4.12 Complete Joint Penetration (CJP) Groove Welds For Thbular Connections

4.12 Complete Joint Penetration (CJP) Groove Welds For Thbular Connections

Uploaded by

Ibrahim shaikOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4.12 Complete Joint Penetration (CJP) Groove Welds For Thbular Connections

4.12 Complete Joint Penetration (CJP) Groove Welds For Thbular Connections

Uploaded by

Ibrahim shaikCopyright:

Available Formats

QUALIFICATION AWS 01.

1 :2000

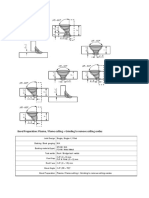

4.11.2 Fillet Weld Test. A fillet welded T-joint, as 4.12 Complete Joint Penetration

shown in Figure 4.19 for plate or Figure 4.20 for pipe

(Detail A or Detail B), shall be made for each WPS and

(CJP) Groove Welds for Thbular

position to be used in construction. One test weld shall Connections

be the maximum size single-pass fillet weld and one test

CJP groove welds shall be classified as follows:

weld shall be the minimum size multiple-pass fillet weld

used in construction. These two fillet weld tests may be (1) CJP butt joints with backing or backgouging (see

combined in a single test weldment or assembly. The 4.12.1 ).

weldment shall be cut perpendicular to the direction of (2) CJP butt joints without backing welded from one

welding at locations shown in Figure 4.19 or Figure 4.20 side only (see 4.12.2).

as applicable. Specimens representing one face of each (3) T-, Y-, K-connections with backing or backgoug-

cut shall constitute a macroetch test specimen and shall ing (see 4.12.3).

be tested in accordance with 4.8.4. (4) T-, Y-, K-connections without backing welded

from one side only (see 4.12.4).

4.11.3 Consumables Verification Test. If both the pro-

posed welding consumable and the proposed WPS for 4.12.1 Complete Joint Penetration (CJP) Butt Joints

welding the fillet weld test plate or test pipe prescribed in with Backing or Backgouging. A WPS with backing or

4.11.2 are neither prequalified nor otherwise qualified by backgouging shall be qualified using the detail shown in

section 4, that is: Figure 4.24 (with backgouging) or Figure 4.25 (with

backing).

(1) If the welding consumables used do not conform

to the prequalified provisions of section 3, and also 4.12.2 Complete Joint Penetration (CJP) Butt Joints

(2) If the WPS using the proposed consumable has without Backing Welded from One Side Only. A WPS

not been established by the contractor in accordance with without backing welded from one side only shall be qual-

either 4.9 or 4.10, then a complete joint penetration ified using the joint detail shown in Figure 4.24.

groove weld test plate shall be welded to qualify the pro-

posed combination. 4.12.3 T-, Y-, or K-Connections with Backing or

The test plate shall be welded as follows: Backgouging. A WPS for tubular T-, Y-, or K-connec-

tions with backing or backgouging shall be qualified

(1) The test plate shall have the groove configuration

using:

shown in Figure 4.21 (Figure 4.22 for SAW), with steel

backing. (1) the appropriate nominal pipe 00 selected from

Table 4.2(2), and

(2) The plate shall be welded in the 1G (flat) position.

(3) The plate length shall be adequate to provide the (2) the joint detail of Figure 4.25, or

test specimens required and oriented as shown in Figure (3) for nominal pipe ODs equal to or greater than

4.23. 24 in. (600 mm), a plate qualification in conformance

(4) The welding test conditions of current, voltage, with 4.9 using the joint detail of Figure 4.25.

travel speed, and gas flow shall approximate those to be

4.12.4 T-, Y-, or K-Connections without Backing

used in making production fillet welds as closely as

Welded from One Side Only. A WPS that conforms to

practical.

the prequalified requirements of section 3 shall be ex-

These conditions establish the WPS from which, empt from qualification testing. When qualification is re-

when production fillet welds are made, changes in essen- quired, the requirements are as follows:

tial variables will be measured in conformance with 4.7.

