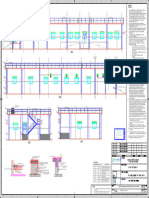

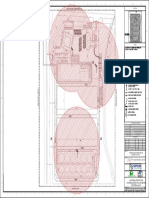

Proposal Drawing Not For Construction

Proposal Drawing Not For Construction

Uploaded by

Mohammad AdilCopyright:

Available Formats

Proposal Drawing Not For Construction

Proposal Drawing Not For Construction

Uploaded by

Mohammad AdilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Proposal Drawing Not For Construction

Proposal Drawing Not For Construction

Uploaded by

Mohammad AdilCopyright:

Available Formats

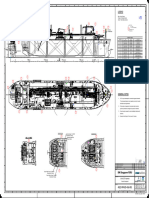

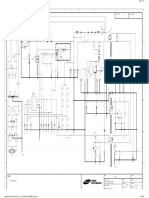

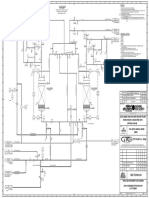

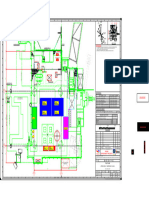

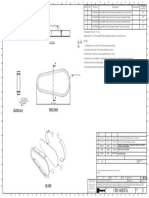

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

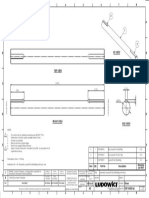

4715

2542 END OF DRIVE SHAFT

1 8985

1 6009 1918 END OF COUPLING

DRIVE ARRANGEMENT

A 3 A

MOTOR 90kW

1 5207 C

L

C

L DRIVE = 2614 EXCITERS CRS =

1 2611 1 4555

1 2

2xLE150S EXCITERS

1 140 1 915 BLANK 1 2 7619 APERTURE 310 BLANK

4

3mm STAINLESS STEEL LINERS

GREASE LUBRICATION POINT

30 OFFSET

I/S SIDE PLATES

55

1 2

°

35mm THICK RUBBER

FEEDBOX BACK LINERS RUBBER WEDGE

4

PROTECTOR

B LIFTING BEAM CL EXCITER SHAFT B

2

200NB

64mm THICK RUBBER

FEEDBOX LINERS LIFTING BEAM

1567

BASE AND SIDES 200NB A

2

CROSS DAMS IN

POSITIONS SHOWN COUPLING AND DRIVE SHAFT

1 1 SUPPLIED BY LUDOWICI / FLSMIDTH

360 1

4057

337

SPRAY BARS

3211

1 1 SUPPLIED BY CLIENT

C 1 TOP DECK: 2 C

1 FLSMIDTH LUDOWICI PIP02 EHP95A 46mm THICK MODULAR

2437

2350

POLYURETHANE PANEL, 5x25mm SRC CROSS FLOW

457

1

1 1 APERTURES c/w 180mm HIGH PU SIDE CLAMP BARS

AND 305mm BLANK DISCHARGE LIP PANELS,

1790

1891

2

CROSS DAMS HALF WAY THROUGH 2ND AND 4TH SECTIONS

1541

1 AND AT THE END OF THE 5TH SECTION

1211

1

1 6

STEEL SPRINGS1RHINO COATED

883

2 2

R8

582

641

6 0

440

BOLTED SPRING SUPPORTS

TO U/S OF DE SPRING BASE PLATE

TOP & LEADING FACES OF CROSS

MEMBERS ARE LINED WITH 10MM THICK 31SPRAY BAR ACCESS 1 BOTTOM DECK:

ADD SHIMS UNDER SPRING

D LUDOWICI 40 ±5 DURO NATURAL RUBBER. HOLES Ø250 SUPPLIED 512 6 BASE PLATES AS REQUIRED FLSMIDTH LUDOWICI PIP02 MDI 85A 46mm THICK MODULAR D

