Flash & Fire Point

Flash & Fire Point

Uploaded by

Harsh ThakurCopyright:

Available Formats

Flash & Fire Point

Flash & Fire Point

Uploaded by

Harsh ThakurCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Flash & Fire Point

Flash & Fire Point

Uploaded by

Harsh ThakurCopyright:

Available Formats

Flash Point & Fire Point Determination

Aim:

To find the flash and fire point of the given oil sample

Theory:

Flash point is the lowest temperature, to which oil must be heated before its vapour,

when mixed with air, will ignite but not continue to burn. The fire point is the temperature at

which oil combustion will be sustained.

The flash and fire points are useful in determining a oils volatility and fire resistance.

The flash point can be used to determine the transportation and storage temperature

requirements for oils. Oil producers can also use the flash point to detect potential product

contamination. Oil exhibiting flash point significantly lower than normal will be suspected of

contamination with volatile product. Products with a flash point less than 38 C (100F) will

usually require special precautions for safe handling. The fire point for oil is usually 8 to 10

percent above the flash point. The flash point and fire point should not be confused with the

auto-ignition temperature of oil, which is the temperature at which a oil will ignite

spontaneously without an external ignition source.

Measuring the flash & fire point:

There are two basic types of flash & fire point measurement: open cup and closed cup.

In open cup devices the sample is contained in an open cup which is heated, and at intervals a

flame is brought over the surface. The measured flash point will actually vary with the height

of the flame above the liquid surface, and at sufficient height the measured flash point

temperature will coincide with the fire point. The best known example is the Cleveland open

cup (COC).

Figure 1.Cleveland Open Cup (COC) Apparatus

There are two types of closed cup testers: non-equilibrium, such as Pensky-Martens where

the vapours above the liquid are not in temperature equilibrium with the liquid, and

equilibrium, such as Small Scale (commonly known as Seta flash) where the vapours are

deemed to be in temperature equilibrium with the liquid. In both these types the cups are

sealed with a lid through which the ignition source can be introduced. Closed cup testers

normally give lower values for the flash point than open cup (typically 5-10 °C) and are a

better approximation to the temperature at which the vapour pressure reaches the lower

flammable limit (LFL).The apparatus here used is Cleveland open cup (COC)

Procedure:

1. Throughly clean and dry all parts of the cup and its accessories before starting the test,

being sure to remove any solvent which had been used to clean the apparatus.

2. Fill the given oil sample up to the mark in the cup which placed upon and insert the

thermometer

3. Switch on the heater, ignite the test flame and monitor the temperature

o

4.When the temperature rises to within up to 15 C of the anticipated flash point ,the test

flame is dipped in to oil vapour for about 2 seconds at every degree rise in the temperature.

NOTE: Don’t make any direct contact with oil sample with test flame; make contact only

with oil vapours. Oil in test is highly inflammable and direct contact may lead to fire

hazard.

5. Record the temperature as a flash point at the time when test flame applied causes a

distinct flash in the interior of the cup.

o

6. The oil sample is further heated and introduction of test flame is done for every 1 C rise in

temperature of oil sample.

7. The temperature at which vapours of the oil sample gives a clear and distinct blue flash

have to be noted as fire point of the oil.

Result:

(i) The Flash point of the given oil sample = o C

(ii) The Fire point of the given oil sample = o C

You might also like

- AssesmentDocument15 pagesAssesmentsubburaj40% (5)

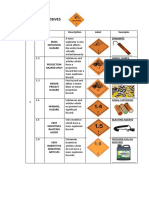

- Class 1 Explosives: Class/ Divisions Description Label Examples DynamiteDocument6 pagesClass 1 Explosives: Class/ Divisions Description Label Examples DynamiteRhyze Leiane OrtizNo ratings yet

- Flash and Fire PointDocument3 pagesFlash and Fire Pointಸಎಸ್100% (1)

- Flash and Fire Point of Lubricant ExperimentDocument5 pagesFlash and Fire Point of Lubricant ExperimentShanti Kiran Z100% (1)

