Effective Span Length: 139 Concrete Deck Slabs

Effective Span Length: 139 Concrete Deck Slabs

Uploaded by

John Royer Araúz FuentesCopyright:

Available Formats

Effective Span Length: 139 Concrete Deck Slabs

Effective Span Length: 139 Concrete Deck Slabs

Uploaded by

John Royer Araúz FuentesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Effective Span Length: 139 Concrete Deck Slabs

Effective Span Length: 139 Concrete Deck Slabs

Uploaded by

John Royer Araúz FuentesCopyright:

Available Formats

Design of Superstructure Elements

Effective Span Length CONCRETE DECK SLABS 139

[3.9.1]

DESIGN EXAMPLE 3.1

DESIGN OF REINFORCED CONCRETE 1 GIVEN PARAMETERS

EXAMPLE 3.1 DET

DECK SLAB—LFD METHOD 5

The design of this slab will be performed

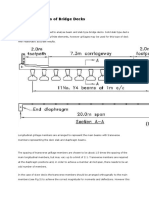

PROBLEM: Design the transversely reinforced concrete deck slab using Load Factor Method (LFD) of AASHTO

shown in the cross section detail below. Standard Specifications.

The top flange width is found by consult-

8" REINFORCED ing the AISC Manual of Steel Construc-

CONCRETE SLAB

1/4" PER FT. tion in the W Shapes Dimension section.

Although this bridge has a monolithic

deck with integrated wearing surface, the

design of the slab should account for a

3'-3 " 8'-0" 8'-0" 4'-0"

future wearing surface to be applied to the

deck surface.

GIVEN:

STEP 1: EFFECTIVE SPAN LENGTH

Bridge to carry two traffic lanes.

Bridge loading specified to be HS20-44. This step follows the verbiage of the

Concrete strength f´=

c

4.5 ksi. AASHTO code explicitly. This makes the

Grade 60 reinforcement fY = 60 ksi. calculation of the effective span length

Account for 25 psf future wearing surface. somewhat involved. A more direct ap-

Assume stringers are W36x150. proach is to take

Deck has integrated wearing surface

STEP 1: Compute the Effective Span Length S = Center to Center Stringers - W/2

From Table 3.7 we see that, for a slab supported on steel stringers and

continuous over more than two longitudinal supports: For slab on girder bridges with identical

stringer properties, this is a more direct

S = Distance Between Flanges + 1/2 Top Flange Width approach. For concrete girder bridges,

Top Flange Width = 12" for W36 × 150 (from AISC) = 1.0 ft

however, the effective span length is the

Distance Between Flanges = 8.0 ft − 2(1 ft / 2) = 7.0 ft

S = 7.0 ft + (0.5)(1.0 ft)

clear span length between the girder top

➠ S = 7.5 ft flanges.

3.9.1 Effective Span Length

Figure 3.22 shows a typical design strip for a reinforced concrete deck slab.

The deck is assumed to act like a beam which is continuous over its supports. In

this case, the supports are the wide flange stringers used as primary members in

the superstructure. A one-foot unit width is assumed for the design beam, with the

T he deck is assumed to act

like a beam which is con-

tinuous over its supports. In

beam running transversely (perpendicular to the primary members). this case, the supports are the

To simplify the design, a segment of the assumed slab-beam is taken and

wide flange stringers used as

analyzed as a simple span. The length of this segment is called the effective span

length. The size of the effective span length is dependent on primary members in the super-

structure.

❏ Whether the slab is continuous over more than two supports

❏ The type of supports (e.g., steel or concrete stringers)

❏ How the slab is integrated with the supports

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

Design of Superstructure Elements

Calculation of Bending Moment CONCRETE DECK SLABS 141

[3.9.2, Part 1]

DESIGN EXAMPLE 3.1

DESIGN OF REINFORCED CONCRETE 2 STEP 2: COMPUTE MOMENT DUE

EXAMPLE 3.1 DET

DECK SLAB—LFD METHOD 5 TO DEAD LOAD

STEP 2: Compute Moment Due to Dead Load The dead load is taken as a distributed

load acting over the effective span length

Dead load includes slab and future wearing surface, so that the total

of the slab. The future wearing surface

dead load on the slab is

load was given as an area load which we

DL = (Thickness of Slab)(Weight of Concrete) + Future WS take to act over the 1 ft wide unit strip of

