Specification: Unit Description Specification System Operation

Specification: Unit Description Specification System Operation

Uploaded by

Kada Ben youcefCopyright:

Available Formats

Specification: Unit Description Specification System Operation

Specification: Unit Description Specification System Operation

Uploaded by

Kada Ben youcefOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Specification: Unit Description Specification System Operation

Specification: Unit Description Specification System Operation

Uploaded by

Kada Ben youcefCopyright:

Available Formats

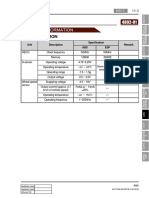

4610-00 14-3

1. SPECIFICATION

Unit Description Specification

System operation Operating type Motor driven power steering system

Operating temperature - 40°C to 80°C

Rated voltage 12 V

Rated current 85 A

Operating voltage Network 8 to 16 V

C-EPS ECU 8 to 16 V

Full Performance 10 to 16 V

Motor Type 3-Phase BLAC (Brushless AC)

cardiagn.com

Rated current/voltage 85 A / 12 V (at idle 0.5 A)

Position sensor type Hall sensor type

Torque & angle sensor Type Non-contact type

Steering column Operating type Manual tilting & telescoping

Lower shaft Type Sliding (Ball slip) type

Steering gear Gear ratio 46.94 mm/rev

Rack stroke 146 mm

Maximum steering angle Inner wheel 39°

Outer wheel 31.24°

ELECTRIC POWER STEERING

korando 2010.10

14-4 4610-00

2. TIGHTENING TORQUE

cardiagn.com

ELECTRIC POWER STEERING

korando 2010.10

4610-00 14-5

1. OVERVIEW

The electric power steering, EPS, does not have any belt-driven steering pump constantly

running, so it is lightweight and the motor consumes energy only when the steering wheel is

turned by the driver, and this leads to improvement in fuel efficiency. Also, the elimination of a

belt-driven pump and its accessories greatly simplifies manufacturing and maintenance. While

offering these benefits, as it does not contain any steering oil, the environment is not polluted

both when the steering system is produced and discarded.

In other words, the electric power steering (EPS) system uses the electric motor to assist the

steering force. It functions independently regardless of whether the engine is running or not,

unlike the existing hydraulic power steering.

The EPS system generates an assist steering force variably depending on the driving

conditions by controlling the motor's operation, based on the input signals from the sensors

such as torque sensor and angle sensor. In turn, the EPS receives the torque signal by the

driver's movements of the steering wheel, as well as the vehicle speed, and uses the motor to

cardiagn.com

determine the assist torque. The EPS controls the motor for this. Another features of EPS are

fail-safe function, diagnosis function, communication function between units and interface

function for external diagnostic device.

The EPS system components such as the torque sensor, steering angle sensor, fail-safe relay,

etc. are located in the steering column and EPS unit assembly.

▶ Advantages:

(1)Assurance of improved steering (2)Reduced fuel consumption

- Provides optimal steering force according - Consumes energy only when steering

to the vehicle speed wheel is turned (improved by 3 to 5%)

- Enhanced steering stability while driving at - Energy saving (reduced by 85% compared

high speed with hydraulic power steering)

- Reduced number of parts: Elimination of

steering pump, hydraulic hose, pump

pulley, oil reservoir, belt, bracket, etc.

▶ Comparison between hydraulic power steering and electric power steering (EPS)

Hydraulic power steering Electric power steering

ELECTRIC POWER STEERING

korando 2010.10

14-6 4610-00

2. OPERATION

cardiagn.com

Output torque = 1) Steering force (manual torque) + 2) Assist torque

When the driver turns the steering wheel, a torque is generated and the torque sensor and the

steering angle sensor in the EPS system detect the rotation of the steering column to run the

electric motor. At this time, the worm gear connected to the motor drives the helical gear

mounted to the steering column to generate the assist torque for the steering column. This

allows the driver to operate the steering wheel easier.