10mm RUBBER CURTAIN = 3666 I/S SIDE PLATES = POLYURETHANE PANEL, 2.5x15mm SRC CROSS FLOW

TOP FACES OF STRINGER BRACKETS WITH RUBBER SEALS

ARE PROTECTED WITH WEAR RESIST. APERTURES c/w 143mm HIGH PU SIDE CLAMP BARS

= 3940 OVER FLANGES = AND 305mm BLANK DISCHARGE LIP PANELS,

1 3768 1220 1220 CROSS DAMS HALF WAY THROUGH 2ND SECTION

6 589

= 4440 SPRING CRS =

AND AT THE END OF THE 4TH & 5TH SECTIONS

1 1338 6100 SPRING CRS

1 901 1 8072

6 END VIEW

NOTE: INTERMEDIATE SHAFT GUARD NOT SHOWN

6 ELEVATION 2

NOTE: 120mm VERTICAL CLEARANCE REQUIRED

FOR REMOVAL OF STEEL COIL SPRINGS

E 8 1 Ø14 HOLES EQUISPACED E

ON Ø155.5 PCD

(6100 SPRING CRS)

3

Ø110 h6

= 800 TYP = 1 2mm THICK BOSS ON COUPLING

1 2.5mm DEEP BORE ON DRIVE SHAFT

= 400 TYP =

16 PLATE TYP Ø18

0x

14 T

H K. F

CL CL

LAN

GE FOR APPROVAL

10 1 Ø18 HOLES

= 160 TYP =

200 TYP

850 TYP THIS DRAWING IS

APPROVED

F VIEW A 1 COUPLING / DRIVE SHAFT APPROVED SUBJECT TO REMARKS F

NOT APPROVED SEE LATER

(= 4440 SPRING CRS =)

6 5 4 3 2 TOTAL SCREEN MASS = 32998 kg INTERFACE DETAIL SCALE 1:5

5 4 3 2 SPRUNG MASS = 32366 kg SIGNED POSITION DATE

CL SCREEN

6 2 MASS OF SPRINGS & BASE PLATES = 632 kg

NOTE: DETAIL DESIGN AND MANUFACTURE WILL NOT

5 4 3 2 VIBRATING STROKE = 10.1 mm @ 843 RPM COMMENCE UNTIL WRITTEN APPROVAL TO PROCEED HAS

BEEN RECEIVED BY LUDOWICI.

PLAN VIEW CLIENT:

BASE PLATE DETAILS 6 5 4 3 2 APPROX. LOADS PER CORNER ORDER NO: 36413

SIGNED BY: T. ELLIOTT

G SURFACE TREATMENT REQUIREMENTS G

2 STATIC OPERATING RESONANCE DATE: 14/12/2012

SCREEN BODY: CORROCOAT PLASMET ZF 843 RPM 01300 RPM

EXCITERS/GUARDS: LUDOWICI STANDARD SPECIFICATION

PROPOSAL DRAWING

QSE SOP 7149 SYSTEM 3 VERT = 76419 N ± 5944 N ±59438 N

OPERATING CLEARANCES FEED END

FINISH PAINT COLOURS : HORIZ = 0N ± 3331 N ± 19983 N

NOT FOR CONSTRUCTION

VERTICAL = 75mm

SCREEN BODY 1 LIGHT GREY HORIZONTAL = 75mm 85436 N ± 5944 N ±59438 N

VERT =

GUARDS 1 AS27001Y14 GOLDEN YELLOW LATERAL = 30mm DISCHARGE END HORIZ = 0N ± 3331 N ± 19983 N All Dimensions and Loadings are approximate only

NOTE :

SPRING RATES

and are Subject to Change Pending Final Design

NATURAL FREQUENCIES OF SUPPORT MEMBERS

SHOULD BE AT LEAST EQUAL TO THE FOLLOWING: VERTICAL = 350 N/mm bmah1in lbad1au msaw1au TOLERANCES UNLESS DIMENSIONS IN DO NOT SCALE

H PRIMARY MEMBERS 2.5 x OPERATING SPEED

4 ET6651:3mm SS Side liner, Rubber wedge protector added. Stroke,Mass and loadings updated.

26/08/2013 29/08/2013 25/09/2013 SPECIFIED OTHERWISE MILLIMETRES DRAWING Title Installation Layout Screen BRU1213673H12xLE150S H

