Selectomat - PL - User Manual - ENG

Selectomat - PL - User Manual - ENG

Uploaded by

Mus BentCopyright:

Available Formats

Selectomat - PL - User Manual - ENG

Selectomat - PL - User Manual - ENG

Uploaded by

Mus BentOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Selectomat - PL - User Manual - ENG

Selectomat - PL - User Manual - ENG

Uploaded by

Mus BentCopyright:

Available Formats

Instructions for use

Steam sterilizer

Selectomat PL

Manufacturer's original user manual

MMM Münchener Medizin Mechanik GmbH

Semmelweisstraße 6

D-82152 Planegg

www.mmmgroup.com

Selectomat PL | 010044945 | REV 26.1 | 2019 - 04

General information

General information

Observe the following sections in particular of the original user manual:

■ Intended use

■ Rules of conduct during operation

■ Standards and directives

This user manual describes the operation of your steam sterilizer.

Legend of symbols and hazard warnings

The following hazard warnings and symbols may appear in this user

manual:

Handling instruction

■ List

Ignoring hazard warnings may cause injury!

Danger

Ignoring these warnings may cause damage to the machine or the

load!

Indicates practical tips or important information about the functioning of the

machine.

List of abbreviations

BW Loading trolley For transporting goods into a sterilizer with

raised loading

EW Loading trolley For transporting goods into a sterilizer with

floor level loading.

TW Transport trolleys For transporting loading trolleys or racks

TW Height-adjustable transport For transporting loading trolleys

HUB trolley

ED Internal steam Version with integrated or associated

steam generator

FD External steam Connection to an on-site steam supply, e.g.

domestic steam

StU Sterilization unit Dimensions: 300 x 300 x 600 mm

REV 26.12019 - 04 3 / 136

General information

SOP Standard Operating Standard operating procedure

Procedure

Warning signs on the machine

The following warning signs may be present on the machine:

Warning dangerous electrical voltage! Open only by trained personnel.

Warning hot surface! Wear protective gloves.

Warning risk of crushing injury to hands.

Do not sit on the conveyor.

Warning instructions before entering the chamber.

Protective ground

Wear protective glasses!

Wear protective gloves!

4 / 136 REV 26.12019 - 04

General information

Device labelling

The specification of this steam sterilizer is indicated by the following device labeling:

This can be explained by way of an example: Selectomat PL 9612 - 2 H R

Machine name Nominal chamber size Number Variant Position of the chamber

HWD of doors

Selectomat PL 9 6 12 2 H R

series

The chamber size (9 x 6 x 12) is based on the 1-door See the R Chamber right

dimensions for a sterilization unit 2-door table below Panel left

(1 STU = 3 x 3 x 6 dm).

L Chamber left

Example:

Panel right

Chamber size 9 6 12 = 12 STU

The Selectomat PL steam sterilizer is available in the following variants:

Variant Version

Position of the Integrated Opening direction

chamber steam generator of the chamber door

H Right / left option Horizontal

V Right / left Option Vertical

G Right / left -------- Horizontal

CL ----- According to model Vertical

Chamber specifications: Variant H

Number Volume Internal chamber clear- Loading height

Chamber size

of StUs in liters ance* in mm (H x W x D)

666 4 320 710 x 650 x 690 625 mm

669 6 460 710 x 650 x 990 625 mm

6612 8 622 710 x 650 x 1340 625 mm

966 6 451 1000 x 650 x 690 390 mm

969 9 647 1000 x 650 x 990 390 mm

9612 12 875 1000 x 650 x 1350 390 mm

9618 18 1267 1000 x 650 x 1940 390 mm

Machines with raised loading (variant H) are loaded and unloaded with a transport trolley and a loading

trolley positioned on it.

REV 26.12019 - 04 5 / 136

General information

Chamber specifications: Variant V

Number Volume Internal chamber clear- Loading height

Chamber size

of StUs in liters ance* in mm (H x W x D)

636 2 160 670 x 350 x 700 850 mm

666 4 314 702 x 652 x 690 850 mm

669 6 453 702 x 652 x 990 850 mm

6612 8 610 702 x 652 x 1340 850 mm

Machines with raised loading (variant V) are loaded and unloaded with a transport trolley and a loading

trolley positioned on it.

Chamber specifications: Variant G

Number Volume Internal chamber clear- Loading height

Chamber size

of StUs in liters ance* in mm (H x W x D)

969 9 1067 1360 x 720 x 1090 Floor level

9612 12 1361 1360 x 720 x 1390 Floor level

9618 18 2095 1360 x 720 x 2140 Floor level

Floor-level, passable machines (variant G) are loaded and unloaded using trolleys.

Chamber specifications: Variant CL

Number Volume Internal chamber clear- Loading height

Chamber size

of StUs in liters ance* in mm (H x W x D)

636 2 160 670 x 350 x 700 850 mm

666 4 314 702 x 652 x 690 850 mm

669 6 453 702 x 652 x 990 850 mm

6612 8 610 702 x 652 x 1340 850 mm

6618 12 885 702 x 652 x 1940 850 mm

Machines with raised loading (variant CL) are loaded and unloaded with a transport trolley and a loading

trolley positioned on it.

* Standard dimensions only. The dimensions may vary for each project.