= [(8 in)(1 ft/12 in)(0.15 K/ft3) + (0.025 K/ft2)](1 ft Strip) slab (see Figure 3.22). The moment due

to dead load is computed in accordance

➠ DL = 0.125 K/ft

with Equation 3.33. If the slab is continu-

wS2 DL ⋅ S2 ( 0.125 k/ft )( 7.5 ft ) ous over more than two supports, as we

2

MDL = = = have here, be careful not to use the stan-

10 10 10

dard wL2/8 equation for a simple span

➠ MDL = 0.70 ft-kips under distributed load.

STEP 3: Compute Moment Due to Live Load + Impact STEP 3: COMPUTE MOMENT DUE

TO LIVE LOAD

Live load is computed as per Equation 3.29

Since the slab is continuous over more

S+2 7.5 ft + 2

than two supports, we use Equation 3.29,

MLL = 0.8 P = 0.8 ⋅ ⋅ 16 kips which has the 0.8 multiplier. The value of

32 32

P used is 16 kips since our live loading

➠ MLL = 3.80 ft-kips was specified to be HS20-44 (see the

variable definitions for Equation 3.28).

Impact for spans between 2 ft and 24 ft will always be 30%, so use an We computed the live load plus impact

impact factor of 1.30 to obtain moment by multiplying the live load

moment by 1.30. Another way of doing

MLL+I = (3.80 ft-kips)(1.30) this is to compute an impact only moment

➠ MLL+I = 4.94 ft-kips

by multiplying the live load moment by

0.30. Then the two moments are added

together. This way saves a step.

I f the designer so wishes, a

more exact analysis can be per-

formed using the AASHTO speci-

vary depending on whether the main reinforcement is perpendicular or parallel fied tire contact area. The contact

to the direction of traffic. Additional criteria cover bending moments for area is based on a wheel of the

cantilever slabs, slabs supported on four sides, and edge beams. The reader standard H or HS design vehicles.

should keep in mind that the AASHTO bending moment equations do not

include impact.

If the designer so wishes, a more exact analysis can be performed using

the AASHTO specified tire contact area. For the standard HS-20 or Alternative

Military Loadings, the contact area should have a length of 10 inches (in the

T he placement of main re-

inforcement perpendicular

to the direction of traffic typi-

traffic direction), and a width of 20 inches (AASHTO 3.30).

cally occurs in structures where

1. Main Reinforcement Perpendicular to Traffic. The place- the concrete deck slab rests

ment of main reinforcement perpendicular to the direction of traffic on a set of longitudinally ori-

typically occurs in structures where the concrete deck slab rests on a set of ented primary members.

longitudinally oriented primary members. The most common example of

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

Design of Superstructure Elements

Calculation of Bending Moment CONCRETE DECK SLABS 143

[3.9.2, Part 2]

DESIGN EXAMPLE 3.1

EXAMPLE 3.1 DESIGN OF REINFORCED CONCRETE 3 STEP 4: COMPUTE TOTAL

DET

DECK SLAB—LFD METHOD 5 FACTORED MOMENT

STEP 4: Compute Total Factored Bending Moment The load factors are (see Table 3.2):

Mu = 1.3MDL + 2.17MLL+I = (1.30) (0.70 ft-kips) + (2.17) (4.94 ft-kips) DL = 1.3

➠ Mu = 11.63 ft-kips LL = 1.3×1.67 = 2.17

STEP 5: Compute Effective Depth of Slab STEP 5: COMPUTE EFFECTIVE

DEPTH OF SLAB

Slab depth = 8.0 in

Sacrificial surface = 0.5 in The effective depth of slab for bending

Concrete cover at bottom of slab = 1.0 in moment capacity is the distance between

#5 reinforcing steel bar diameter = 0.625 in the center of the main reinforcement and

The effective depth of slab (from center of bottom reinforcement to the the top surface of the slab. Since this deck

deck top surface):

does not have a separate wearing surface,

d = 8.0 − 0.5 − 1.0 − 0.625/2

➠ d = 6.19 in

we assume 0.5 inch of the deck on top will

be lost. We also assume a 1.0 inch

concrete cover at bottom, and #5 bars

STEP 6: Compute Required Main Reinforcement will be used.

