Multilayer Ceramic Capacitors Soft Termination High Voltage Series (SH) X7R Dielectric 0805 To 1812 Sizes, 500V To 3Kv Rohs Compliance

Multilayer Ceramic Capacitors Soft Termination High Voltage Series (SH) X7R Dielectric 0805 To 1812 Sizes, 500V To 3Kv Rohs Compliance

Uploaded by

rezaCopyright:

Available Formats

Multilayer Ceramic Capacitors Soft Termination High Voltage Series (SH) X7R Dielectric 0805 To 1812 Sizes, 500V To 3Kv Rohs Compliance

Multilayer Ceramic Capacitors Soft Termination High Voltage Series (SH) X7R Dielectric 0805 To 1812 Sizes, 500V To 3Kv Rohs Compliance

Uploaded by

rezaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Multilayer Ceramic Capacitors Soft Termination High Voltage Series (SH) X7R Dielectric 0805 To 1812 Sizes, 500V To 3Kv Rohs Compliance

Multilayer Ceramic Capacitors Soft Termination High Voltage Series (SH) X7R Dielectric 0805 To 1812 Sizes, 500V To 3Kv Rohs Compliance

Uploaded by

rezaCopyright:

Available Formats

Approval sheet

Soft Termination High voltage (SH_500V~3kV)

MULTILAYER CERAMIC CAPACITORS

Soft Termination High Voltage Series (SH)

X7R Dielectric

0805 to 1812 Sizes, 500V to 3kV

RoHS Compliance

*Contents in this sheet are subject to change without prior notice.

Page 1 of 9 ASC_Soft term high voltage_(SH_500V~3kV)_021D_AS Jan. 2012

Approval sheet

Soft Termination High voltage (SH_500V~3kV)

1. INTRODUCTION

WTC Multilayer Ceramic Chip Capacitors supplied in tape & reel package are ideally suitable for thick-film hybrid

circuits and automatic surface mounting on any printed circuit boards. All of WTC’s MLCC products meet RoHS directive.

SH series use a special material between nickel-barrier and ceramic body. It provides excellent performance to

against bending stress occurred during process and provide more security for PCB process.

The nickel-barrier terminations are consisted of a nickel barrier layer over the silver metallization and then finished by

electroplated solder layer to ensure the terminations have good solderability. The nickel barrier layer in terminations

prevents the dissolution of termination when extended immersion in molten solder at elevated solder temperature.

2. FEATURES 3. APPLICATIONS

a. Withstanding 5mm of substrate bending. a. DC to DC converter.

b. High Voltage in a given case size. b. High voltage coupling/DC blocking.

c. High reliability and stability. c. Back-lighting inverters.

d. Snubbers in high frequency power convertors.

4. HOW TO ORDER

SH 21 B 102 K 102 C T

Series Size Dielectric Capacitance Tolerance Rated voltage Termination Packaging

SH=Soft 21=0805 (2012) B=X7R Two significant digits J=±5% Two significant C=Cu/Polymer T=7” reeled

termination 31=1206 (3216) followed by no. of zeros. K=±10% digits followed by Ag/Ni/Sn G=13” reeled

High Voltage 32=1210 (3225) And R is in place of M=±20% no. of zeros. And

42=1808 (4520) decimal point. R is in place of

43=1812 (4532) Eg. decimal point.

102=10x102

=1000pF 501=500 VDC

631=630 VDC

102=1000 VDC

202=2000 VDC

302=3000 VDC

Note 1: Please see below product range to find right termination code.