The test plate shall be tested as follows: 4.12.4.1 WPSs without Prequalified Status. For a

(1) Two side bend (Figure 4.13) specimens and one WPS whose essential variables are outside the prequali-

all-weld-metal tension (Figure 4.18) test specimen shall fied range, qualification for complete joint penetration

be removed from the test plate, as shown in Figure 4.23. tubular groove welds shall require the following:

(2) The bend test specimens shall be tested in con- (1) Qualification in conformance with Figure 4.27 for

formance with 4.8.3.1. Those test results shall conform pipes or Figure 4.27 and Figure 4.28 for box tubes.

to the requirements of 4.8.3.3. (2) A Sample Joint or Tubular Mock-up. The sample

(3) The tension test specimen shall be tested in con- joint or tubular mock-up shall provide at least one mac-

formance with 4.8.3.6. The test result shall determine the roetch test section for each of the following conditions:

strength level for the welding consumable, which shall (a) The groove combining the greatest groove

conform to the requirements of Table 2.3 or the base depth with the smallest groove angle, or combination of

metal strength level being welded. grooves to be used: test with welding position vertical.

129

You might also like

- Kristen Proby - Safe With Me HalloweenDocument8 pagesKristen Proby - Safe With Me HalloweenryujiLLNo ratings yet

- AWS D1.2 at Extent of TestingDocument1 pageAWS D1.2 at Extent of TestingIbrahim shaikNo ratings yet

- Chapter 4 Section Design For MomentDocument60 pagesChapter 4 Section Design For MomentdavidNo ratings yet

- AWS D17.1 WPQR Guides PDFDocument2 pagesAWS D17.1 WPQR Guides PDFTAGUI100% (3)

- Modul Tambahan Kualifikasi Las (KL)Document27 pagesModul Tambahan Kualifikasi Las (KL)Nurhamsyah Susianto0% (1)

- AWS D1.1-D1.1M-2015 - Pagina-110Document1 pageAWS D1.1-D1.1M-2015 - Pagina-110Gedalías MartínezNo ratings yet

- 3.6 Visual Examination: Part B Types of Tests, Test Methods, and Acceptance CriteriaDocument1 page3.6 Visual Examination: Part B Types of Tests, Test Methods, and Acceptance CriteriaIbrahim shaikNo ratings yet

- Extracted Pages From ASME BPVC 2021 Section IX-2Document2 pagesExtracted Pages From ASME BPVC 2021 Section IX-2Roberto Carlos Arana ChumpitazNo ratings yet

- Table 4.1 WPS Qualification-Production Welding Positions Qualified by Plate, Pipe, and Box Tube Tests (See 4.3)Document1 pageTable 4.1 WPS Qualification-Production Welding Positions Qualified by Plate, Pipe, and Box Tube Tests (See 4.3)Mohamed AtefNo ratings yet

- Bend Test AceptenDocument1 pageBend Test AceptenArung IdNo ratings yet

- Asme Viii Div 1 2013 Cri-1Document4 pagesAsme Viii Div 1 2013 Cri-1vivicastedoNo ratings yet

- RP 2007-18 App.BDocument24 pagesRP 2007-18 App.BdrailotaNo ratings yet

- Pages From Asme Sec Ix 2017Document1 pagePages From Asme Sec Ix 2017Akhtar Ansari0% (1)

- Moment Coupler - Codal RequirementsDocument3 pagesMoment Coupler - Codal Requirementskvamshi_1971No ratings yet

- Module 1: Code Basics: Part QW WeldingDocument12 pagesModule 1: Code Basics: Part QW WeldingaliNo ratings yet

- ASME IX Temper Bead WeldingDocument4 pagesASME IX Temper Bead WeldingAhmadiBinAhmadNo ratings yet

- Piling Specification 23.06.09Document8 pagesPiling Specification 23.06.09kanishkaNo ratings yet

- ASME Sec IX Groove To Fillet WeldDocument3 pagesASME Sec IX Groove To Fillet WeldAzhar Ali50% (2)

- Allowable Stress Design and Strength Design For ShearDocument36 pagesAllowable Stress Design and Strength Design For ShearMarc Jasson CalaylayNo ratings yet

- Prueba macroetch-ACV#010Document1 pagePrueba macroetch-ACV#010Jose AntonioNo ratings yet

- Astm C 900 - 01 PDFDocument8 pagesAstm C 900 - 01 PDFachmadbasisNo ratings yet

- Cyclic Behavior and Seismic Design of Bolted Flange Plate Steel Moment ConnectionsDocument12 pagesCyclic Behavior and Seismic Design of Bolted Flange Plate Steel Moment ConnectionsJoaquin PalermoNo ratings yet

- IX Exercise Rev 02 PDFDocument11 pagesIX Exercise Rev 02 PDFweerasinghekNo ratings yet

- UR W28 Welding Procedure Qualification Tests of Steels (Rev.2 Mar 2012)Document25 pagesUR W28 Welding Procedure Qualification Tests of Steels (Rev.2 Mar 2012)Dagoberto AguilarNo ratings yet

