Tds-Manual Damper

Tds-Manual Damper

Uploaded by

sabir hussainCopyright:

Available Formats

Tds-Manual Damper

Tds-Manual Damper

Uploaded by

sabir hussainOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Tds-Manual Damper

Tds-Manual Damper

Uploaded by

sabir hussainCopyright:

Available Formats

TM

Control Damper Revent Air tech

1

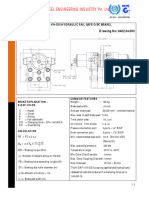

MODEL : M-VCD

Manual Operated Volume Control Damper

INTRODUCTION

Two damper arrangements are used for air-handling system flow control:

parallel-blade and opposed-blade.Parallel-blade dampers are adequate for two position control

and can be used for modulating control when they are the primary source of pressure drop and

directional air flow is not a problem. Opposed-blade damper are preferable, because they normally

provided better control.

Revent standard manual volume control dampers are come with opposed blade 3'V’ style

arrangement with concealed linkage and brass bush/bearing press fit into galvanized steel frame.

However parallel blade 3'V’ style arrangement also available as alternative.

STANDARD CONSTRUCTION

Frame : 18 G (1.2 mm) galvanized steel C channel

reinforced Corners 6 in. x 1 in.

Blade : 18 G (1.2 mm) galvanized steel 3 ‘V’ groove

6" wide opposed action

Bearing/Bush : GI plated collar type 16.5 mm dia.

Axles : 9.5 mm square GI plated.

Linkage : Concealed heavy duty type 12 G galvanized

steel

Handle : Lockable handle quadrant with scaled

indicator plate and open/close handle

indicator galvanized steel.

Finish : Mill Galvanized.

DAMPER RATING

Max. Operating temperature : 240°F

Operating pressure in excess of 2.5 inches w.g.

Operating velocity in excess of 2000 fpm Opposed blade action

3 ‘V’ groove

SIZE LIMITATION arrangement

Minimum size : 200 X 200 mm

Maximum size : 1000 X 1000 mm

For unlimited size damper will be multiple section assembly.

Note:-In a multiple section.

www.reventairtech.com Tel: +91 - 124 -4237502/09

TM

Control Damper Revent Air tech

2

DIMENSIONAL DETAILS

W+F D

Stopper 150 mm

A

W

H+F

H

50 mm

A SECTION A-A

Air Flow

Frame

AVAILABLE OPTIONS

Blade F-Flange-25,30,40 & 50

D-Depth-150 & 200

Handle

Wing Nut Material-GI,SS304 & SS316

Blade action-Opposed & parallel

Linkage Cover Frame Gauge-14G,16G,18G & 20G

Blade Gauge-16G,18G & 20G

Qty SIZE FLANGE DEPTH MATERIAL BLADE ACTION

W H

For Order

Note:-Required all dimensions are in mm

www.reventairtech.com Tel: +91 - 124 -4237502/09

TM

Control Damper Revent Air tech

3

PRESSURE DROP DATA

PRESSURE DROP DATA

Pressure drop testing was conducted in accordance with AMCA Standard 500-D using Figure 5.3.

All data has been corrected to represent standard air at a density of 0.075 Ib/ft 3 (1.201kg/m3)

Actual pressure drop found in any HVAC system is a combination of many factors.This pressure drop

information along with an analysis of other system influences should be used to estimate actual

pressure losses for a damper installed in a given HVAC system

AMCA FIGURES

Figure 5.3 illustrates a fully ducted damper. This configuration has the lowest pressure drop of the

three test configurations because entrance and exit losses are minimized by straight duct runs

upstream and downstream of the damper.

Figure 5.2 illustrates a ducted damper exhausting air into an open area. This configuration has a

lower pressure drop than Figure 5.5because entrance losses are minimized by a straight duct run

upstream of the damper.