Page 2 of 9 ASC_Soft term high voltage_(SH_500V~3kV)_021D_AS Jan. 2012

Approval sheet

Soft Termination High voltage (SH_500V~3kV)

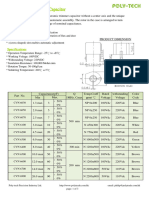

5. EXTERNAL DIMENSIONS

Size

L (mm) W (mm) T (mm) Symbol MB min(mm) L

Inch (mm)

0.80±0.10 B

0805 (2012) 2.00±0.20 1.25±0.10 0.30 T

1.25±0.10 D

1.25±0.10 D

1206 (3216) 3.20+0.4/-0.1 1.60±0.20 0.30

1.60±0.20 G W

1210 (3225) 3.20±0.50 2.50±0.30 1.60±0.20 G 0.30 MB MB

1.25±0.10 D

1808 (4520) 4.50+0.60/-0.4 2.03±0.25 0.25 Fig. 1 The outline of MLCC

2.00±0.20 K

1.25±0.10 D

1812 (4532) 4.50+0.60/-0.4 3.20±0.30 0.25

2.00±0.20 K

6. GENERAL ELECTRICAL DATA

Dielectric X7R

Size 0805, 1206, 1210, 1808, 1812

Capacitance* 100pF to 0.12uF

Capacitance tolerance** J (±5%), K (±10%), M (±20%)

Rated voltage (WVDC) 500V, 630V, 1000V, 2000V, 3000V

Tan δ* ≤2.5%

Insulation resistance at Ur*** ≥10GΩ or RxC≥500Ω-F whichever is smaller

Operating temperature -55 to +125°C

Capacitance characteristic ±15%

Termination Ni/Sn (lead-free termination)

* Measured at 25°C ambient temperature and 30~70% r elated humidity. Apply 1.0±0.2Vrms, 1.0kHz±10%.

** Preconditioning for Class II MLCC: Perform a heat treatment at 150±10°C for 1 hour, then leave in a mbient condition for 24±2 hours

before measurement.

***Measured at 500VDC for 60 sec, for UR>500VDC

Page 3 of 9 ASC_Soft term high voltage_(SH_500V~3kV)_021D_AS Jan. 2012

Approval sheet

Soft Termination High voltage (SH_500V~3kV)

7. PRODUCT RANGE

DIELECTRIC X7R

SIZE 0805 1206 1210 1808 1812

RATED VOLTAGE 500, 500, 500, 500,

1000 2000 1000 1000 2000 3000 1000 2000 3000

(VDC) 630 630 630 630

100pF (101) B

120pF (121) B

150pF (151) B D D D D D D

180pF (181) B D D D D D D

220pF (221) B D D D D D D

270pF (271) B D D D D D D

330pF (331) B D D D D D K

390pF (391) B D D D D D K

470pF (471) B D D D D D K D D D K

560pF (561) B D D D D D K D D D K

680pF (681) B D D D D D K D D D K

820pF (821) B D D G D D K D D D K

1,000pF (102) B D D G G G D K K D D D K

1,200pF (122) B D D G G D K D D D

1,500pF (152) B D D G G D K D D D

1,800pF (182) B D D G G D K D D K

2,200pF (222) B D D G G D D D K

Capacitance

2,700pF (272) B D D G G D D D K

3,300pF (332) B D D G G D D D K

3,900pF (392) B D D G G D D D K

4,700pF (472) D D D G G D D D K

5,600pF (562) D D D G G K D D

6,800pF (682) D D D G G K D D

8,200pF (822) D D D G G K D D

0.010µF (103) D D D G G K D D

0.012µF (123) D G D K

0.015µF (153) D G D K

0.018µF (183) D G D

0.022µF (223) G G D

0.027µF (273) G G D

0.033µF (333) G G D

0.039µF (393) G D

0.047µF (473) G D

0.056µF (563) G D

0.068µF (683) G K

0.082µF (823) K

0.10µF (104) K

0.12µF (124) K

Page 4 of 9 ASC_Soft term high voltage_(SH_500V~3kV)_021D_AS Jan. 2012

Approval sheet

Soft Termination High voltage (SH_500V~3kV)

