0 ratings0% found this document useful (0 votes)

87 viewsTiming Belt (5S-Fe) : Components

Timing Belt (5S-Fe) : Components

Uploaded by

mutasimThe document provides instructions for removing and installing the timing belt on a Toyota 5S-FE engine. It describes 27 steps to remove the belt, including disconnecting the battery, removing various covers and pulleys, and setting the engine to top dead center. It also describes inspecting the removed belt and components and matching marks to ensure proper installation. Finally, it outlines the 2 steps to install the oil pump pulley and crankshaft timing pulley.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Timing Belt (5S-Fe) : Components

Timing Belt (5S-Fe) : Components

Uploaded by

mutasim0 ratings0% found this document useful (0 votes)

87 views14 pagesThe document provides instructions for removing and installing the timing belt on a Toyota 5S-FE engine. It describes 27 steps to remove the belt, including disconnecting the battery, removing various covers and pulleys, and setting the engine to top dead center. It also describes inspecting the removed belt and components and matching marks to ensure proper installation. Finally, it outlines the 2 steps to install the oil pump pulley and crankshaft timing pulley.

Original Description:

Camry

Original Title

timingbelt5sfe

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

The document provides instructions for removing and installing the timing belt on a Toyota 5S-FE engine. It describes 27 steps to remove the belt, including disconnecting the battery, removing various covers and pulleys, and setting the engine to top dead center. It also describes inspecting the removed belt and components and matching marks to ensure proper installation. Finally, it outlines the 2 steps to install the oil pump pulley and crankshaft timing pulley.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

87 views14 pagesTiming Belt (5S-Fe) : Components

Timing Belt (5S-Fe) : Components

Uploaded by

mutasimThe document provides instructions for removing and installing the timing belt on a Toyota 5S-FE engine. It describes 27 steps to remove the belt, including disconnecting the battery, removing various covers and pulleys, and setting the engine to top dead center. It also describes inspecting the removed belt and components and matching marks to ensure proper installation. Finally, it outlines the 2 steps to install the oil pump pulley and crankshaft timing pulley.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 14

EM–67

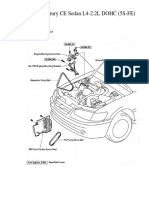

ENGINE MECHANICAL – Timing Belt (5S–FE)

TIMING BELT (5S–FE)

COMPONENTS

REMOVAL OF TIMING BELT

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL

OF BATTERY

CAUTION: Work must be started after approx. 20

seconds or longer from the time the ignition switch is

turned to the ”LOCK” position and the negative (–) ter-

minal cable is disconnected from the battery.

2. REMOVE RH FRONT WHEEL

3. REMOVE RH ENGINE UNDER COVER

4. (w/ CRUISE CONTROL SYSTEM (w/o ABS))

REMOVE CRUISE CONTROL ACTUATOR

(See page 11 on page EM–270)

5. REMOVE ALTERNATOR (See page CH–9)

EM–68

ENGINE MECHANICAL – Timing Belt (5S–FE)

6. REMOVE PS DRIVE BELT

Loosen the two bolts, and remove the drive belt.

7. SLIGHTLY JACK UP ENGINE

Raise the engine enough to remove the weight from the

engine mounting on the right side.

8. DISCONNECT CONNECTOR FROM GROUND WIRE

ON RH FENDER APRON

9. REMOVE RH ENGINE MOUNTING STAY

Remove the bolt, nut and mounting stay.

10. DISCONNECT PS RESERVOIR TANK FROM BRACKET

11. REMOVE RH ENGINE MOUNTING INSULATOR

Remove the through bolt, two nuts and mounting insu-

lator.

12. REMOVE RH ENGINE MOUNTING BRACKET

Remove the three bolts and mounting bracket.

HINT: Lower the jack and perform the operation with

the engine fully down.

