0 ratings0% found this document useful (0 votes)

37 viewsMETHOD Statment MV VISHVA VIJETA

METHOD Statment MV VISHVA VIJETA

Uploaded by

ABDUL GHAFOORThe document provides a method statement for inspecting a boiler on the M.V. Vishva Vijeta vessel. The inspection is being conducted to address issues changing over the boiler from heavy fuel oil to diesel oil. The job will be executed according to the scope of work provided by the client and under technical guidance. Key steps include mobilizing equipment onboard, consulting with engineers, checking for overheating and tight connections, testing the boiler controller, troubleshooting the fuel oil interlock circuit, and testing the system with ship staff after completion.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

METHOD Statment MV VISHVA VIJETA

METHOD Statment MV VISHVA VIJETA

Uploaded by

ABDUL GHAFOOR0 ratings0% found this document useful (0 votes)

37 views1 pageThe document provides a method statement for inspecting a boiler on the M.V. Vishva Vijeta vessel. The inspection is being conducted to address issues changing over the boiler from heavy fuel oil to diesel oil. The job will be executed according to the scope of work provided by the client and under technical guidance. Key steps include mobilizing equipment onboard, consulting with engineers, checking for overheating and tight connections, testing the boiler controller, troubleshooting the fuel oil interlock circuit, and testing the system with ship staff after completion.

Original Title

METHOD statment MV VISHVA VIJETA_.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

The document provides a method statement for inspecting a boiler on the M.V. Vishva Vijeta vessel. The inspection is being conducted to address issues changing over the boiler from heavy fuel oil to diesel oil. The job will be executed according to the scope of work provided by the client and under technical guidance. Key steps include mobilizing equipment onboard, consulting with engineers, checking for overheating and tight connections, testing the boiler controller, troubleshooting the fuel oil interlock circuit, and testing the system with ship staff after completion.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

37 views1 pageMETHOD Statment MV VISHVA VIJETA

METHOD Statment MV VISHVA VIJETA

Uploaded by

ABDUL GHAFOORThe document provides a method statement for inspecting a boiler on the M.V. Vishva Vijeta vessel. The inspection is being conducted to address issues changing over the boiler from heavy fuel oil to diesel oil. The job will be executed according to the scope of work provided by the client and under technical guidance. Key steps include mobilizing equipment onboard, consulting with engineers, checking for overheating and tight connections, testing the boiler controller, troubleshooting the fuel oil interlock circuit, and testing the system with ship staff after completion.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

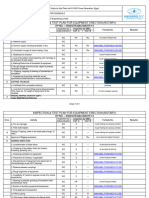

Docs No: VIEM-BA-C-161205

METHOD STATEMENT

VESSEL: M. V. VISHVA VIJETA

BOILER INSPECTION: INSPECTION OF BOILER UNABLE TO

CHANGEOVER TO D.O. FROM HFO.

The scope of work in accordance with scope provided by client vides the enquiry.

The job will be executed by VIBSPECTRUM INTERNATIONAL DUBAI under the technical guidance as per

operating instruction.

Mobilize the manpower and test equipment on board.

Consult with Chief Engineer /port engineer prior to performing the work.

Prior to the start of work, contact the Chief Engineer to coordinate the Implementation of the Tag out

Program for the entire performance period of the boiler.

Check for evidence of overheating, and tightness of all connections in boiler panel.

Check the operation of the Boiler controller as per manufacturer’s specifications.

Isolate the DO/HFO valve and circuit breaker during the loop testing

Perform the self-test and noted down the parameters of boiler controller.

Troubleshooting the HFO and DO Interlock circuit.

After completion the work and language change in controller; testing the system and witness Ship staff.

