassificationsJohn Johnson100% (1)

- Essential Guide To Motor Oil Brochure FINAL PDFDocument16 pagesEssential Guide To Motor Oil Brochure FINAL PDFMauris BelmonteNo ratings yet

- 2010 Impreg Brochure - LubricantsDocument8 pages2010 Impreg Brochure - LubricantsvarundodhiaNo ratings yet

- BMW Oil Specs and RecsDocument5 pagesBMW Oil Specs and RecsSami Mlijy100% (1)

- LNG Sept2009Document52 pagesLNG Sept2009Paul JohnNo ratings yet

- Damaged by Fuel SulfurDocument4 pagesDamaged by Fuel Sulfurbambang eengNo ratings yet

- Understanding API CJ-4 FAQDocument2 pagesUnderstanding API CJ-4 FAQvictor.ciprianiNo ratings yet

- ShellFormula1 36Document3 pagesShellFormula1 36anoble1No ratings yet

- 300tdi Defender Oil SpecDocument10 pages300tdi Defender Oil SpecsebgohgkNo ratings yet

- Designations 111Document5 pagesDesignations 111Oumarba KamandaNo ratings yet

- Porsche Approved Engine OilsDocument5 pagesPorsche Approved Engine OilsRenee Rodriguez100% (1)

- WP Gear Oil SpecificationsDocument2 pagesWP Gear Oil Specificationsmannajoe7No ratings yet

- Product Data Guidecomplete2012Document202 pagesProduct Data Guidecomplete2012parag7676No ratings yet

- 2009 Engine Oil Guide PDFDocument3 pages2009 Engine Oil Guide PDFahmetNo ratings yet

- EngineOilGuide1Q2016Document4 pagesEngineOilGuide1Q2016ngblack81No ratings yet

- API Oil Guide 2010Document4 pagesAPI Oil Guide 2010amsoilromaniaNo ratings yet

- Engine Oil: Operation and Maintenance ManualDocument5 pagesEngine Oil: Operation and Maintenance ManualАлександр БудзинскийNo ratings yet

- Section 5 - Fuel, Lubricating Oil, and CoolantDocument11 pagesSection 5 - Fuel, Lubricating Oil, and CoolantRamon100% (1)

- Camry FAQ P2of2Document8 pagesCamry FAQ P2of2Janet WertNo ratings yet

- Royal Purple Gear Lubrication ManualDocument10 pagesRoyal Purple Gear Lubrication ManualArnaldo Macchi MillanNo ratings yet

- Lubricants - Always Important-Sometimes EssentialDocument2 pagesLubricants - Always Important-Sometimes EssentialGordinhorsNo ratings yet

- EngineDocument8 pagesEnginenobutaNo ratings yet

- Vw-Audi Oil Spec ArticleDocument5 pagesVw-Audi Oil Spec ArticleLindsay MooreNo ratings yet

- API Gear Oil SpecificationsDocument2 pagesAPI Gear Oil SpecificationsperonadoNo ratings yet

- Article Gear Lubrication 101Document4 pagesArticle Gear Lubrication 101SARALLAHNo ratings yet

- It Is Important That You Understand What API CJ-4 Lube Oil Is (And Isn't), and Why It Was DevelopedDocument2 pagesIt Is Important That You Understand What API CJ-4 Lube Oil Is (And Isn't), and Why It Was Developedvoyager1No ratings yet

- Section 1Document38 pagesSection 1EdisonNainggolanNo ratings yet

- API Oil Guide 2010Document4 pagesAPI Oil Guide 2010Tudor RatiuNo ratings yet

- Corvair OilDocument33 pagesCorvair OilMateusNo ratings yet

- 56796646472Document2 pages56796646472david espositoNo ratings yet

- Operating Fluids.11 5.17Document10 pagesOperating Fluids.11 5.17CelsoBrantesNo ratings yet

- Gear Lubrication ManualDocument10 pagesGear Lubrication ManualegarredondoNo ratings yet

- API-SAE Engine Oil Service BoletinDocument2 pagesAPI-SAE Engine Oil Service BoletinElmer PatpaulNo ratings yet

- Approved Lubrication DDocument2 pagesApproved Lubrication DMostafa MohamedNo ratings yet

- 01-Vehicle Quick ReferenceDocument53 pages01-Vehicle Quick ReferenceGustavoNo ratings yet

- Testin G Procedure and EquipmentDocument10 pagesTestin G Procedure and EquipmentClint CooperNo ratings yet

- Renault 5 Buyers GuideDocument4 pagesRenault 5 Buyers Guider5gordini100% (2)