13. REMOVE SPARK PLUGS

EM–69

ENGINE MECHANICAL – Timing Belt (5S–FE)

14. DISCONNECT ENGINE WIRE FROM ALTERNATOR

BRACKET AND ADJUSTING BAR

Remove the two bolts, and disconnect the engine wire

from the alternator bracket and adjusting bar.

15. REMOVE NO.2 TIMING BELT COVER

Remove the five bolts, timing belt cover and two gas-

kets.

16. SET NO.1 CYLINDER TO TDC/COMPRESSION

(a) Turn the crankshaft pulley and align its groove with

timing mark ”0” of the No.1 timing belt cover.

(b) Check that the hole of the camshaft timing pulley is

aligned with the timing mark of the bearing cap.

If not, turn the crankshaft one revolution (360°).

17. REMOVE TIMING BELT FROM CAMSHAFT TIMING

PULLEY

HINT (When re–using timing belt): Place the matchmarks

on the timing belt and camshaft timing pulley, and

place matchmark on timing belt to match the end of the

No.1 timing belt cover.

EM–70

ENGINE MECHANICAL – Timing Belt (5S–FE)

(a) Loosen the mounting bolt of the No.1 idler pulley

and shift the pulley toward the left as far as it will go,

and temporarily tighten it.

(b) Remove the timing belt from the camshaft timing

pulley.

18. REMOVE CAMSHAFT TIMING PULLEY

Using SST, remove the bolt, plate washer and timing

pulley.

SST 09249–63010 and 09278–54012

19. REMOVE CRANKSHAFT PULLEY

(a) Using SST, remove the pulley bolt.

SST 09213–54015 (09214–00030) and 09330–00021

HINT (When re–using timing belt): After loosening the

crankshaft pulley bolt, check that the timing belt match-

mark aligns with the end of the No.1 timing belt cover

when the crankshaft pulley groove is aligned with the

timing mark ”0” of the No.1 timing belt cover. If the

matchmark does not align, align as follows:

EM–71

ENGINE MECHANICAL – Timing Belt (5S–FE)

(When matchmark is out of alignment on clockwise)

• Align the matchmark by pulling the timing belt up

on the water pump pulley side while turning the

crankshaft pulley counterclockwise.

• After aligning the matchmark, hold the timing

belt. And turn the crankshaft pulley clockwise,

and align its groove with timing mark ”0” of the

No.1 timing belt cover.

(When matchmark is out of alignment on counter-

clockwise)

• Align the matchmark by pulling the timing belt up

on the No.1 idler pulley side while turning the

crankshaft pulley clockwise.

• After aligning the matchmark, hold the timing

belt. And turn the crankshaft pulley counterclock-

wise, and align its groove with timing mark ”0” of

the No.1 timing belt cover.

(b) Using SST, remove the pulley.

SST 09213–60017 (09213–00020, 09213–00030,

09213–00050)

HINT (When re–using timing belt): Remove the pulley

without turning it.

EM–72

ENGINE MECHANICAL – Timing Belt (5S–FE)

20. REMOVE NO.1 TIMING BELT COVER

Remove the four bolts, timing belt cover and gasket.

21. REMOVE TIMING BELT GUIDE

22. REMOVE TIMING BELT

HINT (When re–using timing belt): Draw a direction

arrow on the timing belt (in the direction of engine revo-

lution), and place matchmarks on the timing belt and

crankshaft timing pulley.

23. REMOVE NO.1 IDLER PULLEY AND TENSION SPRING

Remove the bolt, pulley and tension spring.

24. REMOVE NO.2 IDLER PULLEY

Remove the bolt and pulley.

EM–73

ENGINE MECHANICAL – Timing Belt (5S–FE)

25. REMOVE CRANKSHAFT TIMING PULLEY

If the pulley cannot be removed by hand, use two

screwdrivers.

HINT: Position shop rags as shown to prevent damage.

26. REMOVE Oil PUMP PULLEY

Using SST, remove the nut and pulley.

SST 09616–30011

INSPECTION OF TIMING BELT

COMPONENTS

1. INSPECT TIMING BELT

NOTICE:

• Do not bend, twist or turn the timing belt inside out.