You might also like

- Testing & Commissioning of Fan Coil Units FCU'sDocument3 pagesTesting & Commissioning of Fan Coil Units FCU'svin ssNo ratings yet

- Hwi Apo CN MSS 0030 02Document119 pagesHwi Apo CN MSS 0030 02Nideesh RobertNo ratings yet

- 25.tank Water Fill TestDocument4 pages25.tank Water Fill TestShubham ShuklaNo ratings yet

- Blind Flange Failure 1Document6 pagesBlind Flange Failure 1Hamdan Rifai100% (1)

- Hydro Test ProcedureDocument14 pagesHydro Test ProcedureARJUN100% (6)

- CB Testing and Commissioning 76-92 PDFDocument17 pagesCB Testing and Commissioning 76-92 PDFVijaya Kumar100% (3)

- Precommissioning & Commissioning Procedure For Vavs & CavsDocument3 pagesPrecommissioning & Commissioning Procedure For Vavs & Cavsvin ssNo ratings yet

- SOP - Standard Repair Procedure For PipingDocument3 pagesSOP - Standard Repair Procedure For PipingBrahim BahriNo ratings yet

- Repairing and Maintenance Work PlanDocument5 pagesRepairing and Maintenance Work PlanMalik RiazNo ratings yet

- G3ir 4 0201 01 00025 1 - AwDocument1 pageG3ir 4 0201 01 00025 1 - AwAkshat JainNo ratings yet

- Std-Insp-0127 Procedure For Commissioning ProcedureDocument54 pagesStd-Insp-0127 Procedure For Commissioning ProcedureAkshay KalraNo ratings yet

- Testing & CommssioningDocument11 pagesTesting & CommssioningRehan KhanNo ratings yet

- Grouding System Field Test ProcedureDocument9 pagesGrouding System Field Test Proceduremilton1987No ratings yet

- Checklist For Above Ground Water Piping InstallationDocument1 pageChecklist For Above Ground Water Piping InstallationBelal Alrwadieh50% (2)

- CPF 016 HydrotestingDocument5 pagesCPF 016 HydrotestingThennarasu KumarNo ratings yet

- Testing & Commissioning of Fan Coil Units FCU'sDocument2 pagesTesting & Commissioning of Fan Coil Units FCU'sDong VanraNo ratings yet

- Instructions To Manufacturer: Project #:replacement of Valves in Mab Refinery Contract NumberDocument1 pageInstructions To Manufacturer: Project #:replacement of Valves in Mab Refinery Contract Numberritoh8657No ratings yet

- Commissioning ProcedureDocument24 pagesCommissioning ProcedureSumitskb100% (15)

- 28.1 Rotary Erection ItpDocument3 pages28.1 Rotary Erection ItpShubham ShuklaNo ratings yet

- Vacuum TestDocument3 pagesVacuum TestHarry DobleNo ratings yet

- Procedure For Vacuum Box TestingDocument3 pagesProcedure For Vacuum Box TestingZakirUllahNo ratings yet

- SDK GDH B4 FPS Rams 009 02Document26 pagesSDK GDH B4 FPS Rams 009 02md zubairNo ratings yet

- WI03-QCD-03 Procedure For Hydrotest InspectionDocument9 pagesWI03-QCD-03 Procedure For Hydrotest InspectionPhu PhuocNo ratings yet

- Procedures Manual Volume Four: RevalidationDocument13 pagesProcedures Manual Volume Four: RevalidationTalha UsmaniNo ratings yet

- Valve Testing Preservation Installation Sequence - UZ750Document15 pagesValve Testing Preservation Installation Sequence - UZ750Gaurav KhamkarNo ratings yet

- CB Testing and Commissioning 76-92Document17 pagesCB Testing and Commissioning 76-92Vijaya KumarNo ratings yet

- VAV Method of StatementDocument6 pagesVAV Method of StatementRanjith KumarNo ratings yet

- Inspection Method Statemen2Document8 pagesInspection Method Statemen2Klaus Janssen Johanssen100% (2)

- Hydrotest Supportive DocumentsDocument27 pagesHydrotest Supportive Documentsqadeer55afridiNo ratings yet

- Mos of MV SWGDocument22 pagesMos of MV SWGGajendran SriramNo ratings yet

- IQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFDocument15 pagesIQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFAli MajeedNo ratings yet

