Val - WhitePaper - Warehouse-temperature-Mapping v.4

Val - WhitePaper - Warehouse-temperature-Mapping v.4

Uploaded by

Azeddine LACopyright:

Available Formats

Val - WhitePaper - Warehouse-temperature-Mapping v.4

Val - WhitePaper - Warehouse-temperature-Mapping v.4

Uploaded by

Azeddine LAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Val - WhitePaper - Warehouse-temperature-Mapping v.4

Val - WhitePaper - Warehouse-temperature-Mapping v.4

Uploaded by

Azeddine LACopyright:

Available Formats

Planning a Successful

Warehouse Mapping Study

asy

SM

Author: Alex Debreceni

BioServices

The Importance of

Thermal Mapping

Pharmaceutical, biological and medical device products require controlled environmental storage conditions.

Degradation can occur when the storage environment of the product exceeds the range of safe conditions

of the product. For example, some pharmaceutical materials need to be stored at ambient temperature to

preserve the potency of the product. If the temperature of the storage environment goes outside that range,

damage to the pharmaceutical material may occur. Thermal mapping of all storage areas is required to assess

the environmental conditions stored pharmaceutical materials will be exposed to. This is especially true of

warehouse storage due to large seasonal variations of environmental conditions.

Create a Plan

A critical step when temperature mapping

warehouses is to determine the scope of the

project. A number of factors must be considered

when determining the scope; the number of

mapping studies, study length, the temperature

range acceptable for operation, quantity of sensors,

sensor locations, storage envelope parameters,

and any other information deemed important by

the end user, all are critical pieces of information

to ensure a successful mapping study whereas

the storage envelope refers to a specific section

of the warehouse designated for product storage. the winter months. This is due to the greater

Parameters relevant to the storage envelope include temperature difference between the outside and

storage rack numbers, storage rack dimensions, inside conditions of the warehouse. Warehouses

storage rack and product spacing, and thermal mass located in colder environments will most likely

distribution. require more HVAC power in the colder months for

the same reason. This will be true for most ambient

Information about the geographic location of storage areas, as they are temperature controlled

the warehouse or storage area is necessary for by facility HVAC systems. Airflow in storage areas

planning a mapping study. For example, warehouses is extremely important for temperature regulation.

located in a tropical environment will require more If air is not properly circulated throughout the

HVAC power to maintain ambient temperature storage area, a stratification effect can occur.

and humidity during the summer months than This means there will be a distinct temperature

2 ©2019 Masy Bioservices | (978) 433-6279 | www.masy.com

gradient, with temperatures increasing from the

floor of the area to the roof. Warm air will become

stagnant on the upper levels of the storage space

during the summer months. Thermal conduction or previously qualified where the ”As-Is” loaded

through the walls of the warehouse will transfer condition is identified and documented with

heat to any product stored up against it. The walls respect to current load.

will also allow for the transfer of heat through

convection and conduction throughout the Temperature mapping studies need to capture

warehouse. normal operation of the storage area as well

as low foot traffic days to get the full range of

Seasonal temperature swings will greatly affect the temperature variations. Temperature excursions

operation of the HVAC systems in place to regulate can occur during normal operation events such

the temperature of the storage environment. It as opening a door, excessive foot traffic, product

is required by the United States Pharmacopeia, movement, and daily HVAC operation. For these

Article 36, Chapter 1079, to perform two mapping reasons, warehouse mapping studies are run for

studies; one in the winter, and one in the summer a minimum of 7 consecutive days to demonstrate

to capture warehouse environmental data for the area uniformity during both weekdays and

most extreme outdoor low and high temperatures. weekends.

Studies are usually performed under “As-Is”

conditions for warehouses already in operation

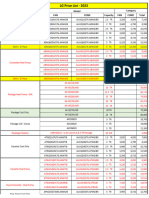

Fig. 1: This graph

represents a Summer

profile, 7 day thermal

mapping study shown in

Fahrenheit. Sensor 36

was located outside of the

warehouse where it was

exposed to the extreme

seasonal temperatures.