• Do not allow the timing belt to come into contact

with oil, water or steam.

• Do not utilize timing belt tension when installing or

removing the mounting bolt of the camshaft timing

pulley.

If there are any defects as shown in the illustrations,

check the following points:

(a) Premature parting

• Check the proper installation.

• Check the timing cover gasket for damage and

proper installation.

(b) If the belt teeth are cracked or damaged, check to

see if either camshaft or water pump is locked.

EM–74

ENGINE MECHANICAL – Timing Belt (5S–FE)

(c) If there is noticeable wear or cracks on the belt face,

check to see if there are nicks on the side of the idler

pulley lock.

(d) If there is wear or damage on only one side of the

belt, check the belt guide and the alignment of each

pulley.

(e) If there is noticeable wear on the belt teeth, check

the timing cover for damage, correct gasket installa-

tion, and the foreign material on the pulley teeth.

If necessary, replace the timing belt.

2. INSPECT IDLER PULLEYS

Check that the idler pulley turns smoothly.

3. INSPECT TENSION SPRING

(a) Measure the free length of tension spring.

Free length: 46.0 mm (1.811 in.)

If the free length is not as specified, replace the tension

spring.

(b) Measure the tension of the tension spring at the

specified installed length.

Installed tension:

32 – 37 N (3.25 – 3.75 kgf, 7.2 – 8.3 lbf)

at 50.5 mm (1.988 in.)

If the installed tension is not as specified, replace the

tension spring.

EM–75

ENGINE MECHANICAL – Timing Belt (5S–FE)

INSTALLATION OF TIMING BELT

(See page EM–67)

1. INSTALL OIL PUMP PULLEY

(a) Align the cutouts of the pulley and shaft, and slide

on the pulley.

(b) Using SST, install the nut.

SST 09616–30011

Torque:. 28 N–m (290 kgf–cm, 21 ft–lbf)

2. INSTALL CRANKSHAFT TIMING PULLEY

(a) Align the timing pulley set key with the key groove

of the pulley.

(b) Slide on the timing pulley, facing the flange side

inward.

3. INSTALL NO.2 IDLER PULLEY

(a) Install the pulley with the bolt.

Torque: 42 N–m (425 kgf–cm, 31 ft–lbf)

HINT: Use bolt 35 mm (1.38 in.) in length.

(b) Check that the idler pulley moves smoothly.

4. TEMPORARILY INSTALL NO.1 IDLER PULLEY AND

TENSION SPRING

(a) Install the pulley with the bolt. Do not tighten the

bolt yet.

HINT: Use bolt 42 mm (1.65 in.) in length.

(b) Install the tension spring.

(c) Pry the pulley toward the left as far as it will go and

tighten the bolt.

(d) Check that the idler pulley moves smoothly.

5. TEMPORARILY INSTALL TIMING BELT

NOTICE: The engine should be cold.

(a) Using the crankshaft pulley bolt, turn the crankshaft

and align the timing marks of the crankshaft

timing pulley and oil pump body.

EM–76

ENGINE MECHANICAL – Timing Belt (5S–FE)

(b) Remove any oil or water on the crankshaft pulley, oil

pump pulley, water pump pulley, No.1 idler pulley,

No.2 idler pulley, and keep them clean.

(c) Install the timing belt on the crankshaft timing pulley,

oil pump pulley, No.1 idler pulley, water pump

pulley and No.2 idler pulley.

HINT (When re–using timing belt): Align the points

marked during removal, and install the belt with the ar-

row pointing in the direction of engine revolution.

6. INSTALL TIMING BELT GUIDE

Install the guide, facing the cup side outward.

7. INSTALL NO.1 TIMING BELT COVER

(a) Install the gasket to the timing belt cover.

(b) Install the timing belt cover with the four bolts.

8. INSTALL CRANKSHAFT PULLEY

(a) Align the pulley set key with the key groove of the

pulley, and slide on the pulley.