6 / 136 REV 26.12019 - 04

Contents

Contents

1 Safety.........................................................................................11

1.1 Intended use.............................................................................. 11

1.2 Responsibilities of the operator................................................. 12

1.2.1 Commissioning - equipment requirements................................ 13

1.2.1.1 Connection to the electrical power supply................................. 14

1.2.1.2 Blow off line................................................................................14

1.2.1.3 Media..........................................................................................15

1.2.2 Installation and operation of the machine.................................. 16

1.2.3 Maintaining efficiency................................................................. 17

1.2.3.1 Process validation...................................................................... 18

1.2.3.2 Routine inspections.................................................................... 18

1.2.4 Operation of pressure equipment.............................................. 19

1.2.5 Disposal......................................................................................20

1.3 Users.......................................................................................... 21

1.3.1 Approved operators....................................................................22

1.3.2 System supervisor......................................................................22

1.3.3 Specialist.................................................................................... 22

1.4 Rules of Conduct during Operation........................................... 23

1.4.1 Personal protective equipment.................................................. 23

1.4.2 Starting a program..................................................................... 23

1.4.3 Working inside the chamber...................................................... 23

1.4.4 Working on the assemblies........................................................24

1.4.5 Working in the electrical control cabinet.................................... 24

1.4.6 Maintenance work...................................................................... 24

1.4.7 Automatic transport system (option).......................................... 24

1.5 Machine safety devices..............................................................25

1.5.1 Safety strip................................................................................. 25

1.5.2 Automatic program cancellation.................................................25

1.5.3 Program cancellation button...................................................... 25

1.5.4 Program stop switch.................................................................. 26

1.5.5 Master switch............................................................................. 26

1.5.6 Safety valve................................................................................27

1.5.7 Locking the chamber door and door release............................. 27

1.5.8 Monitoring the sterilization parameters...................................... 27

1.5.9 Access protection....................................................................... 28

1.6 Residual risks and measures to prevent them...........................28

1.7 Maintenance and Safety inspection........................................... 30

1.8 Equipment log............................................................................ 31

REV 26.12019 - 04 7 / 136

Contents

1.9 Standards and directives........................................................... 31

2 Machine description.................................................................33

2.1 Standard equipment................................................................... 33

2.2 Optional additional features....................................................... 35

2.2.1 Optional programs......................................................................35

2.2.1.1 Special programs....................................................................... 35

2.2.1.2 APPcycles® (option).................................................................. 35

2.2.2 Additional monitoring equipment................................................35

2.2.3 Reducing the consumption of media......................................... 37

2.2.4 Optional services........................................................................38

2.2.5 Automatic transport system....................................................... 40

2.2.6 Uninterruptible power supply (UPS) (option)............................. 40

2.3 Accessories Transport trolley.....................................................40

2.4 User administration.................................................................... 42

2.5 Batch documentation................................................................. 43

2.6 Automatic program selection using the barcode (option)...........44

2.7 Process description.................................................................... 45

2.7.1 Sterilization programs................................................................ 46

2.7.2 Heating and SteamSpy heating................................................. 49

2.7.3 Test programs............................................................................ 49

2.7.3.1 Vacuum test................................................................................49

2.7.3.2 Bowie-Dick test.......................................................................... 50

2.7.3.3 Air detector function test (option)...............................................51

2.7.4 Special programs....................................................................... 51

2.7.4.1 Alloplast...................................................................................... 51

2.7.4.2 Disinfection (option)................................................................... 51

2.7.4.3 Rack hatch................................................................................. 51

3 Display and control elements................................................. 53

3.1 View of the machine - loading side............................................53

3.2 View of the machine - unloading side........................................53

3.2.1 H, V and G machines (manual)................................................. 53

3.2.2 G machines (automatic).............................................................54

3.3 Acknowledgement button (optional)...........................................55

3.4 Pressure gauge display............................................................. 56

3.5 Color touch screen.....................................................................56

3.6 Colored status displays..............................................................59

4 Operation...................................................................................61

4.1 Logging users in and out........................................................... 61

8 / 136 REV 26.12019 - 04

Contents

4.2 Daily start-up.............................................................................. 62

4.2.1 Vacuum test................................................................................63

4.2.2 Heating program........................................................................ 63

4.2.3 Bowie-Dick test.......................................................................... 64

4.3 Sterilization mode.......................................................................65

4.3.1 Reading barcodes...................................................................... 65

4.3.2 Loading the loading trolley.........................................................67

4.3.3 Waiting times..............................................................................68

4.3.4 Loading the sterilization chamber.............................................. 69

4.3.5 Program selection and program start........................................ 70

4.3.6 Cancelling the program..............................................................72

4.3.7 Program end.............................................................................. 73

4.3.8 Unloading the chamber..............................................................73

4.3.9 Passing through......................................................................... 75

4.4 Batch release............................................................................. 75

4.4.1 Displaying and printing saved batch records............................. 76

4.4.2 External saving of batch files.....................................................77

4.5 Standby mode............................................................................ 77

4.6 Shut-off....................................................................................... 78

5 Machine configuration............................................................. 79

5.1 Configuring user administration (option).................................... 79

5.2 Setting batch print and save options......................................... 81

5.3 Print settings.............................................................................. 82

5.4 Setting the network addresses of the control panel................... 83

5.5 Activating auto start (option)...................................................... 84

5.6 Activating standby mode............................................................85

5.7 Setting the time.......................................................................... 85

5.8 Activating the steam manager (option)...................................... 86

5.9 Activating the cooling circuit vacuum pump...............................86

5.10 Calibration screen...................................................................... 88

6 Operating safety and faults.................................................... 89

6.1 Unexpected cancellation of the program sequence................... 89

6.2 Acknowledging messages..........................................................91

6.3 Time taken to switch off the vacuum pump exceeded............... 91

6.4 Faults in door movement........................................................... 91

6.5 Manual advance.........................................................................93

6.6 Analysis options in the event of faults....................................... 95

6.6.1 Sending a debug e-mail.............................................................95

6.6.2 Function check for specific components.................................... 96

REV 26.12019 - 04 9 / 136

Contents

6.7 Status and alarm messages...................................................... 98

7 Maintenance............................................................................111

7.1 Preparatory measures..............................................................112

7.2 Service module (option)........................................................... 113

7.3 Maintenance activities.............................................................. 113

7.4 Exchanging the door seal........................................................ 117

7.5 Thermal printer paper exchange (option).................................117

7.6 Periodic inspections of pressure vessels................................. 118

7.7 Cleaning................................................................................... 120

7.7.1 Chamber interior...................................................................... 121

7.7.2 Assemblies compartment......................................................... 122

7.7.3 External care............................................................................ 122

7.7.4 Cleaning of transport trolleys................................................... 123

8 Software Licence Agreement................................................125

9 Warranty (Liability for defects)............................................. 133

10 Index........................................................................................ 135

10 / 136 REV 26.12019 - 04

Safety

1 Safety

Read this user manual carefully and save it for future reference.

Observe the safety instructions.

Your personal safety and the correct functioning of the machine are

at stake.

To be able to operate and maintain this machine safely in a hazard-free and

problem-free manner, the user must be familiar with the safety instructions

and warnings contained in this user manual and be capable of carrying out

the instructions provided correctly.

The machine and accessories must not be modified. This especially applies

to the safety mechanisms.

This user manual contains information on the proper use of the machine.

It is intended not only for the authorized operators ( Chapter 1.3.1,

"Approved operators") and the system supervisor ( "System supervisor "),

but also for all persons involved in the set up, commissioning, operation or

maintenance of the machine.

For reasons of clarify, this user manual only contains the necessary instruc-

tions for normal operation and routine maintenance, as well as a description

of the essential functions of the machine.

For more information about your machine, please contact the manufacturer.

1.1 Intended use

The Selectomat PL is suitable for treating the following materials:

Sterilization of solid and porous items

• Instruments

• Utensils (e.g. kidney dishes, saline bowls)

• Laundry

• Other porous items (e.g. dressings, swabs)

• Heat resistant rubber items and plastic articles

• Implants (e.g. alloplastic prosthetics)

• Medical products that have been used for operations on high-risk

tissues (prion prevention, e.g. patients with suspected CJK/vCJK)

REV 26.12019 - 04 11 / 136

Safety

Disinfection of

• Utensils and anesthesia supplies

The sterilizer is not suitable for treating:

■ Flammable and explosive items

Danger

■ Liquids

■ Infectious hospital waste (e.g. C waste)

■ Pathogenic materials

Service life of the machine

If the specified maintenance work is regularly performed, the expected

service life of the machine is 10 years (under standard usage conditions,

see 93/42/EEC Annex I, 4).

During the service life of the product, the properties and performance char-

acteristics are not influenced in a way that could endanger the safety of

patients, users and, if applicable, third parties.

If you wish to continue using the machine beyond the above period, please

contact the manufacturer or an authorised service company for inspection

of the machine to assess the wear, technical status and the possibility of

repair.

1.2 Responsibilities of the operator

This machine is a medical product in accordance with directive 93/42 EEC

Annex I on medical products, and a pressure vessel in accordance with

directive 2014/68/EU on pressure equipment.