- Asme Section II A-2 Sa-476 Sa-476mDocument6 pagesAsme Section II A-2 Sa-476 Sa-476mAnonymous GhPzn1xNo ratings yet

- TighteningofStructuralBolts 31-35Document5 pagesTighteningofStructuralBolts 31-35masaud akhtarNo ratings yet

- BS 1881 Part 120 83Document8 pagesBS 1881 Part 120 83tss13723100% (1)

- WPS Guides For Plug and Slot WeldsDocument4 pagesWPS Guides For Plug and Slot WeldsBrad BorgesNo ratings yet

- Connections, Joints, and Fasteners: 7.1. ScopeDocument4 pagesConnections, Joints, and Fasteners: 7.1. ScopeQuốc KhánhNo ratings yet

- Cold-Formed Steel Frame, SarawitDocument349 pagesCold-Formed Steel Frame, SarawitSérgio MartinsNo ratings yet

- AWS D1.1 GuidesDocument7 pagesAWS D1.1 GuidesMuhammad FakhriNo ratings yet

- Ur W28rev2Document25 pagesUr W28rev2Karla JTNo ratings yet

- CH4 (1) MergedDocument231 pagesCH4 (1) Mergedأزهار برديNo ratings yet

- Reinforced Concrete DesignDocument68 pagesReinforced Concrete Designأزهار برديNo ratings yet

- Asme B31.3,341.3.4Document1 pageAsme B31.3,341.3.4mzarei_1982No ratings yet

- API 650-Impact TestDocument4 pagesAPI 650-Impact TestBashu PoudelNo ratings yet

- ASTM-A501.-Acero Carbono Soldado y Sin Tubos. Fy250MpaDocument6 pagesASTM-A501.-Acero Carbono Soldado y Sin Tubos. Fy250MparafabiobioNo ratings yet

- The Effect of Web Corrugation in Cold-Formed Steel Beam With Trapezoidally Corrugated WebDocument6 pagesThe Effect of Web Corrugation in Cold-Formed Steel Beam With Trapezoidally Corrugated WebAJER JOURNALNo ratings yet

- Vitrified Clay Pipe: T 281 Methods of Sampling and TestingDocument3 pagesVitrified Clay Pipe: T 281 Methods of Sampling and TestingricardojesussardinasalzugarayNo ratings yet

- Table 302.3.4 Longitudinal Weld Joint Quality Factor, E: ASME B31.3-2018Document32 pagesTable 302.3.4 Longitudinal Weld Joint Quality Factor, E: ASME B31.3-2018GabrielNo ratings yet

- Norma Aisc 341 (Capítulo E)Document22 pagesNorma Aisc 341 (Capítulo E)ElmerNo ratings yet

- Test Procedure A S Per EN 1994-1-1 2004 (E)Document5 pagesTest Procedure A S Per EN 1994-1-1 2004 (E)nrtparNo ratings yet

- DS 1 VOL 3 4TH Parte Dos PDFDocument8 pagesDS 1 VOL 3 4TH Parte Dos PDFsushilNo ratings yet

- Spec Tn1946Document8 pagesSpec Tn1946Kumara SubramanianNo ratings yet

- ''C496.142250 Splitting Tensile Strength of ConcreteDocument5 pages''C496.142250 Splitting Tensile Strength of ConcreteAbu Bakar Muzamil ButtNo ratings yet

- C12 - Installing Vitrified Clay Pipe LinesDocument7 pagesC12 - Installing Vitrified Clay Pipe LinesKingNo ratings yet

- API 5L 45-th Edition: Item No SawlDocument6 pagesAPI 5L 45-th Edition: Item No SawlRob WillestoneNo ratings yet

- Chapter 5: Steel: FEMA 356Document10 pagesChapter 5: Steel: FEMA 356mrea130No ratings yet

- B31.3 Code Case 178 PDFDocument16 pagesB31.3 Code Case 178 PDFmfathi1356No ratings yet

- Tube-To-Tube Sheet Joint RequirementsDocument2 pagesTube-To-Tube Sheet Joint RequirementsWaqas WaqasNo ratings yet

- 340 INSPECTION (PG 112 - 121) : Para. 302.3.3Document3 pages340 INSPECTION (PG 112 - 121) : Para. 302.3.3r_ramiresNo ratings yet