- Flash and Fire Point (Pensky Martens Closed Cup Apparatus) : Experiment No: 1Document65 pagesFlash and Fire Point (Pensky Martens Closed Cup Apparatus) : Experiment No: 1Pranay SudhanNo ratings yet

- Flash Point ApparatusDocument5 pagesFlash Point ApparatusKavindu UmayangaNo ratings yet

- Practical Petroleum Properties Lab. 2 Year Level: University of ZakhoDocument7 pagesPractical Petroleum Properties Lab. 2 Year Level: University of ZakhoMalik ZainNo ratings yet

- Flash Anf Fire PointDocument8 pagesFlash Anf Fire PointMUHAMMAD AKRAM100% (2)

- Abel'S Flash and Fire Point: Apparartus RequiredDocument2 pagesAbel'S Flash and Fire Point: Apparartus RequiredMuddukrishna C ShettyNo ratings yet

- 01. Flash n Fire PointDocument8 pages01. Flash n Fire Pointryu42tmxqfNo ratings yet

- JC MeDocument61 pagesJC Mev sharvan kumar asst.prof(mech)No ratings yet

- Fuels Lubricants Lab ManualDocument60 pagesFuels Lubricants Lab ManualAbdurabu AL-MontaserNo ratings yet

- Lab - Manual Bt-101 (Chemistry)Document39 pagesLab - Manual Bt-101 (Chemistry)Krishna MahajanNo ratings yet

- ECE Lab ManualDocument73 pagesECE Lab ManualPrasad ChamarajanagarNo ratings yet

- Flash PointDocument10 pagesFlash PointellilNo ratings yet

- Wa0000.Document2 pagesWa0000.AkasH BinDNo ratings yet

- FL Lab ManualDocument24 pagesFL Lab Manualv sharvan kumar asst.prof(mech)No ratings yet

- Flash PointDocument10 pagesFlash Pointvv vvNo ratings yet

- Acropolis Institute of Technology & Research, Indore: BT101 Engg ChemistryDocument6 pagesAcropolis Institute of Technology & Research, Indore: BT101 Engg ChemistryTanmay Jain100% (1)

- Flash Point and Fire PointDocument3 pagesFlash Point and Fire PointM ZarakNo ratings yet

- Flash PointDocument8 pagesFlash Pointمحمود محمدNo ratings yet

- Flash Point and Fire PointDocument10 pagesFlash Point and Fire Pointahmed tobaNo ratings yet

- Able's ApparatusDocument2 pagesAble's ApparatusRaghu Ram100% (1)

- Scan 04 Feb 2021Document4 pagesScan 04 Feb 2021Sreeramya NairNo ratings yet

- PRE Lab-Manual - Doc NewDocument37 pagesPRE Lab-Manual - Doc NewSOURABH GANGWARNo ratings yet

- Experiment No. 6Document8 pagesExperiment No. 6JunNo ratings yet

- Experiment NO 2Document5 pagesExperiment NO 2jdedfvNo ratings yet

- Balitian - Me Lab - Exp5Document9 pagesBalitian - Me Lab - Exp5JB_0929No ratings yet

- Fuel TestsDocument33 pagesFuel Testsmuhammad.ali.shehzad22No ratings yet

- B.tech. Engineering ExpDocument39 pagesB.tech. Engineering ExpMr. CuriousNo ratings yet

- Property Lab 6Document5 pagesProperty Lab 6Lulav BarwaryNo ratings yet

- Abel's Flash Point Apparatus.Document5 pagesAbel's Flash Point Apparatus.sunil100% (1)

- King Khalid University College of Engineering Department of Chemical EngineeringDocument9 pagesKing Khalid University College of Engineering Department of Chemical EngineeringbaderNo ratings yet

- Flash and Fire PointDocument6 pagesFlash and Fire Pointabth99No ratings yet

- Activity 3 - Properties of Organic Compounds (Boiling and Melting Point)Document4 pagesActivity 3 - Properties of Organic Compounds (Boiling and Melting Point)ariesjay.reyesNo ratings yet