8. PACKAGING DIMENSION AND QUANTITY

Paper tape Plastic tape

Size Thickness (mm)/Symbol

7” reel 13” reel 7” reel 13” reel

0.80±0.10 B 4k 15k - -

0805(2012)

1.25±0.10 D - - 3k 10k

1.25±0.10 D - - 3k 10k

1206(3216)

1.60±0.20 G - - 2k -

1210 (3225) 1.60±0.20 G - - 2k -

1.25±0.10 D - - 2k 10k

1808 (4520)

2.00±0.20 K - - 1k 6k

1.25±0.10 D - - 1k -

1812 (4532)

2.00±0.20 K - - 1k -

Unit: pieces

Size 0603, 0805, 1206, 1210, 1808, 1812

Reel size 7” 10” 13”

C 13.0+0.5/-0.2 13.0+0.5/-0.2 13.0+0.5/-0.2

W1 8.4+1.5/-0 8.4+1.5/-0 8.4+1.5/-0

A 178.0±0.10 250.0±1.0 330.0±1.0

N 60+1.0/-0 100.0±1.0 100±1.0

Fig. 2 The dimension of reel

Page 5 of 9 ASC_Soft term high voltage_(SH_500V~3kV)_021D_AS Jan. 2012

Approval sheet

Soft Termination High voltage (SH_500V~3kV)

9. RELIABILITY TEST CONDITIONS AND REQUIREMENTS

No. Item Test Condition Requirements

1. Visual and --- * No remarkable defect.

Mechanical * Dimensions to conform to individual specification sheet.

2. Capacitance 1.0±0.2Vrms, 1kHz±10% * Shall not exceed the limits given in the detailed spec.

3. Q/ D.F. X7R: D.F. ≤2.5%

(Dissipation

Factor)

4. Dielectric * To apply voltage: * No evidence of damage or flash over during test.

Strength 1.2 times of UR

* Duration : 1 to 5 sec.

5. Insulation To apply voltage at 500VDC for 60 sec. ≥10GΩ or RxC≥500Ω-F whichever is smaller.

Resistance

6. Temperature With no electrical load. Within ±15%.

Coefficient Operating temperature: -55~125°C at 25°C

7. Adhesive * Pressurizing force:5N * No remarkable damage or removal of the terminations.

Strength of * Test time: 10±1 sec.

Termination

8. Solderability * Solder temperature: 235±5°C 75% min. coverage of all metalized area.

* Dipping time: 2±0.5 sec.

9. Bending Test *The middle part of substrate shall be pressurized by * No remarkable damage.

means of the pressurizing rod at a rate of about 1 mm * Cap change: X7R: within ±12.5%

per second until the deflection becomes : 5 mm** & 3 (This capacitance change means the change of

mm*** and then the pressure shall be maintained for capacitance under specified flexure of substrate from the

5±1 sec.

capacitance measured before the test.)

*Measurement to be made after keeping at room temp.

for 48±4 hrs..

(** Thickness >1.0mm; *** Thickness≦1.0mm)

5 & 3 mm

10. Resistance * Solder temperature: 260±5°C * No remarkable damage.

to Soldering * Dipping time: 10±1 sec * Cap change: X7R: within ±7.5%

Heat * Preheating: 120 to 150°C for 1 minute before * 25% max. leaching on each edge.

immerse the capacitor in a eutectic solder.

* Before initial measurement: Perform 150+0/-10°C f or

1 hr and then set for 48±4 hrs at room temp.

* Measurement to be made after keeping at room

temp. for 48±4 hrs.

Page 6 of 9 ASC_Soft term high voltage_(SH_500V~3kV)_021D_AS Jan. 2012

Approval sheet

Soft Termination High voltage (SH_500V~3kV)

No. Item Test Condition Requirements

11. Temperature * Conduct the five cycles according to the * No remarkable damage.

Cycle temperatures and time. * Cap change:X7R: within ±15%

Step Temp. (°C) Time (min.) * D.F. : ≤ 1.5 x initial requirement

1 Min. operating temp. +0/-3 30±3 * I.R. : ≥ 0.25 x initial requirement

2 Room temp. 2~3

3 Max. operating temp. +3/-0 30±3

4 Room temp. 2~3

* Before initial measurement (Class II only): Perform

150+0/-10°C for 1 hr and then set for 48±4 h rs at room

temp.

