QCS 2010 Evennes PDF

QCS 2010 Evennes PDF

Uploaded by

Nadine BarghothiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QCS 2010 Evennes PDF

QCS 2010 Evennes PDF

Uploaded by

Nadine BarghothiCopyright:

Available Formats

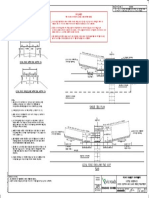

QCS 2010 Section 6 Part 5 Asphalt Works Page 26

4 The tolerances herein specified shall not invalidate the tolerances set forth for the evenness

of surface of the asphalt paving course.

5 As directed by the engineer the laid thickness shall be checked by cutting test pits and/or

using Ground Penetrating Radar (GPR) for the determination of the structural capacity of the

pavement.

5.11.6 Evenness of Surface

1 The Engineer shall test the evenness of surface for each course of the various asphalt

paving courses to determine compliance.

2 The Contractor shall put at the disposal of the Engineer a 3 m long straightedge and a crown

template of sturdy and approved design and enough labour to assist in the checking

Qatar Project Management

operations.

3 Any layer containing deviations or variations exceeding the tolerances specified here shall

be corrected or removed and replaced in accordance with the instructions of the Engineer

and to his satisfaction.

4 The longitudinal regularity of the surface of the wearing course shall be within the relevant

limits given in Table 5.3.

Table 5.3

Wearing Course Road Surface

Irregularity 4 mm 7 mm

Length (m) 300 75 300 75

Minor Roads 40 18 4 2

Major Roads1 20 9 2 1

1- Major Roads shall mean primary, secondary and any dual carriageways. Minor Roads are all other roads.

5 Any irregularity is a variation of not less than 4 mm or 7 mm of the profile of the road surface

as measured by a rolling straight edge. No irregularity exceeding 10 mm shall be permitted.

6 Compliance with Table 5.3 above shall be tested with a rolling straight edge along any line or

lines parallel to the centre line of the pavement on sections of 300 m selected by the

Engineer, whether or not it is constructed in shorter lengths. Sections shorter than 300 m

forming part of a longer pavement shall be assessed using the number of irregularities for a

300 m length prorated to the nearest whole number. Where the total length of pavement is

less than 300 m the measurements shall be taken in 75 m lengths.

7 Pavements shall also be measured transversely for irregularities at points decided by the

Engineer by a 3 m long straight edge placed at right angles to the centre line of the road.

The maximum allowable differences between the pavement surface and the straight edge

shall be 3 mm.

8 For major roads the International Roughness Index (IRI) shall be used to monitor the

roughness and condition of the pavement surface. The acceptable IRI for ride quality shall

be decided by the engineer.

5.11.7 Pavement Evaluation Techniques

1 Pavement evaluation tests shall be carried out for the completed pavement structure at any

point of the road as directed by the Engineer to assess the serviceability condition of the

pavement and verify compliance with specifications.

QCS 2010

You might also like

- SOP - 06 - Visual and Dimensional ProcedureDocument22 pagesSOP - 06 - Visual and Dimensional ProcedureSuci YatiningtiyasNo ratings yet

- Method Statement - Pipe WorksDocument14 pagesMethod Statement - Pipe WorksDarl Anthony Veloso100% (5)

- E2133 PDFDocument4 pagesE2133 PDFDannyChaconNo ratings yet

- Highway Geometric DesignDocument40 pagesHighway Geometric Designharikeerthan84% (19)

- Asme Section II A Sa-435 Sa-435mDocument4 pagesAsme Section II A Sa-435 Sa-435mAnonymous GhPzn1xNo ratings yet

- C 174 .C 174M Test Method For Measuring Length of Drilled Concrete CoresDocument2 pagesC 174 .C 174M Test Method For Measuring Length of Drilled Concrete Coresjjaavenido100% (1)

- Astm A578 - 07 PDFDocument5 pagesAstm A578 - 07 PDFMuhammad Maulana100% (1)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Owners Manual For Colombia - Daewoo ManualDocument333 pagesOwners Manual For Colombia - Daewoo ManualEdgar Gonzalez100% (1)

- Emta 2019Document51 pagesEmta 2019ValenNo ratings yet

- Garden CityDocument7 pagesGarden Citysweetloverz100% (2)

- 网上下载 - General Construction Requirements for Road PavementsDocument12 pages网上下载 - General Construction Requirements for Road PavementsSimon liNo ratings yet

- Surface IrregulatiesDocument3 pagesSurface Irregulatiesbuddy1971No ratings yet

- MoRTH Specifications Pocket Book 09.04.2019 FinalDocument92 pagesMoRTH Specifications Pocket Book 09.04.2019 FinalsombansNo ratings yet

- Astm E1703 - E1703m-10 (2023)Document2 pagesAstm E1703 - E1703m-10 (2023)yasirNo ratings yet

- Methodology For Track LinkingDocument11 pagesMethodology For Track LinkingAnkala Saibaba100% (2)

