DP - TXT (2021-01-18 4:12:14 PM)

DP - TXT (2021-01-18 4:12:14 PM)

Uploaded by

Rufus D SCopyright:

Available Formats

DP - TXT (2021-01-18 4:12:14 PM)

DP - TXT (2021-01-18 4:12:14 PM)

Uploaded by

Rufus D SOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

DP - TXT (2021-01-18 4:12:14 PM)

DP - TXT (2021-01-18 4:12:14 PM)

Uploaded by

Rufus D SCopyright:

Available Formats

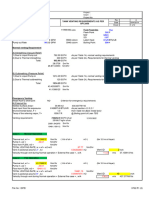

Boiler & Pressure Vessel Design Program - BPVM version 1639.07.74.

85

Date - 23 Nov 2019

Job description - Boiler study

Customer - Chapleau Cogeneration Limited

Client - New

Calculation ID - 00001 - BPVM - 25/2019

Job number - 36247

Files used

Boiler file - WT 30TPH-25bar.bd10

Customer file - Design boiler

Fuel file - natural gas.bd10

Site file - NewTown Country.bs10

Registration status - Legal copy.

This program run 0/1

This calculation 2

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Grit collector data - XW

______________________________________________________________________

Grit collector model = Vendor

Gas handling option = None

Gas handling final = None

Fly ash is reinjected into the furnace = False

Fly ash is screened - overs returned = False

Fly ash returned = 0 [%]

Internal diameter of chimney = 1600 [mm]

Internal diameter at top of chimney = 830 [mm]

Height above ground of the chimney = 30000 [mm]

Ducting length = 20000 [mm]

Induced draught fan efficiency = 75 [%]

ID air infiltration = 0 [%]

Forced draught fan efficiency = 65 [%]

Grit collector mass = 5000 [kg]

Collector efficiency = 90 [%]

Grit Limit = 250 [mg/Nm³]

Pressure loss of vendors multicyclone collect = 1100 [Pa]

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Pressure drop results

______________________________________________________________________

Boiler pressure loss details(77.9% thermal efficiency)...

Boiler Operating Load 30000 kg/hour

Excess air 15.0 %

dp.txt[2021-01-18 4:12:14 PM]

Ancilliary equipment...

Chimney friction loss 8.787 Pa

Chimney entrance loss 40.399 Pa

Chimney cone exit loss 55.727 Pa

Totals with 15 % excess air...

Boiler draught loss 179.959 Pa 0.7 in W.G.

Duct losses (ASHRAE L= 20.0m) 3.363 Pa 0.0 in W.G.

Evaporator 1- Loss 650.199 Pa 2.6 in W.G.

Open damper (SMACNA Table A-15F) 35.620 Pa 0.1 in W.G.

Chimney 104.913 Pa 0.4 in WG

____________ __________________

Total draught loss 974.054 Pa 3.9 in W.G.

The pressure drop above does not include the following:

Combustion air fan silencer loss

Combustion air fan damper

Combustion air fan ducting

Burner windbox losses

Specify (ABB, MCR + 30%) 1266.3 Pa 5.1 in W.G

Specify (Basu, MCR + 20%) 1168.9 Pa 4.7 in W.G.

Specify (Babcock min, MCR + 20%) 1168.9 Pa 4.7 in W.G.

Specify (Babcock max, MCR + 30%) 1266.3 Pa 5.1 in W.G.

Specify (Combustion Eng, MCR + 30%) 1266.3 Pa 5.1 in W.G.

Specify (EPI minimum, MCR + 15%) 1120.2 Pa 4.5 in W.G.

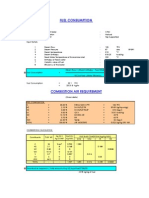

Gas properties (SASOL natural gas - 15.0% excess air)...