- II. Properties of Fuels Density, Specific Volume and Specific GravityDocument24 pagesII. Properties of Fuels Density, Specific Volume and Specific Gravitybaeby chuNo ratings yet

- Flash Point TemperatureDocument6 pagesFlash Point TemperatureDilhan RajasekaraNo ratings yet

- Experiment No. 5 PDFDocument9 pagesExperiment No. 5 PDFJanrelle SagumNo ratings yet

- Abel Flash Point Apparatus: INDLAB Equipments PVT LTD Fuel Laboratory 1Document2 pagesAbel Flash Point Apparatus: INDLAB Equipments PVT LTD Fuel Laboratory 1koushikaerosNo ratings yet

- Fuel Property TestingDocument3 pagesFuel Property TestingGorilla GrooveNo ratings yet

- Property Lab 3Document5 pagesProperty Lab 3Lulav BarwaryNo ratings yet

- Flash Point by Abel's ApparatusDocument3 pagesFlash Point by Abel's ApparatusAbhishek JoshiNo ratings yet

- 06 Flash and Fire PointDocument9 pages06 Flash and Fire PointanmarNo ratings yet

- Petroleum Product Testing Lab ManualDocument40 pagesPetroleum Product Testing Lab ManualVishesh Sharma100% (1)

- Fire and Flash PointDocument4 pagesFire and Flash PointAnonymous BNa0nEHNo ratings yet

- Flash PointDocument6 pagesFlash PointAbhilash AbhiNo ratings yet

- Lab ManualDocument24 pagesLab ManualBHAVISHA GOHILNo ratings yet

- Experiment 1 Determination of Flash PointDocument7 pagesExperiment 1 Determination of Flash Pointismat irfanNo ratings yet

- Flash and Fire Point TestDocument7 pagesFlash and Fire Point TestAisyah Ibrahim89% (18)

- Thermal Engineering Practical (N - Scheme)Document93 pagesThermal Engineering Practical (N - Scheme)vk2836815No ratings yet

- Property Lab 3Document5 pagesProperty Lab 3Lulav BarwaryNo ratings yet

- Experiment 2Document12 pagesExperiment 2Ria Divine Dela CruzNo ratings yet

- Koya University Faculty of Engineering Chemical Engineering DepDocument10 pagesKoya University Faculty of Engineering Chemical Engineering Depahmed tobaNo ratings yet

- OrgChem Prelim ManualDocument13 pagesOrgChem Prelim ManualCHEA MICH L. ABELLANONo ratings yet

- Pensky Marten ApparatusDocument2 pagesPensky Marten Apparatusghambira100% (6)

- Chapter 2-2Document18 pagesChapter 2-2Ameer AlawadiNo ratings yet

- Dutch Oven for Two: 40 Healthy One-Pot Recipes and Dump Meals for Indoor Dutch Oven Cooking: Dump Meals for TwoFrom EverandDutch Oven for Two: 40 Healthy One-Pot Recipes and Dump Meals for Indoor Dutch Oven Cooking: Dump Meals for TwoNo ratings yet

- Dutch Oven Cooking: 30 Mouthwatering Dutch Oven, One Pot Recipes for Quick and Easy Campfire Meals: Outdoor CookingFrom EverandDutch Oven Cooking: 30 Mouthwatering Dutch Oven, One Pot Recipes for Quick and Easy Campfire Meals: Outdoor CookingNo ratings yet

- Learn to Drive: Everything New Drivers Need to KnowFrom EverandLearn to Drive: Everything New Drivers Need to KnowRating: 4 out of 5 stars4/5 (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Ie SeDocument42 pagesIe SeSwati PathakNo ratings yet

- Going To - Do TëDocument3 pagesGoing To - Do TëjehonaNo ratings yet

- I8160 Image en 3818 Neu 08 18 WebDocument21 pagesI8160 Image en 3818 Neu 08 18 WebFarhan MalekNo ratings yet

- Free Log1ns - pw1580Document18 pagesFree Log1ns - pw1580Katraj NawazNo ratings yet