(b) Using SST, install the pulley bolt.

SST 09213–54015 (09214–00030) and

09330–00021

Torque: 108 N–m (1,100 kgf–cm, 80 ft–lbf)

9. INSTALL CAMSHAFT TIMING PULLEY

(a) Align the camshaft knock pin with the knock pin

groove of the pulley, and slide on the timing pulley.

(b) Using SST, install the plate washer and bolt.

SST 09249–63010 and 09278–54012

Torque: 54 N–m (550 kgf–cm, 40 ft–lbf)

37 N–m (380 kgf–cm, 27 ft–lbf) for SST

HINT: Use a torque wrench with a fulcrum length of

340 mm (13.39 in.)

EM–77

ENGINE MECHANICAL – Timing Belt (5S–FE)

10. SET NO.1 CYLINDER–TO TDC/COMPRESSION

(a) Turn the crankshaft pulley, and align its groove with

timing mark ”0” of the No.1 timing belt cover.

(b) Using SST, turn the camshaft, and align the hole of

the camshaft timing pulley with the timing mark of

the bearing cap.

SST 09278–54012

11. INSTALL TIMING BELT

HINT (When re–using timing belt):

• Check that the matchmark on the timing belt matches

the end of the No.1 timing belt cover.

If the matchmark does not align, shift the meshing of the

timing belt and crankshaft timing pulley until they align.

(See page EM–71)

• Align the matchmarks of the timing belt and camshaft

timing pulley.

(a) Remove any oil or water on the camshaft timing

pulley, and keep it clean.

(b) Install the timing belt, and checking the tension

between the crankshaft timing pulley and camshaft

timing pulley.

EM–78

ENGINE MECHANICAL – Timing Belt (5S–FE)

12. CHECK VALVE TIMING

(a) Loosen the No.1 idler pulley bolt 1 /2 turn.

(b) Slowly turn the crankshaft pulley two revolutions

from TDC to TDC.

NOTICE: Always turn the crankshaft clockwise.

(c) Check that each pulley aligns with the timing marks

as shown in the illustration.

If the timing marks do not align, remove the timing belt

and reinstall it.

(d) Slowly turn the crankshaft pulley 1 7/8 revolutions,

and align its groove with the mark at BTDC 45° (for

No.1 cylinder) of the No.1 timing belt cover.

NOTICE: Always turn the crankshaft clockwise.

(e) Torque the mounting bolt of the No.1 idler pulley.

Torque: 42 N–m (425 kgf–cm, 31 ft–lbf)

(f) Recheck the valve timing.

EM–79

ENGINE MECHANICAL – Timing Belt (5S–FE)

13. INSTALL NO.2 TIMING BELT COVER

(a) Disconnect the engine Wire protector between the

No.3 timing belt cover and cylinder head cover.

(b) Install the two gaskets to the No.1 and No.2 belt

covers.

(c) Install the belt cover with the five bolts.

(d) Install the two clamps of the engine wire protector

to each bolt.

14. INSTALL ENGINE WIRE TO ALTERNATOR BRACKET

AND ADJUSTING BAR

Install the engine wire with the two bolts.

15. INSTALL SPARK PLUGS

Torque: 18 N–m (180 kgf–cm, 13 ft–lbf)

16. INSTALL RH ENGINE MOUNTING BRACKET

Install the bracket with the three bolts.

Torque: 52 N–m (530 kgf–cm, 38 ft–lbf)

17. INSTALL RH ENGINE MOUNTING INSULATOR

Install the mounting insulator with the through bolt and

two nuts.

Torque:

Nut 52 N–m (530 kgf–cm, 38 ft–lbf)

Through bolt 87 N–m (890 kgf–cm, 64 ft–lbf)

18. INSTALL PS RESERVOIR TANK TO BRACKET

EM–80

ENGINE MECHANICAL – Timing Belt (5S–FE)

19. INSTALL RH ENGINE MOUNTING STAY

Install the mounting stay with the bolt and nut.

