ESAB Weld Metal Cost Worksheet: Labor & Overhead

ESAB Weld Metal Cost Worksheet: Labor & Overhead

Uploaded by

Smith SivaCopyright:

Available Formats

ESAB Weld Metal Cost Worksheet: Labor & Overhead

ESAB Weld Metal Cost Worksheet: Labor & Overhead

Uploaded by

Smith SivaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

ESAB Weld Metal Cost Worksheet: Labor & Overhead

ESAB Weld Metal Cost Worksheet: Labor & Overhead

Uploaded by

Smith SivaCopyright:

Available Formats

Covered

Electrodes

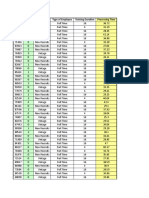

ESAB Weld Metal Cost Worksheet

Stainless Prepared For: Customer Name Date:

Steel

Products (1) Proposed Method Cost Calculation (2) Present Method Cost Calculation Result

Formulas for Calculating Dual Shield 7100 Ultra (E71T-1) E7018 3/16" (4.8 mm) (Cost Reduction)

Cost per Pound Deposited Weld Metal 1/16" (1.6 mm) @ 300 Amps @250 Amps Cost Increase

Solid Wire (3) (4) (5) (4) (6) (5-6)

& Rod Labor & Overhead

Products Labor & = Cost/Hr = $45.00 = $45.00 = $9.80 $45.00 = $45.00 = $27.78 ($17.98)

Overhead Deposition XOperating 10.2 X 0.45 = 4.59 5.4 X 0.3 = 1.62

Rate Factor

ESAB (3) (4) (9) (5) (4) (6) (5-6)

TIG & MIG Electrode Electrode Cost/lb = 1.78 = 2.05 0.85 = 1.33 0.72

Wires Deposition Efficiency 0.87 0.64

2" (50mm) stub

(3) (4) (5) (4) (6) (5-6)

Cored Gas Flow Rate (Cu ft/hr)

Gas = 40 X 0.02 = 0.8 = 0.08 0 X 0 = 0 = 0 0.08

X Gas Cost/Cu ft.

Wire 10.2 5.4

Products Deposition Rate (lbs/hr)

(7) (8) (7-8)

Total Variable Cost/lb Total Variable Cost/lb

Sum of the Above = $11.93 = $29.11 ($17.18)

Submerged Deposited Weld Metal Deposited Weld Metal

Total

Arc

Products

Pounds of Weld Metal and Welder Man Hours Required to Amortize Equipment Cost

Equipment Cost

Power Supply Equipment Cost in Dollars Pounds of Weld Metal ÷ Deposition Factor = Welder Man Hours

Hard- Wire Feeder Savings/lb Required to Required to

surfacing Gun & Accessories Amortize Cost Amortize Cost

Filler Metal $2,900 (9)

Products Total $2,900 $17.18 = 168.8 ÷ 4.59 = 37 Hours

Consumption

StubLoss

Correction

Calculations

Electrode/Wire

Consumption

Weld Metal Cost

Filler Metals Worksheet

ASTM

Steels Weight/Foot

Weld Metal

Weight/Meter

Conversion Weld Metal

Tables 8

You might also like

- 2021 Global Construction Costs Yearbook SAMPLE 1Document14 pages2021 Global Construction Costs Yearbook SAMPLE 1Smith SivaNo ratings yet

- Niro Granite - Pedestrian CollectionDocument2 pagesNiro Granite - Pedestrian CollectionRezaNo ratings yet

- 20230410-Khs0325-Spesifikasi Material Kantor CabangDocument11 pages20230410-Khs0325-Spesifikasi Material Kantor CabangariefNo ratings yet

- Gear Box With Parallel ShaftDocument142 pagesGear Box With Parallel ShaftmaebelhmariamNo ratings yet

- High Configuration Conveyor Belt Metal DetectorDocument2 pagesHigh Configuration Conveyor Belt Metal Detectordummy sharerNo ratings yet

- 0eecf9 Rockwool Technical DataDocument1 page0eecf9 Rockwool Technical DatarohaanmumtazNo ratings yet

