Flexion Vigas Rectangulares +acero en Compresión - RC

Flexion Vigas Rectangulares +acero en Compresión - RC

Uploaded by

David GoñiCopyright:

Available Formats

Flexion Vigas Rectangulares +acero en Compresión - RC

Flexion Vigas Rectangulares +acero en Compresión - RC

Uploaded by

David GoñiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Flexion Vigas Rectangulares +acero en Compresión - RC

Flexion Vigas Rectangulares +acero en Compresión - RC

Uploaded by

David GoñiCopyright:

Available Formats

Materiales

f'c (kg/cm2) = 210 = 3.00 ksi

f'r (kg/cm2) = 45 = 0.64 ksi

b1 = 0.85

fy (kg/cm2) = 4200

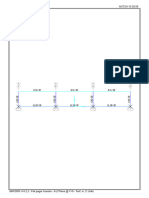

VIGA CON ACERO EN COMPRESIÓN

b (cm) = 30 30 30

h (cm) = 60 60 60

ds (cm) = 48 48 48

As = F3/4

33/4 F3/4

33/4 F3/4

33/4

31F1

d´s (cm) = 6 6 6

A´s = F3/4

33/4 F3/4

33/4 F3/4

33/4

0.75xAsbal + A´s (cm2) = 31.50 31.50 31.50 0.00 0.00

As (cm2) = 8.55 23.75 8.55 0.00 0.00

As / bd = 0.59% 1.65% 0.59% #DIV/0! #DIV/0!

A´s (cm2) = 8.55 8.55 8.55 0.00 0.00

A´s / bd = 0.53% 0.53% 0.53% #DIV/0! #DIV/0!

c (cm) = 6.70 15.12 6.70 11.73 16.49

T (kg) 35913 99758 35913 0 0

Cc (kg) 30519 68815 30519 0 0

Tc (kg) 5394 30943 5394 0 0

T-Cc-Tc=0 0.00 0.00 0.00 0.00 0.00

Tc (kg) 5394 30943 5394 0 0

et = 0.018 0.0065 0.018 -0.003 -0.003

et/ey 8.798 3.107 8.798 -1.429 -1.429

e´t = 0.000 0.002 0.000 0.003 0.003

e´t/ey 0.150 0.862 0.150 1.429 1.429

Controlada Controlada Controlada

Controlada Controlada

Condición : por por por

por tensión por tensión

tensión compresión compresión

f= 0.90 0.90 0.90 0.90 0.90

Mn (t-m) = 16.04 41.61 16.04 0.00 0.00

FMn (t-m) = 14.44 37.45 14.44 0.00 0.00

Mu (t-m) = 16 16 55 155 155

Check: No oK! No No No

MOMENTO NOMINAL OPUESTO

c´ (cm) = 10.06 10.94 10.06 6.39 12.24

T (kg) 35913 35913 35913 0 0

Cc (kg) 45797 49778 45797 0 0

Tc (kg) -9885 -13865 -9885 0 0

T-Cc-Tc=0 0.00 0.00 0.00 0.00 0.00

Tc (kg) -9885 -13865 -9885 0 0

Mn (t-m) = 15.87 15.76 15.87 0.00 0.00

FMn (t-m) = 14.29 14.18 14.29 0.00 0.00

Verificación de Refuerzo Mínimo

S (cm3) = 11520 11520 11520 0 0

Mcr (t-m) = 5 5 5 0 0

1.20*Mcr (t-m) = 6 6 6 0 0

1.33*Mu (t-m) = 21 21 73 206 206

Mmin (t-m) = 6 6 6 0 0

Check: oK! oK! oK! No No

DISEÑO POR CORTE

Procedimiento ACI-318

Vu_enve(t) = 30

V Dead (t)= 0.00 0.00 0.00 0.00 0.00

V Live (t)= 0.00 0.00 0.00 0.00 0.00

Ln (m)= 1.20 1.70 6.00 3.40 3.30

Vd_cap(t) = 33.25 42.18 6.65 0.00 0.00

Vd_diseño (t) 33 42 7 0 0

Pu(t) = 0.00 0.00 0.00 0.00 0.00

s (cm)= 10.00 10.00 10.00 15.00 15.00

Av (cm2) = 5.08 4.26 3.81 3.81 2.54

f= 0.85 0.85 0.85 0.85 0.85

Factor = 2.65 2.65 2.65 2.65 2.65

Vc (t) = 11 11 11 0 0

Vc_cap (t)= 0 0 11 0 0

Vs (t) = 102 86 77 0 0

Vs max(t) = 55 55 55 0 0

fVn (t) = 47 47 56 0 0

RATIO demanda/capacidad 0.71 0.90 0.12 #DIV/0! #DIV/0!

