0 ratings0% found this document useful (0 votes)

47 viewsLecturer:Hanan Adel: Principles of Transportation

Lecturer:Hanan Adel: Principles of Transportation

Uploaded by

Alaraqi AlaraqiThe document discusses the key components of a railway track, including rails, sleepers/ties, ballast, and subgrade. It describes the materials typically used for each component and compares the advantages and disadvantages of different sleeper materials, such as timber, steel, cast iron, and concrete. Standard railway gauge is defined as 4 feet 8.5 inches. Proper drainage and foundation layers are also highlighted as important aspects of railway track design and construction.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Lecturer:Hanan Adel: Principles of Transportation

Lecturer:Hanan Adel: Principles of Transportation

Uploaded by

Alaraqi Alaraqi0 ratings0% found this document useful (0 votes)

47 views17 pagesThe document discusses the key components of a railway track, including rails, sleepers/ties, ballast, and subgrade. It describes the materials typically used for each component and compares the advantages and disadvantages of different sleeper materials, such as timber, steel, cast iron, and concrete. Standard railway gauge is defined as 4 feet 8.5 inches. Proper drainage and foundation layers are also highlighted as important aspects of railway track design and construction.

Original Title

lecture No. 10 railway

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

The document discusses the key components of a railway track, including rails, sleepers/ties, ballast, and subgrade. It describes the materials typically used for each component and compares the advantages and disadvantages of different sleeper materials, such as timber, steel, cast iron, and concrete. Standard railway gauge is defined as 4 feet 8.5 inches. Proper drainage and foundation layers are also highlighted as important aspects of railway track design and construction.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

47 views17 pagesLecturer:Hanan Adel: Principles of Transportation

Lecturer:Hanan Adel: Principles of Transportation

Uploaded by

Alaraqi AlaraqiThe document discusses the key components of a railway track, including rails, sleepers/ties, ballast, and subgrade. It describes the materials typically used for each component and compares the advantages and disadvantages of different sleeper materials, such as timber, steel, cast iron, and concrete. Standard railway gauge is defined as 4 feet 8.5 inches. Proper drainage and foundation layers are also highlighted as important aspects of railway track design and construction.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 17

LEC. NO.

10

Principles of transportation

Lecturer :Hanan Adel

Railway Track

• The track on a railway or railroad, also known as

the permanent way, is the structure consisting of the

rails, railroad ties (sleepers) and ballast , plus the

underlying subgrade.

Traditional track structure

• The track ballast is customarily crushed stone, and the purpose

of this is to support the ties and allow some adjustment of their

position, while allowing free drainage.

• Section through railway track and foundation showing the ballast and

formation layers. The layers are slightly sloped to help drainage.

• Rail

Cross-sections of flat-bottomed rail.

• Modern track typically uses Hot rolled steel

with a profile of an asymmetrical rounded I-

beam. Unlike some other uses

of iron and steel, railway rails are subject to

very high stresses and have to be made of very

high-quality steel alloy. It took many decades

to improve the quality of the materials,

including the change from iron to steel. The

heavier the rails and the rest of the trackwork,

the heavier and faster the trains the track can

carry.

•

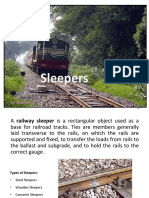

• Rail support (sleeper/tie)

• A railroad tie ( a railway sleeper ) is a

rectangular object on which the rails are

supported and fixed. The tie has two main

roles: to transfer the loads from the rails to

the track ballast and the ground underneath,

and to hold the rails to the correct width apart

(to maintain the rail gauge). They are generally

laid transverse (perpendicular) to the rails.

• Railway Sleepers - Types of Sleepers -

Longitudinal, Transvers

• Depending upon the position in a railway track,

sleepers may be classified as:

• 1. Longitudinal Sleepers

• 2. Transverse Sleepers

•

• sleepers may be classified as:

• · Timber/wooden sleepers

• · Steel sleepers

• · Cast Iron Sleepers

• · Concrete Sleepers

• Timber/Wooden Sleepers

• The timber sleepers nearly fulfilled all the requirements

of ideal sleepers .

•

• The most important advantages of Timber Sleepers

• · They are much useful for heavy loads and high speeds

• · They have long life of 10-12 years depending upon

the climate, condition, rain, intensity, nature of traffic,

quality of wood etc

• · They are able to accommodate any gauge

• · Can be used with any section of rail

• · Can be handled and placed easily

• · Cheaper than any other types of sleepers

• Disadvantages of Timber Sleepers

• · Liable to be attacked by vermin so, they must

be properly treated before use

• · Liable to catch fire

• · They are affected by dry and wet rot

• · Become expensive day by day

• · Life is shorter compare to others

Steel sleepers

• Advantages of Steel Sleepers

• · Have a useful life of 20-25 years.