- Rotary Screw Compressor: Frick RWF IiDocument6 pagesRotary Screw Compressor: Frick RWF IiEmanuel SotoNo ratings yet

- Environmental Fact Sheet (# 33) Crude Palm Kernel Oil (CPKO)Document6 pagesEnvironmental Fact Sheet (# 33) Crude Palm Kernel Oil (CPKO)eefgtgNo ratings yet

- Bidding Document For Procurement of Pipe & FittingsDocument101 pagesBidding Document For Procurement of Pipe & FittingsARSENo ratings yet

- API 650 Tank Nozzle Stand OutDocument5 pagesAPI 650 Tank Nozzle Stand OutratitariNo ratings yet

- Pe100 Water Pressure Pipes pn10 sdr17 1672050128Document2 pagesPe100 Water Pressure Pipes pn10 sdr17 1672050128MikiNo ratings yet

- Profile Metal DetectorDocument102 pagesProfile Metal Detectorcoonce.davidNo ratings yet

- Product Application GuideDocument37 pagesProduct Application GuideEGNo ratings yet

- Cooling Water Treatment PDFDocument3 pagesCooling Water Treatment PDFdineshkbunker08No ratings yet

- What's The Difference Between Parallel Flow, Counter Flow and Crossflow Heat ExchangersDocument7 pagesWhat's The Difference Between Parallel Flow, Counter Flow and Crossflow Heat ExchangersRanjani J DeepakNo ratings yet

- Grout Calculator For TileDocument1 pageGrout Calculator For TilemohdrashidNo ratings yet

- 2.3. Synthite-Recipes - For - Success PDFDocument17 pages2.3. Synthite-Recipes - For - Success PDFĐặng Phương AnhNo ratings yet

- Palm Oil & Saturated Steam PropertiesDocument4 pagesPalm Oil & Saturated Steam PropertiesStefanusNo ratings yet

- For The Inspection of Tank Shell Plates Before WeldingDocument2 pagesFor The Inspection of Tank Shell Plates Before WeldingAmbreen SheikhNo ratings yet

- Furniture OfficeDocument2 pagesFurniture OfficePutra YasaNo ratings yet

- GS Resting TubeDocument2 pagesGS Resting TubeEvan KeeNo ratings yet

- Cable CapacityDocument5 pagesCable CapacityRaja ManiNo ratings yet

- Check List For Fire Hydrant Safety StandardDocument3 pagesCheck List For Fire Hydrant Safety StandardPrakash KumarNo ratings yet

- Engineering Specification For Electrical Heat-Tracing SystemsDocument7 pagesEngineering Specification For Electrical Heat-Tracing SystemsArindomNo ratings yet

- Resistance+List+Tank+Linings,+Protective (1) JotunDocument28 pagesResistance+List+Tank+Linings,+Protective (1) JotunIbrahim KhalilNo ratings yet

- 14.72 KL PP FRP TankDocument24 pages14.72 KL PP FRP TankmaheshdgavaliNo ratings yet

- Welding CostsDocument13 pagesWelding CostsJohan AviantoNo ratings yet

- Marine Colour Card PDFDocument2 pagesMarine Colour Card PDFLuis Miguel ToscanoNo ratings yet

- Scrubber Design & Costing FRP Sheet Costing 1.2 Dia 4.8m HighDocument29 pagesScrubber Design & Costing FRP Sheet Costing 1.2 Dia 4.8m HighmaheshdgavaliNo ratings yet

- Weld Procedure Specification (WPS) : According To Asme Ix &Document1 pageWeld Procedure Specification (WPS) : According To Asme Ix &Mina Roger SamyNo ratings yet

- Plastic Density TableDocument2 pagesPlastic Density TableRamadani Dwi KNo ratings yet

- Additional Tech Details For Polybond STP at DewasDocument2 pagesAdditional Tech Details For Polybond STP at DewasAnimesh JainNo ratings yet

- Calculation Hot Water Heating PumpDocument1 pageCalculation Hot Water Heating PumpwvwintersNo ratings yet