The operator is responsible for adhering to all regulations and regular

inspections under these directives over the entire product life cycle.

The operator is required to observe the national laws and regulations

applicable to the installation site of the machine.

The operator is solely responsible for determining which legal provi-

sions cover the installation and the operation of this device. These

may differ from the information provided in this user manual!

12 / 136 REV 26.12019 - 04

Safety

The operator must comply with their reporting obligations to manu-

facturers and authorities in accordance with the European Directive

93/42/EEC, Article 10, or from 25 May, 2020 in accordance with the

Regulation (EU) 2017/745, Article 87.

Before commissioning

The operator must ensure that the following requirements are met:

■ the device has been properly assembled and installed

■ the inspection and maintenance plan is available

■ the system supervisors and users have been trained

■ the operating permit has been issued (if required by national regula-

tions)

■ the operator must have given approval

■ the standard operating procedure is available

■ The validation has been performed ( see Chapter 1.2.3.1, "Process

validation")

■ unused programmes have been locked.

Network security

MMM recommends performing a cybersecurity assessment of the network

interface, and implementing any necessary measures as part of a risk

management process in accordance with the EN 80001 standard.

1.2.1 Commissioning - equipment requirements

The sterilizer must be connected to the supply lines (e.g. drinking water

network) and secured to prevent pressure overshoots according to the

manufacturer's planning drawing and the dimension drawingpiping diagram

and the local regulations.

Observe the national legal regulations on drinking water protection

(e.g. DIN EN 1717).

REV 26.12019 - 04 13 / 136

Safety

1.2.1.1 Connection to the electrical power supply

Make sure that the voltage, current type and frequency specified on

the type plate correspond to those at the site.

EN 61010-1, Section 6.10.2 must be observed when connecting the

machine to the electrical power supply. In particular, it must be ensured

that:

■ the cable gland is used as strain relief

■ the protective conductor is the longest of all individual lines in the

connection cable

When working on the machine, turn off the master switch and secure

it with a lock to prevent it from being switched back on unintention-

ally.

Danger

1.2.1.2 Blow off line

The standard version of the machine needs to be connected to a blow-off

line provided on-site. This line must safely discharge the steam into the

open.

Observe the instructions in the installation preparation drawing and

technical data sheet.

Blow off line exiting in the bottom tray (option)

When using suitable supplementary equipment (for example a pressure

limiter), the blow-off line of the safety valve can exit in the bottom tray of the

machine. An on-site blow-off line is then not required.

The operator must inspect and assess the installation location as to

whether blow off via the safety valve can safely be implemented!

Danger Observe the instructions in the installation preparation drawing and

technical data sheet.

Ensure that the line is unobstructed at all times, and that the steam can be

blown off safely.

14 / 136 REV 26.12019 - 04

Safety

The blow off line must be adequately dimensioned so that no impermis-

sibly high counter-pressure develops when blowing off the safety valve (see

technical connection data).

1.2.1.3 Media

The media, particularly the sterilization steam, must meet the requirements

specified in the planning drawing or the technical dimension drawing and

the piping diagram (e.g. max. permissible pressure, steam quality etc.) to

prevent damage due to excess pressure and corrosion. The media must be

regularly checked in this regard.

The steam is supplied either

■ via the integrated or assigned steam generator (ED version) or

■ via a connection to an external steam supply (FD version).

Requirements for the sterilization steam

The sterilization steam must have the following quality:

■ The supply line of an external steam supply must be sufficiently drained.

■ The last condensate drain may lie a maximum of 2 m upstream of the

sterilizer's connection point.

■ Steam pressure fluctuations at the sterilizer's connection point must not

exceed the required rated pressure by more than +/-10% as specified

by EN 285.

■ Pressure reduction stages in the supply lines must not exceed a reduc-

tion ratio of 2:1.

■ The last pressure reduction must be located a minimum of 5 m

upstream from the connection point to the sterilizer.

■ The steam velocity in the supply line must not exceed 36 m/s.

■ The volume of non-condensible gases in the steam condensate must

not exceed 3.5%.

REV 26.12019 - 04 15 / 136

Safety

1.2.2 Installation and operation of the machine

Observe all relevant national regulations when installing and operating the

machine.

The following is applicable for machines installed and operated in

Germany:

■ BetrSichV German Ordinance on Industrial Safety and Health

■ TRBS Technical rules for operating safety

■ MPBetreibV - German Medical Device Operator Ordinance

■ AD 2000 - leaflets and DIN EN 13445

■ DIN 58946 T7 Sterilization, steam sterilization

■ DIN EN ISO 17665-1 Sterilization of health care products - Moist heat

■ ProdSG German Product Safety Act

■ 14th ProdSV Fourteenth ordinance pertaining to the German Product

Safety Act

■ Accident prevention regulation DGUV Regulation 1

Observe the German Occupational Safety Act, and the Ordinance on Indus-

trial Safety and Health (BetrSichV). In accordance with BetrSichV, a risk

assessment must be performed regarding the operation within the company

of an installation subject to monitoring ( Chapter 1.2.4, "Operation of pres-

sure equipment").

We recommend documenting the measures resulting from the risk assess-

ment for safe operation and use of the machine (e.g. operating readiness,

down times, qualification of operating personnel, etc.) in a standard oper-

ating procedure (SOP).

The operator is responsible for performing periodic inspections

pursuant to the German Ordinance on Industrial Safety and Health

(BetrSichV).

Observe the inspection intervals of BetrSichV.

Sound emissions

The average A-weighted emission sound pressure level of the device

during operation measured pursuant to DIN EN 3746 is less than 70 dB(A).

16 / 136 REV 26.12019 - 04

Safety

The operator must take the noise emission of the system into account when

performing a risk assessment.

Training the users

The machine operator is responsible for adequately training the authorized

users and the system supervisor.

At delivery at the latest, the staff entrusted with operating the machine

must be trained for this task by a qualified person ( see Chapter 1.3.3,

"Specialist" e.g. MMM customer service) and be familiar with the user

manual.

The names of persons authorized to use the machine as well as the system

supervisor ( see Chapter 1.3.2, "System supervisor ") must be recorded

in the medical products log / equipment log. When changes in staff occur,

new users must be inducted using this user manual and also recorded in

the medical products / equipment log.

The operator is required to prepare a standard operating procedure

governing the internal organization for operation of the device.

Incorrect operation of the system, or non-observance of the warning

signs can result in personal injury or damage to equipment.

Danger

1.2.3 Maintaining efficiency

The operator is in responsible for ensuring the permanent process effi-

ciency of the device. This is ensured, among other things, by means of the

process validation and routine testing.

As part of the validation process, the materials and loading configuration

that are to be prepared during the respective process are specified.

A process validation must be provided for all the types of material to be

treated. Materials not listed in the validation report must not be treated in

the Selectomat PL steam sterilizer.

REV 26.12019 - 04 17 / 136

Safety

1.2.3.1 Process validation

A validation is the proof required of the effectiveness of this process. This

involves inspecting and documenting the medical products actually used

with the packaging used by the respective operator and the processing

conditions. The operator must ensure that the "worst case" load has been

inspected during the validation.

The reproducibility of the process must also be documented as part of

the validation so that it can be assumed that the desired result will always

occur. The inspections and the results must be documented.