0.0313 0.0313

VIGA SIMPLE 0.0126 0.0186

b (cm) = 60 60 60 60 0.028125 0.02813

h (cm) = 100 100 60 60 0.2812 0.3066

ds (cm) = 90 90 51 51

As = F1-3/8

61-3/8 F1-3/8

61-3/8 101F1 101F1

F1-3/8

61-3/8 F1-3/8

61-3/8 101F1 101F1

F1-3/8

41-3/8 F1-3/8

51-3/8 21F1 21F1

0.75xAsbal (cm2) = 86.06

As (cm2) = 153.28 162.86 111.48 111.48

As / bd = 2.84% 3.02% 3.64% 3.64%

wM 0.72 0.5

wL 1.05 0.21

Wu 2.54 0.94

c (cm) = 70.72 75.14 51.43 51.43 L 7.6 7.6

et = 0.001 0.001 0.000 0.000

Mu 18.37 6.76

Controlada Controlada Controlada Controlada

Condición : por por por por

compresión compresión compresión compresión

f= 0.90 0.90 0.90 0.90

a (cm) = 60.11 63.87 43.72 43.72

Mn (t-m) = 385.91 397.18 136.44 136.44

FMn (t-m) = 347.32 357.46 122.80 122.80

Mu (t-m) = 155 155 155 155

Check: oK! oK! No No

Verificación de Refuerzo Mínimo

S (cm3) = 81000 81000 26010 26010

Mcr (t-m) = 36 36 12 12

1.20*Mcr (t-m) = 44 44 14 14

1.33*Mu (t-m) = 206 206 206 206

Mmin (t-m) = 44 44 14 14

Check: oK! oK! oK! oK!

Materiales

f'c (kg/cm2) = 210 = 3.00 ksi

f'r (kg/cm2) = 45 = 0.64 ksi

b1 = 0.85

fy (kg/cm2) = 4200

VIGA CON ACERO EN COMPRESIÓN

b (cm) = 30 30 30

h (cm) = 60 60 60

ds (cm) = 48 48 48

As = F3/4

33/4 F3/4

33/4 F3/4

33/4

31F1

d´s (cm) = 6 6 6

A´s = F3/4

33/4 F3/4

33/4 F3/4

33/4

0.75xAsbal + A´s (cm2) = 31.50 31.50 31.50 0.00 0.00

As (cm2) = 8.55 23.75 8.55 0.00 0.00

As / bd = 0.59% 1.65% 0.59% #DIV/0! #DIV/0!

A´s (cm2) = 8.55 8.55 8.55 0.00 0.00

A´s / bd = 0.53% 0.53% 0.53% #DIV/0! #DIV/0!