General

Mass flow 32887.691 kg/hour

Mass flow 9.135 kg/s

Gas constant- wet 298.971 J/kg K

Gas molecular weight- wet 27.810

Atmospheric pressure 83.030 kPa

Gas temperature 270.3 °C

Boiler exit

Flow from rear smoke box duct 17.877 m³/s

Gas temperature 270.315 °C

Gas specific volume 2.056 m³/kg

Gas density 0.486 kg/m³

Gas specific heat capacity 1.158 kJ/kg K

Boiler exit (chimney inlet)

Flow into the chimney (T = 270.3 °C) 17.877 m³/s

Gas temperature 270.315 °C

Gas specific volume 2.056 m³/kg

Gas density 0.486 kg/m³

Gas specific heat capacity 1.158 kJ/kg K

Chimney...

Flow into the chimney (@ T and P) 17.877 m³/s

Chimney normal flow 7.363 Nm³/s

Maximum chimney diameter 1646 mm

Suggested chimney top exit diamter 823 mm

Min. chimney exit velocity (BS clean air act) 8.4 m/s

dp.txt[2021-01-18 4:12:14 PM]

Chimney velocity(Stack ID= 1600 mm) 8.9 m/s

Chimney exit velocity(Cone ID= 830 mm) 33.0 m/s

Ducting...

Duct velocity limit (32888 kg/h) 0.0 m/s

Forced draught fan...

FD fan volume 9.119 m³/s

FD fan pressure drop 249.000 Pa

Absorbed power of FD fan impellor 3493.3 W

FD air temperature 27.0 °C

Gas constant for moist air 288.5 J/kg K

Air molecular weight 29.0

Specific volume 1.0511 m³/kg

Specific heat capacity 1.021 kJ/kg K

Density 0.951 kg/m³

Mass flow 8.676 kg/s

FD purge time (Satronic 3 air changes) 0 seconds

FD purge time (Honeywell 4 air changes at 50%) 0 seconds

No secondary air requirement.

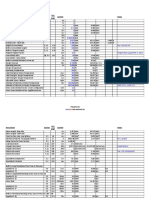

UFGS- Test block (design point)

ID/FD Fan - flow margin 10.0 % over

ID/FD Fan - static pressure margin 20.0 % over

FD Fan - temperature margin 25.0 °F over

L10 Bearing life 100000 hours

Ducting design pressure...

Operating positive pressure (FD on, ID off) 249.0 Pa

Operating negative pressure (FD off, ID on) 974.1 Pa

NFPA 85 Sect' 6.5.1.3.2.1, positive 8700.0 Pa 35.0 in W.G.

Or the test block capability of the FD fan.

NFPA 85 Section 6.5.1.3.2.2, negati 8700.0 Pa 35.0 in W.G.

Or the test block capability of the ID fan.

______________________________________________________________________

Notes...

Normal Pressure 101.325 kPa 14.695 psi

Normal Temperature 0 °C 32 °F

Normal Temperature 273.15 K 491.67 R

AMCA (fans) standard for air...

Pressure 101.325 kPa 14.695 psi

Pressure 759.968 mm Hg 29.920 in Hg

Density 1.201 kg/m³ 0.075 lb/ft³

Temperature 21.111 °F 70.000 °C

Standards

AMCA Publication 201-02 (R2011) - Fans and Systems

AMCA Publication 303-79 (R2012) - Application of Sound Power Level Ratings for Fans

AMCA Publication 850-02 (R2011) - Heavy Duty Dampers for Isolation and Control

ANSI/AMCA Standard 204-05 (R2012) - Balance Quality and Vibration Levels for Fans

ANSI/AMCA Standard 320-08 (R2013) - Laboratory Method of Sound Testing of Fans Using Sound Intensity

dp.txt[2021-01-18 4:12:14 PM]

ANSI/AMCA Standard 500-L-12 - Laboratory Methods of Testing Louvers for Rating

ANSI/AMCA Standard 803-02 (R2008) - Industrial Process/Power Generation Fans: Site Performance Test Standard

ISO 1940 - Mechanical vibration — Balance quality requirements for rotors in a constant (rigid) state —

Part 1: Specification and verification of balance tolerances

ISO 14694 (2003) - Industrial fans — Specifications for balance quality and vibration levels

______________________________________________________________________

dp.txt[2021-01-18 4:12:14 PM]