* Measurement to be made after keeping at room

temp. for 48±4 hrs.

12. Humidity * Test temp.: 40±2°C * No remarkable damage.

(Damp Heat) * Humidity: 90~95% RH * Cap change: X7R: within ±15%

Steady State * Test time: 500+24/-0hrs. * D.F. value: ≤7.0%

* Measurement to be made after keeping at room * I.R.: ≥1GΩ or RxC≥50Ω-F whichever is smaller.

temp. for 48±4 hrs.

13. High * Test temp.: X7R: 125±3°C * No remarkable damage.

Temperature * To apply voltage: * Cap change: X7R: within ±20%

Load 120% of rated voltage. * D.F. value: ≤7.0%

(Endurance) * Test time: 1000+24/-0 hrs. * I.R.: ≥1GΩ or RxC≥50Ω-F whichever is smaller.

* Measurement to be made after keeping at room

temp. for 48±4 hrs.

Page 7 of 9 ASC_Soft term high voltage_(SH_500V~3kV)_021D_AS Jan. 2012

Approval sheet

Soft Termination High voltage (SH_500V~3kV)

APPENDIXES

◙ Tape & reel dimensions

Fig. 3 The dimension of paper tape

Fig. 4 The dimension of plastic tape

Size 0805 1206 1210 1808 1812

Thickness B C, D, I B C, D G C, D, G M D K D, K

A0 1.50±0.10 <1.65 2.00±0.10 <2.00 <2.00 <3.05 <3.10 <2.50 <2.50 <3.90

B0 2.30±0.10 <2.40 3.50±0.10 <3.60 <3.70 <3.80 <4.00 <5.30 <5.30 <5.30

T 0.95±0.05 0.23±0.05 0.95±0.05 0.23±0.05 0.23±0.05 0.23±0.05 0.23±0.05 0.25±0.05 0.25±0.05 0.25±0.05

K0 - <2.50 - <2.50 <2.50 <2.50 <3.50 <2.50 <2.50 <2.50

W 8.00±0.10 8.00±0.10 8.00±0.10 8.00±0.10 8.00±0.10 8.00±0.10 8.00±0.10 12.0±0.20 12.0±0.20 12.0±0.20

P0 4.00±0.10 4.00±0.10 4.00±0.10 4.00±0.10 4.00±0.10 4.00±0.100 4.00±0.10 4.00±0.10 4.00±0.10 4.00±0.10

10xP0 40.0±0.20 40.0±0.20 40.0±0.20 40.00±0.20 40.00±0.20 40.00±0.20 40.0±0.20 40.0±0.20 40.0±0.20 40.0±0.20