SECONDARY MEMBERS 1.5 x OPERATING SPEED. HORIZONTAL = 280 N/mm prapu1in sal1au sal1au Drn mahadeb Scale

5 ET94121 Updated Mass,Stroke & Corresponding Loads

31/08/2015 03/09/2015 03/09/2015

FABRICATION ±2mm 28/11/2012 1:25 Job No 03381171111 Client

MACHINING ±0.25mm

Property of FLSmidth A/S. This drawing contains confidential, proprietary, and/or trade secret information of FLSmidth A/S. This drawing frsu1in sor1au cgo1au Chkd sor1au

and/or the information contained therein, may only be used for the limited purposes of evaluating proposals or installing, operating or

6 ET96581Updated Springs Type, Spring compressed length, Packers removed, Mass and load datas updated.

07/12/2015 141Dec115 131Jan116

ANGULAR ±0.25°

SURFACE FINISH 3.2Am 12/12/2012

® Model BRU1213673H

maintaining FLSmidth® equipment. Disclosure, distribution, duplication, modification, manufacturing from, or use of this drawing and/or Appd te1au Sheet Rev

the information therein is not permitted without the prior written permission of FLSmidth A/S © 2012, FLSmidth A/S. All rights reserved. Rev Description Rev Drawn Rev Checked Rev Appd DEBURR ALL SHARP EDGES 14/12/2012 A1 Drg No AU13381171D001 1 of 1 6

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

You might also like

- Ent MCQDocument9 pagesEnt MCQMuhammad Bilal69% (13)

- Bridge Design Sample Autocad-2Document1 pageBridge Design Sample Autocad-2DINESHNo ratings yet

- SM-J701M Esquematico Completo Anibal Garcia IrepairDocument54 pagesSM-J701M Esquematico Completo Anibal Garcia IrepairYo HamterNo ratings yet

- Pos. Description / Descripción: TP-CA3 TP-CO1 TP-CO1 Tp-Coh1Document1 pagePos. Description / Descripción: TP-CA3 TP-CO1 TP-CO1 Tp-Coh1omarNo ratings yet

- American Audio V5000preampDocument1 pageAmerican Audio V5000preampdavid julio diazNo ratings yet

- Fig 1. 331/47239 - Issue 1: V2 C2 CC/rev CC/revDocument1 pageFig 1. 331/47239 - Issue 1: V2 C2 CC/rev CC/revNikNo ratings yet

- CT and MR Angiography of The Peripheral Circulation - 1841846066 PDFDocument350 pagesCT and MR Angiography of The Peripheral Circulation - 1841846066 PDFDididNo ratings yet

- Leron Leron Sinta For Rondalla-Score - and - PartsDocument7 pagesLeron Leron Sinta For Rondalla-Score - and - PartsMusicondallaNo ratings yet

- 1eec E4021Document1 page1eec E4021UP MOCHINo ratings yet

- Construction NOC Drawing - TL27, TLB7, TLB8 & TLB9Document1 pageConstruction NOC Drawing - TL27, TLB7, TLB8 & TLB9AnuNo ratings yet

- E2302-SMA-EUT-DG-20506-AADocument1 pageE2302-SMA-EUT-DG-20506-AAArun RajahNo ratings yet

- Amazing Grace - Violino IDocument1 pageAmazing Grace - Violino IThiago José da SilvaNo ratings yet

- Layout Plan SEPDocument1 pageLayout Plan SEPprakashNo ratings yet

- I G L J: +el 2468 (Tos) +el 2468 (Tos)Document1 pageI G L J: +el 2468 (Tos) +el 2468 (Tos)Gnanasekar VaishniNo ratings yet

- PressedDocument6 pagesPressedVijay KumarNo ratings yet

- Elevation: All Fabrication Drawing Shall Be in Accordance With RDSO Drg. B-10408 SetDocument1 pageElevation: All Fabrication Drawing Shall Be in Accordance With RDSO Drg. B-10408 SetParikh DhavalNo ratings yet