ELECTRIC POWER STEERING

korando 2010.10

You might also like

- 스미토모 카운터Document212 pages스미토모 카운터01033948385pjhNo ratings yet

- CT100-NT05 Service Manual PDFDocument93 pagesCT100-NT05 Service Manual PDFDwane Duncan100% (1)

- Steam Tracing With MS ExcelDocument14 pagesSteam Tracing With MS ExcelRaul Bautista100% (2)

- UPS User ManualDocument52 pagesUPS User ManualStephen Rey CaldeaNo ratings yet

- DC G240 eDocument14 pagesDC G240 eHany Mohamed100% (12)

- BV350 Workshop Manual PDFDocument346 pagesBV350 Workshop Manual PDFEMILENo ratings yet

- A Smart Motor Controller For E-Bike Applications PDFDocument4 pagesA Smart Motor Controller For E-Bike Applications PDFaungwinnaing100% (1)

- Electrical Wiring Colour Codes PDFDocument9 pagesElectrical Wiring Colour Codes PDFRavi KrishnanNo ratings yet

- EPS (Electric Power Steering)Document21 pagesEPS (Electric Power Steering)EngForAutoService100% (3)

- User 'S Guide For MT-DAE: Learning Model: Electric Power SteeringDocument45 pagesUser 'S Guide For MT-DAE: Learning Model: Electric Power SteeringShifat UllahNo ratings yet

- Electric Power Steering - 2Document9 pagesElectric Power Steering - 2Tilahun Worku100% (2)

- FACTSHEET_Nissan KICKS e-POWER Test driveDocument5 pagesFACTSHEET_Nissan KICKS e-POWER Test driveSanny HamdaniNo ratings yet

- Piaggio Runner 125 - 200 Scooter Shop ManualDocument327 pagesPiaggio Runner 125 - 200 Scooter Shop Manualmylitter5391100% (1)

- Description: Eps System Description - Eps ControlDocument34 pagesDescription: Eps System Description - Eps ControlpaniyaNo ratings yet

- Yale Forklifts SpecDocument4 pagesYale Forklifts Specnguyen.db.1106No ratings yet

- EV PPTDocument58 pagesEV PPTSnataksuraj KarajadaNo ratings yet

- Z40 Service Training 139240 RevP1Document98 pagesZ40 Service Training 139240 RevP1DANIEL100% (1)

- Report On Electronic Power SteeringDocument14 pagesReport On Electronic Power SteeringSatadru Bera60% (5)

- Brochure 20240517100552Document5 pagesBrochure 20240517100552em2021bNo ratings yet

- Specification: Unit Description Specification Remark ABS ESPDocument22 pagesSpecification: Unit Description Specification Remark ABS ESPmanualNo ratings yet

- SsangYong-Korando 2012 EN US Manual de Taller Control de Estabilidad 228ecf8b96Document66 pagesSsangYong-Korando 2012 EN US Manual de Taller Control de Estabilidad 228ecf8b96Bigo AntonioNo ratings yet

- E - BikeDocument17 pagesE - BikeSaurabh Deshmukh100% (1)

- Major Automotive SystemsDocument11 pagesMajor Automotive Systemsismailshaikce0115No ratings yet

- EPS AC Wire Guidance Itens 1.0-5.2Document8 pagesEPS AC Wire Guidance Itens 1.0-5.2Jose SantosNo ratings yet

- Focus On Iveco TransmissionsDocument31 pagesFocus On Iveco TransmissionsBroCactus100% (3)

- Esl15 SC ManualDocument31 pagesEsl15 SC ManualRobert Nie WiemNo ratings yet

- Web Energicabr 2019eva - enDocument9 pagesWeb Energicabr 2019eva - enStiward BautistaNo ratings yet

- 650 Kva Volvo Motorlu Dizel JeneratorDocument3 pages650 Kva Volvo Motorlu Dizel JeneratorAnonymous tXzjQAJttHNo ratings yet

- Project Report ON Eps Motor: Submitted By:Rajnish ROLL NO:08614803609Document16 pagesProject Report ON Eps Motor: Submitted By:Rajnish ROLL NO:08614803609Ankit VermaNo ratings yet