You might also like

- Burner CalculationDocument6 pagesBurner CalculationAnonymous 3ESYcrKP100% (4)

- TBG 616Document4 pagesTBG 616sdiaman50% (2)

- Plant Design of Cryogenic Distillation of Air To Oxygen and NitrogenDocument34 pagesPlant Design of Cryogenic Distillation of Air To Oxygen and Nitrogenkumar100% (1)

- Chapter 1,2Document25 pagesChapter 1,2Илья СергеевNo ratings yet

- Centrifugal Compresor CalculationDocument2 pagesCentrifugal Compresor CalculationgrabettyNo ratings yet

- Controlled Blasting Techniques: National Institute of Technology Karnataka, SurathkalDocument17 pagesControlled Blasting Techniques: National Institute of Technology Karnataka, SurathkalNikhil Ranjan0% (1)

- Chapter - 1 Stress and Strain PDFDocument21 pagesChapter - 1 Stress and Strain PDFAnonymous rT6y7298% (44)

- Tank Venting Requirements (API 2000) 2Document3 pagesTank Venting Requirements (API 2000) 2RubensBoerngenNo ratings yet

- Tank Venting API 2000Document3 pagesTank Venting API 2000Gusfi CarsurinNo ratings yet

- 00 Hvac CalcDocument71 pages00 Hvac CalcnapoNo ratings yet

- TBG616K PDFDocument4 pagesTBG616K PDFTyler GoodwinNo ratings yet

- Tanks Venting CalcDocument2 pagesTanks Venting CalcChitu Ionut-LaurentiuNo ratings yet

- R2 00 MGS2800HV (50Hz 10kV)Document4 pagesR2 00 MGS2800HV (50Hz 10kV)luat1983No ratings yet

- Anggi Bagus FixDocument23 pagesAnggi Bagus FixAbdul QodirNo ratings yet

- 00 HVAC CalcDocument52 pages00 HVAC Calcibson045001256No ratings yet

- Tính Toán Phòng MáyDocument4 pagesTính Toán Phòng MáyTuấnNo ratings yet

- InstDocument60 pagesInstTyronNo ratings yet

- Burner CalculationDocument11 pagesBurner CalculationBùi Hắc HảiNo ratings yet

- All in One HVAC Calculation 1Document51 pagesAll in One HVAC Calculation 1Youssry Elsayed Mohamed100% (2)

- Model Calculation NKarthickDocument24 pagesModel Calculation NKarthickSeenu Hassan100% (2)

- 00 HVAC CalcDocument51 pages00 HVAC CalcMd HossainNo ratings yet

- All HVAC CalculationDocument52 pagesAll HVAC CalculationSlam Hassan100% (1)

- Cyclonic Furnace Sizing ExampleDocument4 pagesCyclonic Furnace Sizing ExampleRufus D SNo ratings yet

- Tbg620k 50hz enDocument4 pagesTbg620k 50hz enEhsanur RahmanNo ratings yet

- Heat BalenceDocument544 pagesHeat BalenceSantanu PachhalNo ratings yet

- The Process IGSDocument8 pagesThe Process IGSFaiz Ziafumi Kura'No ratings yet

- Turbine Heat Rate and EfficiecyDocument48 pagesTurbine Heat Rate and EfficiecyPralay Raut100% (10)

- 1) Flow: 239869283.xls - Ms - Office Piping Pressure Drop and Pump Design Calculation SheetDocument4 pages1) Flow: 239869283.xls - Ms - Office Piping Pressure Drop and Pump Design Calculation SheetHemantk8731100% (1)

- Nad 5830 DC enDocument3 pagesNad 5830 DC enmnezamiNo ratings yet

- Steam Calculation On Basis of Flow-Temperature (1) 2222Document5 pagesSteam Calculation On Basis of Flow-Temperature (1) 2222hmaza shakeelNo ratings yet

- TBG 620Document4 pagesTBG 620sdiamanNo ratings yet

- MGS2800B (2.500 - 2.750 kVA)Document4 pagesMGS2800B (2.500 - 2.750 kVA)kesitiNo ratings yet