- Bassbutler Final Corrected 3Document1 pageBassbutler Final Corrected 3Beckenbauer ErnstbergerNo ratings yet

- G2Le Board Schematic Diagram (55") : Stby FBDocument1 pageG2Le Board Schematic Diagram (55") : Stby FBAntonio CalabreseNo ratings yet

- Conn 4 Conn 34: MTR BatDocument1 pageConn 4 Conn 34: MTR BatKevinCollenNo ratings yet

- 4522-MM-ED-416-001 - R03 GA of CCTV CamerasDocument7 pages4522-MM-ED-416-001 - R03 GA of CCTV CamerasNikul PanchalNo ratings yet

- 1eec E4012Document1 page1eec E4012UP MOCHINo ratings yet

- Min Ido 00 Civ CA 1024 00 GT Area Secondary FoundationsDocument19 pagesMin Ido 00 Civ CA 1024 00 GT Area Secondary Foundationscrusher28No ratings yet

- AQ 30-55 VSD Aircooled Dimension Drawing en 9820494300Document2 pagesAQ 30-55 VSD Aircooled Dimension Drawing en 9820494300gritchenko.maxNo ratings yet

- Drainage LayoutDocument1 pageDrainage Layoutمحمد عدوانNo ratings yet

- SM-J700T Esquematico Completo Anibal Garcia IrepairDocument8 pagesSM-J700T Esquematico Completo Anibal Garcia IrepairJuanNo ratings yet

- Stop/ Control Valves: 1X-M6-AB-00006Document1 pageStop/ Control Valves: 1X-M6-AB-00006wael zakariaNo ratings yet

- For Cont. See DWG P-1632-0000-DW-1332-004: D e F GDocument2 pagesFor Cont. See DWG P-1632-0000-DW-1332-004: D e F Gabrahan aularNo ratings yet

- HD3600 MK4Document3 pagesHD3600 MK4Dheeraj kumar YadavNo ratings yet

- Building Principle: Plan View Detail For Tm1-Tm2Document1 pageBuilding Principle: Plan View Detail For Tm1-Tm2Maroua HammamiNo ratings yet

- SLD - Fan Starters From EMDB02Document1 pageSLD - Fan Starters From EMDB02shrikanth5singhNo ratings yet

- Component Placing Layout Xperia Z3+ Plus E6553, E6553 PDFDocument2 pagesComponent Placing Layout Xperia Z3+ Plus E6553, E6553 PDFCelublack CkNo ratings yet

- Samsung Bn44-00354a Bn44-00355a Power-Supply SCH PDFDocument4 pagesSamsung Bn44-00354a Bn44-00355a Power-Supply SCH PDFAnonymous vgeqhfZcNo ratings yet

- Hydraulic Schematic 6050 FS: Old Hydraulikschaltplan 6050 LSDocument1 pageHydraulic Schematic 6050 FS: Old Hydraulikschaltplan 6050 LSJHONATAN ESTEBAN VALENZUELA ALBIÑONo ratings yet

- CRB Plan Sheet1Document1 pageCRB Plan Sheet1ARUN RAWATNo ratings yet

- 915 11531 - Rev 4Document1 page915 11531 - Rev 4Sonu KumarNo ratings yet

- Etihad Rail Network: Longitudinal Section DDocument1 pageEtihad Rail Network: Longitudinal Section DDanielVadjkeVađinaNo ratings yet

- Dimension Drawing XAVS 1800 WUX 9829 3587 00-01 EN - Support MountedDocument1 pageDimension Drawing XAVS 1800 WUX 9829 3587 00-01 EN - Support MountedMarkus SitanggangNo ratings yet

- Rbs College StationDocument1 pageRbs College StationPooja waniNo ratings yet

- FENIX CAMP - AR-FEN-10-ROEC-500045 - ATT1 - 06 - Plot Plan Upper-ModelDocument1 pageFENIX CAMP - AR-FEN-10-ROEC-500045 - ATT1 - 06 - Plot Plan Upper-ModeljoeripaNo ratings yet

- Water Intake Plant SLDDocument1 pageWater Intake Plant SLDali mohammedNo ratings yet