c (cm) = 6.70 15.12 6.70 11.73 16.49

T (kg) 35913 99758 35913 0 0

Cc (kg) 30519 68815 30519 0 0

Tc (kg) 5394 30943 5394 0 0

T-Cc-Tc=0 0.00 0.00 0.00 0.00 0.00

Tc (kg) 5394 30943 5394 0 0

et = 0.018 0.0065 0.018 -0.003 -0.003

et/ey 8.798 3.107 8.798 -1.429 -1.429

e´t = 0.000 0.002 0.000 0.003 0.003

e´t/ey 0.150 0.862 0.150 1.429 1.429

Controlada Controlada Controlada

Controlada Controlada

Condición : por por por

por tensión por tensión

tensión compresión compresión

f= 0.90 0.90 0.90 0.90 0.90

Mn (t-m) = 16.04 41.61 16.04 0.00 0.00

FMn (t-m) = 14.44 37.45 14.44 0.00 0.00

Mu (t-m) = 16 16 55 155 155

Check: No oK! No No No

MOMENTO NOMINAL OPUESTO

c´ (cm) = 10.06 10.94 10.06 6.39 12.24

T (kg) 35913 35913 35913 0 0

Cc (kg) 45797 49778 45797 0 0

Tc (kg) -9885 -13865 -9885 0 0

T-Cc-Tc=0 0.00 0.00 0.00 0.00 0.00

Tc (kg) -9885 -13865 -9885 0 0

Mn (t-m) = 15.87 15.76 15.87 0.00 0.00

FMn (t-m) = 14.29 14.18 14.29 0.00 0.00

Verificación de Refuerzo Mínimo

S (cm3) = 11520 11520 11520 0 0

Mcr (t-m) = 5 5 5 0 0

1.20*Mcr (t-m) = 6 6 6 0 0

1.33*Mu (t-m) = 21 21 73 206 206

Mmin (t-m) = 6 6 6 0 0

Check: oK! oK! oK! No No

DISEÑO POR CORTE

Procedimiento ACI-318

Vu_enve(t) = 30

V Dead (t)= 0.00 0.00 0.00 0.00 0.00

V Live (t)= 0.00 0.00 0.00 0.00 0.00

Ln (m)= 1.20 1.70 6.00 3.40 3.30

Vd_cap(t) = 33.25 42.18 6.65 0.00 0.00

Vd_diseño (t) 33 42 7 0 0

Pu(t) = 0.00 0.00 0.00 0.00 0.00

s (cm)= 10.00 10.00 10.00 15.00 15.00

Av (cm2) = 5.08 4.26 3.81 3.81 2.54

f= 0.85 0.85 0.85 0.85 0.85

Factor = 2.65 2.65 2.65 2.65 2.65

Vc (t) = 11 11 11 0 0

Vc_cap (t)= 0 0 11 0 0

Vs (t) = 102 86 77 0 0

Vs max(t) = 55 55 55 0 0

fVn (t) = 47 47 56 0 0

RATIO demanda/capacidad 0.71 0.90 0.12 #DIV/0! #DIV/0!

0.0313 0.0313

VIGA SIMPLE 0.0126 0.0186

b (cm) = 60 60 60 60 0.028125 0.02813

h (cm) = 100 100 60 60 0.2812 0.3066

ds (cm) = 90 90 51 51

As = F1-3/8

61-3/8 F1-3/8

61-3/8 101F1 101F1

F1-3/8

61-3/8 F1-3/8

61-3/8 101F1 101F1

F1-3/8

41-3/8 F1-3/8

51-3/8 21F1 21F1

0.75xAsbal (cm2) = 86.06

As (cm2) = 153.28 162.86 111.48 111.48

As / bd = 2.84% 3.02% 3.64% 3.64%

wM 0.72 0.5

wL 1.05 0.21

Wu 2.54 0.94

c (cm) = 70.72 75.14 51.43 51.43 L 7.6 7.6

et = 0.001 0.001 0.000 0.000

Mu 18.37 6.76

Controlada Controlada Controlada Controlada

Condición : por por por por

compresión compresión compresión compresión

f= 0.90 0.90 0.90 0.90

a (cm) = 60.11 63.87 43.72 43.72

Mn (t-m) = 385.91 397.18 136.44 136.44

FMn (t-m) = 347.32 357.46 122.80 122.80

Mu (t-m) = 155 155 155 155

Check: oK! oK! No No

Verificación de Refuerzo Mínimo

S (cm3) = 81000 81000 26010 26010

Mcr (t-m) = 36 36 12 12

1.20*Mcr (t-m) = 44 44 14 14

1.33*Mu (t-m) = 206 206 206 206

Mmin (t-m) = 44 44 14 14

Check: oK! oK! oK! oK!