The validation process comprises validation of the installation, operation

and performance.

The operator is responsible for performing the validation process. National

regulations must be observed. The validation must be performed using

state-of-the-art technology.

Notes for devices operated in Germany:

Validation requirements are given in e.g. DIN EN ISO 17665 and the

recommendations of the Commission for Hospital Hygiene and Infection

Prevention (Kommission für Krankenhaushygiene und Infektionsprävention

- KRINKO) on the hygiene recommendations when preparing medical prod-

ucts (Anforderungen an die Hygiene bei der Aufbereitung von Medizinpro-

dukten).

Contact MMM customer service for further information on the inspection

and validation of sterilization processes.

1.2.3.2 Routine inspections

The ongoing effectiveness of the processes must be verified by routine

checks during the entire service life of the machines.

These include, for example, periodic inspections such as performing the

Bowie-Dick test and the vacuum test, planned maintenance activities

including checking the measurement and control technology, regular cali-

bration and adjustment of the measurement chain, and revalidation without

a specific reason.

As a rule, revalidation, i.e. repeating the performance validation, is

performed annually.

18 / 136 REV 26.12019 - 04

Safety

In the case of changes which affect the process, e.g. changes to pack-

aging, introduction of new, design-critical instruments or after maintenance

activities, it is essential to perform a revalidation for a specific reason. The

content of the inspections depends on the change.

National regulations (in Germany: DIN EN ISO 17665 T1 P. 12 and

KRINKO recommendations) must be observed.

1.2.4 Operation of pressure equipment

The sterilizer is a pressure vessel designed in accordance with AD2000

regulations and DIN EN 13445. Its operation is regulated by European and

national legal regulations.

Data on the classification of the pressure vessel can be found on the pres-

sure vessel drawing or the test report according to Annex I of the Pressure

Equipment Directive.

Before commissioning a test of the status of the machine checking

assembly, installation, set-up conditions and safe function must be

conducted. The technical safety functions have already been tested during

factory testing, which means that the operator is not required to run new

tests after installation.

During operation the machine is subject to regular inspections, which are

required after a specific period or after the machine has reached a specified

number of cycles.

The operator must define the test programme before commissioning

based on a technical risk assessment and manufacturer's information

( Chapter 7.6, "Periodic inspections of pressure vessels").

Contact your national regulatory authority, which is responsible for

conducting the inspections.

Note for machines that are operated in Germany

The assembly components relevant to safety were tested in the factory as

per TRBS 1201 Part 2, 3.4.

The German Ordinance on Industrial Safety and Health (BetrSichV) and the

Technical Rules for Operating Safety (TRBS) are applicable. The BetrSichV

regulates the intervals for regular tests and the requirements for the testers

(qualified person as per TRBS 1203 or accredited inspection body (ZÜS)).

REV 26.12019 - 04 19 / 136

Safety

The pre-commissioning inspection and the regular inspections for Category

III pressure vessels (Pressure Equipment Directive) must be conducted by

an accredited inspection body (ZÜS).

1.2.5 Disposal

The operator is responsible for disposing of the machine and the acces-

sories in the environmentally correct and appropriate manner in accordance

with the applicable local regulations.

The machine must not be disposed of with normal domestic waste. Please

contact the manufacturer if you have any questions about how to dispose of

individual components in an environmentally correct way.

Notes for operators in the EU:

■ According to the regulations of European Directive 2006/66/EC and the

German Batteries Act, used batteries and rechargeable batteries must

be returned to a municipal collecting point or to the manufacturer.

■ Furthermore, the European Directive 2012/19/EU on Waste Electrical

and Electronic Equipment (WEEE Directive) and the German Electrical

and Electronic Equipment Act (ElektroG) apply. The company MMM

GmbH is registered with the EAR Foundation under the WEEE Regis-

tration No. DE18670731.

20 / 136 REV 26.12019 - 04

Safety

1.3 Users

Only persons with the required training or knowledge and experi-

ence are permitted to operate this device . Untrained persons are not

permitted to operate the machine .

The machine comes with a user administration feature that can be used to

configure the authorizations of individual operators.

REV 26.12019 - 04 21 / 136

Safety

The system distinguishes between three groups of users:

■ Approved operator

■ System supervisor (e.g. building services)

■ Specialist (e.g., MMM service technician)

1.3.1 Approved operators

The operators of the machine must be trained by a specialist

( Chapter 1.3.3, "Specialist" e.g. MMM customer service) on the basis of

the user manual how to use the machine correctly.

Incorrectly using the device or failing to observe the warnings may

result in personal injury or damage to property.

Danger

1.3.2 System supervisor

The operator must appoint an employee to be responsible for the device.

The name of the supervisor can be documented in the medical products /

equipment log.

When the machine is handed over by the manufacturer, the supervisor

receives the following documents:

■ Technical documentation

■ Medical devices / equipment log (depending on the machine type)

■ Keys (for the EMERGENCY STOP switch or program stop button, main-

tenance hatch, and control cabinet depending on the machine type)

■ The supervisor password ( see Chapter 2.4, "User administration")

The supervisor must confirm receipt of the above with his or her signature.

1.3.3 Specialist

The term specialist within this user manual refers to persons who have the

required expertise due to their training, experience and recent employment,

who perform the assigned work and are capable of independently identi-

fying potential hazards and avoiding dangers.

22 / 136 REV 26.12019 - 04

Safety

They specifically refer to persons or companies authorised by MMM

customer service.

1.4 Rules of Conduct during Operation

To ensure the safety of all persons working with or on the machine, the

following guidelines must be observed.

1.4.1 Personal protective equipment

The metal walls of the sterilization chamber and door become so hot during

operation that touching them with a bare hand may cause burns.

Risk of burns!

Wear gloves to protect your hands and long-sleeved, fastened work

Danger clothing when loading and unloading the chamber!

1.4.2 Starting a program

Before the program is started, it must be ensured that the chamber has

been correctly loaded and that all chamber doors and service doors are

closed.

1.4.3 Working inside the chamber

Only trained personnel may work inside the chamber (e.g. 1.3.1

"Approved operators", Page 22).

When working in the chamber (e.g. for cleaning, maintenance, etc.),

press the program stop switch and store the key during the work to

prevent unintentional unlocking.

Danger

The master switch can also be shut off and locked with a padlock to prevent

unauthorized reactivation.

REV 26.12019 - 04 23 / 136

Safety

1.4.4 Working on the assemblies

Risk of crushing from the door movement!

When working on the assemblies, turn off the master switch and

Danger secure it with a lock to prevent it from being switched back on. Keep

the key with you when carrying out work to prevent unintentional

unlocking.

Only suitably trained persons are permitted to access the assemblies

( Chapter 1.3.2, "System supervisor " and Chapter 1.3.3, "Special-

ist"),e.g. for inspection or maintenance purposes.

Work on the assemblies must only be performed while the machine is

switched off.

The assemblies compartment is locked. The key is kept by the system

supervisor to ensure that only technicians have access to the assemblies.

Risk of injury!

The assemblies (e.g. valves, uninsulated pipework) are hot!

Danger Wear personal protective clothing when working on the assemblies!