Torque: 73 N–m (740 kgf–cm, 54 ft–lbf)

20. CONNECT GROUND CONNECTOR TO GROUND WIRE

ON RH FENDER APRON

21. INSTALL PS DRIVE BELT

Install the drive belt with the pivot bolt and adjusting

bolt.

22. INSTALL ALTERNATOR (See page CH–25)

23. (w/ CRUISE CONTROL SYSTEM (w/o ABS)

INSTALL CRUISE CONTROL ACTUATOR

(See step 33 on page EM–309)

24. INSTALL RH FRONT WHEEL

25. CONNECT CABLE TO NEGATIVE TERMINAL OF

BATTERY

26. CHECK AND ADJUST DRIVE BELTS

Adjust the drive belts.

Drive belt tension:

Alternator

w/ A/C New belt 165 ± 10 lbf

Used belt 110 ± 10 lbf

w/o A/C New belt 125 ± 25 lbf

Used belt 95 ± 20 lbf

PS pump New belt 125 ± 10 lbf

Used belt 80 ± 20 lbf

27. INSTALL RH ENGINE UNDER COVER

You might also like

- Daihatsu Engine Mechanical EJ-DE and EJ-VEDocument61 pagesDaihatsu Engine Mechanical EJ-DE and EJ-VEJohnny Vanther92% (26)

- Sienna Timing Belt ReplacementDocument8 pagesSienna Timing Belt ReplacementGlenn Martin100% (1)

- Timing Belt Replacement Tata XenonDocument8 pagesTiming Belt Replacement Tata XenonMichele Colombo80% (5)

- Partial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulDocument26 pagesPartial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulNelson Caño Basalo100% (3)

- Suzuki APV Service ManualDocument7 pagesSuzuki APV Service ManualdhgdfgNo ratings yet

- Kelisa: PeroduaDocument64 pagesKelisa: PeroduaZamirul Syafiq100% (1)

- Daihatsu Sirion m100 Workshop ManualDocument21 pagesDaihatsu Sirion m100 Workshop Manualmutasim0% (1)

- Camry Solara SEV6Document13 pagesCamry Solara SEV6arturmikieNo ratings yet

- Toyota Truck Sienna FWD V6 3.3L 3MZ FE 2005.PDF Versión 1Document12 pagesToyota Truck Sienna FWD V6 3.3L 3MZ FE 2005.PDF Versión 1FranciscoNo ratings yet

- Jeep WJ 2004 Grand Cherokee MOPAR Parts CatalogDocument432 pagesJeep WJ 2004 Grand Cherokee MOPAR Parts Catalogravenpisuerga100% (2)

- Toyota 4efe - Correa de Distribucion PDFDocument11 pagesToyota 4efe - Correa de Distribucion PDFRonald Gareca RuedaNo ratings yet

- Disassembly: 2Uz-Fe Engine Mechanical - Engine UnitDocument21 pagesDisassembly: 2Uz-Fe Engine Mechanical - Engine UnitMateusz Jaskuła100% (1)

- Removal: 2Tr-Fe Engine Mechanical - CamshaftDocument12 pagesRemoval: 2Tr-Fe Engine Mechanical - CamshaftNorberto Calcina100% (1)

- Grand Vitara 2004 1 PDFDocument453 pagesGrand Vitara 2004 1 PDFUrrea ChechaNo ratings yet

- Toyota Avalon XL V6-3.0L (1MZ-FE) 2001: Timing Belt: Service and RepairDocument15 pagesToyota Avalon XL V6-3.0L (1MZ-FE) 2001: Timing Belt: Service and RepairFrancisco Guillen-DorantesNo ratings yet

- 5sfe Timing Belt DYIDocument14 pages5sfe Timing Belt DYIchasquareNo ratings yet

- Toyota Truck RAV4 2WD L4-2.0L (1AZ-FE) 2002: Timing Chain: Service and RepairDocument15 pagesToyota Truck RAV4 2WD L4-2.0L (1AZ-FE) 2002: Timing Chain: Service and RepairyosnielNo ratings yet