1F3/8 0.71 1 3/8

2F 3/8 1.43 2 3/8

3F 3/8 2.14 3 3/8

4F 3/8 2.85 4 3/8

5F 3/8 3.56 5 3/8

6F 3/8 4.28 6 3/8

1F1/2 1.27 1 1/2

21F1 /2 2.53 2 1/2

3F 1/2 3.80 3 1/2

4F 1/2 5.07 4 1/2

5F 1/2 6.33 5 1/2

6F 1/2 7.60 6 1/2

7F 1/2 8.87 7 1/2

8F 1/2 10.13 8 1/2

9F 1/2 11.40 9 1/2

10F 1/2 12.67 10 1/2

1F5/8 1.98 1 5/8

2F 5/8 3.96 2 5/8

3F 5/8 5.94 3 5/8

4F 5/8 7.92 4 5/8

5F 5/8 9.90 5 5/8

6F 5/8 11.88 6 5/8

7F 5/8 13.86 7 5/8

8F 5/8 15.83 8 5/8

9F 5/8 17.81 9 5/8

10F 5/8 19.79 10 5/8

11F 5/8 21.77 11 5/8

12F 5/8 23.75 12 5/8

13F 5/8 25.73 13 5/8

14F 5/8 27.71 14 5/8

15F 5/8 29.69 15 5/8

1F3/4 2.85 1 3/4

2F 3/4 5.70 2 3/4

3F 3/4 8.55 3 3/4

4F 3/4 11.40 4 3/4

5F 3/4 14.25 5 3/4

6F 3/4 17.10 6 3/4

7F 3/4 19.95 7 3/4

8F 3/4 22.80 8 3/4

9F 3/4 25.65 9 3/4

10F 3/4 28.50 10 3/4

11F 3/4 31.35 11 3/4

12F 3/4 34.20 12 3/4

13F 3/4 37.05 13 3/4

14F 3/4 39.90 14 3/4

15F 3/4 42.75 15 3/4

11F1 5.07 1 1

21F1 10.13 2 1

31F1 15.20 3 1

41F1 20.27 4 1

51F1 25.34 5 1

61F1 30.40 6 1

71F1 35.47 7 1

81F1 40.54 8 1

91F1 45.60 9 1

101F1 50.67 10 1

111F1 55.74 11 1

121F1 60.80 12 1

131F1 65.87 13 1

141F1 70.94 14 1

151F1 76.01 15 1

2F5/8 + 1F3/4 6.81

2F3/4 + 1F5/8 7.68

2F5/8 + 2F3/4 9.66

3F5/8 + 2F3/4 11.64

2F5/8 + 3F3/4 12.51

3F5/8 + 3F3/4 14.49

4F3/4 + 2F5/8 15.36

4F5/8 + 2F3/4 13.62

3F5/8 + 4F3/4 17.34

4F3/4 + 1F1 16.47

2F3/4 + 2F1 15.83

5F 5/8 + 2F3/4 15.60

3F 3/4 + 2F1 18.68

3F 3/4 + 3F1 23.75

3F 1 + 2F3/4 20.90

4F 3/4 + 2F1 21.54

4F 3/4 + 1F1 16.47

5F 3/4 + 2F1 24.39

6F 3/4 + 2F1 27.24

4F 1 + 2F3/4 25.97

4F 3/4 + 4F1 31.67

4F 3/4 + 5F1 36.74

6F 1 + 2F3/4 36.10

6F 1 + 4F3/4 41.80

1F 3/4 + 3F1 18.05

1F 3/4 + 2F1 12.98

F1-3/8

11-3/8 9.58 1 1 3/8

F1-3/8

21-3/8 19.16 2 1 3/8

F1-3/8

31-3/8 28.74 3 1 3/8

F1-3/8

41-3/8 38.32 4 1 3/8

F1-3/8

51-3/8 47.90 5 1 3/8

F1-3/8

61-3/8 57.48 6 1 3/8

F1-3/8

71-3/8 67.06 7 1 3/8

F1-3/8

81-3/8 76.64 8 1 3/8

F1-3/8

91-3/8 86.22 9 1 3/8

F1-3/8

101-3/8 95.80 10 1 3/8

F1-3/8

111-3/8 105.38 11 1 3/8

F1-3/8

121-3/8 114.96 12 1 3/8

F1-3/8

131-3/8 124.54 13 1 3/8

F1-3/8

141-3/8 134.12 14 1 3/8

F1-3/8

151-3/8 143.70 15 1 3/8

You might also like

- Corps Simple DoubleDocument5 pagesCorps Simple DoubleAbdelhay ElomariNo ratings yet

- Diag M-C Concreto Confinado - Kent y ParkDocument4 pagesDiag M-C Concreto Confinado - Kent y ParkAriel Chavarría HernándezNo ratings yet

- Lembar Perhitungan Variabel 1: Asam Asetat A ADocument10 pagesLembar Perhitungan Variabel 1: Asam Asetat A AMuhammad FarhanNo ratings yet

- Math Model For Calculating Coeff. of Static & Kinetic Friction + Linear ExpansionDocument3 pagesMath Model For Calculating Coeff. of Static & Kinetic Friction + Linear Expansionamrah2No ratings yet

- EjerciciosDocument1 pageEjerciciosdaniel gonzalezNo ratings yet

- Solve The Following Problems From The Book Intro To ChE Thermo by Smit1Document10 pagesSolve The Following Problems From The Book Intro To ChE Thermo by Smit1kojuo isseiNo ratings yet