©2019 Masy Bioservices | (978) 433-6279 | www.masy.com 3

Executing the Plan

Temperature ranges in the warehouse are

defined with respect to the product in storage

and the ability of the environmental control

system to maintain the proper conditions.

From this information, acceptance criteria for

a passing mapping study can be determined.

Mapping studies can also be performed to

determine that the area mapped is suitable

for a specific pharmaceutical material that

requires a certain temperature and humidity

range. For ambient temperature storage, a

range of 15°C to 30°C is acceptable with

brief excursions due to outside environmental

variation.

Sensor locations and quantity will depend

greatly on the size and shape of the storage

area. Three sensors should be placed on

all corners of the storage area, one at the

top of the storage space, one in the middle

of the storage space, one at the bottom Sensors should be labeled with unique

of the storage space. Three sensors should identifiers to mark their location. A map

also be placed in the center of the area with sensor locations allows anyone to easily

and individual sensors should be placed determine locations of hot and cold areas

next to all monitoring probes, thermostats, in the warehouse. Well-documented sensor

entrances, or any other sources that influence placement allows for consistency in each of

temperature. It may also be beneficial to the seasonal mapping studies. Dataloggers

place sensors in storage rack areas to capture used for data acquisition must be calibrated

temperature conditions next to product. An and traceable to NIST or equivalent followed

additional sensor should be placed in an area by a calibration-verification after the

representative of outside temperature and qualification. This ensures the dataloggers

humidity for reference purposes only. This remained accurate within the application

is done to capture the outdoor temperature temperature range throughout the data

and humidity conditions the warehouse will collection process. Sensors should be secured

experience throughout the mapping study. to their locations for the entirety of the study.

4 ©2019 Masy Bioservices | (978) 433-6279 | www.masy.com

Analyzing the Results

After the mapping has ended, the data is

analyzed. Results from the mapping study

should be compared to the acceptance

criteria defined by the end user. In order

for the warehouse to pass the qualification,

the minimum and maximum temperatures

during the study must be within the specified

operating range. The humidity readings are

typically recorded and utilized as a reference

only. Because all of the sensors and locations

are labeled, the minimum and maximum

temperatures recorded will identify the coldest

and the warmest locations in the warehouse

as well as any non-conforming areas that fall

outside of the specified operating range. With

that information the end user can make key

decisions with regards to product storage. The Mean Kinetic Temperature

One way to eliminate non-conforming areas is defined as:

is to demarcate those as outside the range, if

any are identified. Monitoring sensors can be TK is the mean kinetic temperature in kelvin;

placed in locations that challenge the limits ΔH is the activation energy in kJ, R is the

universal gas constant, n is the number of

of the operating ranges so those areas are

sample events, when the samples are taken

constantly monitored and can be addressed

after the same time period, and Tn is the

if an excursion occurs. The maximum and

temperature taken at a sample point n in

minimum temperature locations may vary

kelvin. This equation weighs each data point

depending on season, so monitoring systems

against all of the other data points taken in

sensor placement should account for seasonal

a study, so small excursions from the normal

extremes. operation of the storage area, such as product

loading or movement, and door openings, will

Another key tool used to analyze data for not have a great effect on the calculation of

warehouse mapping is the Mean Kinetic the mean temperature of a specific location

Temperature (MKT). The MKT can be used to of the storage space.

evaluate readings from a single datalogger if

the temperature profile fluctuates in a distinct

pattern, such as a sinusoidal wave with

repeating temperature peaks and dips. The MKT

will give an accurate mean temperature for a

datalogger that experiences short excursions.

©2019 Masy Bioservices | (978) 433-6279 | www.masy.com 5

Conclusion

Pharmaceutical materials require controlled

environmental storage conditions to preserve

and protect the efficacy of the product.

