Bayer Makrolon 2407

Bayer Makrolon 2407

Uploaded by

DiegoTierradentroCopyright:

Available Formats

Bayer Makrolon 2407

Bayer Makrolon 2407

Uploaded by

DiegoTierradentroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Bayer Makrolon 2407

Bayer Makrolon 2407

Uploaded by

DiegoTierradentroCopyright:

Available Formats

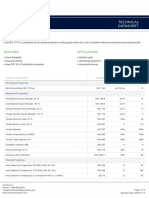

Makrolon® 2407 PC Bayer MaterialScience - 2006-07-18

Product text

ISO 7391-PC,MLR,49-18-9

Global grade; MVR 19 cm³/10 min; General purpose; Low viscosity; UV

stabilized; Easy release; Injection molding; Available in transparent,

translucent and opaque colors

plastics.bayer.com

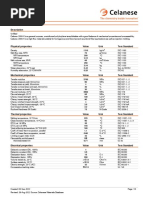

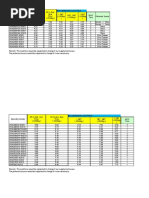

Single-point data

Rheological properties

Melt volume-flow rate 19 cm³/10min ISO 1133

Temperature 300 °C ISO 1133

Load 1.2 kg ISO 1133

Molding shrinkage (parallel) 0.6 % ISO 2577,294-4

Molding shrinkage (normal) 0.65 % ISO 2577,294-4

Mechanical properties

Tensile modulus 2400 MPa ISO 527-1/-2

Yield stress 66 MPa ISO 527-1/-2

Yield strain 6 % ISO 527-1/-2

Nominal strain at break >50 % ISO 527-1/-2

Stress at 50% strain - MPa ISO 527-1/-2

Stress at break - MPa ISO 527-1/-2

Strain at break - % ISO 527-1/-2

Tensile creep modulus (1h) 2200 MPa ISO 899-1

Tensile creep modulus (1000h) 1900 MPa ISO 899-1

Charpy impact strength (+23°C) N kJ/m² ISO 179/1eU

Charpy impact strength (-30°C) N kJ/m² ISO 179/1eU

Charpy notched impact strength (+23°C) - kJ/m² ISO 179/1eA

Charpy notched impact strength (-30°C) - kJ/m² ISO 179/1eA

Tensile notched impact strength (+23°C) - kJ/m² ISO 8256/1

Puncture - maximum force (+23°C) 5200 N ISO 6603-2

Puncture - maximum force (-30°C) 6200 N ISO 6603-2

Puncture energy (+23°C) 55 J ISO 6603-2

Puncture energy (-30°C) 60 J ISO 6603-2

Thermal properties

Melting temperature (10°C/min) - °C ISO 11357-1/-3

Glass transition temperature (10°C/min) 145 °C ISO 11357-1/-2

Temp. of deflection under load (1.80 MPa) 124 °C ISO 75-1/-2

Temp. of deflection under load (0.45 MPa) 137 °C ISO 75-1/-2

Temp. of deflection under load (8.00 MPa) * °C ISO 75-1/-2

Vicat softening temperature (50°C/h 50N) 144 °C ISO 306

Coeff.of linear therm. expansion (parallel) 0.65 E-4/°C ISO 11359-1/-2

Coeff.of linear therm. expansion (normal) 0.65 E-4/°C ISO 11359-1/-2

Burning Behav. at 1.5mm nom. thickn. V-2 class IEC 60695-11-10

Thickness tested 1.5 mm IEC 60695-11-10

All data is subject to the producer's disclaimer.

CAMPUS® 5.0 - Bayer MaterialScience - 2006-07-18 - Printed: 2006-10-29 Page 1 of 3