- Toyota Truck Highlander 2WD V6-3.0L (1MZ-FE) 2002: Timing Belt: Service and RepairDocument6 pagesToyota Truck Highlander 2WD V6-3.0L (1MZ-FE) 2002: Timing Belt: Service and RepairROSA GIMENEZNo ratings yet

- Toyota 4EFE - Correa de Distribucion PDFDocument11 pagesToyota 4EFE - Correa de Distribucion PDFAlvaro Garcia100% (4)

- Normal Checklist A320Document1 pageNormal Checklist A320tej swaroopNo ratings yet

- Toyota Camry CE Sedan L4-2.2L DOHC (5S-FE) MFI 2001: Timing Belt: Service and RepairDocument17 pagesToyota Camry CE Sedan L4-2.2L DOHC (5S-FE) MFI 2001: Timing Belt: Service and RepairWenceslao Francisco Mejía EspinozaNo ratings yet

- Lexus Barometer SettingDocument8 pagesLexus Barometer Settingjcarlsony2kNo ratings yet

- Dokumen - Tips - Engine Mechanical DaihatsuDocument33 pagesDokumen - Tips - Engine Mechanical DaihatsuJovie GrohlNo ratings yet

- Toyota Camry LE Sedan V6-3.0L (1MZ-FE) 2001: Timing Belt: Service and RepairDocument14 pagesToyota Camry LE Sedan V6-3.0L (1MZ-FE) 2001: Timing Belt: Service and RepairEutério SilvaNo ratings yet

- Toyota Celica l4 2.2l Dohc 5s Fe 1990Document16 pagesToyota Celica l4 2.2l Dohc 5s Fe 1990ORLANDO0301No ratings yet

- Timing Chain Retainer-Block and Wedge User GuideDocument16 pagesTiming Chain Retainer-Block and Wedge User GuideRickNo ratings yet

- AdjuDocument6 pagesAdjuSolomon TubebuNo ratings yet

- Valve Clearance: AdjustmentDocument6 pagesValve Clearance: AdjustmentBoncu BoncuNo ratings yet

- Timing Belt: Service and Repair Timing Belt Removal and InstallationDocument3 pagesTiming Belt: Service and Repair Timing Belt Removal and InstallationJosé Carlos da silvaNo ratings yet

- Cylinder Bloc DissasemblyDocument8 pagesCylinder Bloc DissasemblyYannick de WalqueNo ratings yet

- Fax 001Document14 pagesFax 001daniel ignatNo ratings yet

- Removal: 2Uz-Fe Engine Mechanical - CamshaftDocument14 pagesRemoval: 2Uz-Fe Engine Mechanical - Camshaftmarran100% (1)

- Timing Belt RemovalDocument4 pagesTiming Belt RemovalGiancarlo PossumNo ratings yet

- Timing Belt RemovalDocument4 pagesTiming Belt RemovalrenimoNo ratings yet

- Toyota Truck SequoiaDocument16 pagesToyota Truck SequoiaD3NYNo ratings yet

- Camry Solara SLEV6Document13 pagesCamry Solara SLEV6arturmikieNo ratings yet

- Sti Timing Belt InstructionsDocument19 pagesSti Timing Belt InstructionsPablo DpNo ratings yet

- Jeep Truck Liberty 2004 2WD L4-2.4L: Timing Belt ChangeDocument15 pagesJeep Truck Liberty 2004 2WD L4-2.4L: Timing Belt ChangeJuan vaizNo ratings yet

- Motor 1AZ-FE OverhaulDocument29 pagesMotor 1AZ-FE Overhaulfredh100% (1)

- Toyota Celica GT L4 1.8L 1ZZ FEDocument21 pagesToyota Celica GT L4 1.8L 1ZZ FEWolfgang WilliamsNo ratings yet