- APP169Document12 pagesAPP169bungykitNo ratings yet

- Appendix N - Prequalification of Beam-To-Column Moment ConnectionsDocument4 pagesAppendix N - Prequalification of Beam-To-Column Moment ConnectionsTarif Aziz MarufNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- Boolean Circuit Rewiring: Bridging Logical and Physical DesignsFrom EverandBoolean Circuit Rewiring: Bridging Logical and Physical DesignsNo ratings yet

- Pipe Bending: Case StudyDocument4 pagesPipe Bending: Case StudyIbrahim shaikNo ratings yet

- Univeral WPS For Pipe To Plate Fillet Welding (6800009)Document1 pageUniveral WPS For Pipe To Plate Fillet Welding (6800009)Ibrahim shaikNo ratings yet

- Pipe & Tube BrochureDocument18 pagesPipe & Tube BrochureIbrahim shaikNo ratings yet

- 2.7 Filler Plates: AWS D1.2/D1.2M:2014 Clause 2. DesignDocument1 page2.7 Filler Plates: AWS D1.2/D1.2M:2014 Clause 2. DesignIbrahim shaikNo ratings yet

- Induction Training Record - Itr: Elmar Marinas LLC PO Box 4955, Umm Al Quwain, United Arab EmiratesDocument1 pageInduction Training Record - Itr: Elmar Marinas LLC PO Box 4955, Umm Al Quwain, United Arab EmiratesIbrahim shaikNo ratings yet

- ISO 9001 2015 CluasesDocument1 pageISO 9001 2015 CluasesIbrahim shaikNo ratings yet

- Figure 4.19-Fillet Weld Soundness Tests For WPS Qualification (See 4.11.2)Document1 pageFigure 4.19-Fillet Weld Soundness Tests For WPS Qualification (See 4.11.2)Ibrahim shaikNo ratings yet

- 3.3 Qualification of Welders, Welding Operators, and Tack WeldersDocument1 page3.3 Qualification of Welders, Welding Operators, and Tack WeldersIbrahim shaikNo ratings yet

- 4.13 PJP Tubular T-, Y-, or K-Connections and Butt JointsDocument1 page4.13 PJP Tubular T-, Y-, or K-Connections and Butt JointsIbrahim shaikNo ratings yet

- 2.5 Fillet Welds: Clause 2. Design AWS D1.2/D1.2M:2014Document1 page2.5 Fillet Welds: Clause 2. Design AWS D1.2/D1.2M:2014Ibrahim shaikNo ratings yet

- Figure 4.21-Test Plate For Unlimited Thickness-Welder Qualification (See 4.23.1)Document1 pageFigure 4.21-Test Plate For Unlimited Thickness-Welder Qualification (See 4.23.1)Ibrahim shaikNo ratings yet

- Figure 4.20-Pipe Fillet Weld Soundness Test-WPS Qualification (See 4.11.2)Document1 pageFigure 4.20-Pipe Fillet Weld Soundness Test-WPS Qualification (See 4.11.2)Ibrahim shaikNo ratings yet

- Joints Edge PreparationDocument4 pagesJoints Edge PreparationIbrahim shaikNo ratings yet

- Bevel PreparationDocument1 pageBevel PreparationIbrahim shaikNo ratings yet

- Stainless Steel Socket Button and Flat Countersunk Head Cap Screws (Metric)Document6 pagesStainless Steel Socket Button and Flat Countersunk Head Cap Screws (Metric)Ibrahim shaikNo ratings yet

- MasterspecDocument11 pagesMasterspecIbrahim shaikNo ratings yet

- 14 EN 14509:2013 AVCP3: Declared Performance For IND - INDUSTRIAL Panel 1120 - 1180mmDocument1 page14 EN 14509:2013 AVCP3: Declared Performance For IND - INDUSTRIAL Panel 1120 - 1180mmIbrahim shaikNo ratings yet

- FAB-QMF-60 (Outsources Process Audit Report)Document6 pagesFAB-QMF-60 (Outsources Process Audit Report)Ibrahim shaikNo ratings yet

- Dokumen - Tips - Astm d1037 12 For Bio CompositesDocument16 pagesDokumen - Tips - Astm d1037 12 For Bio CompositesIbrahim shaikNo ratings yet

- Type Approval Certificate: Hydratight LTDDocument3 pagesType Approval Certificate: Hydratight LTDIbrahim shaikNo ratings yet

- Background:: Public Health & Safety Department Guidelines For First-Aid Requirement DM-PH&SD-P4-TG17Document4 pagesBackground:: Public Health & Safety Department Guidelines For First-Aid Requirement DM-PH&SD-P4-TG17Ibrahim shaikNo ratings yet