Figure 5.5 illustrates a plenum mounted damper. This configuration has the highest pressure

drop because of extremely high entrance and exit losses due to the sudden changes of area in

the system.

www.reventairtech.com Tel: +91 - 124 -4237502/09

TM

Control Damper Revent Air tech

4

PRESSURE DROP DATA

SIZE(mm) 203 X 203 406 X 406 610 X 610 813 X 813 1220 X 915

Velocity(fpm) Pressure Drop(in.w.g)

500 0.09 0.03 0.02 0.01 0.005

1000 0.37 0.11 0.06 0.03 0.02

1500 0.83 0.24 0.14 0.06 0.04

2000 1.48 0.44 0.26 0.12 0.08

Size(mm)

Pressure drop(in.w.g)

Pressure Drop For Only (610 X 610 mm)

0.7

0.5

The pressure drop data in the tables above is for fully ducted 0.3

dampers as represented by Figure 5.3 on page 1. For dampers not 0.2

fully ducted, represented by Figure 5.2 and Figure 5.5 on page

Pressure Drop in.w.g

For example, the pressure drop across a 610 x 610 mm 0.1

damper in an air system with a velocity of 1,000 FPM is .03 inches .07

w.g. If the application more closely resembles Figure 5.2, the actual

pressure drop is closer to .09 inches w.g. (.03 x 3). .05

.03

.02

.01

200 300 500 700 1000 2000 3000

Velocity (fpm)

www.reventairtech.com Tel: +91 - 124 -4237502/09

You might also like

- Co2 Damper6Document4 pagesCo2 Damper6sabir hussainNo ratings yet

- 304 1.5MM PCDocument1 page304 1.5MM PCsabir hussain100% (1)

- Screw Compressors: Model: VD55-10DGDocument20 pagesScrew Compressors: Model: VD55-10DGVoştinar IoanNo ratings yet

- Disc Brake Units Be 100, Be 125, and Be 200: Technical InformationDocument6 pagesDisc Brake Units Be 100, Be 125, and Be 200: Technical InformationJose Maria Castro PazosNo ratings yet

- GrilleDocument4 pagesGrillesabir hussainNo ratings yet

- Kateel CalculationDocument2 pagesKateel Calculationfamousmind66No ratings yet

- D-Series Engine Overspeed Shut Down Valves (Auto/Manual Spindle Types) Selection, Application and MaintenanceDocument7 pagesD-Series Engine Overspeed Shut Down Valves (Auto/Manual Spindle Types) Selection, Application and MaintenancedfheardNo ratings yet

- كتالوج الشيلراتDocument54 pagesكتالوج الشيلراتFathy RakhaNo ratings yet

- MS Data Sheet TanqueDocument2 pagesMS Data Sheet TanqueLION_FIRENo ratings yet

- Toggle-Injection-Moulding-Machines 2Document16 pagesToggle-Injection-Moulding-Machines 2Vimal AathithanNo ratings yet

- Screw Compressor ASY (R-134) Series PDFDocument52 pagesScrew Compressor ASY (R-134) Series PDFNajam2450% (2)

- Chalwyn-D-AutoManual-Spindle-CE210 (7) 0716Document8 pagesChalwyn-D-AutoManual-Spindle-CE210 (7) 0716Dhiven VesNo ratings yet

- 01 - Agitator Specification - 2001064277 10 R0Document4 pages01 - Agitator Specification - 2001064277 10 R0Erkan TakNo ratings yet

- VAV TerminalsDocument18 pagesVAV TerminalsFaquruddinNo ratings yet

- HD 242 Flexible HoseDocument4 pagesHD 242 Flexible HoseSelvakumar EkambaramNo ratings yet

- MPDFDocument2 pagesMPDFsaad naser aldeenNo ratings yet

- MeasurIT Tideflex - 37 0906Document1 pageMeasurIT Tideflex - 37 0906cwiejkowskaNo ratings yet

- Brosur Breaker SOOSAN SB Series (New)Document8 pagesBrosur Breaker SOOSAN SB Series (New)HidayatNo ratings yet

- Icp - 25797 2Document35 pagesIcp - 25797 2Mike StebenneNo ratings yet

- 083959XYZDocument2 pages083959XYZnorthernwolf123No ratings yet

- Drift Eliminators: Product ProfileDocument2 pagesDrift Eliminators: Product ProfileYohanes Joko TriyantoNo ratings yet

- 1118mm - Thickness Calculator For MS or DI PipesDocument8 pages1118mm - Thickness Calculator For MS or DI Pipesanirbanpwd76No ratings yet

- Wadbros CatelogueDocument36 pagesWadbros Cateloguepistolfire99No ratings yet

- 083960XYZDocument2 pages083960XYZnorthernwolf123No ratings yet

- Silo (210 × 297 MM)Document12 pagesSilo (210 × 297 MM)kreasiyalada20No ratings yet