- 5G Timing BeltDocument10 pages5G Timing Beltraúl_palomo_10% (1)

- Toyota Supra L6 3.0L 1994 PDFDocument13 pagesToyota Supra L6 3.0L 1994 PDFAndrés ThompsonNo ratings yet

- 1gr Fe - Cadena de DistribucionDocument5 pages1gr Fe - Cadena de DistribucionMartin KoopmannNo ratings yet

- Rack and Pinion2Document18 pagesRack and Pinion2Romy MNo ratings yet

- Timing BeltDocument5 pagesTiming BeltPabloricardo ChamorrobNo ratings yet

- Carter Yf ManualDocument34 pagesCarter Yf ManualgpavmanNo ratings yet

- Chain Sub Assembly2Document11 pagesChain Sub Assembly2agranadilloscNo ratings yet

- Check Timing-Engine - Mechanical - 5s-FeDocument1 pageCheck Timing-Engine - Mechanical - 5s-FeNato DlAngelesNo ratings yet

- Cat3512camshaft TimingDocument4 pagesCat3512camshaft TimingEfrain FlorezNo ratings yet

- Timing Chain Sprockets - Installation (Timing Chain) - ALLDATA RepairDocument10 pagesTiming Chain Sprockets - Installation (Timing Chain) - ALLDATA RepairRafael RafaelNo ratings yet

- Toyota MR2 Spyder L4-1.8L (1ZZ-FE) 2001: Timing Chain: Service and RepairDocument18 pagesToyota MR2 Spyder L4-1.8L (1ZZ-FE) 2001: Timing Chain: Service and RepairROSA GIMENEZNo ratings yet

- Timing Belt: 2000 Acura Integra GS Coupe L4 1.8L Dohc MfiDocument10 pagesTiming Belt: 2000 Acura Integra GS Coupe L4 1.8L Dohc MfiVicctor PiñaNo ratings yet

- Tranmission - Clutch - 6090 PRODocument19 pagesTranmission - Clutch - 6090 PROGerman100% (1)

- ToyotaDocument12 pagesToyotaZarate CruzNo ratings yet

- Timing BeltDocument8 pagesTiming BeltSteve FosterNo ratings yet

- Toyota Celica ST Sport Coupe L4 1.8L DOHC MFI 1997Document11 pagesToyota Celica ST Sport Coupe L4 1.8L DOHC MFI 1997carlos martinezNo ratings yet

- w040001 PDFDocument31 pagesw040001 PDFresolution8878No ratings yet

- Poner A Tiempo ContourDocument4 pagesPoner A Tiempo ContourJuan Carlos Nuñez CastilloNo ratings yet

- Camshaft (1Nz Fe/2Nz Fe) : ReplacementDocument8 pagesCamshaft (1Nz Fe/2Nz Fe) : ReplacementMaung KyawNo ratings yet

- I20 TimingDocument11 pagesI20 Timingkb gagsNo ratings yet

- C014 Assembly-Disassembly ManualDocument21 pagesC014 Assembly-Disassembly Manualwillyan100% (3)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsFrom EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Robert Louis Stevenson'S "Treasure Island" As An Adventure NovelDocument9 pagesRobert Louis Stevenson'S "Treasure Island" As An Adventure NovelmutasimNo ratings yet

- Tuesday, February 21, 2012 1:43 PM: Unfiled Notes Page 1Document47 pagesTuesday, February 21, 2012 1:43 PM: Unfiled Notes Page 1mutasimNo ratings yet

- Fuel Trim PDFDocument7 pagesFuel Trim PDFmutasimNo ratings yet

- مكتبة نور تحفة العروس أو الزواج الإسلامي السعيد PDFDocument339 pagesمكتبة نور تحفة العروس أو الزواج الإسلامي السعيد PDFmutasimNo ratings yet

- Tps SensorDocument15 pagesTps SensormutasimNo ratings yet

- Case Dozers 650k 750k 850k Tier 2 Operator ManualDocument10 pagesCase Dozers 650k 750k 850k Tier 2 Operator Manualcarolyn100% (62)