- (NGOC) Proposing - A - BSPID - Control - Strategy - Considering - External - Disturbances - For - Electric - Power - Steering - EPS - SystemsDocument20 pages(NGOC) Proposing - A - BSPID - Control - Strategy - Considering - External - Disturbances - For - Electric - Power - Steering - EPS - Systemshakyno2003No ratings yet

- Principle of Operation: Key Elements Interacting To Produce MotionDocument5 pagesPrinciple of Operation: Key Elements Interacting To Produce MotionamitbslpawarNo ratings yet

- Steering 2 TextbookDocument14 pagesSteering 2 Textbookអែម៚ ពីន៚No ratings yet

- Specification: Unit Description Specification ABS ESP HecuDocument22 pagesSpecification: Unit Description Specification ABS ESP HecuKada Ben youcefNo ratings yet

- Controller Design For Electric Power Steering System Using T-S Fuzzy Model Approach PDFDocument6 pagesController Design For Electric Power Steering System Using T-S Fuzzy Model Approach PDFsenthilduraiNo ratings yet

- Q150 WML 510Document22 pagesQ150 WML 510manualNo ratings yet

- PowerDocument25 pagesPowerHarith HaiqalNo ratings yet

- Power Steering System Description and Operation (Electric Power Steering) PDFDocument2 pagesPower Steering System Description and Operation (Electric Power Steering) PDFAlonso BarrónNo ratings yet

- JGM857E JinGong 5.5-Ton Pure Electric Wheel LoaderDocument6 pagesJGM857E JinGong 5.5-Ton Pure Electric Wheel LoaderChalil FachroniNo ratings yet

- Dynamometer For E-Bikes According To New EPAC/EMC Standard: FeaturesDocument12 pagesDynamometer For E-Bikes According To New EPAC/EMC Standard: FeaturesenekomNo ratings yet

- Esd5111 enDocument4 pagesEsd5111 enMahdi Dehghankar100% (1)

- Esd5111 enDocument4 pagesEsd5111 enRicardo MonteroNo ratings yet

- ACE150 Specsheet Nov 2024Document2 pagesACE150 Specsheet Nov 2024kuresha.nandsNo ratings yet

- FINALDocument23 pagesFINALShashank Gautam100% (1)

- Electromechanical SteeringDocument34 pagesElectromechanical Steeringzaka_cz100% (1)

- Final PPT On E-BikeDocument29 pagesFinal PPT On E-BikeAdityaveer SinghNo ratings yet

- UNIT-II-part-I .Servo, Hydraulics and Pneumatic & Electrical ActuatorsDocument66 pagesUNIT-II-part-I .Servo, Hydraulics and Pneumatic & Electrical ActuatorsRajakumar SaiNo ratings yet

- PerkinsDocument3 pagesPerkinsDella AstariNo ratings yet

- Master Ahmed Hussnain 2014Document8 pagesMaster Ahmed Hussnain 2014Hary YoskovichNo ratings yet

- Energy SavingDocument50 pagesEnergy SavingKuna MarndiNo ratings yet

- Eceg-5401 2Document37 pagesEceg-5401 2Kide Bay0% (1)

- Summer Internship: National Institute of Technology DelhiDocument16 pagesSummer Internship: National Institute of Technology DelhiAjay kumarNo ratings yet

- AutoSpeed - Modifying Electric Power SteeringDocument6 pagesAutoSpeed - Modifying Electric Power SteeringgoundenaNo ratings yet

- EDC16C9 v1.6Document79 pagesEDC16C9 v1.6Michał BajdaNo ratings yet

- 2011 33 MaintenanceDocument16 pages2011 33 MaintenanceKrishna Khandige100% (2)

- Chapter3 Automotive Embedded ApplicationsDocument156 pagesChapter3 Automotive Embedded ApplicationsKomal Kalkutkar100% (1)

- Diesel LocomotivesDocument20 pagesDiesel LocomotivesAashish Singhal100% (2)