• · Free from decay and are not attacked by vermins

• · Connection between rail and sleeper is stronger

• · Good scrap value

• · Suitable for high speeds and load

Disadvantages of Steel sleepers

• · Liable to corrosion by moisture

• · Cannot be used for all sections of rails and

gauges

• · Very costly

Cast Iron Sleepers

• Advantages of Cast Iron Sleepers

• · Long life upto 50-60 years

• · High scrape value as they can be remolded

• · They are not attacked by vermin

Disadvantages Cast Iron Sleepers

• · They are prone to corrosion and cannot be used

in salty formations .

• · Not suitable for track with circuited portions of

railways

• · Difficult to maintain the gauge

• · Difficult to handle and may be easily damaged

• · Lack of good shock absorber

• · They are expensive

Concrete sleepers

Advantages Concrete Sleepers

• · Durable with life range from 40-50 years

• · They can be produced on large quantities by installing a plant

• · Heavier than all other types thus giving better lateral stability to

the track

• · suitable for use in track circuited lines

• · They are not attacked by corrosion

• · Free from attacks of vermin and decay, suitable for all types of

soils

•

• · Prevent buckling more efficiently

• · Initial cost is high but proves to be economical in long run

• · Effectively and strongly hold the track to gauge

• · Inflammable and fire resistant

Disadvantages Concrete Sleepers

• · Difficult to be handled

• · Difficult to be manufactured in different sizes

• · Can be damaged easily while loading and

unloading

.Gauge

• Measuring rail gauge

• During the early days of rail, there was

considerable variation in the gauge used by

different systems. Today, 60% of the world's

railways use a gauge of (4 ft 8 1⁄2 in), known

as standard or international gauge. Gauges

wider than standard gauge are called broad

gauge; narrower, narrow gauge.

Foundation

• Railway tracks are generally laid on a bed of

stone track ballast, in turn is supported by

prepared earthworks known as the track

formation. The formation comprises the

subgrade and a layer of sand or stone dust .

• The sub-grade layers are slightly sloped to one

side to help drainage of water.

•

You might also like

- NRL2TRK3011 ISSUE 07 Continuously Welded Rail PDFDocument82 pagesNRL2TRK3011 ISSUE 07 Continuously Welded Rail PDFChris Avo100% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Railway SleepersDocument13 pagesRailway Sleepersaustin otienoNo ratings yet

- Railway SleepersDocument34 pagesRailway SleepersMJ MJNo ratings yet

- Sleepers For Railway TrackDocument14 pagesSleepers For Railway TrackChukhu Aane DuiNo ratings yet

- Components of RailwayDocument10 pagesComponents of RailwayRitwik PoddarNo ratings yet

- SS SleepersDocument6 pagesSS SleepersManoj BhutaniNo ratings yet

- Airport EngineeringDocument164 pagesAirport Engineeringanand100% (1)

- Railways and Airports PDFDocument94 pagesRailways and Airports PDFAkshay AradhyaNo ratings yet

- Chapter-3 Railway Track StructureDocument88 pagesChapter-3 Railway Track StructureTsegaye TsegayeNo ratings yet

- Railway EngineeringDocument15 pagesRailway EngineeringSheikh UbaidNo ratings yet

- Railway EngineeringDocument40 pagesRailway Engineeringlals_rckstrNo ratings yet

- Unit 2 Railway EngineeringDocument16 pagesUnit 2 Railway EngineeringHanamant HunashikattiNo ratings yet

- Railways and SubwaysDocument31 pagesRailways and SubwaysPRINCE HOPE MEDIA TZNo ratings yet

- Sleepers: Present ByDocument15 pagesSleepers: Present ByEngr Shahzad HashimNo ratings yet

- Hydraulic Design of SewersDocument57 pagesHydraulic Design of SewersAnu Babu Thaikkattil67% (3)

- BridgeDocument53 pagesBridgePARMAR DASHRATHNo ratings yet

- ConvffDocument27 pagesConvffPrajaya RajhansaNo ratings yet

- Elements of Railway TracksDocument27 pagesElements of Railway Trackscajimenezb8872No ratings yet

- Materials Used in Laying of Permenant WayDocument11 pagesMaterials Used in Laying of Permenant WayMourya Teja VuddandiNo ratings yet

- Bridge Introduction 8th CivilDocument56 pagesBridge Introduction 8th Civilsamrudh kamalapurkarNo ratings yet

- ch-3 Railway Track StructuresDocument125 pagesch-3 Railway Track Structuresyoabijo0No ratings yet

- 5 - Lecture 5 RailsDocument45 pages5 - Lecture 5 Railsaditya kumarNo ratings yet