First, try to use #5 @ 6" STEP 6: COMPUTE REQUIRED

MAIN REINFORCEMENT

As = (0.31)(12/6) = 0.62 in2

Next, we determine the actual bar spacing

A ⋅f based on an assumed #5 bar. We first try

a= S y

0.85fcb to use #5 @ 6". Readers can refer to any

reinforced concrete text books for calcu-

(0.62 in2 )(60 ksi) lating the bending moment capacity.

a= = 0.81in

0.85(4.5 ksi)(12 in) AASHTO uses the same equations as ACI

code.

(Step 6: Continued on Next Sheet)

The effective width cannot be greater than 7.0 ft (2.13 m). This value

is given for truck wheel loading. If lane loading governs, though, a width of

2E is to be used. If the slab is simply supported, AASHTO specifies

approximate maximum live load moments based on the loading conditions,

where for HS20 loading

M LL = 900S for S ≤ 50 (Eq. 3.31a)

M LL = 1000 (1.30S − 20.0 ) for 50<S < 100 (Eq. 3.31b)

where M LL = live load moment, ft-lb

S = effective span length, ft

When the slab is continuous over two or more supports, truck or lane

loads should be positioned so as to cause maximum positive and negative

moment.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

Design of Superstructure Elements

Distribution Reinforcement CONCRETE DECK SLABS 145

[3.9.3]

DESIGN EXAMPLE 3.1

DESIGN OF REINFORCED CONCRETE 4 STEP 6: COMPUTE REQUIRED

EXAMPLE 3.1 DET

DECK SLAB—LFD METHOD 5 MAIN REINFORCEMENT

STEP 6: Compute Required Main Reinforcement (Continued) (CONTINUED)

a The moment capacity in the first try is

φMn = φAS fy d − 39% more than the total factored moment.

2

So we increase bar spacing by approxi-

0.81 1 mately 33%, using #5 @ 8". By recalcu-

φMn =(0.9)(0.62)(60) 6.19 −

2 12 lating the moment capacity, we know that

the moment capacity is still more than

φMn = 16.14 K ⋅ FT >Mu =11.63 K ⋅ FT what is required. Therefore, #5 @ 8" will

be used for the design.

Since the reinforcement assumed is more than what is required, the

designer can reduce the amount of reinforcing steel by increasing the Like any reinforced concrete beams, the

rebar spacing to: deck should also be checked for the

minimum reinforcement requirement

φ ⋅ Mn 16.14

(6.0 in) =(6.0) = 8.3 in (AASHTO 8.17.1), and the maximum

Mu 11.63 allowable reinforcement ratio (AASHTO

8.16.3.1).

Now, use #5 @ 8" reinforcement

12

AS = 0.31 ⋅ = 0.465 in2

8

A S ⋅ fy

a=

0.85fcb

(0.465 in2 )(60 ksi)

a= = 0.61in

0.85(4.5 ksi)(12 in)

(Step 6: Continued on Next Sheet)

To determine the amount of distribution steel required, the amount of

main reinforcement needed is multiplied by a specified percentage. This

percentage varies, depending on whether the main reinforcement is parallel or

perpendicular to the direction of traffic.

For main reinforcement perpendicular to the direction of traffic the

percentage is given as

220

Percent of Main = ≤ 67 percent (Eq. 3.34)

S

or, when the reinforcement is parallel to the direction of traffic, we use the

expression

100

Percent of Main = ≤ 50 percent (Eq. 3.35)

S

where S = effective span length, ft

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

Design of Superstructure Elements

Railing Loads CONCRETE DECK SLABS 147

[3.9.5]

DESIGN EXAMPLE 3.1

EXAMPLE 3.1 DESIGN OF REINFORCED CONCRETE 5

DET STEP 7: DISTRIBUTION STEEL IN

DECK SLAB—LFD METHOD 5

BOTTOM OF SLAB

STEP 6: Compute Required Main Reinforcement (Continued) Distribution steel is computed in ac-

a cordance with Equation 3.34. Since

φMn = φA S fy d − the value cannot be greater than 67

2

percent, we use this percentage to ob-

0.61 1 tain the 0.31 in2/ft required distribution

φMn =(0.9)(0.465)(60) 6.19 − steel. #5 bars at a 12 in spacing gives

2 12

0.31 in2/ft.