- 0-FW-360-11087Document1 page0-FW-360-11087AKHIL REDDYNo ratings yet

- 0-FW-360-11087Document1 page0-FW-360-11087AKHIL REDDYNo ratings yet

- Issued For Construction: Deep Underground Stations Line 1 - 1F4 Bus Station Architecture Key Plan R02 Roof PlanDocument1 pageIssued For Construction: Deep Underground Stations Line 1 - 1F4 Bus Station Architecture Key Plan R02 Roof PlanAmarnathNo ratings yet

- Screenshot 2024-01-14 at 1.12.36 PMDocument1 pageScreenshot 2024-01-14 at 1.12.36 PMavaisrasulNo ratings yet

- Electrical 2528C.fmDocument1 pageElectrical 2528C.fmmayobanex moyaNo ratings yet

- TV HierDocument1 pageTV Hierjesus cautivoNo ratings yet

- Issued For Construction: Level 0 FFL 0.022Document1 pageIssued For Construction: Level 0 FFL 0.022Sadique PkNo ratings yet

- M BMF 1a2ds0 CPHC SDR 620406Document1 pageM BMF 1a2ds0 CPHC SDR 620406pmcdasygeeNo ratings yet

- China TD21P8 M61266, M37160, Tea1506p, La9302Document1 pageChina TD21P8 M61266, M37160, Tea1506p, La9302Luis Liammas PerezNo ratings yet

- China Haier 8859 050324.DDB STR-G9656 Tmpa8859 - 8829 La78041 Tda7496sa Ta1343nDocument1 pageChina Haier 8859 050324.DDB STR-G9656 Tmpa8859 - 8829 La78041 Tda7496sa Ta1343njohn quiros100% (1)

- Richmond HillDocument1 pageRichmond HilltrifenNo ratings yet

- 40 00001 B Piping Complete: RevisionsDocument1 page40 00001 B Piping Complete: RevisionsAlfonso LópezNo ratings yet

- Notes:: View - ADocument1 pageNotes:: View - AHitesh DabhiNo ratings yet

- Lay Out CDocument1 pageLay Out CMuhammad FauzanNo ratings yet

- Solis 1.0 DC Rv10Document1 pageSolis 1.0 DC Rv10wellingtonNo ratings yet

- Defect Plot Plan U32Document1 pageDefect Plot Plan U32jk.jackycheokNo ratings yet

- Samsung Gt-p6800 Service SchematicsDocument12 pagesSamsung Gt-p6800 Service SchematicsC. Lennin MendozaNo ratings yet

- 10 723711 4800000299 PCC Ict DRG 102403 - DWG - 05 PS06Document1 page10 723711 4800000299 PCC Ict DRG 102403 - DWG - 05 PS06Zeeshan YasinNo ratings yet

- CEPP-01570-INS-03-201Document1 pageCEPP-01570-INS-03-201khan thompsonNo ratings yet

- Ed 0900 PRS Pid 000 09021HDocument1 pageEd 0900 PRS Pid 000 09021HMohamed ArafaNo ratings yet

- Poulbot Blues Solf PDFDocument1 pagePoulbot Blues Solf PDFRedouane SaioudNo ratings yet

- Poulbot Blues Solf PDFDocument1 pagePoulbot Blues Solf PDFjilali mohcinNo ratings yet

- TC NylonDocument1 pageTC NylonMohammad AdilNo ratings yet

- RT Part-4Document80 pagesRT Part-4Mohammad AdilNo ratings yet

- Spring SnapDocument1 pageSpring SnapMohammad AdilNo ratings yet

- 4 Inspection and Final Manufacturing: 4.1 Welding NDT (Non-Destructive Testing)Document2 pages4 Inspection and Final Manufacturing: 4.1 Welding NDT (Non-Destructive Testing)Mohammad AdilNo ratings yet

- Item Release Note: 1 Already DespatchedDocument1 pageItem Release Note: 1 Already DespatchedMohammad AdilNo ratings yet

- Arcoplate BrouchureDocument112 pagesArcoplate BrouchureMohammad AdilNo ratings yet