- Larsen & Toubro Limited - Ecc Division: Page 1 of 3Document3 pagesLarsen & Toubro Limited - Ecc Division: Page 1 of 3Akhilesh DwivediNo ratings yet

- Speci. Slab Drain On Moti Amrol To Sangpur Road Ta. Jetpur PaviDocument116 pagesSpeci. Slab Drain On Moti Amrol To Sangpur Road Ta. Jetpur PaviPranav ChovatiyaNo ratings yet

- Critére D'acceptation PT API 650 ASME VIIIDocument4 pagesCritére D'acceptation PT API 650 ASME VIIITahar DabbarNo ratings yet

- Surface TolerancesDocument9 pagesSurface Tolerancesshrinivast100% (1)

- IGGA Guide Specification: Conventional Diamond Grinding For Pavement PreservationDocument5 pagesIGGA Guide Specification: Conventional Diamond Grinding For Pavement PreservationNoelia VargasNo ratings yet

- Man Appendix 6 PDFDocument2 pagesMan Appendix 6 PDFAshokMechNo ratings yet

- Asphalt Base, Binder and Wearing Course - Adm Part SpecDocument9 pagesAsphalt Base, Binder and Wearing Course - Adm Part SpecRolando de GuzmanNo ratings yet

- 0.1. General Techical Specification - RoadDocument4 pages0.1. General Techical Specification - Roadpatel jatinNo ratings yet

- Driveway and Footpath SpecificationDocument7 pagesDriveway and Footpath SpecificationYi WUNo ratings yet

- Method Statement MechanicalDocument24 pagesMethod Statement Mechanicalsunjay_shanker93% (14)

- Standard Test Method For Measuring Thickness of Concrete Elements Using Drilled Concrete Cores1Document3 pagesStandard Test Method For Measuring Thickness of Concrete Elements Using Drilled Concrete Cores1Lupita RamirezNo ratings yet

- Plagiarism Scan Report: Plagiarised UniqueDocument2 pagesPlagiarism Scan Report: Plagiarised UniqueAsr FlowerNo ratings yet

- Astm E1703 2000Document2 pagesAstm E1703 2000Nick AndroulakisNo ratings yet

- Asphalt Paving Course - Adm Standard SpecDocument15 pagesAsphalt Paving Course - Adm Standard SpecRolando de GuzmanNo ratings yet

- 5 - Proof Rolling TestDocument8 pages5 - Proof Rolling Testnasoha rashidNo ratings yet

- Test Method OthersDocument15 pagesTest Method OthersEnd End100% (1)

- Proposed Methodology - 4.0 Design Standard & Perimeter 1Document20 pagesProposed Methodology - 4.0 Design Standard & Perimeter 1Zaidi MohamadNo ratings yet

- Vitrified Clay Pipe: T 281 Methods of Sampling and TestingDocument3 pagesVitrified Clay Pipe: T 281 Methods of Sampling and TestingricardojesussardinasalzugarayNo ratings yet

- 1600 - Quality Contorl of WorkDocument10 pages1600 - Quality Contorl of Workruwan.smb1No ratings yet

- A5.3.8 - WorkmanshipDocument3 pagesA5.3.8 - WorkmanshipJesseNo ratings yet

- Hollow Clay Tiles For Floors and Roofs - Specification: Indian StandardDocument12 pagesHollow Clay Tiles For Floors and Roofs - Specification: Indian StandardDevesh Kumar PandeyNo ratings yet

- 1 - 700 - Road Pavements GeneralDocument8 pages1 - 700 - Road Pavements GeneralBleriNo ratings yet

- Criterios de Aceptacion y Rechazo Asme ViiiDocument4 pagesCriterios de Aceptacion y Rechazo Asme ViiiGAlberto VillaPerezNo ratings yet

- Asme Section Viii Liquidos Penetrantes CriteriosDocument2 pagesAsme Section Viii Liquidos Penetrantes CriteriosLorena JimenezNo ratings yet

- Kerbs & Inl SpecDocument4 pagesKerbs & Inl Specabdulrehman731No ratings yet

- Method Statement - Portland Cement Concrete PavementDocument26 pagesMethod Statement - Portland Cement Concrete PavementTAHER AMMAR100% (2)

- 4-Specification For Box CellDocument110 pages4-Specification For Box CellMaulik RavalNo ratings yet

- Appendix-7 (IRC 81-1981)Document9 pagesAppendix-7 (IRC 81-1981)Anonymous g1LSaANo ratings yet

- Sow Road Construction 022610Document25 pagesSow Road Construction 022610Nercio BulaundeNo ratings yet

- MPT Mandatory Appendix 6Document2 pagesMPT Mandatory Appendix 6Ashfaq Khan100% (1)

- RT API 650 12th - 2013Document1 pageRT API 650 12th - 2013Đỗ Thị HuyềnNo ratings yet

- Mandatory Appendix 6 Methods For Magnetic Particle Examination (MT)Document2 pagesMandatory Appendix 6 Methods For Magnetic Particle Examination (MT)Usman TahirNo ratings yet

- 5.0 Fabrication-7 PDFDocument1 page5.0 Fabrication-7 PDFRohit KambleNo ratings yet