Thermal mapping of warehouse storage areas

is essential to assess the environmental

conditions the products will experience.

Certain considerations need to be made prior

to the mapping study. Mapping studies should Citations

be planned to capture seasonal temperature

extremes and daily operations the storage area USP-NF. Good Storage and Distribution for Drug

can experience. Sensors should be placed in Products. USP 36 General Information / Good Storage and

Shipping Practices. Retrieved September 14, 2018

locations to identify at risk temperature areas

during mapping. Data collected through the

study should be analyzed and compared to the

acceptance criteria. Warehouse storage is a key

step in many pharmaceutical product life cycles.

Understanding all stages of the process is

essential in successful pharmaceutical storage.

Learn more at www.masy.com

6 ©2019 Masy Bioservices | (978) 433-6279 | www.masy.com

You might also like

- Pda TR70 2015Document75 pagesPda TR70 2015ammaostsNo ratings yet

- AIR HANDLING SYSTM IN PHARMACEUTICAL MANUFACTURING - Pharm R.A. BinitieDocument86 pagesAIR HANDLING SYSTM IN PHARMACEUTICAL MANUFACTURING - Pharm R.A. BinitieDinesh babuNo ratings yet

- Manual V100-V30-70 ENGDocument38 pagesManual V100-V30-70 ENGAzeddine LANo ratings yet

- SOP For Analytical Method ValidationDocument41 pagesSOP For Analytical Method ValidationPravin GaIkwadNo ratings yet

- MINITAB User's Guide Chap - 11Document32 pagesMINITAB User's Guide Chap - 11Ernesto Neri100% (3)

- Stability Q ADocument16 pagesStability Q Amaneshdixit4312No ratings yet

- GAMP5 Process Control System ValidationDocument1 pageGAMP5 Process Control System Validationkrisna8154No ratings yet

- Computer Systems Validation Specialist Resume Profile, Lansing, MI - Hire IT People - We Get IT DoneDocument6 pagesComputer Systems Validation Specialist Resume Profile, Lansing, MI - Hire IT People - We Get IT DoneSenthil NathanNo ratings yet

- ChemDraw TrainingDocument64 pagesChemDraw Trainingslash_de_law7484No ratings yet

- ACTD On QualityDocument21 pagesACTD On QualityDrSyeda RimaNo ratings yet

- ACTD PartIVClinical Nov05Document50 pagesACTD PartIVClinical Nov05TueNo ratings yet

- Vaisala Mapping Made Easy Presentation 0Document43 pagesVaisala Mapping Made Easy Presentation 0LeonardoNo ratings yet

- DAX Functions List Quick ReferenceDocument29 pagesDAX Functions List Quick Referencepedro 2009No ratings yet

- (NORMA) Request For Quality MetricsDocument14 pages(NORMA) Request For Quality MetricsJhovanaNo ratings yet

- Glatt Production of Solid DrugsDocument16 pagesGlatt Production of Solid Drugsteatoom100% (4)

- Validation Part2Document48 pagesValidation Part2gvasNo ratings yet

- 9 Temperature Mapping Mistakes To AvoidDocument5 pages9 Temperature Mapping Mistakes To AvoidReema IshaqNo ratings yet

- Seizure Care ProformaDocument3 pagesSeizure Care ProformaUdhav GoenkaNo ratings yet

- 9 Steps To GMP Warehouse Mapping VaisalaDocument9 pages9 Steps To GMP Warehouse Mapping VaisalaAmol AdsulNo ratings yet

- Robust Technology Transfer EMADocument24 pagesRobust Technology Transfer EMASilke Igemann100% (1)

- QM - FDA - Request For Quality MetricsDocument31 pagesQM - FDA - Request For Quality Metricspchakravarty_2No ratings yet

- Drug Accountability - An Important Aspect of Clinical ResearchDocument15 pagesDrug Accountability - An Important Aspect of Clinical ResearchTrialJoinNo ratings yet