- Controlador de Direccion 1Document6 pagesControlador de Direccion 1JOEL APONTE ORTIZNo ratings yet

- Scrambler X2 Specification Sheet R20231029-004Document8 pagesScrambler X2 Specification Sheet R20231029-004Joe Who?No ratings yet

- Perkins 1300Document2 pagesPerkins 1300ahmedalgalo50% (2)

- Electronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesFrom EverandElectronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesNo ratings yet

- Model Predictive Control of High Power Converters and Industrial DrivesFrom EverandModel Predictive Control of High Power Converters and Industrial DrivesNo ratings yet

- 19 Cat Devant Des Vomissements de L'enfantDocument45 pages19 Cat Devant Des Vomissements de L'enfantKada Ben youcefNo ratings yet

- C200 - Pre-Heating SystemDocument7 pagesC200 - Pre-Heating SystemKada Ben youcefNo ratings yet

- 12 Cat Devant Une Creatinine EleveeDocument13 pages12 Cat Devant Une Creatinine EleveeKada Ben youcefNo ratings yet

- Engine Data ListDocument45 pagesEngine Data ListKada Ben youcefNo ratings yet

- 01 FcuDocument35 pages01 FcuKada Ben youcefNo ratings yet

- C200 - Intake SystemDocument9 pagesC200 - Intake SystemKada Ben youcefNo ratings yet

- C200 - Lubrication SystemDocument5 pagesC200 - Lubrication SystemKada Ben youcefNo ratings yet

- D20Dtf Engine: 1. SpecificationDocument26 pagesD20Dtf Engine: 1. SpecificationKada Ben youcefNo ratings yet

- C200 - CDPF SystemDocument12 pagesC200 - CDPF SystemKada Ben youcefNo ratings yet

- C200 - Starting SystemDocument5 pagesC200 - Starting SystemKada Ben youcefNo ratings yet

- Suspension SystemDocument13 pagesSuspension SystemKada Ben youcefNo ratings yet

- C200 - Cruise Control SystemDocument12 pagesC200 - Cruise Control SystemKada Ben youcefNo ratings yet

- Propeller Shaft (4Wd Only) : 1. SpecificationDocument3 pagesPropeller Shaft (4Wd Only) : 1. SpecificationKada Ben youcefNo ratings yet

- C200 - Cooling SystemDocument11 pagesC200 - Cooling SystemKada Ben youcefNo ratings yet

- C200 - Charge SystemDocument10 pagesC200 - Charge SystemKada Ben youcefNo ratings yet

- C200 - Engine GeneralDocument16 pagesC200 - Engine GeneralKada Ben youcefNo ratings yet

- C200 - E-Egr SystemDocument9 pagesC200 - E-Egr SystemKada Ben youcefNo ratings yet

- Specification: 1) Appearance of WheelsDocument6 pagesSpecification: 1) Appearance of WheelsKada Ben youcefNo ratings yet

- General Information ChassisDocument28 pagesGeneral Information ChassisKada Ben youcefNo ratings yet

- Description SpecificationDocument7 pagesDescription SpecificationKada Ben youcefNo ratings yet

- Specification: Unit ConstructionDocument7 pagesSpecification: Unit ConstructionKada Ben youcefNo ratings yet

- Power Steering SystemDocument5 pagesPower Steering SystemKada Ben youcefNo ratings yet

- System Overview: 1) Terms and DefinitionDocument9 pagesSystem Overview: 1) Terms and DefinitionKada Ben youcefNo ratings yet

- Drive Shaft and AxleDocument4 pagesDrive Shaft and AxleKada Ben youcefNo ratings yet

- Dsi 6 Speed Auto TransaxleDocument24 pagesDsi 6 Speed Auto TransaxleKada Ben youcefNo ratings yet

- Specification: Unit Description Specification ABS ESP HecuDocument22 pagesSpecification: Unit Description Specification ABS ESP HecuKada Ben youcefNo ratings yet