- CulvertsDocument37 pagesCulvertsPRINCE HOPE MEDIA TZNo ratings yet

- SDM College of Engineering and TechnologyDocument19 pagesSDM College of Engineering and TechnologypramilaNo ratings yet

- Aerial Ropeways1Document60 pagesAerial Ropeways1Anshul yadavNo ratings yet

- Types of Railway SleepersDocument4 pagesTypes of Railway SleepersAtish KumarNo ratings yet

- Railway Track Structure and Rock Types Used in Railway Track BallastDocument20 pagesRailway Track Structure and Rock Types Used in Railway Track Ballastdinesh raj SharmaNo ratings yet

- Fluid ConveyanceDocument59 pagesFluid ConveyanceLovely Mae Cruza GawinganNo ratings yet

- Basic Introduction and Geometric Design of RailwaysDocument113 pagesBasic Introduction and Geometric Design of RailwaysSeetunya Jogi100% (4)

- Module 2 - Wastewater NotesDocument31 pagesModule 2 - Wastewater Notessureshtm1203No ratings yet

- Pipe Materials and Types of JointsDocument28 pagesPipe Materials and Types of JointsTPT CIVILNo ratings yet

- Lec 3 SleepersDocument21 pagesLec 3 Sleepershaidarullah0060116No ratings yet

- Wastewater NotesDocument34 pagesWastewater Notesdeekshith gowdaNo ratings yet

- Amrutvahini College of Engineering, Sangamner. Department of Civil EngineeringDocument22 pagesAmrutvahini College of Engineering, Sangamner. Department of Civil EngineeringJayraj Maghade100% (1)

- RailDocument30 pagesRailTripathi 70100% (1)

- Chapter 3Document69 pagesChapter 3Zewdie Tadesse GebremariamNo ratings yet

- Railway PDFDocument42 pagesRailway PDFSarankumar ThathuruNo ratings yet

- BridgesDocument26 pagesBridgesPRINCE HOPE MEDIA TZNo ratings yet

- Road EngineeringDocument38 pagesRoad EngineeringshilubaxNo ratings yet

- Steel Bridge: Prepared By: Christian J. EjocDocument13 pagesSteel Bridge: Prepared By: Christian J. EjocAlfredo VillanuevaNo ratings yet

- Lecture - 05 - Elements of Civil EngineeringDocument18 pagesLecture - 05 - Elements of Civil EngineeringSanthoshMBSanthuNo ratings yet

- G DPPT FinalDocument149 pagesG DPPT FinalPrabesh ShresthaNo ratings yet

- Department of Civil Engineering: Permanent Way of RailwayDocument26 pagesDepartment of Civil Engineering: Permanent Way of RailwayFarooq AhmedNo ratings yet

- Rajlway RoadDocument29 pagesRajlway Roadjhshj834No ratings yet

- Chapter - 5 Engineering Geology of TunnelsDocument24 pagesChapter - 5 Engineering Geology of Tunnelssiraj likiNo ratings yet

- COnveyance of Water and ValveDocument25 pagesCOnveyance of Water and ValveMadan GorathokiNo ratings yet

- Chapter-3 TrackDocument77 pagesChapter-3 TrackGoytom yigezuNo ratings yet

- T&D - Unit1 - Mechanical Design of OH LinesDocument72 pagesT&D - Unit1 - Mechanical Design of OH LinesKiran KumarNo ratings yet

- Week 1 - Railway BasicsDocument26 pagesWeek 1 - Railway Basicsisic.mirjanaNo ratings yet

- Chapter 3 TrackDocument78 pagesChapter 3 TrackBabangida Gida NessreNo ratings yet

- 5 Bridge N Tunnel - Lecture 71 PDFDocument103 pages5 Bridge N Tunnel - Lecture 71 PDFGajendra Joshi100% (1)

- SleepersDocument39 pagesSleepersJunaidAhmedNo ratings yet

- Intoduction To BridgesDocument52 pagesIntoduction To BridgesAbhishekNo ratings yet

- Tunnel EngineeringDocument134 pagesTunnel EngineeringEd100% (2)

- Conveyance of WaterDocument23 pagesConveyance of WaterRNo ratings yet

- Materials of SewerDocument31 pagesMaterials of Sewerfarhan arainNo ratings yet

- Lecture-1 - Introduction To BridgesDocument109 pagesLecture-1 - Introduction To Bridgesjoy cho100% (1)

- Toss Sem 9 17.7.2023Document168 pagesToss Sem 9 17.7.2023SHRUSHTI SURVENo ratings yet

- Building Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksFrom EverandBuilding Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksNo ratings yet