- Design and Specifications of Speed BreakeDocument8 pagesDesign and Specifications of Speed BreakeAditya PatilNo ratings yet

- MST of Road KerbDocument2 pagesMST of Road KerbMital Damani100% (1)

- Arc StrikeDocument7 pagesArc StrikekhirouNo ratings yet

- Portland Cement PavementDocument36 pagesPortland Cement PavementMenchebelle Grace Talha TabarnoNo ratings yet

- 311 ItemDocument3 pages311 ItemDominador MatbaganNo ratings yet

- Section 7 - Median, Left Turn, and Right Turn Design RequirementsDocument7 pagesSection 7 - Median, Left Turn, and Right Turn Design RequirementsJoenard LaglivaNo ratings yet

- Design GuidelinesDocument29 pagesDesign GuidelinesSusheel KumarNo ratings yet

- Construction Methodologies & Procedures for Civil Engineers - Part -1From EverandConstruction Methodologies & Procedures for Civil Engineers - Part -1No ratings yet

- Civil Engineering Structures According to the Eurocodes: Inspection and MaintenanceFrom EverandCivil Engineering Structures According to the Eurocodes: Inspection and MaintenanceNo ratings yet

- Bishop Avenue RedesignDocument1 pageBishop Avenue RedesignrappletonNo ratings yet

- Highway ReportDocument269 pagesHighway ReportMarlon RampersadNo ratings yet

- Future of Cpim in West Bengal-Article by Archan Kar at Uttarbanga SambadDocument1 pageFuture of Cpim in West Bengal-Article by Archan Kar at Uttarbanga SambadArchan KarNo ratings yet

- Hdsa SS MD 1004 PDFDocument2 pagesHdsa SS MD 1004 PDFRasoolKhadibiNo ratings yet

- 2011 Ucr 1 Ut Kandy City Transport Study Rda 123ppDocument123 pages2011 Ucr 1 Ut Kandy City Transport Study Rda 123ppsanduni dissanayakaNo ratings yet

- Timber Bridges & Foundations Forestry CommissionDocument79 pagesTimber Bridges & Foundations Forestry CommissionAqilahShafie100% (1)

- 11-Highway SafetyDocument36 pages11-Highway SafetyKingNo ratings yet

- 7Document250 pages7rivcoclerkoftheboardNo ratings yet

- Am Logistics DXB Warehouse Location MapDocument1 pageAm Logistics DXB Warehouse Location MapDolon DasNo ratings yet

- EIA Letter For Clifton FlyoverDocument24 pagesEIA Letter For Clifton Flyoverexpresstribune100% (1)

- 2014 Work Area Traffic Control Handbook WATCHDocument89 pages2014 Work Area Traffic Control Handbook WATCHmy TVNo ratings yet

- Managing Traffic Congestion With GIS PDFDocument10 pagesManaging Traffic Congestion With GIS PDFReynaldo AldamarNo ratings yet

- 4 Term 1 Test QuestionsDocument11 pages4 Term 1 Test QuestionstinoNo ratings yet

- Pavement Condition Analysis Using GISDocument6 pagesPavement Condition Analysis Using GISAmul ShresthaNo ratings yet

- InvoiceDocument2 pagesInvoiceFurkan GhoriNo ratings yet

- Lesson Plan 3 Attitude of Road UsersDocument4 pagesLesson Plan 3 Attitude of Road UsersShahbaz SharifNo ratings yet

- Developing A Computer-Aided Methodology For District Road Network Planning and Prioritization in NepalDocument31 pagesDeveloping A Computer-Aided Methodology For District Road Network Planning and Prioritization in NepalChandra Bahadur ShresthaNo ratings yet

- Attachment-4 Bill of QuantityDocument1 pageAttachment-4 Bill of QuantitysparkCENo ratings yet

- 28Document18 pages28mh mithu7162No ratings yet

- Abstract Estimates of Propose Bridges at Polavaram - Spill ChannelDocument41 pagesAbstract Estimates of Propose Bridges at Polavaram - Spill Channelharsha vardhanNo ratings yet

- Traffic Management Plan Procedure - Rev0Document7 pagesTraffic Management Plan Procedure - Rev0Nestor Mijares100% (2)

- 2011 12 Dec (North-East Focus - Assam)Document72 pages2011 12 Dec (North-East Focus - Assam)drupscNo ratings yet

- Standard Drawing 4083B Cattle Underpass Road Cross Section and Guard Fence TreatmentDocument1 pageStandard Drawing 4083B Cattle Underpass Road Cross Section and Guard Fence Treatmentshravan38No ratings yet

- Civil50 PDFDocument6 pagesCivil50 PDFSaran KumarNo ratings yet

- Which Way Is The Post OfficeDocument6 pagesWhich Way Is The Post OfficeMuhammadDanyNo ratings yet

- EA TOR For Ports HarboursDocument16 pagesEA TOR For Ports HarboursHerum ManaluNo ratings yet

- 2trfel P1Document4 pages2trfel P1pelajar otomotifNo ratings yet