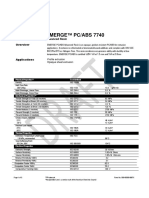

Makrolon® 2407, PC, Bayer MaterialScience - 2006-07-18

UL recognition UL - -

Burning Behav. at thickness h V-2 class IEC 60695-11-10

Thickness tested 2.6 mm IEC 60695-11-10

UL recognition UL - -

Burning Behav. 5V at thickn. h - class IEC 60695-11-20

Thickness tested - mm IEC 60695-11-20

UL recognition - - -

Oxygen index 27 % ISO 4589-1/-2

Electrical properties

Relative permittivity (100 Hz) 3.1 - IEC 60250

Relative permittivity (1 MHz) 3 - IEC 60250

Dissipation factor (100 Hz) 5 E-4 IEC 60250

Dissipation factor (1 MHz) 85 E-4 IEC 60250

Volume resistivity >1E13 Ohm*m IEC 60093

Surface resistivity >1E15 Ohm IEC 60093

Electric strength 33 kV/mm IEC 60243-1

Comparative tracking index 275 - IEC 60112

Other properties

Water absorption 0.3 % Similar to ISO 62

Humidity absorption 0.12 % Similar to ISO 62

Density 1200 kg/m³ ISO 1183

Material specific properties

Viscosity number 51 cm³/g ISO 307, 1157, 1628

Indicative density (PE only) - kg/m³ ISO 1872-1

Luminous transmittance 89 % ISO 13468-1, -2

Rheological calculation properties

Density of melt 1020 kg/m³

Thermal conductivity of melt 0.173 W/(m K)

Spec. heat capacity of melt 1700 J/(kg K)

Eff. thermal diffusivity 1E-7 m²/s

Ejection temperature 130 °C

Test specimen production

Processing conditions acc. ISO 7391 - ISO....-2

Injection Molding, melt temperature 280 °C ISO 294

Injection Molding, mold temperature 80 °C ISO 10724

injection velocity 200 mm/s ISO 294

pressure at hold - MPa ISO 294

Compression Molding, molding temperature - °C ISO 293

cooling rate - K/min ISO 293

molding time - min ISO 293

demolding temperature - °C ISO 293

Characteristic

Regional availability

North America, Europe, Asia Pacific, South and Central America, Near East/Africa, India

Processing

Injection Molding

Delivery form

All data is subject to the producer's disclaimer.

CAMPUS® 5.0 - Bayer MaterialScience - 2006-07-18 - Printed: 2006-10-29 Page 2 of 3

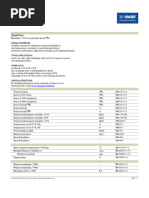

Makrolon® 2407, PC, Bayer MaterialScience - 2006-07-18

Pellets

Additives

Release agent

Special Characteristics

Transparent, High impact or impact modified, Light stabilized or stable to light, U.V. stabilized or stable to weather

Other Text Information

Injection Molding

PREPROCESSING

Max. Water content: 0,02 %

Drying temperature: 120 °C

Drying time:

Circulating air drying oven (50 % fresh air) 4-12 h

Fresh air dryer (high speed dryer) 2-4 h

Dry air dryer 2-3 h

PROCESSING

Melt temperature: 280 - 320 °C

Mold temperature: 80 - 120 °C

All data is subject to the producer's disclaimer.

CAMPUS® 5.0 - Bayer MaterialScience - 2006-07-18 - Printed: 2006-10-29 Page 3 of 3

You might also like

- (Jay Shoemaker) Moldflow Design Guide 'A ResourcDocument3 pages(Jay Shoemaker) Moldflow Design Guide 'A ResourcFahri ibişoğluNo ratings yet

- Material Safety Data Sheet: 1. IdentificationDocument10 pagesMaterial Safety Data Sheet: 1. IdentificationDiegoTierradentroNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)DiegoTierradentroNo ratings yet

- Samsung MX-H630 PDFDocument50 pagesSamsung MX-H630 PDFboroda241080% (5)

- Cooling TowerDocument6 pagesCooling Towerʞǝǝs Uǝ Ǝpıɥ100% (4)

- Makrolon® 2805Document8 pagesMakrolon® 2805Dridi BadredineNo ratings yet

- 37 Styrolux656CDocument4 pages37 Styrolux656Cyassineamn115No ratings yet

- Celanex 3300-2 PBTDocument3 pagesCelanex 3300-2 PBTDiegoTierradentroNo ratings yet

- Celanex 3316Document5 pagesCelanex 3316klausoshoNo ratings yet

- R42000249GKF - Celanex 2003 - PBT - TDSDocument4 pagesR42000249GKF - Celanex 2003 - PBT - TDSCarlos AgianiNo ratings yet

- Luran S757 GDocument5 pagesLuran S757 GPeter EvansNo ratings yet

- Asa Ineos Styrolution Europe GMBH: Luran® S 776seDocument6 pagesAsa Ineos Styrolution Europe GMBH: Luran® S 776sebobNo ratings yet

- Fortron 6165A4Document5 pagesFortron 6165A4maria.goncalvesNo ratings yet

- Technical DatasheetDocument10 pagesTechnical DatasheetAnass El IdrissiNo ratings yet

- TerluranGP 22Document5 pagesTerluranGP 22Chu ChuNo ratings yet

- TDS PC - LEXAN+141R - enDocument2 pagesTDS PC - LEXAN+141R - enSơn Nguyễn ĐắcNo ratings yet