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- Design Criteria Manual For Metro Light Rail Transit Projects PDFDocument375 pagesDesign Criteria Manual For Metro Light Rail Transit Projects PDFMirko Mendoza ZuazoNo ratings yet

- Module 1 Noise Control (Unit 3)Document29 pagesModule 1 Noise Control (Unit 3)arp.manishkumarNo ratings yet

- List Harmonised National Restriction Codes enDocument21 pagesList Harmonised National Restriction Codes enmiangolaNo ratings yet

- Indian Railway PPP - Product Concept CONFIDENTIALDocument19 pagesIndian Railway PPP - Product Concept CONFIDENTIALnebodepa lyftNo ratings yet

- Lab Report - Building TransportationDocument28 pagesLab Report - Building TransportationLUQMAN AMMARNo ratings yet

- Technical Memorandum: California High-Speed Train ProjectDocument46 pagesTechnical Memorandum: California High-Speed Train ProjectHéctor VargasNo ratings yet

- Chép chính tả Cam 15Document4 pagesChép chính tả Cam 15LucyLucyNo ratings yet

- Provisional Answer Key For Preliminary Examination (Elimination Test) Conducted On 07-05-2023 For Direct Recruitment To The Cadre of Civil JudgeDocument3 pagesProvisional Answer Key For Preliminary Examination (Elimination Test) Conducted On 07-05-2023 For Direct Recruitment To The Cadre of Civil JudgegajendraburagaNo ratings yet

- Sumande - Field Work No.10 - Laying of Simple Curve Using Theodolite and TapeDocument8 pagesSumande - Field Work No.10 - Laying of Simple Curve Using Theodolite and TapeCedrix SumandeNo ratings yet

- FX - MB - 1B2Y SM1000 - Shaft - ConnectionDocument1 pageFX - MB - 1B2Y SM1000 - Shaft - ConnectionAssir El DjazairiNo ratings yet

- CareerCarve GD WorkshopDocument17 pagesCareerCarve GD WorkshopSai sundarNo ratings yet

- BOM ProjectT 2024-03-30Document2 pagesBOM ProjectT 2024-03-30spamingalertNo ratings yet

- Lifelines of National Economy 2018-19 GeographyDocument9 pagesLifelines of National Economy 2018-19 GeographyARSHAD JAMILNo ratings yet

- 13071/Hwh JMP Express Third Ac (3A) : WL WLDocument2 pages13071/Hwh JMP Express Third Ac (3A) : WL WLANSARI MOHD MOKARRAM ZAINUL ABD-CSE SORTNo ratings yet

- Impact of Metro Rail Transit System On Residential PropertiesDocument8 pagesImpact of Metro Rail Transit System On Residential PropertiesHARNEET KAURNo ratings yet

- Moss Feature Codes For Road Survey and MappingDocument25 pagesMoss Feature Codes For Road Survey and Mappingjeem1880% (5)

- Test - B1 Unit 7 Transportation - QuizletDocument7 pagesTest - B1 Unit 7 Transportation - QuizletRomina MoncayoNo ratings yet

- Rcs C Instructions For Assembly and UseDocument178 pagesRcs C Instructions For Assembly and UseMix UpNo ratings yet

- 3 X 45°chamfer 2 X 45°chamfer: Stamp 5 Type "Irs-W/Pn - 68"Document3 pages3 X 45°chamfer 2 X 45°chamfer: Stamp 5 Type "Irs-W/Pn - 68"alokrajamanNo ratings yet

- Correction Slip No. 7 IRPWM - 3 - HLDocument1 pageCorrection Slip No. 7 IRPWM - 3 - HLsoupNo ratings yet

- AC DC Railway Electrification and Protection: November 2014Document43 pagesAC DC Railway Electrification and Protection: November 2014Akhilesh kumar Srivastava100% (1)

- Letter To VCCDocument2 pagesLetter To VCCRinku MandalNo ratings yet

- Gyanshu TicketDocument3 pagesGyanshu Ticketgyanshusoni81No ratings yet

- Duronto Express Third Ac (3A)Document3 pagesDuronto Express Third Ac (3A)amruta UNo ratings yet

- Urban Design Public Realm Guidelines LowresDocument38 pagesUrban Design Public Realm Guidelines LowresJohn DeepthiNo ratings yet

- Unit - 3 Curve Surveying: Prateek SharmaDocument34 pagesUnit - 3 Curve Surveying: Prateek SharmaGour PramodNo ratings yet

- Surplus Items Aug'20Document4 pagesSurplus Items Aug'20Abhishek Kumar TiwariNo ratings yet

- 7 Mega Projects in Bangladesh That Will Transform The Country Rapidly - Business Inspection BDDocument8 pages7 Mega Projects in Bangladesh That Will Transform The Country Rapidly - Business Inspection BDSufiaNo ratings yet