1.4.5 Working in the electrical control cabinet

Only qualified personnel are permitted to open the control cabinet

( Chapter 1.3.3, "Specialist").

Danger due to electric current!

When working on the electrical equipment (e.g. replacing compo-

nents), turn off the load disconnect switch.

Danger

1.4.6 Maintenance work

Maintenance work Chapter 7, "Maintenance " may only be performed by

qualified personnel ( Chapter 1.3.3, "Specialist").

1.4.7 Automatic transport system (option)

For machines with an automatic loading or unloading system, the safety

instructions and guidelines in the Cart Logistik System user manual must

be observed.

24 / 136 REV 26.12019 - 04

Safety

1.5 Machine safety devices

The machine is equipped with multiple safety devices, that allow immediate

program abort in case of danger.

If a power failure occurs, the machine is safe.

1.5.1 Safety strip

The self-closing chamber doors are fitted with a safety strip that stops door

movement as soon as the door encounters an obstacle (e.g. if an object or

a person is in the way of the door). The door is then opened again.

1.5.2 Automatic program cancellation

In the event of a fault that prevents the program sequence from completely

correctly, the control system cancels the program, e.g. faults with the

messages Pressure transducer controls defective or Motor protection

switch vacuum pump.

The process is regarded as incorrect.

The material to be sterilized must be regarded as unsterile.

Danger

On machines with two doors, only the door on the loading side can be

opened.

1.5.3 Program cancellation button

The program cancellation button is visible on the touch screen as soon as a

program is started. It must be pressed, for example, if an incorrect program

was started and the material could be damaged.

Pressing the "Cancel program" button ends the program as quickly

as possible ( Chapter 6.1, "Unexpected cancellation of the program

sequence").

The process is regarded as incorrect.

The material to be sterilized must be regarded as unsterile.

Danger

REV 26.12019 - 04 25 / 136

Safety

On machines with two doors, only the door on the loading side can be

opened.

1.5.4 Program stop switch

The program stop switch is on the control panel and must be used in case

of imminent danger, or if irregularities or malfunctions occur during the

program.

The program stop switch stops all movement of the machine by hardware,

i.e. the door close movement is stopped or prevented (this is also a safety

measure for work in an accessible chamber) and a program that has been

started is stopped.

When it is actuated the machine is placed in a safe state,

i.e. the media valves are closed.

The program stop switch must be pressed in the following cases:

■ Irregularities in the program sequence

■ Unusual noises

■ Steam emission from the machine room

■ Trapping during door movement

■ Fire

The process is regarded as incorrect.

The material to be sterilized must be regarded as unsterile.

Danger

For machines with two doors, only the door on the loading side can be

opened.

The program stop switch can only be unlocked with the specific key

supplied ( Chapter 1.3.2, "System supervisor " and Chapter 6.1, "Unex-

pected cancellation of the program sequence").

1.5.5 Master switch

The master switch is located inside the assemblies compartment.

It completely disconnects the machine from the mains.

26 / 136 REV 26.12019 - 04

Safety

Turn off the master switch if there is a hazard and when working on

the device (e.g. rectifying faults, performing maintenance, etc.).

To prevent unintentional switching on of the machine, secure the

master switch with a lock and keep the key with you when carrying

out work.

1.5.6 Safety valve

The steam sterilizer is optionally fitted with the following safety valve:

■ Compressed air (option): For certain variants, the compressed air

supply line is protected by a safety valve. The safety valve safely

discharges the compressed air into the assemblies compartment of the

machine in the event the permissible pressure is exceeded.

1.5.7 Locking the chamber door and door release

The control system prevents the door from being opened during the

program sequence. Consequently, the door buttons are not shown on the

display.

Forcibly opening the doors during the program sequence is prohib-

ited.

Danger

On completion of the program, the chamber door can only be opened when

the following conditions are met:

■ The pressure in the chamber is equal to the atmospheric pressure

■ The door seal has been released

See also see Chapter 4.3.8, "Unloading the chamber ".

Escape of steam possible!

For your personal protection, stand to the side of the chamber when

opening the chamber door.

Danger

1.5.8 Monitoring the sterilization parameters

The sterilization parameters (temperature, time and pressure) are moni-

tored by the control system. The temperature is measured by a reference

temperature sensor.

REV 26.12019 - 04 27 / 136

Safety

The time measurement is stopped if the temperature falls short of the

temperature set for the respective program by maximum 0.5 K. The time

measurement continues once the nominal temperature has been reached

again.

In the event of a deviation as described below, an automatic program

cancellation ( Chapter 1.5.2, "Automatic program cancellation") is trig-

gered:

■ The temperature falls below the sterilization temperature set for the

respective program by less than - 0.5 K; however, the time measure-

ment of the sterilization time is interrupted from a total of more than

90 s. The message “Sterilization temperature too low for too long”

appears on the screen.

■ The temperature falls below the sterilization temperature set for the

respective program by more than - 0.5 K. The message “Temperature

has fallen below sterilization temperature” appears on the screen.

■ The temperature exceeds the sterilization temperature set for the

respective program by +3 K. The message "Sterilization temperature

exceeded" appears on the screen.

The message is printed on the batch record.

1.5.9 Access protection

Operators have different authorizations for operation of the machine

depending on their user group.

Access to specific menu levels of the machine controller is pass-

word-protected. This prevents unauthorized access to process parameters

and settings relevant to safety.

Preset authorization levels with restricted rights are available for daily oper-

ation. These can be individually changed using the option User adminis-

tration ( Chapter 2.4, "User administration").

1.6 Residual risks and measures to prevent them

The machine is fitted with state-of-the-art safety mechanisms.

Furthermore, the parameters relevant to a successful sterilization

process are constantly monitored by the control system and comply with

DIN EN 285.

28 / 136 REV 26.12019 - 04

Safety

Nevertheless, fault-free completion of a sterilization program is no guar-

antee of the sterility of the treated material.

Residual risks

The following influencing factors cannot be constantly monitored in all

process steps and therefore represent a residual risk for the process effec-

tiveness:

■ Poor (in particular fluctuating) steam quality due to an impermissibly

high proportion of inert gas in the steam. Inadequate steam penetra-

tion due to inert gases is determined periodically by means of the Bowie

Dick test, which must be performed daily.

■ Poor ventilation of the material due to leaks in the chamber or an oper-

ating error (e.g. an incorrect load configuration that hinders ventilation or

steam access, preparation instructions of the medical device manufac-

turer not being observed). Leaks are checked for periodically using the

vacuum test.

■ Incompatibility of the selected program with the materials to be treated.

The selected program is not suitable or has not been validated for the

materials to be treated (e.g. use of a solid materials program for porous

goods).

Measures to prevent the risks listed above and to guarantee

successful sterilization:

Make sure that the steam quality meets the require-

ments( Chapter 1.2.1.3, "Media") .

Observe the guidelines in the national regulations on the treatment of

medical products ( Chapter 1.2.3.1, "Process validation").

The machine may only be operated by trained, authorized operators.

Only trained, authorized operators are permitted to release the batch on

the basis of the batch record and visual check (e.g. no moisture in the

load when using vacuum programs).

Conduct regular routine tests, such as maintenance and safety inspec-

tion, including checking the measurement and control technology,

regular calibration and, if necessary, adjustment of the measurement

chain.