- Project Cost For Injection Moulding Plant: SL No Description Capacity Short Weight Condition Basic PriceDocument2 pagesProject Cost For Injection Moulding Plant: SL No Description Capacity Short Weight Condition Basic PriceNihar RanjanNo ratings yet

- Thermal Conductivity of WaterDocument6 pagesThermal Conductivity of Waterhiddenkey1No ratings yet

- Deaerator Stream RequirementDocument1 pageDeaerator Stream Requirementdeepdaman18891No ratings yet

- Filter Solutions - Filter BagsDocument6 pagesFilter Solutions - Filter BagsF.IglesiasNo ratings yet

- 64360-K60 - B600 Cover, L Under Side - DoneDocument17 pages64360-K60 - B600 Cover, L Under Side - DoneMiguel HernandezNo ratings yet

- Dimensionless Designator of Pipe Size PDFDocument1 pageDimensionless Designator of Pipe Size PDFleoscbdNo ratings yet

- Inspection and Tests: Instrument Air Receiver TWO Code Stamp: Not RequiredDocument2 pagesInspection and Tests: Instrument Air Receiver TWO Code Stamp: Not RequiredSean DavisNo ratings yet

- 64350-K60 - B600 Cover, R Under Side - DoneDocument17 pages64350-K60 - B600 Cover, R Under Side - DoneMiguel HernandezNo ratings yet

- Service Philips 2005Document188 pagesService Philips 2005acostaricciNo ratings yet

- DiscussionDocument8 pagesDiscussionATUL SONAWANENo ratings yet

- Ruchi Soya IndustriesDocument8 pagesRuchi Soya IndustriesAkhilesh KumarNo ratings yet

- HDPE Pipes Fittings PDFDocument56 pagesHDPE Pipes Fittings PDFInthees RagavanNo ratings yet

- TruckDocument1 pageTruckamritNo ratings yet

- Price List 2022 in SQM (Eff 1 November 2022) CL JBTBDocument23 pagesPrice List 2022 in SQM (Eff 1 November 2022) CL JBTBsrt droneNo ratings yet

- Runners, Gates and Feed System Data PDFDocument27 pagesRunners, Gates and Feed System Data PDFBade BhausahebNo ratings yet

- General: Insulated Aluminium CladdingDocument5 pagesGeneral: Insulated Aluminium Claddingeccos3338No ratings yet

- CAF No Defects Operator Type of Employee Training Duration Processing TimeDocument11 pagesCAF No Defects Operator Type of Employee Training Duration Processing TimeEmba MadrasNo ratings yet

- Free Air Delivery (FAD) - CalculationDocument1 pageFree Air Delivery (FAD) - CalculationMitulNo ratings yet

- Epoxy CatalogueDocument21 pagesEpoxy CatalogueChinthamani PandiNo ratings yet

- Design. Ref - Decuments: API 650, 11TH - ED M09Document31 pagesDesign. Ref - Decuments: API 650, 11TH - ED M09hgagNo ratings yet

- Basic Heat TreatmentDocument8 pagesBasic Heat TreatmentAnonymous VRspXsmNo ratings yet

- RFQ - Piping & FittingsDocument4 pagesRFQ - Piping & FittingsSyed ZamanNo ratings yet

- Bom For Residential BuildingsDocument3 pagesBom For Residential BuildingsAaron Casey LorectoNo ratings yet

- Carbon FootprintDocument2 pagesCarbon FootprinthimanshusonberNo ratings yet

- Tiles Order FormatDocument6 pagesTiles Order Formatvhdalvi100% (1)

- Bucket Elevator InspectionDocument8 pagesBucket Elevator InspectionTeuku AlkhaitamiNo ratings yet

- Weld Metal Cost Calculator 3Document1 pageWeld Metal Cost Calculator 3Naresh Tammineedi100% (1)

- ESAB Weld Metal Cost Worksheet: Labor & Ov ErheadDocument1 pageESAB Weld Metal Cost Worksheet: Labor & Ov ErheadsachinshirnathNo ratings yet