- GEA Drying and Particle Formation Technologies For The CHEMICAL Industry - tcm11-24003Document28 pagesGEA Drying and Particle Formation Technologies For The CHEMICAL Industry - tcm11-24003Sergio A. Rdz. F.No ratings yet

- Validation TutorialDocument20 pagesValidation TutorialbahrulNo ratings yet

- Journal of Drug Discovery and Therapeutics 1 (9) 2013, 13-19Document7 pagesJournal of Drug Discovery and Therapeutics 1 (9) 2013, 13-19anandhra2010No ratings yet

- Continuous Processing in Pharmaceutical Manufacturing: Matthew J. Mollan JR., Ph.D. and Mayur Lodaya, PH.D., Pfizer IncDocument11 pagesContinuous Processing in Pharmaceutical Manufacturing: Matthew J. Mollan JR., Ph.D. and Mayur Lodaya, PH.D., Pfizer IncAMMY THAKURNo ratings yet

- Selection of Material Handling EquipmentDocument6 pagesSelection of Material Handling EquipmentAkif ZubairNo ratings yet

- U R T System (I) : Blank TemplateDocument26 pagesU R T System (I) : Blank TemplatesakshiNo ratings yet

- Validation of HPLC Techniques For Pharmaceutical AnalysisDocument54 pagesValidation of HPLC Techniques For Pharmaceutical Analysisfatos-osmani-5248No ratings yet

- Data Integrity Background and FAQDocument4 pagesData Integrity Background and FAQMina Maher MikhailNo ratings yet

- IVT Network - Incorporate Domestic and International Regulations For Effective GMP Auditing - 2013-08-20Document3 pagesIVT Network - Incorporate Domestic and International Regulations For Effective GMP Auditing - 2013-08-20huykhiemNo ratings yet

- Navigation Search: or Is Required On Packaged Perishable FoodsDocument4 pagesNavigation Search: or Is Required On Packaged Perishable FoodsAaron Paul Hernandez OcampoNo ratings yet

- Draft Standard Operating Procedure - Tubular Reactor and CSTRDocument5 pagesDraft Standard Operating Procedure - Tubular Reactor and CSTRshivaNo ratings yet

- MCB 1000L: Applied Microbiology Laboratory ManualDocument70 pagesMCB 1000L: Applied Microbiology Laboratory Manualmahsamoradi100% (1)

- Cleanroom DesignDocument10 pagesCleanroom DesignshwampaNo ratings yet

- Preventing Metal ContaminationDocument6 pagesPreventing Metal Contaminationlouish9175841No ratings yet

- Deming PDCADocument3 pagesDeming PDCARajaram SastryNo ratings yet

- EU-GMP Chapter 5 (Production)Document7 pagesEU-GMP Chapter 5 (Production)bvsc77035No ratings yet

- Calibration and Metrology PDFDocument10 pagesCalibration and Metrology PDFMano NegraNo ratings yet

- MadgeTech Data Logger 101 GuideDocument7 pagesMadgeTech Data Logger 101 GuideËdwin Carlossma HiguëraNo ratings yet

- Mecart Brochure PDFDocument20 pagesMecart Brochure PDFShenina KnightleyNo ratings yet

- Gas Leak Alarm Systems PDFDocument87 pagesGas Leak Alarm Systems PDFAvYlashKumbharNo ratings yet

- Aspen HYSYS BrochureDocument4 pagesAspen HYSYS BrochureLuiz OviedoNo ratings yet

- 17 Questions PDFDocument19 pages17 Questions PDFmuzammil21_adNo ratings yet

- Class Notes 5 Quantification of Pharmaceutical ProductsDocument21 pagesClass Notes 5 Quantification of Pharmaceutical ProductsNdatasha PambweNo ratings yet