- Sop Panel Coil Tubes Standard Repair ProcedureDocument3 pagesSop Panel Coil Tubes Standard Repair ProcedureMoustafa FaresNo ratings yet

- Bypass Terminal Reheat Units Testing & Commissioning MethodDocument1 pageBypass Terminal Reheat Units Testing & Commissioning MethodDong VanraNo ratings yet

- 8.2.4 - JSL QMS QP 14 Hydrotest - ProcedureDocument5 pages8.2.4 - JSL QMS QP 14 Hydrotest - ProcedureGbenga MoboladeNo ratings yet

- Method of Statement VBDocument9 pagesMethod of Statement VBAhmed IrakyNo ratings yet

- DCC T&C Ms-PlumbingDocument11 pagesDCC T&C Ms-Plumbing721917114 47100% (2)

- Welding Consumable Control Procedure - Flare KOD Rev ADocument8 pagesWelding Consumable Control Procedure - Flare KOD Rev ARajesh K PillaiNo ratings yet

- Hydrotest Supportive Documents-4-25Document22 pagesHydrotest Supportive Documents-4-25qadeer55afridiNo ratings yet

- ATTL - METHOD OF STATEMENT FOR TANK HYDROTESTINGdocxDocument8 pagesATTL - METHOD OF STATEMENT FOR TANK HYDROTESTINGdocxMohammed Mostafa El Haddad100% (1)

- Testing & Commissioning of Chilled Water Pressurization UnitsDocument3 pagesTesting & Commissioning of Chilled Water Pressurization Unitsvin ssNo ratings yet

- Method Statement For Precommissioning & Commissioning of Close Control Units CCU'sDocument3 pagesMethod Statement For Precommissioning & Commissioning of Close Control Units CCU'svin ssNo ratings yet

- P 54 Holiday Testing Procedure R1Document43 pagesP 54 Holiday Testing Procedure R1rahul reyashNo ratings yet

- Check List For DB InstallationDocument2 pagesCheck List For DB InstallationNaing Win TunNo ratings yet

- Man GueraDocument3 pagesMan GueraSarema VazquezNo ratings yet

- Checklist For Installation of Chemical Fire Suppression SystemDocument1 pageChecklist For Installation of Chemical Fire Suppression Systembeho2000100% (2)

- 3890137e Tech Spec Data Sheets 1556604052Document14 pages3890137e Tech Spec Data Sheets 1556604052Prakash AnnamalaiNo ratings yet

- VAV Method of Statement - V1Document7 pagesVAV Method of Statement - V1Ranjith KumarNo ratings yet

- API 510 VesselsDocument11 pagesAPI 510 Vesselsmoonstar_dmeNo ratings yet

- MST Valve TestingDocument7 pagesMST Valve TestingSiva RamNo ratings yet

- 09.033-ITP 007-FTB HDPE DB Rev 2-15.06.10Document2 pages09.033-ITP 007-FTB HDPE DB Rev 2-15.06.10bcdavid100% (3)

- WI-150 Check Valve TestingDocument2 pagesWI-150 Check Valve TestingSaeed GhaniNo ratings yet

- HVAC Commissioning Checklist - SafetyCultureDocument10 pagesHVAC Commissioning Checklist - SafetyCultureMaxmore KarumamupiyoNo ratings yet

- Jawhart Berlin Co. General Trading & Cont. W.L.L - C-O - Sea Bright - AZAYEZ-JOB COMPLETION REPORTDocument5 pagesJawhart Berlin Co. General Trading & Cont. W.L.L - C-O - Sea Bright - AZAYEZ-JOB COMPLETION REPORTFebilaNo ratings yet

- Check List For Sub Main Distribution Board InstallationDocument2 pagesCheck List For Sub Main Distribution Board InstallationNaing Win Tun0% (1)

- That HousesDocument9 pagesThat HousesAri BinukoNo ratings yet

- Ug FF Pipes. MS For Flushing and Cleaning Underground Fire Fighting NetworkDocument9 pagesUg FF Pipes. MS For Flushing and Cleaning Underground Fire Fighting NetworkAbd Al Rahman OmaryNo ratings yet