- Equipment Layout of Solid Waste YardDocument1 pageEquipment Layout of Solid Waste YardSmith SivaNo ratings yet

- Manhole CoverDocument5 pagesManhole CoverSmith SivaNo ratings yet

- 02 Design Basis Report - Solid Waste Processing PlantDocument12 pages02 Design Basis Report - Solid Waste Processing PlantSmith SivaNo ratings yet

- 20 1+NoticetoClaim-Disruption PDFDocument2 pages20 1+NoticetoClaim-Disruption PDFSmith SivaNo ratings yet

- Borrow Area - Test SummaryDocument1 pageBorrow Area - Test SummarySmith SivaNo ratings yet

- MAterial Rate KWADocument59 pagesMAterial Rate KWASmith SivaNo ratings yet

- Sagar Smart City Limited: RFP No: SSCL/TENDER/ - /2019-20Document129 pagesSagar Smart City Limited: RFP No: SSCL/TENDER/ - /2019-20Smith SivaNo ratings yet

- Travel PolicyDocument14 pagesTravel PolicySmith Siva100% (1)

- Smart Spaces For Smart BusinessesDocument18 pagesSmart Spaces For Smart BusinessesSmith SivaNo ratings yet

- Market Rate KWADocument21 pagesMarket Rate KWASmith SivaNo ratings yet

- Rating & Ranking of National Highway StretchesDocument33 pagesRating & Ranking of National Highway StretchesSmith SivaNo ratings yet

- Handbook - Calculations 4 PDFDocument1 pageHandbook - Calculations 4 PDFSmith SivaNo ratings yet

- Nabard Project BoqDocument34 pagesNabard Project BoqSmith SivaNo ratings yet

- Kerala BOQDocument47 pagesKerala BOQSmith SivaNo ratings yet

- Handbook - Calculations 10 PDFDocument1 pageHandbook - Calculations 10 PDFSmith SivaNo ratings yet

- Cost IndexDocument1 pageCost IndexSmith SivaNo ratings yet

- Handbook - Calculations PDFDocument1 pageHandbook - Calculations PDFSmith SivaNo ratings yet

- Weld Metal Cost Worksheet Instructions: Covered ElectrodesDocument1 pageWeld Metal Cost Worksheet Instructions: Covered ElectrodesSmith SivaNo ratings yet

- Handbook - Calculations 5 PDFDocument1 pageHandbook - Calculations 5 PDFSmith SivaNo ratings yet

- Handbook - Calculations 3 PDFDocument1 pageHandbook - Calculations 3 PDFSmith SivaNo ratings yet

- Handbook - Calculations 2Document1 pageHandbook - Calculations 2Smith SivaNo ratings yet

- OM Rig EngineDocument136 pagesOM Rig Enginedsyadav926No ratings yet

- Liquid Milk Products: UHT Sterilized Milks: M Rosenberg, University of California-Davis, Davis, CA, USADocument9 pagesLiquid Milk Products: UHT Sterilized Milks: M Rosenberg, University of California-Davis, Davis, CA, USAMy Pham Thi DiemNo ratings yet

- PO Pangling SalonDocument1 pagePO Pangling SalonArlin RomansyahNo ratings yet

- ANAPHY Lec Session #2 - SAS (Agdana, Nicole Ken)Document8 pagesANAPHY Lec Session #2 - SAS (Agdana, Nicole Ken)Nicole Ken AgdanaNo ratings yet

- Cellular RespirationDocument37 pagesCellular RespirationTHELMA PONCENo ratings yet

- Mas 7 PDFDocument16 pagesMas 7 PDFAbbas ALhasnawyNo ratings yet

- Exp 4Document11 pagesExp 4masuma lovelyNo ratings yet

- Practical 5 Title: Enzymes and Digestion Objective: (1) To Show The Action of Amylase On StarchDocument12 pagesPractical 5 Title: Enzymes and Digestion Objective: (1) To Show The Action of Amylase On StarchkanishiniNo ratings yet

- (Sika) Icoment 504 Safety Data SheetDocument4 pages(Sika) Icoment 504 Safety Data Sheet_at_to_No ratings yet