P1 4.00±0.10 4.00±0.10 4.00±0.10 4.00±0.10 4.00±0.10 4.00±0.10 4.00±0.10 4.00±0.10 4.00±0.10 8.00±0.10

P2 2.00±0.05 2.00±0.05 2.00±0.05 2.00±0.05 2.00±0.05 2.00±0.05 2.00±0.05 2.00±0.05 2.00±0.05 2.00±0.05

D0 1.55±0.05 1.50+0.1/-0 1.50±0.05 1.50±0.1/-0 1.50±0.1/-0 1.50±0.1/-0 1.50±0.1/-0 1.50±0.1/-0 1.50+0.1/-0 1.50+0.1/-0

D1 - 1.00±0.10 - 1.00±0.10 1.00±0.10 1.00±0.10 1.00±0.10 1.50±0.10 1.50±0.10 1.50±0.10

E 1.75±0.05 1.75±0.10 1.75±0.10 1.75±0.10 1.75±0.10 1.75±0.10 1.75±0.10 1.75±0.10 1.75±0.10 1.75±0.10

F 3.50±0.05 3.50±0.05 3.50±0.05 3.50±0.05 3.50±0.05 3.50±0.05 3.50±0.05 5.50±0.05 5.50±0.05 5.50±0.05

Page 8 of 9 ASC_Soft term high voltage_(SH_500V~3kV)_021D_AS Jan. 2012

Approval sheet

Soft Termination High voltage (SH_500V~3kV)

◙ Description of customer label

a. Customer name

b. WTC order series and item number

c. Customer P/O

d. Customer P/N

e. Description of product

f. Quantity

g. Bar code including quantity & WTC P/N or customer

h. WTC P/N

i. Shipping date

j. Order bar code including series and item numbers

k. Serial number of label

◙ Recommended soldering conditions

The lead-free termination MLCCs are not only to be used on SMT against lead-free solder paste, but also suitable

against lead-containing solder paste. If the optimized solder joint is requested, increasing soldering time, temperature and

concentration of N2 within oven are recommended.

℃/ sec max

4℃

Over 60sec at least by

natural cooling

Fig. 5 Recommended reflow soldering profile for SMT process Fig. 6 Recommended wave soldering profile for SMT process

with SnAgCu series solder paste. with SnAgCu series solder.

Use middy activated rosin RA and RMA fluxes do not use activated flux. The amount of solder in each solder joint

should be controlled to prevent the damage of chip capacitors caused by the stress between solder, chips, and substrate.

Hand soldering with temperature-controlled iron not exceeding 30 watts and diameter of tip less than 1.2 mm is

recommended, tip of iron should not contact the ceramic body directly, and the temperature of iron should be set to not

more than 260℃.

For bigger chips such as 1210, 1808, 1812, 2220 and 2225, etc. wave soldering and hand soldering are no

recommended.

Page 9 of 9 ASC_Soft term high voltage_(SH_500V~3kV)_021D_AS Jan. 2012

You might also like

- A Level Physics Unit 3 Mark Scheme Jan19No ratings yetA Level Physics Unit 3 Mark Scheme Jan1911 pages

- 2018 NMAT REVIEW Reinforcement - Physics Module A100% (1)2018 NMAT REVIEW Reinforcement - Physics Module A2 pages

- Optically Coupled Bilateral Switch Non-Zero Crossing TriacNo ratings yetOptically Coupled Bilateral Switch Non-Zero Crossing Triac3 pages

- Mos Field Effect Transistor: Switching N-Channel Power Mos Fet Industrial UseNo ratings yetMos Field Effect Transistor: Switching N-Channel Power Mos Fet Industrial Use9 pages

- Mos Field Effect Transistor: Switching N-Channel Power Mos Fet Industrial UseNo ratings yetMos Field Effect Transistor: Switching N-Channel Power Mos Fet Industrial Use9 pages

- Film Capacitors: Interference Suppression Capacitors (MPX Class X2)No ratings yetFilm Capacitors: Interference Suppression Capacitors (MPX Class X2)7 pages

- Infineon IDH02G120C5 DataSheet v02 - 02 ENNo ratings yetInfineon IDH02G120C5 DataSheet v02 - 02 EN11 pages

- 1N5342 THRU 1N5388: 5W Silicon Planar Zener DiodesNo ratings yet1N5342 THRU 1N5388: 5W Silicon Planar Zener Diodes2 pages

- Elcon (Radial Thru-Hole) 2006 EZX SeriesNo ratings yetElcon (Radial Thru-Hole) 2006 EZX Series2 pages

- Contact Data Characteristics: 100A Power Latching RelayNo ratings yetContact Data Characteristics: 100A Power Latching Relay3 pages