- Witch Mode Rectifier (Se-Smr-1400)Document10 pagesWitch Mode Rectifier (Se-Smr-1400)Bala Dharma Srinivas KNo ratings yet

- Benzene, 1,4-Bis (1-Methylethyl) - : Physical PropertiesDocument3 pagesBenzene, 1,4-Bis (1-Methylethyl) - : Physical PropertiesLAURA LUC�A ATENCIA CASTILLONo ratings yet

- Session 1: Kinematics QuestionsDocument2 pagesSession 1: Kinematics Questionsapi-3804363100% (1)

- Answer Essay 18 Capacitor 2005 PDFDocument3 pagesAnswer Essay 18 Capacitor 2005 PDFWong Chai YenNo ratings yet

- Al Aalamy Company: For Engineering TestingDocument3 pagesAl Aalamy Company: For Engineering Testingzehra alloteesNo ratings yet

- Een 202 Lab 8 ReportDocument5 pagesEen 202 Lab 8 Reportapi-296881750No ratings yet

- Solar Drive EM15 SP User ManualDocument41 pagesSolar Drive EM15 SP User ManualRinaldyNo ratings yet

- Pabna University of Science and Technology Dept. of EEEDocument10 pagesPabna University of Science and Technology Dept. of EEEZannat E Noor AobonyNo ratings yet

- A M Forrest 1983 Eur. J. Phys. 4 011Document5 pagesA M Forrest 1983 Eur. J. Phys. 4 011Eduardo Latorre LópezNo ratings yet

- SS2 Physics PraticalDocument3 pagesSS2 Physics PraticalAriyo olawaleNo ratings yet

- Science Notes For Forces and MotionDocument6 pagesScience Notes For Forces and Motiontoe masterNo ratings yet

- AC CircuitsDocument19 pagesAC Circuitsdummy accountNo ratings yet

- Ventilator CJTHTDocument6 pagesVentilator CJTHTAndrei PantaNo ratings yet

- Lightning Protection of Low-Voltage Networks Working Group C4.408Document81 pagesLightning Protection of Low-Voltage Networks Working Group C4.408carlosticozNo ratings yet

- P - Ch-01 - Motion in A Straight LineDocument4 pagesP - Ch-01 - Motion in A Straight LineNikhil KumarNo ratings yet

- Maxwell-Boltzmann Distribution For Ideal Gases: 3/2 2 (-Mmvv/2Rt)Document6 pagesMaxwell-Boltzmann Distribution For Ideal Gases: 3/2 2 (-Mmvv/2Rt)Safitri RaufaNo ratings yet

- Transformer QuestionsDocument2 pagesTransformer QuestionsReneboy Lambarte0% (4)

- t4 M 009 Gcse Maths Formulae Posters Ver 8Document27 pagest4 M 009 Gcse Maths Formulae Posters Ver 8Joel OkohNo ratings yet

- Crane Technical Data SheetDocument7 pagesCrane Technical Data Sheet98675No ratings yet

- Heating Ventilation and Air Conditioning - HVACDocument40 pagesHeating Ventilation and Air Conditioning - HVACRaheel AhmedNo ratings yet

- SM PDF Chapter2Document28 pagesSM PDF Chapter2kyara906No ratings yet

- Questions Chap 2 Electrostatic Potential & Capacit_80152Document5 pagesQuestions Chap 2 Electrostatic Potential & Capacit_80152mayankbiwal48No ratings yet

- Design of Speed Control Circuit For Adams MotorDocument6 pagesDesign of Speed Control Circuit For Adams MotorCris VillarNo ratings yet

- Electrical Notes LL224 Bell CircuitDocument14 pagesElectrical Notes LL224 Bell CircuitSeun100% (2)

- AC For Mechanical EngineeringDocument77 pagesAC For Mechanical EngineeringHasen Yunne ShemsiNo ratings yet

- L-2 (DK) (Pe) ( (Ee) Nptel) 5Document6 pagesL-2 (DK) (Pe) ( (Ee) Nptel) 5GagneNo ratings yet