- Coa Asp PreseptDocument1 pageCoa Asp PreseptfennyNo ratings yet

- Max Speciality Films - Corporate Presentation Jul'18Document31 pagesMax Speciality Films - Corporate Presentation Jul'18Sachin KothariNo ratings yet

- MEC-JTB-SF-M-DTS-900-00023 - 0 - 5-Datasheet - MP-Condensate-Flash-Tank - (410-D-9003) - (REPLACE) - Commented-SA-MC.1 (Code 2)Document5 pagesMEC-JTB-SF-M-DTS-900-00023 - 0 - 5-Datasheet - MP-Condensate-Flash-Tank - (410-D-9003) - (REPLACE) - Commented-SA-MC.1 (Code 2)Yusri FakhrizalNo ratings yet

- Nanoscience & Nanotechnology (Done)Document23 pagesNanoscience & Nanotechnology (Done)shailesh mahtoNo ratings yet

- Bioreactors LatestDocument34 pagesBioreactors LatestSyeda KazmiNo ratings yet

- Igneous RockDocument9 pagesIgneous Rockdeboline mitraNo ratings yet

- Civil Engineering Materials: Timber and Wood ProductsDocument73 pagesCivil Engineering Materials: Timber and Wood ProductsSyed Muhammad KhizarNo ratings yet

- NITOCOTE ET402 - TechnicalSubmittalDocument65 pagesNITOCOTE ET402 - TechnicalSubmittaladilabad newsNo ratings yet

- Activity Test and Formulation of Antioxidant Cream From Ethanol Extract Combination of Several Citrus Fruit Peels (Document8 pagesActivity Test and Formulation of Antioxidant Cream From Ethanol Extract Combination of Several Citrus Fruit Peels (SrihrtnNo ratings yet

- EST Microproject 5th SemDocument23 pagesEST Microproject 5th SemOm ShelkeNo ratings yet

- Savvas NS CalculationDocument10 pagesSavvas NS CalculationBosh DoshNo ratings yet

- 10 - Emulsions and Foams - 1992 - Introduction To Colloid and Surface ChemistryDocument15 pages10 - Emulsions and Foams - 1992 - Introduction To Colloid and Surface ChemistryAZUCENANo ratings yet

- 8.19.3 Laying: 8.20 Curtain W T T ALL W W With Aluminium Composite Panels (Acp) Cladding P P 8.20.1 GeneralDocument5 pages8.19.3 Laying: 8.20 Curtain W T T ALL W W With Aluminium Composite Panels (Acp) Cladding P P 8.20.1 GeneralAnshuman RathNo ratings yet

- Flanges: Technical Conditions For Supply ofDocument2 pagesFlanges: Technical Conditions For Supply ofradharaman_znaNo ratings yet

- Class 12 Chemistry Chapter 2 Electro Chemistry Extentand Exercise QuestionsDocument18 pagesClass 12 Chemistry Chapter 2 Electro Chemistry Extentand Exercise QuestionsSaraswati maharanaNo ratings yet

- Rahul PPT Phase 1Document26 pagesRahul PPT Phase 1Rahul kumarNo ratings yet

- AS LEVEL COURSE Enthalpy Change MODULE 4Document32 pagesAS LEVEL COURSE Enthalpy Change MODULE 4shepherdwishmorengwenyaNo ratings yet

- PROTEOBACTERIADocument35 pagesPROTEOBACTERIANurul AnisshaNo ratings yet

- CNS Stimulants: Pharmacology IIDocument30 pagesCNS Stimulants: Pharmacology IIRocky KhanNo ratings yet

- Ground Granulated Blast-Furnace Slag: Quality AssuranceDocument13 pagesGround Granulated Blast-Furnace Slag: Quality AssuranceKiranNo ratings yet

- CHEMICAL PLANT AND LABORATORY SAFETY - McGraw-Hill Education - Access EngineeringDocument25 pagesCHEMICAL PLANT AND LABORATORY SAFETY - McGraw-Hill Education - Access EngineeringTJ SabadoNo ratings yet