- Abs Elix p2mcDocument2 pagesAbs Elix p2mcRui BarradasNo ratings yet

- Styrolution TDS401200140449Document3 pagesStyrolution TDS401200140449maria.goncalvesNo ratings yet

- P2MC 20151201Document2 pagesP2MC 20151201Ivan MontenegroNo ratings yet

- TDS MakrolonET3113Document3 pagesTDS MakrolonET3113It WittayaNo ratings yet

- CAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfDocument4 pagesCAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfAngererNo ratings yet

- CELANEX® 2000-K-EnDocument3 pagesCELANEX® 2000-K-EnCarlos AgianiNo ratings yet

- Bayblend T85 XF - en - 00942879 00003130 18266741Document3 pagesBayblend T85 XF - en - 00942879 00003130 18266741Anass El IdrissiNo ratings yet

- Luran S 797se: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 797se: Acrylonitrile Styrene Acrylate (ASA)bobNo ratings yet

- LANXESS Durethan B40FKA 000000 ISO ENDocument3 pagesLANXESS Durethan B40FKA 000000 ISO ENmubashir488No ratings yet

- Covestro Makrolon-LED5902FR Tds 2023Document3 pagesCovestro Makrolon-LED5902FR Tds 2023vicyahooNo ratings yet

- ABS - Novodur P2HGVDocument2 pagesABS - Novodur P2HGVarmandoNo ratings yet

- Makrolon UVDocument2 pagesMakrolon UVSérgio FreireNo ratings yet

- en-badamid-b-b70-gf50-h-uv-black-725-lbDocument2 pagesen-badamid-b-b70-gf50-h-uv-black-725-lbAnis BorchaniNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- 76 StyrolutionPS454NDocument5 pages76 StyrolutionPS454N59074No ratings yet

- ASA Styrolution: Luran® S 778 TDocument2 pagesASA Styrolution: Luran® S 778 TayyappanNo ratings yet

- Styro Lution Tds 200400070602Document3 pagesStyro Lution Tds 200400070602Nazmul HudaNo ratings yet

- Luran 368 RDocument5 pagesLuran 368 RmucahitkaraballNo ratings yet

- Emerge™ Pc/Abs 7740: Technical InformationDocument3 pagesEmerge™ Pc/Abs 7740: Technical InformationbobNo ratings yet

- Technyl C 102 NCDocument3 pagesTechnyl C 102 NCGiampietro PiccoliNo ratings yet

- Bayblend FR1514 - en - 56967951 05122960 20070851Document3 pagesBayblend FR1514 - en - 56967951 05122960 20070851phairyNo ratings yet

- Bayblend T85 XF ISO enDocument3 pagesBayblend T85 XF ISO enryanNo ratings yet

- LANXESS Durethan A30SFN31 000000 ISO ENDocument3 pagesLANXESS Durethan A30SFN31 000000 ISO ENNguyen Dinh VinhNo ratings yet

- Kynar Flex® 2800-20 ResinDocument5 pagesKynar Flex® 2800-20 ResinmohammedNo ratings yet

- Technyl Safe C 116FC NCDocument3 pagesTechnyl Safe C 116FC NCkls.thorodinsonNo ratings yet

- Grilon As V0Document5 pagesGrilon As V0Roshan Melvil TitusNo ratings yet

- Elastollan1195ADocument5 pagesElastollan1195AMohammad Naser ShahabadiNo ratings yet

- Pe1000 PDFDocument2 pagesPe1000 PDFrohitdakngNo ratings yet

- Luran S 778T: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 778T: Acrylonitrile Styrene Acrylate (ASA)jineshdmehtaNo ratings yet

- Bayblend FR3010 - en - 00800632 00001688 16072598Document3 pagesBayblend FR3010 - en - 00800632 00001688 16072598AyushiNo ratings yet

- NORYL GTX™ Resin - GTX820 - Europe - Technical - Data - SheetDocument2 pagesNORYL GTX™ Resin - GTX820 - Europe - Technical - Data - Sheetmaria.goncalvesNo ratings yet

- PocanB3235000000 GF30 1Document5 pagesPocanB3235000000 GF30 1rihabNo ratings yet

- SABIC® PPcompound - H1030 - Global - Technical - Data - SheetDocument2 pagesSABIC® PPcompound - H1030 - Global - Technical - Data - SheetRobertoNo ratings yet

- HOSTAFORM® C 9021 TF-enDocument4 pagesHOSTAFORM® C 9021 TF-enshahin_723No ratings yet