φMn=12.31 K . FT > Mu=11.63 K.FT ✔ In a real design, the maximum rein-

forcement and minimum reinforcement

Note that the same reinforcement should be used for both top and should also be check. See AASHTO

bottom of the slab. 8.16.3.1 and 8.17.1 for details.

STEP 7: Compute Distribution Steel in Bottom of Slab

220 220

D= = = 80% > 67% so use 67%

S 7.5 ft

Distribution Steel = (As)(67%) = (0.465 in2/ft)(0.67) = 0.31 in2/ft

#5 Bars @ 12 in Spacing ✔

a parapet is not present, the effective length of slab resisting the post loads is

given as

E = 0.8 X + 3.75 (Eq. 3.38)

or, when a parapet is provided, the effective length of slab is defined by the

following:

E = 0.8 X + 5.0 (Eq. 3.39)

where E = effective length of slab resisting railing load, ft

X = distance from center of a post to point of analysis, ft

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

You might also like

- Solucionario Completo Concreto Jack 8 Edithion100% (1)Solucionario Completo Concreto Jack 8 Edithion569 pages

- 2.6 Design Example Two Span Continuous Box Girder BridgeNo ratings yet2.6 Design Example Two Span Continuous Box Girder Bridge17 pages

- SDH2-Chapter 05-Linear Static Lateral Force Procedures PDFNo ratings yetSDH2-Chapter 05-Linear Static Lateral Force Procedures PDF28 pages

- Chapter-4 Design of Column & Column BaseNo ratings yetChapter-4 Design of Column & Column Base26 pages

- Structural Bridge Design Example Manual - New Zealand & Australia50% (2)Structural Bridge Design Example Manual - New Zealand & Australia388 pages

- Dead Load Calculation For RCC T-Girder Deck100% (1)Dead Load Calculation For RCC T-Girder Deck3 pages

- AStrutTie - Design - Example Manual Deep BeamNo ratings yetAStrutTie - Design - Example Manual Deep Beam31 pages

- Cable Profile For Prestressing and Calculation of Eccentricities of Substiture Cable0% (1)Cable Profile For Prestressing and Calculation of Eccentricities of Substiture Cable4 pages

- M54 Unit 2 Traffic Load On Highway Bridges BS5400-2No ratings yetM54 Unit 2 Traffic Load On Highway Bridges BS5400-219 pages

- Numerical Evaluation of Duhamel's Integral: Undamped SystemNo ratings yetNumerical Evaluation of Duhamel's Integral: Undamped System11 pages

- Pier Design Example - US Units - Design Step 8100% (1)Pier Design Example - US Units - Design Step 845 pages

- Design of Rigid Frame Bridges (With Diagram)No ratings yetDesign of Rigid Frame Bridges (With Diagram)9 pages

- Bridge Bearings, Expansion Joints & ParapetsNo ratings yetBridge Bearings, Expansion Joints & Parapets81 pages

- Biaxial Bending (Beams in Both Axis) : Ce 514 - Steel DesignNo ratings yetBiaxial Bending (Beams in Both Axis) : Ce 514 - Steel Design6 pages

- 2f. Eccentric Connections Ce134p 2 EscruzNo ratings yet2f. Eccentric Connections Ce134p 2 Escruz16 pages

- AISC ASD PARAMETERS KX, KY, KZ, LX, LY, LZ, MAIN, TMAIN - STAAD PRO - Bentley Colleague Blogs - Bentley CommunitiesNo ratings yetAISC ASD PARAMETERS KX, KY, KZ, LX, LY, LZ, MAIN, TMAIN - STAAD PRO - Bentley Colleague Blogs - Bentley Communities9 pages