- Unit - 1 16 Marks Questions and Answers PDFDocument24 pagesUnit - 1 16 Marks Questions and Answers PDFGopi RaguNo ratings yet

- Boiler ManualDocument68 pagesBoiler ManualAnwar AliNo ratings yet

- Nad 5938 DC enDocument4 pagesNad 5938 DC enmnezamiNo ratings yet

- ZainalDocument23 pagesZainalAbdul QodirNo ratings yet

- Burner Operating and Flame Momentum Calculation: InputsDocument6 pagesBurner Operating and Flame Momentum Calculation: InputsIrfan Ullah100% (2)

- Computations of Estimated EmissionDocument4 pagesComputations of Estimated EmissionYtterbiteNo ratings yet

- Package Hygienic Air Handling Units: - PHK SeriesDocument6 pagesPackage Hygienic Air Handling Units: - PHK SeriesTanveer AzizNo ratings yet

- Fan Efficiency CalculatorDocument109 pagesFan Efficiency CalculatorSantanu Pachhal100% (1)

- KelomplkDocument23 pagesKelomplkAbdul QodirNo ratings yet

- Blank Calculation Sheet of Steam Turbine Test RigDocument14 pagesBlank Calculation Sheet of Steam Turbine Test Rigchaitanyakshirsagar2001No ratings yet

- 250 HP Engine For Unmanned HelicopterDocument52 pages250 HP Engine For Unmanned HelicopteryanfengzhangNo ratings yet

- V5 RatioMatic RM0200 Datasheet 110-3 A4 PDFDocument4 pagesV5 RatioMatic RM0200 Datasheet 110-3 A4 PDFcarlosloucaoNo ratings yet

- Air CompDocument1 pageAir CompHsein WangNo ratings yet

- Calculated Primary Air Flow and MomentumDocument4 pagesCalculated Primary Air Flow and MomentummadhuNo ratings yet

- 4.HVAC and Refrigeration SystemDocument32 pages4.HVAC and Refrigeration SystemPrudhvi RajNo ratings yet

- Steam Trap & InsulationDocument16 pagesSteam Trap & InsulationArindomNo ratings yet

- SKS Separator CalculationDocument18 pagesSKS Separator CalculationPramod Kumar100% (2)

- GT Class TKGTPSDocument84 pagesGT Class TKGTPSGnanaseharan Arunachalam100% (1)

- Chimney Design CalcDocument5 pagesChimney Design CalcDenny ThomasNo ratings yet

- All in One HVAC CalculationDocument52 pagesAll in One HVAC CalculationAli TekinNo ratings yet

- NT 2178 GKDocument3 pagesNT 2178 GKAlla weerNo ratings yet

- شيتات تربوDocument15 pagesشيتات تربومحمد عفيفىNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- Superheat HeaderDocument2 pagesSuperheat HeaderRufus D SNo ratings yet

- 8000.1700 - Wood - 30% Moisture - 8760 HoursDocument1 page8000.1700 - Wood - 30% Moisture - 8760 HoursRufus D SNo ratings yet

- 0574 - CR240-80Document2 pages0574 - CR240-80Rufus D SNo ratings yet

- Chimney CodesDocument3 pagesChimney CodesRufus D SNo ratings yet

- 0611 - HPS200-250Document2 pages0611 - HPS200-250Rufus D SNo ratings yet

- 0234 - Chimney Structural - R0Document7 pages0234 - Chimney Structural - R0Rufus D SNo ratings yet

- 0259 - HMIP Chimney HeightDocument1 page0259 - HMIP Chimney HeightRufus D SNo ratings yet

- 0611 - WindLoads-R2Document2 pages0611 - WindLoads-R2Rufus D SNo ratings yet

- SMACNA - Panel CalcsDocument4 pagesSMACNA - Panel CalcsRufus D SNo ratings yet

- Rectangular Expansion Joint: Description Section PDF Symbol NotesDocument3 pagesRectangular Expansion Joint: Description Section PDF Symbol NotesRufus D SNo ratings yet