- En 131-2-2010+a2-2017Document6 pagesEn 131-2-2010+a2-2017Ibrahim shaik100% (1)

- Ponuda LaptopaDocument6 pagesPonuda LaptopaFranjo IličićNo ratings yet

- Scaredy Pants Encyclopedia SpongeBobia FandomDocument1 pageScaredy Pants Encyclopedia SpongeBobia FandomFarid RahmanNo ratings yet

- Fisa de Lucru EcuatiiDocument3 pagesFisa de Lucru EcuatiiMARIANA DOINA NEACSUNo ratings yet

- Project Abstract 3Document5 pagesProject Abstract 3Oni Khalid AyobamiNo ratings yet

- HJPF304040 enDocument2 pagesHJPF304040 encihanNo ratings yet

- 5 Code of Conduct & Ethical Standards 20170717Document30 pages5 Code of Conduct & Ethical Standards 20170717Maria Gracia100% (1)

- North American: Manufacturing Company, LTDDocument2 pagesNorth American: Manufacturing Company, LTDRodrigo RuizNo ratings yet

- Coagulant Tank RWTPDocument3 pagesCoagulant Tank RWTPAbu SuraisyNo ratings yet

- MASS TRANSFER - 2.weekDocument43 pagesMASS TRANSFER - 2.weekAlexNo ratings yet

- Syntax For Job Restart in 202 and 203 Server Using PuttyDocument2 pagesSyntax For Job Restart in 202 and 203 Server Using PuttyAnurag RajakNo ratings yet

- Drug Formulary 2013Document108 pagesDrug Formulary 2013Kai XinNo ratings yet

- Nandita Sahgal-Tully Managing Director ThomasLloydDocument14 pagesNandita Sahgal-Tully Managing Director ThomasLloydSid KaulNo ratings yet

- Software Engineering Unit-5Document24 pagesSoftware Engineering Unit-5rishaliNo ratings yet

- Applications of Machine and Deep Learning in Adaptive ImmunityDocument27 pagesApplications of Machine and Deep Learning in Adaptive ImmunityIrguard AdminNo ratings yet

- Operation Gladio - CIA Network of "Stay Behind" Secret ArmiesDocument14 pagesOperation Gladio - CIA Network of "Stay Behind" Secret Armiesunroman121100% (1)

- Deductive Tasting Grid March 2022Document3 pagesDeductive Tasting Grid March 2022Htin Lin KyawNo ratings yet

- BS 1722 Part 4 (Chestnut Pale Fences)Document16 pagesBS 1722 Part 4 (Chestnut Pale Fences)nandi_scrNo ratings yet

- Vitamin EDocument29 pagesVitamin ESiva Krishna NeppaliNo ratings yet

- Design and Study of Ventilation Systems PDFDocument22 pagesDesign and Study of Ventilation Systems PDFJothimanikkam SomasundaramNo ratings yet

- 2-Stroke-Porting TerminologyDocument5 pages2-Stroke-Porting TerminologyMithun Miranda100% (2)

- E-Collaboration Concepts, Systems, and Applications: July 2008Document19 pagesE-Collaboration Concepts, Systems, and Applications: July 2008NAGENDRA ANUMULANo ratings yet

- 22 - Altenhuber - Guidance For The Application of Low Voltage FusesDocument10 pages22 - Altenhuber - Guidance For The Application of Low Voltage FusesRagowo Tri WicaksonoNo ratings yet

- Department of Education: Guide For The Home Learning FacilitatorDocument8 pagesDepartment of Education: Guide For The Home Learning FacilitatorSheran Manlongat BallesterosNo ratings yet

- C348 Mathematics For General Relativity Chapters 1 and 2 (UCL)Document37 pagesC348 Mathematics For General Relativity Chapters 1 and 2 (UCL)ucaptd3No ratings yet

- Electrical Cable PriceDocument9 pagesElectrical Cable PriceDayo DweezyNo ratings yet

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument2 pagesStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalancedivaNo ratings yet

- Un Kartu Soal Submatif Xii SMKN 2 Konawe 2024Document34 pagesUn Kartu Soal Submatif Xii SMKN 2 Konawe 2024Naftali PatalaNo ratings yet

- Ds4windows Log 20230508.0Document1 pageDs4windows Log 20230508.0werferNo ratings yet

- Company Law IntroDocument38 pagesCompany Law Introgaurav singhNo ratings yet