- Dehumdifier 1Document46 pagesDehumdifier 1tssuwimal5973No ratings yet

- Krausz Spesifications Hymax-Flensemuffe enDocument4 pagesKrausz Spesifications Hymax-Flensemuffe enibrahimNo ratings yet

- "ADCATROL" TDS Blowdown Control Valves VPC SeriesDocument3 pages"ADCATROL" TDS Blowdown Control Valves VPC SeriesMuzakir Al ZakirNo ratings yet

- CY SeriesDocument22 pagesCY SeriesMohamed AmrNo ratings yet

- Datasheet 1001th Panel Mount Gauge 1Document4 pagesDatasheet 1001th Panel Mount Gauge 1RUN GONo ratings yet

- M/1000 Heavy Duty Cylinders, Double Acting: Medium: Operating Pressure: Operating Temperature: MaterialsDocument8 pagesM/1000 Heavy Duty Cylinders, Double Acting: Medium: Operating Pressure: Operating Temperature: MaterialsBahador YazdiNo ratings yet

- Hekadrill 213-ENDocument8 pagesHekadrill 213-ENMuddasirNo ratings yet

- Volume Control DampersDocument20 pagesVolume Control DampersSMBEAUTYNo ratings yet

- Axial Fan 5Document5 pagesAxial Fan 5aspiratorlefantNo ratings yet

- Disipador BGA Heat Sink - High Performance maxiFLOW W/thermal TapeDocument1 pageDisipador BGA Heat Sink - High Performance maxiFLOW W/thermal Tapewilmer_tkNo ratings yet

- Subros Ac XYLODocument36 pagesSubros Ac XYLOjag18718No ratings yet

- Volume Damper PDFDocument8 pagesVolume Damper PDFMahmoud Abd El-kaderNo ratings yet

- Volume DamperDocument8 pagesVolume Damperislamiprahim77779No ratings yet

- Volume Control Damper Opposed Blade: 1. Casing 2. Blade 3. Plastic Gear 4. Drive Arm Hand Locking QuadrantDocument8 pagesVolume Control Damper Opposed Blade: 1. Casing 2. Blade 3. Plastic Gear 4. Drive Arm Hand Locking QuadrantAmr Adeeb Abd-ElaahNo ratings yet

- CATALOGO Generale VMC PDFDocument32 pagesCATALOGO Generale VMC PDFMaciekLembryk100% (1)

- FDS 2017106 SKUM HIEX Louvers DampersDocument2 pagesFDS 2017106 SKUM HIEX Louvers Dampersbosko.vukovicNo ratings yet

- ZCL Rwy 02 20 PDFDocument3 pagesZCL Rwy 02 20 PDFErick RodriguezNo ratings yet

- FRP FRP FRP FRP: Cooling Tower Cooling Tower Cooling Tower Cooling Tower Cooling TowerDocument35 pagesFRP FRP FRP FRP: Cooling Tower Cooling Tower Cooling Tower Cooling Tower Cooling TowerAhmed KhattabNo ratings yet

- 707 Reflux 819 Ct-S502-E November 10 Mod Novembre WebDocument12 pages707 Reflux 819 Ct-S502-E November 10 Mod Novembre WebRolando PradaNo ratings yet

- Bridgeport Series I - BrochureDocument2 pagesBridgeport Series I - BrochureVVNo ratings yet

- Created: Jul 01, 2009 Edited: Apr 20, 2018: Cylinder HeadDocument14 pagesCreated: Jul 01, 2009 Edited: Apr 20, 2018: Cylinder HeadRodnie RodriguezNo ratings yet

- Hudetech Spring IsolatorDocument22 pagesHudetech Spring IsolatorLợi TrầnNo ratings yet

- The Ers Var 15 Brake: Electrically Released Brake For Stage & Theater ApplicationsDocument2 pagesThe Ers Var 15 Brake: Electrically Released Brake For Stage & Theater ApplicationsAli GameelNo ratings yet

- A6d800 Ae05 03 EngDocument6 pagesA6d800 Ae05 03 EngAdemar FukeNo ratings yet

- Flamcovent Clean Smart 300 FDocument2 pagesFlamcovent Clean Smart 300 FFaizal MohammedNo ratings yet