- Static Data Member and Static Data FunctionDocument15 pagesStatic Data Member and Static Data Functionbunsbunny1980No ratings yet

- Leap MotionDocument10 pagesLeap Motionsunilms84No ratings yet

- Din 2462Document14 pagesDin 2462Grcic NamenskaNo ratings yet

- Picture Books Plus MathDocument6 pagesPicture Books Plus Mathkassandraroaspcmoi21No ratings yet

- PST Jest Preparation: 1. Which Country Is Called "Land of Snow"?Document13 pagesPST Jest Preparation: 1. Which Country Is Called "Land of Snow"?Kaleem RazaNo ratings yet

- ELL 100 Introduction To Electrical Engineering: Ecture Perational MplifiersDocument72 pagesELL 100 Introduction To Electrical Engineering: Ecture Perational Mplifierskurnia setiyawanNo ratings yet

- Journal of Rock Mechanics and Geotechnical Engineering: Luis-Fernando Contreras, Edwin T. BrownDocument16 pagesJournal of Rock Mechanics and Geotechnical Engineering: Luis-Fernando Contreras, Edwin T. BrownCimentaciones Geotecnia RiveraNo ratings yet

- DotfilescgggbDocument23 pagesDotfilescgggbcygratecNo ratings yet

- HP Catalog 1992Document732 pagesHP Catalog 1992moocomNo ratings yet

- Data Collecting From Smart Meters in An Advanced Metering InfrastructureDocument6 pagesData Collecting From Smart Meters in An Advanced Metering Infrastructurekedar majethiyaNo ratings yet

- Standards For Efficiency of Electric Motors: IEEE Industry Applications Magazine March 2011Document9 pagesStandards For Efficiency of Electric Motors: IEEE Industry Applications Magazine March 2011Ahmet Yasin BaltacıNo ratings yet

- Report Major Project by ShubhamDocument45 pagesReport Major Project by ShubhamYash KakranNo ratings yet

- Mayamalavagowla: Swaraas - SequencesDocument5 pagesMayamalavagowla: Swaraas - SequencesSpoorthy KrishnaNo ratings yet

- Designs of CMOS Multi-Band Voltage Controlled Oscillator Using Active InductorsDocument4 pagesDesigns of CMOS Multi-Band Voltage Controlled Oscillator Using Active Inductorsrahms79No ratings yet

- Question Paper Periodic Table Elements and Physical ChemistryDocument32 pagesQuestion Paper Periodic Table Elements and Physical ChemistryChi Wang LAWNo ratings yet

- Celebrating40YearsofPanelDataAnalysis PastPresentandFuture MUDocument22 pagesCelebrating40YearsofPanelDataAnalysis PastPresentandFuture MUPiraNo ratings yet

- FLC Contisys Obd User Manual Ver5 0 0enDocument162 pagesFLC Contisys Obd User Manual Ver5 0 0enOctavio LópezNo ratings yet

- TDS PLASMA RemoteDocument1 pageTDS PLASMA Remotepradeep rawatNo ratings yet

- Time Value of MoneyDocument35 pagesTime Value of MoneypptdineshNo ratings yet

- Flexible, Number Coded, Meter MarkingDocument2 pagesFlexible, Number Coded, Meter MarkingJosé LopesNo ratings yet

- Dokumen - Tips - b100 Series User Manual Dynamic Ratings b100 Series User Manual Rev 1Document37 pagesDokumen - Tips - b100 Series User Manual Dynamic Ratings b100 Series User Manual Rev 1Marco CornelioNo ratings yet

- Fluid Mechanics Past Exam AnswersDocument4 pagesFluid Mechanics Past Exam AnswersOsarieme OsakueNo ratings yet

- Workshop 4-1: Radiation Boundaries: ANSYS HFSS For Antenna DesignDocument30 pagesWorkshop 4-1: Radiation Boundaries: ANSYS HFSS For Antenna DesignRicardo MichelinNo ratings yet

- A New Yorker in TondoDocument13 pagesA New Yorker in TondoJessa LiNo ratings yet