- Compressor Surge ControlDocument8 pagesCompressor Surge ControlSIVA100% (2)

- Auto Collimator: by S.Krishna Moorthy (0201)Document19 pagesAuto Collimator: by S.Krishna Moorthy (0201)Moham'medAlthafAs'lamNo ratings yet

- Plastic Manufacturing ProcessesDocument6 pagesPlastic Manufacturing ProcessesHimanshu TiwariNo ratings yet

- Edible Water PodsDocument2 pagesEdible Water PodsDivyashini Mohan100% (1)

- CONSTANT OY K Oils EN enDocument4 pagesCONSTANT OY K Oils EN enSiska JozefNo ratings yet

- Advanced Structures: Amatul Wasey 14131AA001Document27 pagesAdvanced Structures: Amatul Wasey 14131AA001amatul waseyNo ratings yet

- Selina Concise Physics Class 7 ICSE Solutions - SoundDocument10 pagesSelina Concise Physics Class 7 ICSE Solutions - Soundpal.pallav9457100% (1)

- Simulation of Combustion Hybrid Rocket EngineDocument43 pagesSimulation of Combustion Hybrid Rocket EngineFabio BosioNo ratings yet

- En Akraplast Brochure AkrathermDocument2 pagesEn Akraplast Brochure AkrathermPrabartak DasNo ratings yet

- Cross-Hole Seismic TestDocument13 pagesCross-Hole Seismic TestTariq SaleemNo ratings yet

- Integral Railway Bridgesin GermanyDocument10 pagesIntegral Railway Bridgesin GermanyTamaduianu IoanNo ratings yet

- S2-Finite Element Analysis For Geomechanics (516) .Text - MarkedDocument2 pagesS2-Finite Element Analysis For Geomechanics (516) .Text - MarkedHari RamNo ratings yet

- Contract Provison of Hook-Up and Commisioning of Petronas Carigali For YEAR 2012-2018Document6 pagesContract Provison of Hook-Up and Commisioning of Petronas Carigali For YEAR 2012-2018Faiz IshakNo ratings yet

- 4 Catalog LeyboldDocument15 pages4 Catalog LeyboldAnshul JainNo ratings yet

- Ficha Tecnica Ultraform N2320 003Document2 pagesFicha Tecnica Ultraform N2320 003adrbimNo ratings yet

- Q2 Genphysics1 ReviewerDocument11 pagesQ2 Genphysics1 ReviewerRhonavie RangasaNo ratings yet

- Aera - Fan Coil ENDocument20 pagesAera - Fan Coil ENmister_no34No ratings yet

- MH Catalog Fuel Filters enDocument42 pagesMH Catalog Fuel Filters enerwerwerwerwewytiygNo ratings yet

- Course Summary ATASDocument2 pagesCourse Summary ATASWinstonNo ratings yet

- Inter Plant Standardization - Steel IndustryDocument20 pagesInter Plant Standardization - Steel Industrythiru_jsrNo ratings yet

- Midea - Rooftop Package - 5-30 Ton - Creator - 20200928 - V1-b2cfdDocument18 pagesMidea - Rooftop Package - 5-30 Ton - Creator - 20200928 - V1-b2cfdsamorayNo ratings yet

- CAPE Chemistry U1 - Breakdown of SyllabusDocument24 pagesCAPE Chemistry U1 - Breakdown of SyllabusJevon SiddonNo ratings yet

- Lecture No. 5 Phase DiagramDocument32 pagesLecture No. 5 Phase DiagramarslanNo ratings yet

- Three Point Bending Test and Finite Element Analysis 20110103howDocument8 pagesThree Point Bending Test and Finite Element Analysis 20110103howDanielNo ratings yet

- Pipes & Fittings: PricelistDocument18 pagesPipes & Fittings: PricelistMitrasNo ratings yet

- Som QuestionDocument5 pagesSom QuestionjayakumarNo ratings yet

- 03 RockDocument217 pages03 RockYernar Tiyntayev100% (1)

- How Do Earthquakes FormDocument4 pagesHow Do Earthquakes FormMonaoray BalowaNo ratings yet