REV 26.12019 - 04 29 / 136

Safety

The following also applies to the processing of medical devices

Before the sterilization process, thoroughly and properly clean and

disinfect the items to be sterilized in accordance with the medical device

manufacturer’s instructions and the applicable national regulations.

Non-observance of this instruction can have a negative impact on the

sterilization results and also the functionality and appearance of the

items to be sterilized.

Use sterilized material barrier systems to protect the sterile goods from

recontamination. Only sterile goods packaging must be used which

complies with the national EN or DIN standards.

Perform the routine testing ( Chapter 1.2.3.2, "Routine inspections") on

daily start-up of the sterilizer.

Perform the daily vacuum tests ( Chapter 2.7.3.1, "Vacuum test") to

identify any leaks in the chamber.

Perform the daily Bowie-Dick tests ( Chapter 2.7.3.2) to prevent

an impermissibly high fraction of inert gas in the steam. See also

Chapter 4.2, "Daily start-up".

Only those goods for which a process validation exists may be treated.

1.7 Maintenance and Safety inspection

Having the machine regularly inspected and serviced by specialists is the

best possible way to keep your machine in perfect working order. We there-

fore recommend an inspection and maintenance contract.

Maintenance and safety inspections may only be performed by qualified

persons ( Chapter 1.3.3, "Specialist"). Similarly, the machine must only be

repaired by persons who are authorised to do so by the manufacturer.

Only original wear and replacement parts may be used.

Your attention is expressly drawn to the fact that we accept no responsi-

bility for damage to the machine or personal injuries in connection with the

machine if the machine has been repaired or serviced by unauthorised

persons.

National regulations must be observed.

Please take into consideration that many factory insurance policies do

not provide coverage for loss or damage if maintenance has not been

performed.

30 / 136 REV 26.12019 - 04

Safety

Warranty advice

Warranty and guarantee claims can only be considered if maintenance and

safety inspections are performed within the prescribed intervals throughout

the warranty and guarantee period.

We refer to our warranty declaration Chapter 9, "Warranty (Liability for

defects)", according to which wearing parts and damage caused by chem-

ical influences are expressly excluded from our warranty.

1.8 Equipment log

Keeping an equipment log is recommended by MMM. Observe the legal

regulations.

Documenting the following in the equipment log is recommended:

■ Program specification ■ Faults

■ Process parameters ■ Maintenance

■ Amended parameters ■ Subsequent modifications to the

device

■ Name of trained operating

personnel ■ Tests

■ Name of the system supervisor ■ Reported incidents

1.9 Standards and directives

The machine has been designed and manufactured in line with applicable

standards, directives and statutory provisions.

According to the EC declaration of conformity signed by the manufac-

turer, this machine conforms to the applicable provisions and bears the CE

marking.

This machine complies with the following directives, regulations and stan-

dards:

Directives:

■ Directive 93/42/EEC on medical products (until May 25, 2020)

■ Directive 2017/745/EU on medical products (until May 26, 2020)

■ Directive 2014/68/EU on pressure vessels

■ Directive 2011/65/EU on restricting the use of certain hazardous

substances in electrical and electronic equipment (RoHS)

REV 26.12019 - 04 31 / 136

Safety

Application of the directives listed above also covers the requirements of

the following directives:

■ Directive 2014/30/EU on electromagnetic compatibility

■ Directive 2014/35/EU on electrical equipment (Low Voltage Directive)

■ Directive 2006/42/EC on machines, insofar it is more specific than

Directive 93/42 EEC Annex I on medical products

Standards and regulations:

■ DIN EN 285 Steam sterilizers

■ AD 2000 Regulation and DIN EN 13445-1 Unfired Pressure Vessels

■ DIN EN ISO 17665-1 Sterilization of health care products - Moist heat

■ DIN EN 61326-1 Electrical equipment for measurement, control and

laboratory use - EMC requirements - Part 1: General requirements

■ DIN EN 62366 Medical devices - Application of usability engineering to

medical devices

■ DIN EN 61010-1 and 61010-2-040 Safety requirements for electrical

equipment for measurement, control and laboratory use

■ DIN EN 62304 Medical device software

32 / 136 REV 26.12019 - 04

Machine description

2 Machine description

What follows is a general description of the machine and the processes.

For the precise specifications of your machine, please refer to the technical

data sheet or the planning drawings as well as the type plate attached to

the machine and the machine configuration of the technical documentation.

2.1 Standard equipment

Pressure container

The pressure vessel has been calculated, manufactured and tested

according to Pressure Equipment Directive 2014/68/EU for a maximum

permissible pressure (PS) of at least 3.2 bar and a vacuum of -1 bar.

Closure

Depending on configuration, the sterilization chamber is equipped with one

or two sliding door(s) driven by an electric motor.

The safety devices prevent the doors from opening during the program, and

the simultaneous opening of the loading and unloading sides (in the case

of two-door devices). To prevent jamming, the doors are fitted with a safety

strip.

Each sliding door is sealed pressure-tight using a special blow-out seal with

steam .

The sliding doors open horizontally (H and G machines) or vertically (V

machines).

REV 26.12019 - 04 33 / 136

Machine description

Steam supply

The steam is supplied either via the internal steam network (FD) or an

assigned or integrated electric steam generator (ED).

Depending on the equipment, it can be manually switched between steam

supply from the mains power supply and the higher-level steam generator.

Vacuum facility

The machine is equipped with a vacuum facility which enables air extraction

during special programs and program phases, fractionated vacuum drying,

safety extraction and door seal release.

The vacuum pump unit comprises a powerful and quiet double stage water

ring vacuum pump with an upstream heat exchanger and water circulation

container.

The Pt100-regulated supply of cold water ensures optimal water economy.

Electrical equipment

The electrical equipment conforms to DIN EN 61010-1 and 61010-2-040.

The protection class against penetration of foreign bodies and moisture is

IP33 (as per DIN EN 60529).

Instrumentation and control equipment

High-quality industrial controller with no mechanically actuated compo-

nents.

In accordance with DIN EN 285, the process parameters of temperature

and pressure are measured and controlled independently of tempera-

ture and pressure curve registration by two Pt100 resistance temperature

sensors and two absolute pressure transducers.

The independent safety monitoring system records, evaluates and reports

deviations from setpoints, and also monitors the operating states of the

machine.

If a fault occurs in the automatic program sequence, the program is

cancelled.

High degree of connectivity with Ethernet and USB ports. Batches saved

locally to flash memory. Up to 20 000 batches can be saved.

34 / 136 REV 26.12019 - 04

Machine description

2.2 Optional additional features

The equipment and functions described below are available as options.

2.2.1 Optional programs

Further programs can be activated in addition to the standard programs.

2.2.1.1 Special programs

Disinfection (option)

Steam disinfection program based on the pulsed vacuum method for

treating heat-sensitive materials.

Prion prevention (option)

Sterilization program for processing medical products that have been used

for operations on high-risk tissues.

Alloplast (option)

Sterilization program for alloplastic prosthetics, e.g. breast and testicular

implants made from silica gel.