- Brake Fluid Faqs: I Don'T Know Anything About Brake Uid What'S So Special About It?Document5 pagesBrake Fluid Faqs: I Don'T Know Anything About Brake Uid What'S So Special About It?phucdc095041No ratings yet

- What Are Low SAPS Engine OilsDocument5 pagesWhat Are Low SAPS Engine OilsVidyaNo ratings yet

- Mobil Glygoyle Series PDFDocument4 pagesMobil Glygoyle Series PDFKui KimNo ratings yet

- Porsche 930 Turbo & 911 (930) Turbo: Coupé. Targa, Cabriolet, classic & slant-nose models: model years 1975 to 1989From EverandPorsche 930 Turbo & 911 (930) Turbo: Coupé. Targa, Cabriolet, classic & slant-nose models: model years 1975 to 1989No ratings yet

- Top 100 Linux Commands (You Need To Know) - DreamHostEEEDocument63 pagesTop 100 Linux Commands (You Need To Know) - DreamHostEEEAmeer Marco LawanNo ratings yet

- How To Play As Gusion On Mobile Legends - Bang Bang - 9 StepszDocument3 pagesHow To Play As Gusion On Mobile Legends - Bang Bang - 9 StepszAmeer Marco LawanNo ratings yet

- Judicial Titling of Tax Declaration Properties - SAKLAWzDocument10 pagesJudicial Titling of Tax Declaration Properties - SAKLAWzAmeer Marco LawanNo ratings yet

- JessNoLimit's Instant Gusion Guide! Only For Those of You Who Have Quick Fingers! - Dunia GameszDocument4 pagesJessNoLimit's Instant Gusion Guide! Only For Those of You Who Have Quick Fingers! - Dunia GameszAmeer Marco LawanNo ratings yet

- Top 50+ Linux Commands You MUST Know _ DigitalOceanZZZDocument45 pagesTop 50+ Linux Commands You MUST Know _ DigitalOceanZZZAmeer Marco LawanNo ratings yet

- How To Apply Land Title From Tax Declaration in The PhilippineszDocument20 pagesHow To Apply Land Title From Tax Declaration in The PhilippineszAmeer Marco LawanNo ratings yet

- FINAL-Microtel Cabanatuan Sched - PDFDocument2 pagesFINAL-Microtel Cabanatuan Sched - PDFAmeer Marco LawanNo ratings yet

- BDO Credit Card Points Redemption Online Form - HomeDocument2 pagesBDO Credit Card Points Redemption Online Form - HomeAmeer Marco LawanNo ratings yet

- PC Gilmore Pricelist As of 11-26-19Document2 pagesPC Gilmore Pricelist As of 11-26-19Ameer Marco LawanNo ratings yet

- PC Express Dealers Pricelist NOV 2 2020Document2 pagesPC Express Dealers Pricelist NOV 2 2020Ameer Marco LawanNo ratings yet

- Cash Payments or Disbursements Journal - Explanation, Format and Example - Accounting For ManagementDocument4 pagesCash Payments or Disbursements Journal - Explanation, Format and Example - Accounting For ManagementAmeer Marco LawanNo ratings yet

- College of Mass Communication Foundation, Inc.: ProgrammeDocument1 pageCollege of Mass Communication Foundation, Inc.: ProgrammeAmeer Marco LawanNo ratings yet

- HP ProBook 6455b - 6555b Notebook PC Product Specifications - HP® Customer SupportDocument8 pagesHP ProBook 6455b - 6555b Notebook PC Product Specifications - HP® Customer SupportAmeer Marco LawanNo ratings yet

- Seeing Major Key Scales & Chords With Circle of Fifths MAJOR KEY SCALES ANSWER KEYDocument1 pageSeeing Major Key Scales & Chords With Circle of Fifths MAJOR KEY SCALES ANSWER KEYAmeer Marco LawanNo ratings yet

- Technical Data: Silicone Liquid GasketDocument3 pagesTechnical Data: Silicone Liquid GasketAmeer Marco LawanNo ratings yet

- Modified GCQ GCQ Modified ECQ: Test Trace TreatDocument21 pagesModified GCQ GCQ Modified ECQ: Test Trace TreatAmeer Marco LawanNo ratings yet

- Seiko Shutter Repair Manual PDFDocument22 pagesSeiko Shutter Repair Manual PDFAmeer Marco LawanNo ratings yet

- User Guide PDFDocument3 pagesUser Guide PDFShirleyAlbertoNo ratings yet

- ISitePower Integrated Smart Site V100R001C00 Installation Guide (ICC1000-A1-E1)Document203 pagesISitePower Integrated Smart Site V100R001C00 Installation Guide (ICC1000-A1-E1)Typical PhillipsNo ratings yet