- Model 4WI 100 - 800 HP BoilersDocument4 pagesModel 4WI 100 - 800 HP BoilerssebaversaNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Estimator's Piping Man-hours Tool: Estimating Man-hours for Carbon Steel Process Piping Projects. Manual of Man-hours, ExamplesFrom EverandEstimator's Piping Man-hours Tool: Estimating Man-hours for Carbon Steel Process Piping Projects. Manual of Man-hours, ExamplesNo ratings yet

- Power - Technologies - PTSenR SMART GRID IIOT Catalogues 2024 (Screen)Document15 pagesPower - Technologies - PTSenR SMART GRID IIOT Catalogues 2024 (Screen)ABDUL GHAFOORNo ratings yet

- 52.cargo Tank Level Monitoring SyatemDocument3 pages52.cargo Tank Level Monitoring SyatemABDUL GHAFOORNo ratings yet

- Neutral Grounding High VoltageDocument2 pagesNeutral Grounding High VoltageABDUL GHAFOORNo ratings yet

- Pt100-Temperature-Relay Type TR250: Digital, 3 Sensors, 3 LimitsDocument1 pagePt100-Temperature-Relay Type TR250: Digital, 3 Sensors, 3 LimitsABDUL GHAFOORNo ratings yet

- Middle East Fuji Engineering LLCDocument1 pageMiddle East Fuji Engineering LLCABDUL GHAFOORNo ratings yet

- TemPower ACBsDocument56 pagesTemPower ACBsABDUL GHAFOORNo ratings yet

- EC-9A Main SwitchboardDocument130 pagesEC-9A Main SwitchboardABDUL GHAFOOR100% (1)

- Zelio Timer Relays - RE22R2QEMRDocument6 pagesZelio Timer Relays - RE22R2QEMRABDUL GHAFOORNo ratings yet

- Electrical IsolationDocument8 pagesElectrical IsolationABDUL GHAFOORNo ratings yet

- Compact SCP: Plate Mounted Axial Flow FanDocument28 pagesCompact SCP: Plate Mounted Axial Flow FanABDUL GHAFOORNo ratings yet

- Installation: (High Resolution Adjustable Micro Distance)Document1 pageInstallation: (High Resolution Adjustable Micro Distance)ABDUL GHAFOORNo ratings yet

- Risk Assessment: Client VesselDocument3 pagesRisk Assessment: Client VesselABDUL GHAFOORNo ratings yet

- Compact SCP: Installation & MaintenanceDocument12 pagesCompact SCP: Installation & MaintenanceABDUL GHAFOORNo ratings yet

- NSX Catalogue 2008Document256 pagesNSX Catalogue 2008ABDUL GHAFOORNo ratings yet

- Intelligent Electromagnetic Flowmeter: Working PrincipleDocument20 pagesIntelligent Electromagnetic Flowmeter: Working PrincipleABDUL GHAFOORNo ratings yet

- Scope of Work MV Vishva VijetaDocument1 pageScope of Work MV Vishva VijetaABDUL GHAFOORNo ratings yet

- Crompton Protector - Trip PDFDocument50 pagesCrompton Protector - Trip PDFABDUL GHAFOORNo ratings yet

- Bwts Control Panel 1: Unless Otherwise Specified Project DetailsDocument1 pageBwts Control Panel 1: Unless Otherwise Specified Project DetailsABDUL GHAFOORNo ratings yet

- Shnieder Electric PDFDocument616 pagesShnieder Electric PDFABDUL GHAFOORNo ratings yet

- DatasheetDocument2 pagesDatasheetABDUL GHAFOORNo ratings yet

- 18034-AA.1 MSB Modification PDFDocument28 pages18034-AA.1 MSB Modification PDFABDUL GHAFOORNo ratings yet

- Cpro Cat PDFDocument116 pagesCpro Cat PDFABDUL GHAFOORNo ratings yet