- Aluminum Electrolytic Capacitors: SpecificationsNo ratings yetAluminum Electrolytic Capacitors: Specifications5 pages

- 1N5342 THRU 1N5388: 5W Silicon Planar Zener Diodes Features DO-15No ratings yet1N5342 THRU 1N5388: 5W Silicon Planar Zener Diodes Features DO-153 pages

- Jameco Part Number 95038ISOCOM: Distributed byNo ratings yetJameco Part Number 95038ISOCOM: Distributed by4 pages

- CD288/CD288H SERIES: Aluminum Electrolytic CapacitorsNo ratings yetCD288/CD288H SERIES: Aluminum Electrolytic Capacitors2 pages

- Dual N-Channel, Notebook Power Supply MOSFET: June 1999No ratings yetDual N-Channel, Notebook Power Supply MOSFET: June 19999 pages

- Specification: CL 21 F 223 Z B A N N N CNo ratings yetSpecification: CL 21 F 223 Z B A N N N C3 pages

- A Ketin Info Mation FZ 900 R 16 KF 1: M R G RNo ratings yetA Ketin Info Mation FZ 900 R 16 KF 1: M R G R4 pages

- HOW TO ORDER:-Part Number Configuration: 2 Y5P 101 K 102 A56No ratings yetHOW TO ORDER:-Part Number Configuration: 2 Y5P 101 K 102 A5614 pages

- SB120 Thru SB160: Vishay General SemiconductorNo ratings yetSB120 Thru SB160: Vishay General Semiconductor4 pages

- High-Current Switching Applications: Absolute Maximum RatingsNo ratings yetHigh-Current Switching Applications: Absolute Maximum Ratings5 pages

- Hmi Advanced V07.01 For PC / PG - For Solutionline and PowerlineNo ratings yetHmi Advanced V07.01 For PC / PG - For Solutionline and Powerline4 pages

- 2.the Methods and Tools Used To Measure The Static Forces0% (1)2.the Methods and Tools Used To Measure The Static Forces3 pages

- High Frequency Limitation of Conventional Tubes:: Lead Inductance and Inter-Electrode Capacitance EffectNo ratings yetHigh Frequency Limitation of Conventional Tubes:: Lead Inductance and Inter-Electrode Capacitance Effect55 pages

- Btech Me 5 Sem Heat and Mass Transfer Rme 502 2018 19 PDFNo ratings yetBtech Me 5 Sem Heat and Mass Transfer Rme 502 2018 19 PDF2 pages

- Hydrostatic Pressure On Surfaces: Engr. Angelica A. LosaresNo ratings yetHydrostatic Pressure On Surfaces: Engr. Angelica A. Losares26 pages

- A Mini Project/Internship Report: Bachelor of TechnologyNo ratings yetA Mini Project/Internship Report: Bachelor of Technology43 pages

- QUESTIONS: Forms of Energy Soal Part I:: Nama: Mujibul Rijal Nim: 200204003No ratings yetQUESTIONS: Forms of Energy Soal Part I:: Nama: Mujibul Rijal Nim: 2002040032 pages

- A=iαt + jβ t kγ t α, β γ dA/dt d A/dt - A=iαt + jβ t kγ t dA/dt d A/dtNo ratings yetA=iαt + jβ t kγ t α, β γ dA/dt d A/dt - A=iαt + jβ t kγ t dA/dt d A/dt5 pages

- Properties and Characteristics of Materials (1)No ratings yetProperties and Characteristics of Materials (1)34 pages

- Chip Multilayer Ceramic Capacitors For AutomotiveNo ratings yetChip Multilayer Ceramic Capacitors For Automotive15 pages

- DTC P0100 Mass or Volume Air Flow Circuit DTC P0102 Mass or Volume Air Flow Circuit Low Input DTC P0103 Mass or Volume Air Flow Circuit High InputNo ratings yetDTC P0100 Mass or Volume Air Flow Circuit DTC P0102 Mass or Volume Air Flow Circuit Low Input DTC P0103 Mass or Volume Air Flow Circuit High Input1 page