- UT Vs RT Method StatementDocument6 pagesUT Vs RT Method StatementMohammad AdilNo ratings yet

- Item Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemDocument1 pageItem Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemMohammad AdilNo ratings yet

- 660D14 Painting Schedule For Silo 1 - Rev 0Document1 page660D14 Painting Schedule For Silo 1 - Rev 0Mohammad AdilNo ratings yet

- Item Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemDocument1 pageItem Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemMohammad AdilNo ratings yet

- Ut 02Document132 pagesUt 02Mohammad AdilNo ratings yet

- 1313a00057 Bne1Document1 page1313a00057 Bne1Mohammad AdilNo ratings yet

- 3D View: Item Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemDocument1 page3D View: Item Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemMohammad AdilNo ratings yet

- I R Shnametallurgical: Laboratories Pvt. LTDDocument1 pageI R Shnametallurgical: Laboratories Pvt. LTDMohammad AdilNo ratings yet

- 8-17.5 HOLES 100: Item Section Size Material Grade Length (MM) Mass (KG) Per ItemDocument1 page8-17.5 HOLES 100: Item Section Size Material Grade Length (MM) Mass (KG) Per ItemMohammad AdilNo ratings yet

- Vibrating Screen Seal Gasket 80NB ASME B16.5 BRU-1-180/610B Vibrating Screen Seal Gasket 80NB ASME B16.5Document1 pageVibrating Screen Seal Gasket 80NB ASME B16.5 BRU-1-180/610B Vibrating Screen Seal Gasket 80NB ASME B16.5Mohammad AdilNo ratings yet

- Item Section Size Material Grade Length (MM) Mass (KG) Per ItemDocument1 pageItem Section Size Material Grade Length (MM) Mass (KG) Per ItemMohammad AdilNo ratings yet

- 18 - 18 HOLES 10 - 17.5 HOLES CSK 90 X 8 Deep Refer Section A-A 805Document2 pages18 - 18 HOLES 10 - 17.5 HOLES CSK 90 X 8 Deep Refer Section A-A 805Mohammad AdilNo ratings yet

- Preliminary Drawing Not For ConstructionDocument1 pagePreliminary Drawing Not For ConstructionMohammad AdilNo ratings yet

- Stamp Part No. in This Area 10Mm High Lettering: For BOM & Dimensions Refer To RH Drawing 1301P01495Document1 pageStamp Part No. in This Area 10Mm High Lettering: For BOM & Dimensions Refer To RH Drawing 1301P01495Mohammad AdilNo ratings yet

- 3D View: Sideplate 1301P01499Document1 page3D View: Sideplate 1301P01499Mohammad AdilNo ratings yet

- For Internal Use Only: 1684A01608-BNE1 4Document1 pageFor Internal Use Only: 1684A01608-BNE1 4Mohammad AdilNo ratings yet

- 3D View: A1 Spreader Beam 1301A01268Document1 page3D View: A1 Spreader Beam 1301A01268Mohammad AdilNo ratings yet

- Item Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemDocument1 pageItem Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemMohammad AdilNo ratings yet

- Item Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemDocument1 pageItem Section Size Material Grade Length (MM) Width (MM) Mass (KG) Per ItemMohammad AdilNo ratings yet

- Guard Guard BRU Pulley Standard Medium Cover FrontDocument1 pageGuard Guard BRU Pulley Standard Medium Cover FrontMohammad AdilNo ratings yet

- Item Qty Part No Description Mass (KG) Per Item: Rev Checked Rev Drawn Rev Appd Rev DescriptionDocument1 pageItem Qty Part No Description Mass (KG) Per Item: Rev Checked Rev Drawn Rev Appd Rev DescriptionMohammad AdilNo ratings yet

- Item QTY Part No Description Comments Mass (KG) Per Item: Rev Checked Rev Drawn Rev Appd Rev DescriptionDocument1 pageItem QTY Part No Description Comments Mass (KG) Per Item: Rev Checked Rev Drawn Rev Appd Rev DescriptionMohammad AdilNo ratings yet