- Leica M6 InstructionsDocument22 pagesLeica M6 Instructionsamoebahydra67% (3)

- Fault Contribution of Grid Connected InvertersDocument6 pagesFault Contribution of Grid Connected InverterspussykhanNo ratings yet

- CADWorx Equipment User GuideDocument121 pagesCADWorx Equipment User Guidejorge david100% (1)

- Instructions For Returning ABEM MALÅ Instruments (Malå)Document3 pagesInstructions For Returning ABEM MALÅ Instruments (Malå)ENG.YONIS HUSSAINNo ratings yet

- Mosfet DC Analysis: Semiconductor Field Effect Transistor or MOSFET For ShortDocument41 pagesMosfet DC Analysis: Semiconductor Field Effect Transistor or MOSFET For ShortSaley SaeedNo ratings yet

- Blue-Prism - ASDEV01.by .Frankse.26qDocument15 pagesBlue-Prism - ASDEV01.by .Frankse.26q4gw18cs044No ratings yet

- AnimationDocument8 pagesAnimationsonali guptaNo ratings yet

- Bsa Framework Secure Software Update 2020Document44 pagesBsa Framework Secure Software Update 2020Sameh MohamedNo ratings yet

- Data Collection PlanDocument8 pagesData Collection PlansayanNo ratings yet

- Screenshot 2023-05-17 at 8.10.22 PMDocument61 pagesScreenshot 2023-05-17 at 8.10.22 PMADRM JPNo ratings yet

- Cs 218 - Data Structures: HashingDocument18 pagesCs 218 - Data Structures: Hashingowais sultanNo ratings yet

- 2016 Math (AO) (Sample Past Paper)Document10 pages2016 Math (AO) (Sample Past Paper)Shansha DeweNo ratings yet

- PG-6000 Operation ManualDocument24 pagesPG-6000 Operation ManualingpochoNo ratings yet

- TAF C709 C717 - SPMDocument66 pagesTAF C709 C717 - SPMAbraham HernandezNo ratings yet

- MD Yasin Quamer: Oriental House 1 707, Bur Dubai, UAE Contact No: +971506085220Document3 pagesMD Yasin Quamer: Oriental House 1 707, Bur Dubai, UAE Contact No: +971506085220Nexus PathLabsNo ratings yet

- Rural Electric Safety Achievement Program (RESAP) Developing Safety Improvement Plan (Updated: 12-27-2010)Document7 pagesRural Electric Safety Achievement Program (RESAP) Developing Safety Improvement Plan (Updated: 12-27-2010)Yonatn DebebeNo ratings yet

- Taller InglesDocument3 pagesTaller InglesCristian Melchor Velasquez MartinezNo ratings yet

- Lip Syncing Pt3.: - Adding The Eye, Eyebrow and Head Movement To The Predator Lip SyncDocument6 pagesLip Syncing Pt3.: - Adding The Eye, Eyebrow and Head Movement To The Predator Lip SyncJasmine MastersNo ratings yet

- Exhibitor Manual ETBFSI CIO Digital ConclaveDocument8 pagesExhibitor Manual ETBFSI CIO Digital Conclavekaran.shah1No ratings yet

- 2016 CBI Study Guide - Module 5 - 16aDocument98 pages2016 CBI Study Guide - Module 5 - 16aGovil KumarNo ratings yet

- Fiche Technique - Film Agfa CP-BU M (Anglais)Document4 pagesFiche Technique - Film Agfa CP-BU M (Anglais)أنور مازوز أبو يوسفNo ratings yet

- Graphing Calculator Apps Guide For The TI-84 Plus CEDocument65 pagesGraphing Calculator Apps Guide For The TI-84 Plus CEMaxNo ratings yet

- Week 7 GONZALES, CATHERINE M. Individual Workweek Plan and Accomplishment ReportDocument5 pagesWeek 7 GONZALES, CATHERINE M. Individual Workweek Plan and Accomplishment ReportCatherine GonzalesNo ratings yet

- Arup FutureofRail2050 2019Document60 pagesArup FutureofRail2050 2019iamshreejayNo ratings yet

- Anritsu Wiltron MT8802A Service ManualDocument152 pagesAnritsu Wiltron MT8802A Service ManualIsrael MaurenteNo ratings yet

- Strokes Breakthrough by SlidesgoDocument47 pagesStrokes Breakthrough by Slidesgovina syauqiaNo ratings yet

- IP Multicast: Next Steps To Make It RealDocument25 pagesIP Multicast: Next Steps To Make It Realsabe100% (1)