- PBT - Lanxess Pocan B3235 000000Document3 pagesPBT - Lanxess Pocan B3235 000000armandoNo ratings yet

- Luran S 777K: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 777K: Acrylonitrile Styrene Acrylate (ASA)Leonardo DguezNo ratings yet

- StyrolutionTDS400700190196 PDFDocument3 pagesStyrolutionTDS400700190196 PDFMirella FaresNo ratings yet

- Terluran GP35Document5 pagesTerluran GP35cristinamss33No ratings yet

- CELCON® M90-EnDocument8 pagesCELCON® M90-EnJosue OrtizNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- Riteflex 640aDocument3 pagesRiteflex 640aazaleaemersonNo ratings yet

- PC MitsubishiDocument1 pagePC MitsubishiDiegoTierradentroNo ratings yet

- Campus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHDocument2 pagesCampus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHAngererNo ratings yet

- Ultramid A3 KDocument8 pagesUltramid A3 Kmani01kandanNo ratings yet

- Makrolon SF800 - en - 56979992 00009671 17283484Document3 pagesMakrolon SF800 - en - 56979992 00009671 17283484Shinichi SuzukiNo ratings yet

- PD Arnite t06 204 SN (En)Document2 pagesPD Arnite t06 204 SN (En)MuthuswamyNo ratings yet

- PC MitsubishiDocument1 pagePC MitsubishiDiegoTierradentroNo ratings yet

- 170301 - EU-PIM適合宣言書 - NSBC and CLEAREN FDADocument1 page170301 - EU-PIM適合宣言書 - NSBC and CLEAREN FDADiegoTierradentroNo ratings yet

- Akulon FC-X9200: PA6 CopolymerDocument2 pagesAkulon FC-X9200: PA6 CopolymerDiegoTierradentroNo ratings yet

- Torzen® U4820lDocument1 pageTorzen® U4820lDiegoTierradentroNo ratings yet

- 2016 6 12 P The - Polyamide - Market - PDocument7 pages2016 6 12 P The - Polyamide - Market - PDiegoTierradentroNo ratings yet

- CELCONM90Document5 pagesCELCONM90DiegoTierradentroNo ratings yet

- Styrolution PS 1290/1291: General Purpose Polystyrene (GPPS)Document2 pagesStyrolution PS 1290/1291: General Purpose Polystyrene (GPPS)DiegoTierradentroNo ratings yet

- Terluran GP-35: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-35: Acrylonitrile Butadiene Styrene (ABS)DiegoTierradentroNo ratings yet

- Styrolution PS 1300/1301: Technical DatasheetDocument2 pagesStyrolution PS 1300/1301: Technical DatasheetDiegoTierradentroNo ratings yet

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)DiegoTierradentroNo ratings yet

- Resin - ABS Tairalac PDFDocument3 pagesResin - ABS Tairalac PDFDiegoTierradentroNo ratings yet

- UV Stabilized PC WONDERLITE Characteristics PC-115U: January 23, 2014Document1 pageUV Stabilized PC WONDERLITE Characteristics PC-115U: January 23, 2014DiegoTierradentroNo ratings yet

- CELCONM90LFDocument2 pagesCELCONM90LFDiegoTierradentroNo ratings yet

- Acetal Copolymer (POM)Document5 pagesAcetal Copolymer (POM)DiegoTierradentroNo ratings yet

- Tairilac ABS Resin: Properties (1/3)Document3 pagesTairilac ABS Resin: Properties (1/3)DiegoTierradentroNo ratings yet

- General Q Resin KIBITON Characteristics PB-5903: November 13, 2013Document1 pageGeneral Q Resin KIBITON Characteristics PB-5903: November 13, 2013DiegoTierradentroNo ratings yet

- DUPONTandGinarGrade ComparisonDocument9 pagesDUPONTandGinarGrade ComparisonDiegoTierradentroNo ratings yet

- General Purpose ABS, POLYLAC PA-727: Processing ConditionsDocument1 pageGeneral Purpose ABS, POLYLAC PA-727: Processing ConditionsDiegoTierradentroNo ratings yet

- Name: Name: Name: Name: ABS710 ABS710 ABS710 ABS710Document2 pagesName: Name: Name: Name: ABS710 ABS710 ABS710 ABS710DiegoTierradentroNo ratings yet

- Elix Pc-Abs 5130Document4 pagesElix Pc-Abs 5130DiegoTierradentroNo ratings yet

- Elix Ultra hh4115Document3 pagesElix Ultra hh4115DiegoTierradentroNo ratings yet