- Losses in Prestress-Friction, Anchorage SlipNo ratings yetLosses in Prestress-Friction, Anchorage Slip16 pages

- Flow Chart For Doubly Reinforced Beam Design100% (2)Flow Chart For Doubly Reinforced Beam Design2 pages

- Grillage Analysis of Structures Consist of Steel I-BeamsNo ratings yetGrillage Analysis of Structures Consist of Steel I-Beams17 pages

- Numerical Methods and Implementation in Geotechnical Engineering – Part 1From EverandNumerical Methods and Implementation in Geotechnical Engineering – Part 1No ratings yet

- AD 266 - Shear Connection in Composite BeamsNo ratings yetAD 266 - Shear Connection in Composite Beams2 pages

- Aydin Demir Nacir Caglar Hakan Ozturk - Parameters Affecting Diagonal Cracking Behavior of Reinforced Concrete DeepNo ratings yetAydin Demir Nacir Caglar Hakan Ozturk - Parameters Affecting Diagonal Cracking Behavior of Reinforced Concrete Deep15 pages

- Development of Is:456 Shear Design Provisions-Ii: Members With Shear ReinforcementNo ratings yetDevelopment of Is:456 Shear Design Provisions-Ii: Members With Shear Reinforcement10 pages

- Shear Transfer at Top Plate, Drag Strut Design100% (1)Shear Transfer at Top Plate, Drag Strut Design4 pages

- Dapped Ends of Prestressed Concrete Thin-Stemmed Members - Part 1, Experimental Testing and BehaviorNo ratings yetDapped Ends of Prestressed Concrete Thin-Stemmed Members - Part 1, Experimental Testing and Behavior22 pages

- Design For Shear: Slabs Without Shear ReinforcementNo ratings yetDesign For Shear: Slabs Without Shear Reinforcement12 pages

- AD 437 - Curtailment of Transverse Bar Reinforcement in Composite Beams With Steel Decking Designed Using Eurocodes, February 2020No ratings yetAD 437 - Curtailment of Transverse Bar Reinforcement in Composite Beams With Steel Decking Designed Using Eurocodes, February 20201 page

- Petrographic Examination of Hardened Concrete: Standard Practice ForNo ratings yetPetrographic Examination of Hardened Concrete: Standard Practice For17 pages

- Moody Chart Solver J. M. Cimbala, August 2003No ratings yetMoody Chart Solver J. M. Cimbala, August 20033 pages

- Reinforcing Concrete Bridge Decks With PreFabricated FRP Grids and Stay in Place FormworkNo ratings yetReinforcing Concrete Bridge Decks With PreFabricated FRP Grids and Stay in Place Formwork46 pages

- GraybealEtAl BridgeInternationalUHPC ASCEbridge 2020No ratings yetGraybealEtAl BridgeInternationalUHPC ASCEbridge 202016 pages

- Guidance Notes On The Use of Waterprrofing MembranesNo ratings yetGuidance Notes On The Use of Waterprrofing Membranes17 pages

- Evaluation of Damage Equivalent Factor For Roadway BridgesNo ratings yetEvaluation of Damage Equivalent Factor For Roadway Bridges8 pages

- Planning & Design For Construction of Bridges100% (1)Planning & Design For Construction of Bridges131 pages

- Understanding The World's Greatest Structures (Description) PDFNo ratings yetUnderstanding The World's Greatest Structures (Description) PDF5 pages

- Jennifer Dietrich MSC DissertationAnalysis and Design of PDFNo ratings yetJennifer Dietrich MSC DissertationAnalysis and Design of PDF238 pages

- Yanev, Bojidar. Who Is Minding The Bridges? PDFNo ratings yetYanev, Bojidar. Who Is Minding The Bridges? PDF3 pages

- Segmental Concrete Bridges: International Case StudiesNo ratings yetSegmental Concrete Bridges: International Case Studies4 pages

- Jacking Force of Continuous Rigid Frame Bridge On High TemperatureNo ratings yetJacking Force of Continuous Rigid Frame Bridge On High Temperature4 pages