- 1301A00008-BNE1 4: 3 Belt ConfigurationDocument1 page1301A00008-BNE1 4: 3 Belt ConfigurationMohammad AdilNo ratings yet

- Travel Expenses Worksheet Name:-No.: Trip From Date of Tour UptoDocument5 pagesTravel Expenses Worksheet Name:-No.: Trip From Date of Tour UptoMohit JagtapNo ratings yet

- AutoCAD Electrical JIC Admin Course Syllabus SampleDocument3 pagesAutoCAD Electrical JIC Admin Course Syllabus Samplefadapow4uNo ratings yet

- Dizzle RulesDocument6 pagesDizzle Ruleskirules0324No ratings yet

- Sudan EssayDocument1 pageSudan Essayapi-257610814No ratings yet

- History of Basketball and VolleyballDocument1 pageHistory of Basketball and VolleyballBreeNo ratings yet

- "A Study On Impact of Motivation On Employee Performance": Met College of Management StudiesDocument10 pages"A Study On Impact of Motivation On Employee Performance": Met College of Management StudiesDevaNo ratings yet

- Part D-8 Tangible Non Current Assests (ch06)Document68 pagesPart D-8 Tangible Non Current Assests (ch06)hyangNo ratings yet

- Landside Fac BOQ-FinalDocument22 pagesLandside Fac BOQ-FinalIzo SeremNo ratings yet

- 5f10da7c11cd3476cccd9a19 - C7H 6X4 Modern Ejector TruckDocument3 pages5f10da7c11cd3476cccd9a19 - C7H 6X4 Modern Ejector TruckKattie ValerioNo ratings yet

- New Horizon School: Question BankDocument10 pagesNew Horizon School: Question BankMANo ratings yet

- CBC-HEO (Hydraulic Excavator) NC IIDocument60 pagesCBC-HEO (Hydraulic Excavator) NC IIhelaNo ratings yet

- Resysta Interior Design NA Brochure PDFDocument7 pagesResysta Interior Design NA Brochure PDFfireater0% (1)

- CD74HC7046A, CD74HCT7046A: Features DescriptionDocument22 pagesCD74HC7046A, CD74HCT7046A: Features DescriptionDanielNo ratings yet

- "Jiggle" ExcerptDocument6 pages"Jiggle" ExcerptHere & NowNo ratings yet

- ISACA - Use of Risk Assessment in Audit PlanningDocument3 pagesISACA - Use of Risk Assessment in Audit PlanningTodor AnđićNo ratings yet

- Myanmar ICT SWIA - Full Report English PDFDocument285 pagesMyanmar ICT SWIA - Full Report English PDFVicky BowmanNo ratings yet

- Comerica E Statement 2 PDFDocument5 pagesComerica E Statement 2 PDFJonathan Seagull LivingstonNo ratings yet

- NME Magazine Feb 18 2006 PDFDocument75 pagesNME Magazine Feb 18 2006 PDF小松 ラインNo ratings yet

- Rule For Pronunciation of Ed, IngDocument8 pagesRule For Pronunciation of Ed, IngMartin AlberaNo ratings yet

- GS33J62F20 01enDocument8 pagesGS33J62F20 01enBobby SetiawanNo ratings yet

- Pupil Tree Academy Belary.Document5 pagesPupil Tree Academy Belary.Ritu AgrawalNo ratings yet

- 2024 Ahg Camp GTR HandbookDocument8 pages2024 Ahg Camp GTR Handbookapi-245625563No ratings yet

- Workbook Phonics Grade 1Document55 pagesWorkbook Phonics Grade 1Lan TranNo ratings yet

- DSA Presentation Group 6Document34 pagesDSA Presentation Group 6AYUSHI WAKODENo ratings yet

- A. Jill Has Many Restaurants To Choose From For Her BirthdayDocument3 pagesA. Jill Has Many Restaurants To Choose From For Her Birthdayshincee23No ratings yet

- Solar Air Conditioning System 22Document17 pagesSolar Air Conditioning System 22mamona zaheerNo ratings yet

- Listening Beyond The Echoes MediaDocument207 pagesListening Beyond The Echoes Mediab-b-b1230% (1)