- Mapex AN0320SN PDFDocument1 pageMapex AN0320SN PDFDiegoTierradentroNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)DiegoTierradentroNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)DiegoTierradentroNo ratings yet

- Crop Circles and Life at Parallel Space-Time Sheets: Part IDocument47 pagesCrop Circles and Life at Parallel Space-Time Sheets: Part IhahaNo ratings yet

- EE232 - Chapter 1 - Lecture 1Document17 pagesEE232 - Chapter 1 - Lecture 1Si DouNo ratings yet

- Relative Equilibrium OF LiquidsDocument14 pagesRelative Equilibrium OF LiquidsJames Jr.No ratings yet

- 99 Percentile Strategy For JEE Main 2020 - MathonGoDocument27 pages99 Percentile Strategy For JEE Main 2020 - MathonGoabccNo ratings yet

- CSIR-NET/ SET Theory and MCQ'S: February 2019Document12 pagesCSIR-NET/ SET Theory and MCQ'S: February 2019UmaNo ratings yet

- Question Bank Class X Magnetic Effects of Electric CurrentDocument7 pagesQuestion Bank Class X Magnetic Effects of Electric CurrentSuryank sharmaNo ratings yet

- EST QuestionDocument3 pagesEST QuestionashNo ratings yet

- Seismic Design and Performance of Two Isolation Systems Used For Reinforced Concrete Bridge ConstructionDocument10 pagesSeismic Design and Performance of Two Isolation Systems Used For Reinforced Concrete Bridge ConstructionGourab GhoshNo ratings yet

- Solved Examples On High Pressure Vessel Thicknesses & Their Calculations PDFDocument11 pagesSolved Examples On High Pressure Vessel Thicknesses & Their Calculations PDFShriyash DeshpandeNo ratings yet

- Discovery Museum ForcesDocument1 pageDiscovery Museum ForcesHartford CourantNo ratings yet

- High Power 10w Blanco FrioDocument6 pagesHigh Power 10w Blanco Frionestor1209No ratings yet

- CHE 350 Test 1 RehearsalDocument5 pagesCHE 350 Test 1 RehearsalrovugNo ratings yet

- Case Method and The Pda PDFDocument73 pagesCase Method and The Pda PDFStephanie HaynesNo ratings yet

- As Iso 8124.1-2002 - A2-2009Document5 pagesAs Iso 8124.1-2002 - A2-2009Chenren WUNo ratings yet

- Test Methods For Pharmaceutical SuspensionsDocument2 pagesTest Methods For Pharmaceutical SuspensionsHaroon Rahim100% (2)

- Structural Use of Glass in Buildings (Second Edition) by Chris O'Regan Beng (Hons) Ceng MistructeDocument5 pagesStructural Use of Glass in Buildings (Second Edition) by Chris O'Regan Beng (Hons) Ceng MistructealalufNo ratings yet

- MTP 1 Impulse LineDocument4 pagesMTP 1 Impulse LineAbarajithan RajendranNo ratings yet

- Q Bank MetDocument94 pagesQ Bank MetsajjadNo ratings yet

- Jackson 11 14 Homework Solution PDFDocument4 pagesJackson 11 14 Homework Solution PDFJesus Antonio Jimenez AriasNo ratings yet

- 2nd QRTR DLL-G9-Properties-of-metals-Formation-of-IonsDocument20 pages2nd QRTR DLL-G9-Properties-of-metals-Formation-of-Ionsleiziah xyrille maturan0% (1)

- Part II - PumpsDocument242 pagesPart II - PumpsaaaNo ratings yet

- Chapter 9 Flashcards - QuizletDocument3 pagesChapter 9 Flashcards - QuizletYukiko HachiNo ratings yet

- 4 Chapter 6 Morden PhysicsDocument33 pages4 Chapter 6 Morden PhysicsNABIKAMBA PHILIPNo ratings yet

- Heat and Temperature Conceptual QuestionDocument2 pagesHeat and Temperature Conceptual QuestionMohd Hanis 'Ady' Izdihar100% (1)

- Takwim Amali Sains Tingkatan 1 (DLP) 2425Document2 pagesTakwim Amali Sains Tingkatan 1 (DLP) 2425Nadia NasirNo ratings yet

- Experiment#1 - Unit Weight of Fine AggregatesDocument5 pagesExperiment#1 - Unit Weight of Fine AggregatesRiceth Honeylet CancinoNo ratings yet

- Unit - I Lasers: High DirectionalityDocument18 pagesUnit - I Lasers: High DirectionalityRohith RajNo ratings yet

- Plain Bearings Lecture eDocument9 pagesPlain Bearings Lecture eRMLNo ratings yet