- HD Válvulas On-OffDocument1 pageHD Válvulas On-Offcristian W. saravia vegaNo ratings yet

- Rema SlideDocument4 pagesRema SlidedexNo ratings yet

- Instrument Air Dryer and Instrument Air ReceiverDocument4 pagesInstrument Air Dryer and Instrument Air ReceiverAzizul HakimNo ratings yet

- Technical Specification Sailor N163S Power Supply PDFDocument1 pageTechnical Specification Sailor N163S Power Supply PDFseamec2No ratings yet

- Pressure Switches: Vacuum - High CurrentDocument2 pagesPressure Switches: Vacuum - High CurrentJohn ThompsonNo ratings yet

- VAV DamperDocument7 pagesVAV DamperAdades Safede EfdNo ratings yet

- After-Coolers Air Belt GuardDocument2 pagesAfter-Coolers Air Belt GuardMauricioNo ratings yet

- Pm-Clinic Data Sheet Wa180-3L Base Information: Customer Name LocationDocument3 pagesPm-Clinic Data Sheet Wa180-3L Base Information: Customer Name LocationjulianoNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Admire Airtech - Price ListDocument33 pagesAdmire Airtech - Price Listsabir hussainNo ratings yet

- Price Quote 311Document2 pagesPrice Quote 311sabir hussainNo ratings yet

- Quality Assurance Plan: Sheet MetalDocument2 pagesQuality Assurance Plan: Sheet Metalsabir hussain0% (1)

- ADP Final3Document6 pagesADP Final3sabir hussainNo ratings yet

- 57 Supplier Assessment Form Rev 01 DTD 01 07 2017Document4 pages57 Supplier Assessment Form Rev 01 DTD 01 07 2017sabir hussainNo ratings yet

- Painting Specification and ProcedureDocument2 pagesPainting Specification and Proceduresabir hussainNo ratings yet

- TAN CertificateDocument1 pageTAN Certificatesabir hussainNo ratings yet

- GN 949Document1 pageGN 949sabir hussainNo ratings yet

- Company ProfileDocument12 pagesCompany Profilesabir hussainNo ratings yet

- All Gerenal CatlogDocument176 pagesAll Gerenal Catlogsabir hussainNo ratings yet

- Udyam Registration CertificateDocument1 pageUdyam Registration Certificatesabir hussainNo ratings yet

- MAINTENANCEDocument12 pagesMAINTENANCEsabir hussainNo ratings yet

- Revent Store InventoryDocument1 pageRevent Store Inventorysabir hussainNo ratings yet

- Admire Noida - Ledger StatementDocument1 pageAdmire Noida - Ledger Statementsabir hussainNo ratings yet

- Qty 6 Nos Per Unit All Material SS304 VIEW B (1: 10) A-A (1: 10) VIEW A (1: 10) Mounting Slot DetailsDocument1 pageQty 6 Nos Per Unit All Material SS304 VIEW B (1: 10) A-A (1: 10) VIEW A (1: 10) Mounting Slot Detailssabir hussainNo ratings yet

- Revent WPSDocument6 pagesRevent WPSsabir hussainNo ratings yet

- Approved Drawing 1 H14 Gel SealDocument1 pageApproved Drawing 1 H14 Gel Sealsabir hussainNo ratings yet

- Performance Data: AS With Pressurized Ceiling Plenum (Non-Ducted)Document15 pagesPerformance Data: AS With Pressurized Ceiling Plenum (Non-Ducted)sabir hussainNo ratings yet

- Quality Assurance Plan: Sheet MetalDocument2 pagesQuality Assurance Plan: Sheet Metalsabir hussainNo ratings yet

- 1 s2.0 S2666912923000144 Main - CompressedDocument30 pages1 s2.0 S2666912923000144 Main - CompressedFAUZHAN RAMADHAN UBPNo ratings yet

- Red List 2020 EDocument19 pagesRed List 2020 EpuspanovaNo ratings yet

- To Study The Digestion of Starch by Salivary AmylaseDocument15 pagesTo Study The Digestion of Starch by Salivary AmylaseNarender KumarNo ratings yet

- Specific Gravity and Water Absorption of Coarse Aggregate PDFDocument9 pagesSpecific Gravity and Water Absorption of Coarse Aggregate PDFaamirabbashirtrc250% (2)