- Tvs Apache RTR 160 4vDocument7 pagesTvs Apache RTR 160 4vajay tiwariNo ratings yet

- 789C AttachesflexiblesDocument5 pages789C AttachesflexiblesWalid RzigNo ratings yet

- ( ) Organization For Rehabilitation and Development in AmharaDocument2 pages( ) Organization For Rehabilitation and Development in AmharaKidus GetachewNo ratings yet

- Brochure 2017Document2 pagesBrochure 2017debugsterNo ratings yet

- M7R Install InstructionsDocument8 pagesM7R Install InstructionstaylorNo ratings yet

- Airbag ListDocument30 pagesAirbag ListOvidiu MarinNo ratings yet

- SSP - 273 Phaeton Convenience and Safety Electronics 3Document29 pagesSSP - 273 Phaeton Convenience and Safety Electronics 3tekNo ratings yet

- Transmission EngineDocument1 pageTransmission EnginePedroNo ratings yet

- Contact: 9080911189 9500977007Document10 pagesContact: 9080911189 9500977007Srêyas Raj PkNo ratings yet

- OP Proc NO ANSWERSDocument16 pagesOP Proc NO ANSWERStom wautelet100% (1)

- Asses Form-Elevators and Escalators-Technician - TYPE ADocument15 pagesAsses Form-Elevators and Escalators-Technician - TYPE ASUNDAR TNo ratings yet

- Prado Body ElectricalDocument58 pagesPrado Body Electricalsitarazmi82% (11)

- Lifting Capacities: SK10SR-2Document8 pagesLifting Capacities: SK10SR-2PHÁT NGUYỄN THẾNo ratings yet

- SAE Wheel Standards Manual: 2010 EditionDocument2 pagesSAE Wheel Standards Manual: 2010 Editionanon_67479830267% (3)

- TMK 2200 Low-Floor TramcarDocument2 pagesTMK 2200 Low-Floor TramcarSanja KrajinovicNo ratings yet

- Julie - Universal Car Emulator Programs:: Program UseDocument4 pagesJulie - Universal Car Emulator Programs:: Program Usealmia tronicsNo ratings yet

- More Than 75 Years Safety in Flying: Product CatalogDocument138 pagesMore Than 75 Years Safety in Flying: Product CatalogjuaoNo ratings yet

- 140k Motor Grader Jpa00001-Up (Machine) Powered by c7 Engine (Sebp5013-57) - Peças de ReposiçãoDocument9 pages140k Motor Grader Jpa00001-Up (Machine) Powered by c7 Engine (Sebp5013-57) - Peças de Reposiçãokarol1177100% (1)

- Fuel Injection PumpDocument5 pagesFuel Injection PumpanilNo ratings yet

- MG5321Document2 pagesMG5321Manuel Armando Salazar BravoNo ratings yet

- EIC Analysis of Tata MotorsDocument9 pagesEIC Analysis of Tata Motorsrasteherta100% (1)

- 693+ Supertrak: SpecificationDocument4 pages693+ Supertrak: Specificationjiv2011100% (1)

- S.I. 89 of 2021 Control of Goods (Import and Export) (Commerce) (Amendment)Document1 pageS.I. 89 of 2021 Control of Goods (Import and Export) (Commerce) (Amendment)Tapiwa MukandiNo ratings yet

- PG750B1 (GB) 1pp (0409)Document1 pagePG750B1 (GB) 1pp (0409)Ehsan Ur RehmanNo ratings yet

- 2206a-E13tag2 Electropak Pn1880Document2 pages2206a-E13tag2 Electropak Pn1880ibrahemNo ratings yet

- UG 2200 - UG 3000 Super - Special Without Spray Boom) (MH624) - 20240130 - 195300Document19 pagesUG 2200 - UG 3000 Super - Special Without Spray Boom) (MH624) - 20240130 - 195300Adrian NazareNo ratings yet