- White Spots On TabletsDocument6 pagesWhite Spots On Tabletsedgar palominoNo ratings yet

- Thermo King Magnum Plus Maintenance Manual (Tool Catalog-TK5955)Document264 pagesThermo King Magnum Plus Maintenance Manual (Tool Catalog-TK5955)kennykolad1No ratings yet

- TR90 Product PIPagesDocument6 pagesTR90 Product PIPagesaenylevyNo ratings yet

- Lyophilization Competence06!11!2014 Tcm11 17173Document16 pagesLyophilization Competence06!11!2014 Tcm11 17173JPensacolaNo ratings yet

- User Requirements Template RAJADocument25 pagesUser Requirements Template RAJAdrs_mdu480% (1)

- Attachment 23 Criticality Assessment v3Document3 pagesAttachment 23 Criticality Assessment v3bo.ratchadaporn100% (1)

- Guidelines For Optimum Water Consumption in Bulk Drugs Manufacturing Industry PDFDocument128 pagesGuidelines For Optimum Water Consumption in Bulk Drugs Manufacturing Industry PDFSivakumar SelvarajNo ratings yet

- Guidelines On Bacterial Endotoxins Tests Version 2.0 20.01.2023Document16 pagesGuidelines On Bacterial Endotoxins Tests Version 2.0 20.01.2023Dhananjay BalghareNo ratings yet

- Preparative Chromatography for Separation of ProteinsFrom EverandPreparative Chromatography for Separation of ProteinsArne StabyNo ratings yet

- Quality Management Systems A Complete Guide - 2021 EditionFrom EverandQuality Management Systems A Complete Guide - 2021 EditionNo ratings yet

- Temperature Mapping and Monitoring - A SummaryDocument3 pagesTemperature Mapping and Monitoring - A SummaryEduardNo ratings yet

- Ich Q9Document48 pagesIch Q9Azeddine LANo ratings yet

- CAG-014 Final 04012022 SignedDocument19 pagesCAG-014 Final 04012022 SignedAzeddine LANo ratings yet

- Biocontamination NBR PTSDocument1 pageBiocontamination NBR PTSAzeddine LANo ratings yet

- GOOD Risk Assessment of Clean Room Used in Pharmaceutical Industries in Design Manufacturing EquippingDocument7 pagesGOOD Risk Assessment of Clean Room Used in Pharmaceutical Industries in Design Manufacturing EquippingAzeddine LANo ratings yet

- C19 Sonde KIMO KI932-22-01-2019Document3 pagesC19 Sonde KIMO KI932-22-01-2019Azeddine LANo ratings yet

- Certificate of Calibration: in Conformance With ISO 21501-4 Requirements For Calibration IntervalsDocument8 pagesCertificate of Calibration: in Conformance With ISO 21501-4 Requirements For Calibration IntervalsAzeddine LANo ratings yet

- Compressed Air - The Overlooked Element of Cleanroom SpecificationsDocument5 pagesCompressed Air - The Overlooked Element of Cleanroom SpecificationsAzeddine LA100% (1)

- Temperature and Humidity Monitoring Systems For Transport OperationsDocument20 pagesTemperature and Humidity Monitoring Systems For Transport OperationsAzeddine LA100% (1)

- 271 Data Integrity in Pharma - 040218Document7 pages271 Data Integrity in Pharma - 040218Azeddine LANo ratings yet

- + IQ/OQ Protocol: Installation Qualification/ Operation QualificationDocument10 pages+ IQ/OQ Protocol: Installation Qualification/ Operation QualificationAzeddine LANo ratings yet

- 2013 01 28 TemplateDocument2 pages2013 01 28 TemplateAzeddine LANo ratings yet

- Tcont900 InstallerDocument24 pagesTcont900 Installerapi-279886039100% (2)

- 45 Perlite For Non-Evacuated CryogenicDocument2 pages45 Perlite For Non-Evacuated CryogenicAhmar Bhatti100% (1)