2.2.1.2 APPcycles® (option)

APPcycles® is a configuration program that can be used to precisely tailor

the aeration, sterilization and drying process phases to the specific char-

acteristics of the items being sterilized and the sterile barrier system used

in order to optimize the consumption of media and the batch times without

compromising the effectiveness of the process.

The individual process stages were selected based on ISO/TS 17665-3.

The following characteristics of the medical devices to be processed define

the configuration parameters of an APPcycles program: design, material,

weight and packaging.

To configure an APPcycles program, please contact MMM customer

service.

2.2.2 Additional monitoring equipment

Additional equipment for monitoring further process parameters.

REV 26.12019 - 04 35 / 136

Machine description

Air detector (option)

The sterilizer is equipped with an air detector (air detector) for detection of

air leakages.

This monitors compliance with the sterilization conditions, since the effect

of sterilization is significantly impaired in the presence of non-condensable

gases, which tend to form air pockets in porous materials such as .

A corresponding fault message is printed on the batch documentation for

batches which are cancelled as faulty due to an air leak.

Air detector monitoring is only active if the air detector is installed and acti-

vated for the current program.

Air detector function test (option)

Additional function for creating a defined leak when performing a test using

an air-detection device.

Integrated Bowie-Dick test with SteamSpy (option)

The MMM SteamSpy is an integrated physical B&D test, which has been

tested as per ISO11140-4 by an independent test laboratory.

It consists of a tube that is permanently installed in the sterilization chamber

that simulates a cavity and a measuring device that is attached to the outer

chamber wall.

Its design enables verification of the effectiveness of steam penetration

both in the cavities and in porous material.

The temperature, which is measured by a Pt100 sensor, is evaluated by

the control unit of the sterilizer and is continuously compared with the target

values of the Bowie-Dick test program. The result of the B&D test is defined

at the end of the program and it is output on the batch documentation.

The integration of the electronic B&D test in the Autostart option automat-

ically starts the vacuum test, the heating program and the B&D test under

program control, which means that the machine is fully ready for operation

at the start of the shift.

Integrated cycle control with SteamSpy (option)

If the device has the SteamSpy option, the routine cycle control is run via

SteamSpy. The sterilization process conditions tested by MMM SteamSpy

conform to the test body conditions as per DIN EN 867-5.

36 / 136 REV 26.12019 - 04

Machine description

The temperature, which is measured by a Pt100 sensor, is evaluated by

the control unit of the sterilizer and is continuously compared with the target

values of the respective sterilization program. The result of the cycle control

is defined at the end of the program and it is included in the batch docu-

mentation.

Compressed air supply monitor (option)

This optional equipment monitors the on-site compressed air supply and is

triggered if the supply pressure is too low.

Cold water pressure monitor (option)

This optional equipment monitors the on-site cold water pressure and is

triggered if the water pressure of the cold water is too low.

2.2.3 Reducing the consumption of media

Connection for cooling circuit vacuum pump (option)

To reduce the amount of cold water used to cool the vacuum pump, it

is possible to connect the machine to an external cooling circuit ( see

Chapter 5.9, "Activating the cooling circuit vacuum pump").

Cooling circuit automatic switching (option)

If the machine is connected to an on-site cooling circuit, an automatic

switching function can be activated whereby the machine will automatically

switch over to cooling by cold water if the cooling circuit fails.

Steam manager (option)

The steam manager controls the temporal program sequence of several

sterilizers so that steam is taken from the supply network as evenly as

possible.

After a prompt, the sterilizer indicates that it is ready to start by the green

lamp and the display. Only then can the machine be loaded and started. It

must not be loaded beforehand, as the sterilization materials are otherwise

impermissibly pre-heated and dried.

The steam manager is activated and deactivated through corresponding

settings in the machine parameters ( Chapter 5.8, "Activating the steam

manager (option)").

REV 26.12019 - 04 37 / 136

Machine description

In machines with automatic loading this is done only after the steam

manager has sent the start release.

Barcodes can be read before the start release.

Standby mode

Standby mode is used to minimise steam consumption.

If the machine is not operated for a long time (no program active, screen is

not touched), it switches to standby mode after an adjustable time. Standby

mode is activated automatically after the set time has elapsed ( see

Chapter 5.6, "Activating standby mode ").

Jacket control is then paused and the machine cools down (energy saving).

Standby mode switches off as soon as the touch screen is touched. As the

machine cools down in standby mode, we recommend first running a warm-

up program after a long down time.

2.2.4 Optional services

Auto start (option)

When using autostart, the machine automatically starts a configurable

sequence of programs. This feature is typically configured to run the routine

preparatory programs (vacuum test, heating program, Bowie-Dick test) to

ensure that the machine is operational at the start of a shift.

Whether and at what time the auto start should commence can be individ-

ually configured for each weekday. For example, a heating program can be

set from Monday to Friday, while no automatic program start takes place at

the weekend ( Chapter 5.5, "Activating auto start (option)").

A max. of five programs can be configured. Sensibly, auto start is combined

with standby mode.

Service module (Option)

Simplified maintenance planning by indicating on the machine display when

service tasks need to be performed. Information about the following service

tasks is displayed:

■ Preventive maintenance

■ Interval-based maintenance & inspection

38 / 136 REV 26.12019 - 04

Machine description

■ Calibration/adjustment

■ Revalidation

ISA - Intelligent Service Advisor (option)

The machine can send e-mails and/or SMS to the operator or MMM

customer service. This provides immediate information on faults and main-

tenance information (see separate instructions).

Barcode administration (option)

Barcodes are used to identify the sterilization material. They are located on

the goods to be treated and are scanned individually with a handscanner

per batch.

A maximum of 500 barcodes can be entered per batch. The barcode infor-

mation is transferred to the batch record.

The required program can also be stored in the barcodes to enable the

program to be selected automatically ( see Chapter 2.6, "Automatic

program selection using the barcode (option)").

User identification (option)

A user ID that is written to the batch record can be entered via the touch-

screen or the barcode scanner. This makes it possible to establish at a later

time who started the program.

Central control room (option)

To simplify plant management, the device data from one or more machines

is monitored and displayed online by a centrally located, on-site network-

compatible PC.

The following data can be displayed: machine number, batch number,

program start, selected program, next service, current operating status of

the machine (position of doors, current processing step, pressure, temper-

ature), online process curve, and the time remaining until the end of the

program for the purposes of optimizing the loading and unloading time.

The connection to the VNC server is also activated or deactivated at the

machine.

REV 26.12019 - 04 39 / 136

Machine description

Remote maintenance system (option)

By comprehensively analyzing the device status remotely, it is possible to

locate faulty components and initiate any necessary servicing measures.

Access to the remote maintenance function is via a VNC client. This service

can be used to operate the machine, view parameters, check the audit trail,

view the IO list, and much more.

2.2.5 Automatic transport system

Two door machines can be equipped with a Cart Logistik System for auto-

matic loading and unloading of the chamber (see the Cart Logistik user

manual).

The transport system is controlled, and supplied with power and if applic-

able compressed air, by the associated sterilizer.

2.2.6 Uninterruptible power supply (UPS) (option)

Uninterruptible power supply for the control system. In the event of a power

failure, the control system remains active and cycle information is saved.

Process-relevant valves are closed during the power failure.