- Optically Coupled Bilateral Switch Non-Zero Crossing TriacOptically Coupled Bilateral Switch Non-Zero Crossing Triac

- Mos Field Effect Transistor: Switching N-Channel Power Mos Fet Industrial UseMos Field Effect Transistor: Switching N-Channel Power Mos Fet Industrial Use

- Mos Field Effect Transistor: Switching N-Channel Power Mos Fet Industrial UseMos Field Effect Transistor: Switching N-Channel Power Mos Fet Industrial Use

- Film Capacitors: Interference Suppression Capacitors (MPX Class X2)Film Capacitors: Interference Suppression Capacitors (MPX Class X2)

- 1N5342 THRU 1N5388: 5W Silicon Planar Zener Diodes1N5342 THRU 1N5388: 5W Silicon Planar Zener Diodes

- Contact Data Characteristics: 100A Power Latching RelayContact Data Characteristics: 100A Power Latching Relay

- 1N5342 THRU 1N5388: 5W Silicon Planar Zener Diodes Features DO-151N5342 THRU 1N5388: 5W Silicon Planar Zener Diodes Features DO-15

- CD288/CD288H SERIES: Aluminum Electrolytic CapacitorsCD288/CD288H SERIES: Aluminum Electrolytic Capacitors

- Dual N-Channel, Notebook Power Supply MOSFET: June 1999Dual N-Channel, Notebook Power Supply MOSFET: June 1999

- Electromagnetic Foundations of Electrical EngineeringFrom EverandElectromagnetic Foundations of Electrical Engineering

- HOW TO ORDER:-Part Number Configuration: 2 Y5P 101 K 102 A56HOW TO ORDER:-Part Number Configuration: 2 Y5P 101 K 102 A56

- High-Current Switching Applications: Absolute Maximum RatingsHigh-Current Switching Applications: Absolute Maximum Ratings

- Hmi Advanced V07.01 For PC / PG - For Solutionline and PowerlineHmi Advanced V07.01 For PC / PG - For Solutionline and Powerline

- 2.the Methods and Tools Used To Measure The Static Forces2.the Methods and Tools Used To Measure The Static Forces

- High Frequency Limitation of Conventional Tubes:: Lead Inductance and Inter-Electrode Capacitance EffectHigh Frequency Limitation of Conventional Tubes:: Lead Inductance and Inter-Electrode Capacitance Effect

- Btech Me 5 Sem Heat and Mass Transfer Rme 502 2018 19 PDFBtech Me 5 Sem Heat and Mass Transfer Rme 502 2018 19 PDF

- Hydrostatic Pressure On Surfaces: Engr. Angelica A. LosaresHydrostatic Pressure On Surfaces: Engr. Angelica A. Losares

- A Mini Project/Internship Report: Bachelor of TechnologyA Mini Project/Internship Report: Bachelor of Technology

- QUESTIONS: Forms of Energy Soal Part I:: Nama: Mujibul Rijal Nim: 200204003QUESTIONS: Forms of Energy Soal Part I:: Nama: Mujibul Rijal Nim: 200204003

- A=iαt + jβ t kγ t α, β γ dA/dt d A/dt - A=iαt + jβ t kγ t dA/dt d A/dtA=iαt + jβ t kγ t α, β γ dA/dt d A/dt - A=iαt + jβ t kγ t dA/dt d A/dt

- DTC P0100 Mass or Volume Air Flow Circuit DTC P0102 Mass or Volume Air Flow Circuit Low Input DTC P0103 Mass or Volume Air Flow Circuit High InputDTC P0100 Mass or Volume Air Flow Circuit DTC P0102 Mass or Volume Air Flow Circuit Low Input DTC P0103 Mass or Volume Air Flow Circuit High Input