- I-5 - 2010 Varianta in EnglezaDocument128 pagesI-5 - 2010 Varianta in EnglezarpufitaNo ratings yet

- Thermodynamics NotesDocument18 pagesThermodynamics NotesSushil KasabNo ratings yet

- Lesson Plan Deductive Learning Electrolite Non Elektrolite SolutionDocument17 pagesLesson Plan Deductive Learning Electrolite Non Elektrolite SolutionAnis MualifahNo ratings yet

- Vapor Liquid Equilibria: A Review: ArticleDocument16 pagesVapor Liquid Equilibria: A Review: ArticleLeonardo ReyesNo ratings yet

- LG Price List 2023 - UpdatedDocument2 pagesLG Price List 2023 - UpdatedmaazwzNo ratings yet

- MM 321 Lab 4Document6 pagesMM 321 Lab 4Siddhant Vishal ChandNo ratings yet

- Cooling System of High Power Synchronous GeneratorDocument5 pagesCooling System of High Power Synchronous GeneratorLorem53100% (1)

- Fiberglas TIWA Product Data SheetDocument2 pagesFiberglas TIWA Product Data SheetRangaswamy DoraiswamyNo ratings yet

- Brayton CycleDocument9 pagesBrayton CyclevqxknpnkNo ratings yet

- Curriculum Vitae: K.YeshwanthDocument5 pagesCurriculum Vitae: K.YeshwanthShankker KumarNo ratings yet

- Thermal Insulation Market in Lebanon: Le Marché de L'isolation Thermique Au LibanDocument75 pagesThermal Insulation Market in Lebanon: Le Marché de L'isolation Thermique Au Libanroger aklNo ratings yet

- PVT AnalysisDocument41 pagesPVT AnalysisEmad Aamer100% (2)

- MT Ii - HW 1Document1 pageMT Ii - HW 1Omkar RoyNo ratings yet

- S Tudent Exploration: Energy Conversion in A SystemDocument6 pagesS Tudent Exploration: Energy Conversion in A SystemMir Mir0% (4)

- Chapter 8Document84 pagesChapter 8Hafizszul FeyzulNo ratings yet

- Ran KineDocument15 pagesRan KineSatish SaxenaNo ratings yet

- Chapter Test A: Teacher Notes and Answers 16Document6 pagesChapter Test A: Teacher Notes and Answers 16Mogtaba KassimNo ratings yet

- First Law of ThermodynamicsDocument13 pagesFirst Law of ThermodynamicsVictorNo ratings yet

- CH 8. Chemical Equilibrium (Chem +1)Document40 pagesCH 8. Chemical Equilibrium (Chem +1)Dipin Preet SinghNo ratings yet

- Thermodynamic of IC EnginesDocument16 pagesThermodynamic of IC EnginesZemariam GetuNo ratings yet

- Appendix A1-A5 GaskellDocument8 pagesAppendix A1-A5 GaskellIhlasul AmalNo ratings yet

- Transport PhenomenaDocument9 pagesTransport PhenomenadeshendrenNo ratings yet

- PriceListHirePurchase Normal28thapril2020Document68 pagesPriceListHirePurchase Normal28thapril2020kjhfjkfhgjkdfhgjdkfNo ratings yet

- Données Climatiques YAOUNDE - 220908 - 165102Document2 pagesDonnées Climatiques YAOUNDE - 220908 - 165102Michel Mix TankouNo ratings yet

- Chapter Four Heat and ThermodynamicsDocument44 pagesChapter Four Heat and ThermodynamicsmesfinNo ratings yet

- Hukum TermodinamikaDocument3 pagesHukum Termodinamikalele12No ratings yet

- SHC LabDocument1 pageSHC LabAlistair DaleyNo ratings yet

- Test 07 Energy 05dkDocument13 pagesTest 07 Energy 05dkLin Xian XingNo ratings yet