- 2.6 Design Example Two Span Continuous Box Girder Bridge2.6 Design Example Two Span Continuous Box Girder Bridge

- SDH2-Chapter 05-Linear Static Lateral Force Procedures PDFSDH2-Chapter 05-Linear Static Lateral Force Procedures PDF

- Structural Bridge Design Example Manual - New Zealand & AustraliaStructural Bridge Design Example Manual - New Zealand & Australia

- Cable Profile For Prestressing and Calculation of Eccentricities of Substiture CableCable Profile For Prestressing and Calculation of Eccentricities of Substiture Cable

- M54 Unit 2 Traffic Load On Highway Bridges BS5400-2M54 Unit 2 Traffic Load On Highway Bridges BS5400-2

- Numerical Evaluation of Duhamel's Integral: Undamped SystemNumerical Evaluation of Duhamel's Integral: Undamped System

- Biaxial Bending (Beams in Both Axis) : Ce 514 - Steel DesignBiaxial Bending (Beams in Both Axis) : Ce 514 - Steel Design

- AISC ASD PARAMETERS KX, KY, KZ, LX, LY, LZ, MAIN, TMAIN - STAAD PRO - Bentley Colleague Blogs - Bentley CommunitiesAISC ASD PARAMETERS KX, KY, KZ, LX, LY, LZ, MAIN, TMAIN - STAAD PRO - Bentley Colleague Blogs - Bentley Communities

- Grillage Analysis of Structures Consist of Steel I-BeamsGrillage Analysis of Structures Consist of Steel I-Beams

- Numerical Methods and Implementation in Geotechnical Engineering – Part 1From EverandNumerical Methods and Implementation in Geotechnical Engineering – Part 1

- Aydin Demir Nacir Caglar Hakan Ozturk - Parameters Affecting Diagonal Cracking Behavior of Reinforced Concrete DeepAydin Demir Nacir Caglar Hakan Ozturk - Parameters Affecting Diagonal Cracking Behavior of Reinforced Concrete Deep

- Development of Is:456 Shear Design Provisions-Ii: Members With Shear ReinforcementDevelopment of Is:456 Shear Design Provisions-Ii: Members With Shear Reinforcement

- Dapped Ends of Prestressed Concrete Thin-Stemmed Members - Part 1, Experimental Testing and BehaviorDapped Ends of Prestressed Concrete Thin-Stemmed Members - Part 1, Experimental Testing and Behavior

- Design For Shear: Slabs Without Shear ReinforcementDesign For Shear: Slabs Without Shear Reinforcement

- AD 437 - Curtailment of Transverse Bar Reinforcement in Composite Beams With Steel Decking Designed Using Eurocodes, February 2020AD 437 - Curtailment of Transverse Bar Reinforcement in Composite Beams With Steel Decking Designed Using Eurocodes, February 2020

- Petrographic Examination of Hardened Concrete: Standard Practice ForPetrographic Examination of Hardened Concrete: Standard Practice For

- Reinforcing Concrete Bridge Decks With PreFabricated FRP Grids and Stay in Place FormworkReinforcing Concrete Bridge Decks With PreFabricated FRP Grids and Stay in Place Formwork

- GraybealEtAl BridgeInternationalUHPC ASCEbridge 2020GraybealEtAl BridgeInternationalUHPC ASCEbridge 2020

- Guidance Notes On The Use of Waterprrofing MembranesGuidance Notes On The Use of Waterprrofing Membranes

- Evaluation of Damage Equivalent Factor For Roadway BridgesEvaluation of Damage Equivalent Factor For Roadway Bridges

- Understanding The World's Greatest Structures (Description) PDFUnderstanding The World's Greatest Structures (Description) PDF

- Jennifer Dietrich MSC DissertationAnalysis and Design of PDFJennifer Dietrich MSC DissertationAnalysis and Design of PDF

- Segmental Concrete Bridges: International Case StudiesSegmental Concrete Bridges: International Case Studies

- Jacking Force of Continuous Rigid Frame Bridge On High TemperatureJacking Force of Continuous Rigid Frame Bridge On High Temperature