- Diseño Armadura FlexiónDocument6 pagesDiseño Armadura FlexiónElvis JuarezNo ratings yet

- Exel Perhitungan Stabilitas ObatDocument5 pagesExel Perhitungan Stabilitas ObatWilda LutfiyahNo ratings yet

- Design of Tie BeamsDocument11 pagesDesign of Tie Beamssaddiekay0221No ratings yet

- Double Pipe Heat Exchanger (Counter Current)Document17 pagesDouble Pipe Heat Exchanger (Counter Current)deviNo ratings yet

- Calculo de Losas NTCDFDocument2 pagesCalculo de Losas NTCDFbeto032121No ratings yet

- Deber H6 IeffDocument13 pagesDeber H6 IeffmrnicusNo ratings yet

- Hoja de Calculos: Metrado de Cargas y Predimencionamiento de ColumnasDocument14 pagesHoja de Calculos: Metrado de Cargas y Predimencionamiento de ColumnasEdy Cristian ClNo ratings yet

- RC ColumnDocument5 pagesRC ColumnAngusNo ratings yet

- Design PedestalDocument4 pagesDesign Pedestalnefertitie2021No ratings yet

- First Pile AnalyseDocument6 pagesFirst Pile AnalyseMiguel MorenoNo ratings yet

- I General Loading (Damping 0%) Simple Summation: Tugas 05Document10 pagesI General Loading (Damping 0%) Simple Summation: Tugas 05kason huarNo ratings yet

- Data Pengamatan 1. Kurva Baku KloramfenikolDocument7 pagesData Pengamatan 1. Kurva Baku KloramfenikolNaomi Fenty Novita SimatupangNo ratings yet

- Datos 2018 2Document12 pagesDatos 2018 2YordyWilliamsCaceresQuispeNo ratings yet

- Revision Viga AMDC Puente KennedyDocument17 pagesRevision Viga AMDC Puente KennedyjosNo ratings yet

- E Fy F'C Largo (CM) Base (CM) DDocument10 pagesE Fy F'C Largo (CM) Base (CM) DJesus Manuel Inga GarciaNo ratings yet

- 7 Meter Height TankDocument11 pages7 Meter Height TankHasan AlkhateebNo ratings yet

- Calculos IEFFDocument9 pagesCalculos IEFFmrnicusNo ratings yet

- Tarea 6Document8 pagesTarea 6José CarbajalNo ratings yet

- 23 HTO CEP Group A2Document6 pages23 HTO CEP Group A2Hadia SAULATNo ratings yet

- FQ IncompletoDocument2 pagesFQ IncompletoabdielNo ratings yet

- Diseño de Columna 0.25X0.40Document6 pagesDiseño de Columna 0.25X0.40JOSÉ LUIS REQUE QUESQUENNo ratings yet

- Tugas Individu: "Teknologi Lepas Pantai"Document6 pagesTugas Individu: "Teknologi Lepas Pantai"Chesy MeifaniNo ratings yet

- P MMHG: Constantes de Antoine Parámetros Binarios: (G - G) (Cal/Mol K) Parámetros Binarios: AlfaDocument14 pagesP MMHG: Constantes de Antoine Parámetros Binarios: (G - G) (Cal/Mol K) Parámetros Binarios: AlfaXiime WalburgNo ratings yet

- Trabajo EstaticaDocument6 pagesTrabajo EstaticaCESAR EDUARDO CARBONEL ESCOBEDONo ratings yet

- Open Channel '09Document170 pagesOpen Channel '09teguh PrionoNo ratings yet

- Slab Thickness: Short Length FT Long Length FT 2.133333Document18 pagesSlab Thickness: Short Length FT Long Length FT 2.133333Saeed AyeenNo ratings yet

- CTM/CFPM FN 4/CfpmDocument2 pagesCTM/CFPM FN 4/CfpmKuo1018No ratings yet

- Vigas Simplemente ReforzadasDocument5 pagesVigas Simplemente ReforzadasJose Luis Polo CuítivaNo ratings yet

- ImpoDocument6 pagesImpoCupe Flores OliverNo ratings yet

- Ejemplo de Zapata ConectadaDocument14 pagesEjemplo de Zapata Conectadaceci camposNo ratings yet

- Analisa Kolom - Diagram InteraksiDocument231 pagesAnalisa Kolom - Diagram InteraksiLastSaintNo ratings yet