- Extracto LogDocument4 pagesExtracto LogBruno ArellanoNo ratings yet

- Chapter 2: Diagnostic Enzymology: E+S Es E+PDocument87 pagesChapter 2: Diagnostic Enzymology: E+S Es E+PDereje KasuNo ratings yet

- P6 Water Cycle Revision 2 - Evaporation (Edited 27 Feb 2024)Document15 pagesP6 Water Cycle Revision 2 - Evaporation (Edited 27 Feb 2024)Ananth GanigaNo ratings yet

- Duplex Systems. Painting Over Hot-Dipped Galvanized SteelDocument12 pagesDuplex Systems. Painting Over Hot-Dipped Galvanized Steelcpjones100% (1)

- Effect of Tool Rotational Speed On Temperature and Impact Strength of Friction Stir Welded Joint of Two Dissimilar Aluminum AlloysDocument6 pagesEffect of Tool Rotational Speed On Temperature and Impact Strength of Friction Stir Welded Joint of Two Dissimilar Aluminum AlloysMKM OfficialNo ratings yet

- 11kv Cable SpecificationsDocument3 pages11kv Cable SpecificationsHumours JowaNo ratings yet

- Unit 5 Phase Equilibrium and CorrosionDocument29 pagesUnit 5 Phase Equilibrium and CorrosionDr. Ruma Arora SoniNo ratings yet

- PDE-EQS-3120-EC-00005 - 00 Technical Specification of Ammonia Flash VesselDocument9 pagesPDE-EQS-3120-EC-00005 - 00 Technical Specification of Ammonia Flash Vesselhgag selimNo ratings yet

- Evacuation PlanDocument3 pagesEvacuation PlanJohn Christopher OsorioNo ratings yet

- Standard SolutionDocument5 pagesStandard SolutionAmmar Ahmed Malik 834-FBAS/MSES/S20100% (1)

- CH 4 Reading GuideDocument2 pagesCH 4 Reading Guidepuppyluver102No ratings yet

- Chemistry Test - Chapter 1Document4 pagesChemistry Test - Chapter 1ameena-11173No ratings yet

- علم الارصاد الجوية أو شرح الطقس 2Document133 pagesعلم الارصاد الجوية أو شرح الطقس 2albatati99No ratings yet

- Lesson 9Document3 pagesLesson 9Utkarsh MishraNo ratings yet

- Sampling Steam and Water PDFDocument6 pagesSampling Steam and Water PDFShesharam ChouhanNo ratings yet

- D & F Block Elements - Ex. Module-3-2Document12 pagesD & F Block Elements - Ex. Module-3-2Raju SinghNo ratings yet

- RibosomesDocument12 pagesRibosomesEnika baidenNo ratings yet

- DM Lec 8Document7 pagesDM Lec 8Ali NazarNo ratings yet

- Non-Reduced Tryptic Peptide Mapping For The Confirmation of Disulfide Bonds in ALXN1820 - NewDocument10 pagesNon-Reduced Tryptic Peptide Mapping For The Confirmation of Disulfide Bonds in ALXN1820 - NewRupesh PawarNo ratings yet

- Synthesis and Recrystallization of Dibenzalacetone: Experiment - 4Document2 pagesSynthesis and Recrystallization of Dibenzalacetone: Experiment - 4ARYAN CHAVANNo ratings yet

- Active TransportDocument14 pagesActive TransportRjay CruzNo ratings yet

- Autoregulation and Capillary Dynamics: Graphics Are Used With Permission ofDocument10 pagesAutoregulation and Capillary Dynamics: Graphics Are Used With Permission ofUta Provinsiana SukmaraNo ratings yet

- New Price List Suture Fy21Document72 pagesNew Price List Suture Fy21OPERATING THEATER PHSBNo ratings yet

- FERA-Check List Rev.0Document8 pagesFERA-Check List Rev.0Yaser AhmadNo ratings yet

- 2022 JMGM 111 Ferino JaureguiDocument11 pages2022 JMGM 111 Ferino JaureguiFithriana RachmawatiNo ratings yet

- Fired Heater Efficiency CalculationsDocument10 pagesFired Heater Efficiency CalculationsMohamad IbrahimNo ratings yet