2.3 Accessories Transport trolley

The transport trolley is used for loading, unloading, and transporting MMM

loading trolleys.

The transport trolley is available in two variants:

■ TW – transport trolley with a fixed height corresponding to the loading

height of your sterilizer

■ TW HUB – transport trolley with a height-adjustable transport platform

for loading and unloading machines of different heights

Both variants are available in various sizes to suit the loading trolleys you

are using with your sterilizer.

Transport trolley (TW)

Transport trolley (TW) with a fixed loading height of 390 mm, 625 mm or

850 mm.

40 / 136 REV 26.12019 - 04

Machine description

1. Locking bolt, for securing the BW

to the TW.

2. Lever 2 for releasing the BW from

the TW.

3. Lever 3 for releasing the TW from

the chamber.

Height-adjustable transport trolley (TW HUB)

Read the original user manual from the manufacturer of the TW HUB

carefully and save it for future reference.

Observe the safety instructions. Your personal safety and the correct

functioning of the machine are at stake.

Height-adjustable TW HUB with a maximum loading weight of 120 kg. The

TW HUB is equipped with buttons on the handles for moving the platform.

The left button moves the platform upwards, the right button moves the

platform downwards. The middle button between the handles moves the

platform to a preset height.

The TW HUB is configured on site for the required loading height.

REV 26.12019 - 04 41 / 136

Machine description

1. Locking bolt, for securing

the BW to the TW.

2. Lever 2 for releasing the

BW from the TW.

3. Lever 3 for releasing the

TW from the chamber.

4. Button for raising the

transport platform.

5. Button for lowering the

transport platform.

6. Memory button (optional)

for setting a preset height.

The transport platform height must not be adjusted if the TW HUB is

already docked and locked to the sterilizer or conveyor.

Danger

Also observe the cleaning and maintenance instructions and the internal

work instructions!

2.4 User administration

The user administration function can be used to configure the authoriza-

tions of individual users.

The following users and authorizations are pre-configured:

Level User name Users Authorised for:

1 Anonymous Authorised users E.g. program selection, program start,

(no password) viewing the audit trail, certain service

menu functions

2 Supervisor System supervisor E.g. acknowledging faults, alarm coun-

(name: "s") ters, configuration of certain parame-

ters such as early start, standby mode,

cooling circuit, etc.

3 MMM Specialist, MMM System administration, access to all

customer service parameters

42 / 136 REV 26.12019 - 04

Machine description

Log-in is not required for normal operation, as the user "Anonymous" is

automatically logged in. The user name "Anonymous" is listed in the user

bar. There is no automatic logout.

Certain actions can only be performed after user log-in as a supervisor

(e.g. acknowledging fault messages). A user can be logged in and out as a

supervisor at any time.

If the screen is not touched for 5 minutes (individually adjustable) after log-

in, the "Supervisor" user is automatically logged out and the "Anonymous"

user is logged in.

Extended user administration function

The Extended user administration function can optionally be used to require

every user to enter name and password before initiating an action. The

rights of every single user can be assigned regardless of the present autho-

risation levels "Anonymous" and "Supervisor".

The user will only be able to perform the allowable actions after logging in.

When the device is commissioned, an administrator (S) is set up, who will

have the right to create or delete additional users and to assign specific

rights to users ( Chapter 5.1, "Configuring user administration (option)").

If the machine has a control panel on the unloading side, the Extended

user administration function can also be used to specify that the names

of the users who started a program, and who opened the door at the end

of the program, are recorded with the batch and are printed on the batch

record.

The user administration feature is configured in the machine parameters, to

which only a specialist ( Chapter 1.3.3, "Specialist") has access.

2.5 Batch documentation

At the end of a program a batch record with all process-relevant data is

created. The user can release or reject the batches.

The batch record contains the following information:

■ General data about the operator, user, device

■ General data about the program and batch, e.g. selected program,

program start, begin and end sterilisation

■ Course of the pressure and temperature curves over time

REV 26.12019 - 04 43 / 136

Machine description

■ Course of the air detector temperature over time (for air detector option

only)

■ Evaluation of the integrated Bowie&Dick test (for SteamSpy option)

■ Evaluation of the integrated cycle control (for SteamSpy option)

■ Measurement record in plain text

■ All barcode numbers on labels read by the barcode scanner

The batch record saved in the device can be printed out at the end of the

batch ( Chapter 5.2, "Setting batch print and save options") and sent to an

external server, depending on the device equipment.

The transferred batch documents can be permanently archived there (e.g.

on a separate storage device). The operator is responsible for monitoring

that the transmission and saving of the batch record is successful. In partic-

ular, possible disruptions to the network connection must be considered

within this context.

If a record has not been added to the electronic archive, either the corre-

sponding printout must be retained or the batch in question discarded.

The last 20 batches stored on the device can be shown on the display and

reprinted.

2.6 Automatic program selection using the barcode (option)

The barcode entry can be used to automatically preselect the appropriate

program for the scanned goods.

Each barcode contains a program number to which a specific sterilization

time, sterilization temperature and drying method (e.g. SuperDry) has been

assigned.

The appropriate program is automatically highlighted in the program selec-

tion menu. Depending on the configuration, it is not possible to select other

programs. This prevents the selection of unsuitable programs which may

damage the goods to be processed.

The barcode process is configured during commissioning by the customer

service team in consultation with the operator.

Two types of processing mode are available: temperature flexible and

time flexible.

44 / 136 REV 26.12019 - 04

Machine description

Temperature flexible program selection

The compatibility test of the barcode with a suitable program is assessed

according to the following process:

■ The first barcode to be scanned determines the barcode group. All other

scanned barcodes must belong to the same group.

■ If barcodes are scanned that are assigned to different sterilization

temperatures, the lowest temperature is selected.

■ A newly scanned barcode is checked to see whether a program with

the same sterilization temperature but different sterilization time has

already been scanned. If this is the case, the new barcode is rejected.

This means that all programs with the same sterilization temperature

have to have the same sterilization time.

■ If barcodes are scanned that have been allocated the SuperDry (SD)

drying method, the SD program with the lowest previously selected

temperature is selected. If there is no SD program with this temperature,

the barcode is rejected.

■ If barcodes are scanned that have been assigned a program number for

a program that has not been activated, the barcode is rejected.

Time flexible program selection

The compatibility test of the barcode with a suitable program is assessed

according to the following process:

■ If barcodes with different sterilization times are scanned, the program

with the longest sterilization time is selected. However, all of the

scanned barcodes must have the same sterilization temperature.

2.7 Process description

The sterilizer is factory-fitted with the processes described as examples in

the following.

Seven standard programs are available, which can be modified as required.

■ 3 sterilization programs

■ 2 routine test programs

REV 26.12019 - 04 45 / 136

Machine description

■ Heating program

■ 1 rack hatch program (for two-door machines)

The programs defined and set with the operator on commissioning are

displayed in the program selection menu. A maximum of 13 programs can

be activated simultaneously.

On request, the number of available programs can be reduced or increased

(authorisation level 3 required Chapter 1.3.3, "Specialist"). All available

programs which can be selected using the touch screen are displayed in

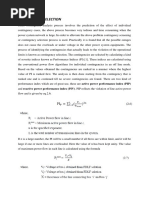

the program selection menu.