- Calculation: Design of Rectangular ColDocument84 pagesCalculation: Design of Rectangular Colakram1978No ratings yet

- Lap Struktur PagarDocument24 pagesLap Struktur PagarEko SolusiNo ratings yet

- Ejemplo 5.2: 200.00 29,000.00 de Peso Normal 4,200.00 4 Var. # 8Document2 pagesEjemplo 5.2: 200.00 29,000.00 de Peso Normal 4,200.00 4 Var. # 8carnalle19No ratings yet

- Footing Upon Pile DesignDocument5 pagesFooting Upon Pile DesignafvilavilanoriegaNo ratings yet

- Perhitungan Gaya Lateral Daerah Banda Aceh Tinggi 3.5Document2 pagesPerhitungan Gaya Lateral Daerah Banda Aceh Tinggi 3.5Jauhari Pras SetiawanNo ratings yet

- Diagrama de Interacción: ¿Resistira P 38 TN y M 12.5 TN X M?Document2 pagesDiagrama de Interacción: ¿Resistira P 38 TN y M 12.5 TN X M?David Arnoldo Alvarez CardenasNo ratings yet

- Result Exp 4 (RTR)Document11 pagesResult Exp 4 (RTR)M Asrar SidonNo ratings yet

- NEW - Structural Design & Analysis (Pt. 1)Document23 pagesNEW - Structural Design & Analysis (Pt. 1)Rein Aira OrdanezNo ratings yet

- Check of BeamsDocument37 pagesCheck of BeamsalslekNo ratings yet

- Lab 4 Experiment On CoolingDocument7 pagesLab 4 Experiment On CoolingDivnesh KumarNo ratings yet

- Gas Absorption Cal CompleteDocument7 pagesGas Absorption Cal CompleteChong Choon KeatNo ratings yet

- Systeme Isostatique RDMDocument6 pagesSysteme Isostatique RDMDayane Mélèdje ADOUNo ratings yet

- 210811-Pad Footing DesignDocument3 pages210811-Pad Footing DesignLance Zhengling YinNo ratings yet

- Calculo de VigaDocument3 pagesCalculo de VigaRonaldo LamahNo ratings yet

- 30 CM X 35 CM: Temperatura (°C)Document6 pages30 CM X 35 CM: Temperatura (°C)Mariana ElizabethNo ratings yet

- Roof Deck SlabDocument24 pagesRoof Deck Slabkalvin vaacoNo ratings yet

- Losa Sin Viga-1 PDFDocument8 pagesLosa Sin Viga-1 PDFRobert BanegasNo ratings yet

- fc= f'c (2𝜖𝑐/ (𝜖∙) 〖 "− (" 𝜖𝑐/ (𝜖∙) ) 〗 ^2)Document18 pagesfc= f'c (2𝜖𝑐/ (𝜖∙) 〖 "− (" 𝜖𝑐/ (𝜖∙) ) 〗 ^2)Diana AlexandraNo ratings yet

- Cálculos de Acero Máximo en VigasDocument13 pagesCálculos de Acero Máximo en VigasRoberth ChombopNo ratings yet

- ShipTheory Project 2Document11 pagesShipTheory Project 2Barış YükselNo ratings yet

- RCC EstimateDocument4 pagesRCC EstimateahnafNo ratings yet

- Laboratory Exercises in Astronomy: Solutions and AnswersFrom EverandLaboratory Exercises in Astronomy: Solutions and AnswersNo ratings yet

- BIM in Housing SS GA Edit Ver 2 (1) NRLDocument20 pagesBIM in Housing SS GA Edit Ver 2 (1) NRLDavid GoñiNo ratings yet

- Borrador Cálculo Análisis EstáticoDocument45 pagesBorrador Cálculo Análisis EstáticoDavid GoñiNo ratings yet

- Design of Slender Concrete Columns : TITLE NO. 67-2Document23 pagesDesign of Slender Concrete Columns : TITLE NO. 67-2David GoñiNo ratings yet

- ReadmeDocument1 pageReadmeDavid GoñiNo ratings yet

- Hoja Ensayo DDocument2 pagesHoja Ensayo DDavid GoñiNo ratings yet

- 5 - Ejemplo - Tabla de Control Proyectos - Examen PMPDocument6 pages5 - Ejemplo - Tabla de Control Proyectos - Examen PMPDavid GoñiNo ratings yet